Used TEL / TOKYO ELECTRON ACT 8 #9285381 for sale

URL successfully copied!

Tap to zoom

ID: 9285381

Vintage: 2002

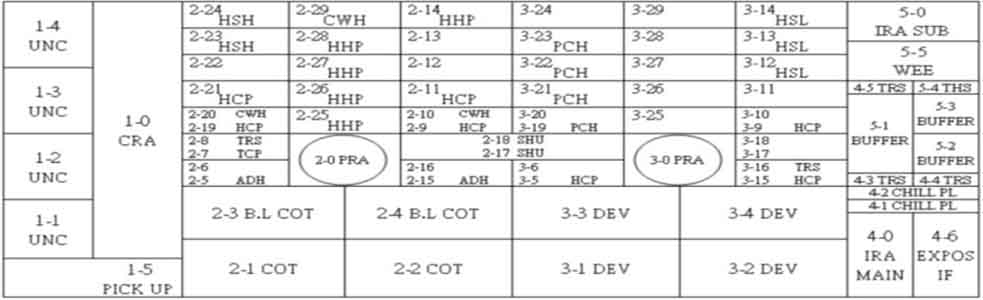

(4) Coater / (4) Developer system

Open cassette

2002 vintage.

TEL / TOKYO ELECTRON ACT 8 is a photoresist equipment used in semiconductor device fabrication. The system is designed to be used in the deposition and dry etching of substrate films in the manufacturing of integrated circuits. TEL ACT 8 unit utilizes an advanced maskless photoresist machine that employs an apertured laser mask to enable high resolution imaging of patterns onto a photo sensitive substrate. The apertured laser mask is positioned a fixed distance above the substrate and is employed in both the scan and exposure functions. The tool is integrated with a resist nozzle which provides the required substrate sputter coating and allows uniform application of the resist materials. The asset has a high resolution for imaging. The model has a high-frequency, modulation-based laser engine which generates high resolution, high accuracy images on the substrate with high uniformity. This feature ensures the enhanced fidelity of the pattern, allowing for a significantly higher process yield. In addition, TOKYO ELECTRON ACT 8 photoresist equipment has an optically active layer technology that allows for interconnection between films and insulator layers for the fabrication of multi-level interconnections. This layer technology also provides improved contact yield and adhesion. The system also has integrated automation which helps to reduce the time and resources required for the fabrication of integrated circuits. This automation is designed to reduce the cost of the end product. TOKYO ELECTRON ACT 8 photoresist unit is suitable for high-temperature bake and etching applications, as well as other difficult process conditions. It is also able to accommodate the latest wafer technologies, such as Cu-AlN films, and enables the manufacturing of complex devices. Overall, ACT 8 photoresist machine is an advanced, high performance tool that is ideal for semiconductor device fabrication and production. The asset has built-in automation and improved resolution of imaging, which help to reduce the costs of producing integrated circuits. It is also able to handle difficult process conditions and is capable of accommodating the latest wafer technologies, making TEL / TOKYO ELECTRON ACT 8 photoresist model an ideal solution for the fabrication of complex devices.

There are no reviews yet