Used TEL / TOKYO ELECTRON ACT 8 #9312079 for sale

URL successfully copied!

Tap to zoom

ID: 9312079

Wafer Size: 8"

Vintage: 2007

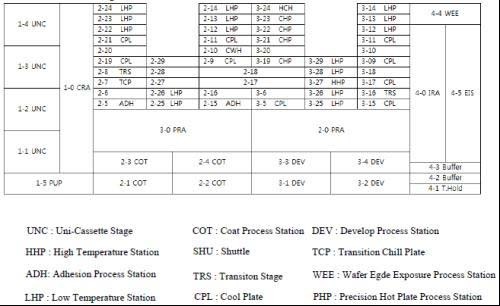

(4) Coater / (4) Developer system, 8"

(2) Chemical boxes

(2) SMC Thermo controllers

TEAM KOREA Temperature and humidity controller

AC Power box

Left to right

Wafer and carrier type: Notch

(25) Slots

(4) Uni-cassette loaders

Carrier station:

Type: Normal uni-cassette

(4) Cassette stages

Pick-up cassette

Uni-cassette system

Coater unit (2-1, 2-2, 2-3, 2-4 Module):

(3) Dispense nozzles with temperature controlled line

RDS Pump

Rinse nozzle: Back / EBR / Solvent bath

Rinse system: 3 Liters (2) buffer tank systems

PR Suck-back valve type: AMC Suck-back valve

Programmable side rinse

Direct drain

Developer unit (3-1, 3-2, 3-3, 3-4 Module):

Nozzle for each unit

2-Stream nozzles for DI rinse

2-Points for back side rinse on each unit

Developer system: 3 Liters (2) buffer tank systems

Developer temperature control system

Direct drain

(2) Adhesion units:

Sealing closed chamber with built-in hot plate

HMDS Tank with float sensor

Interface type: NIKON

High temperature hot plate

(16) Low temp hot plates

(9) Chill Plates (CPL)

(4) Chilling Hot Plate (CHP) process station

(3) Transition Stage (TRS) modules

Transition Chill Plate (TCP) module

Wafer Edge Exposure (WEE) module

(2) Temperature control units

Missing parts:

Main controller

(4) Coater cups (2-1, 2-2, 2-3, 2-4)

(3) Developer cups (3-1, 3-2, 3-3)

Main display panel

CRA X-Axis motor

CSB Add on board

(9) Coater PR pumps (2-1.2-2.2-3)

IRA Y-Axis motor driver

IRA Tweezers

LHP Module cover

Power: AC 208 V, 3 Phase

2007 vintage.

TEL / TOKYO ELECTRON ACT 8 is an advanced exposure equipment designed for photoresist applications. It is a laser-driven system that uses high resolution and precise control of exposure times to reduce mask defects and increase consistency in the exposed photoresist image. This photoresist unit consists of a laser source, a modulator unit, a scanning unit, an analyzer unit, and a photoresist image detector. The laser source generates the photons used to expose the photoresist. This can be of a He-Cd or an argon-ion type. The modulator ensures that each laser pulse has exactly the same duration, permitting precise control of power density and providing a uniform 10ns exposure. The scanning machine utilizes a highly precise and rigid mechanical design to accurately expose the photoresist. It operates by scanning an XY motor-driven stage at 1.2 meters per second. The analyzer unit uses a CCD sensor to confirm exact exposure of the photoresist image. The photoresist image detector allows for deflection-independent measurement of extremely accurate resist patterns. It combines a stage for measurement, a control unit for data input, and a display unit for signal output. It can detect positional errors as small as 0.2 micrometres. TEL ACT 8 is suitable for use in a variety of industries such as semiconductor manufacturing. It enables chipmakers to quickly and accurately produce devices with improved resolution and eliminates mask flipping. This advanced tool is capable of achieving a printing accuracy of 0.1 micrometres. It also offers excellent resource utilization with its ability to process large products at high speed.

There are no reviews yet