Used TEL / TOKYO ELECTRON ACT 8 #9312218 for sale

URL successfully copied!

Tap to zoom

ID: 9312218

Coater / Developer system, 8"

System controller

(2) Chemical cabinets:

Chemical cabinet 1: HMDS, Solvent and developer

Chemical cabinet 2: PR

(2) SMC Temperature Control Unit (TCU)

AC Power box

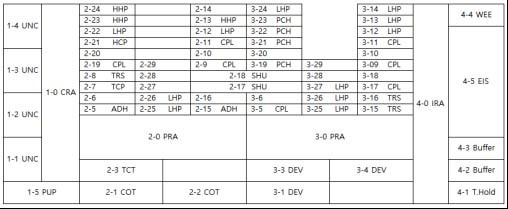

Carrier station:

Type: Uni-cassette

4-Cassette stages, 1 pick-up

Coater unit:

(4) Dispense nozzles with temperature control line

Mini RRC pump

Rinse nozzle: EBR, Back rinse, solvent bath

Rinse system: 3 Liters (2) buffer tank systems

PR Suck back valve type: Suck-back valve

Direct drain

TARC Coater unit:

(3) Dispense nozzles with temperature control line

Mini RRC pump

Rinse nozzle: EBR, Back rinse, solvent bath

Rinse system: 3 Liters (2) buffer tank systems

PR Suck back valve type: Suck-back valve

Direct drain

Developer unit:

H Nozzle

(2) Stream nozzles for D.I W rinse

2 Points for back side rinse

Developer system: 3 Liters (2) buffer tank systems

Developer temperature control system

Direct drain

(2) Adhesion units:

Closed chamber (Built-in hot plate)

HMDS Tank with float sensor

Interface

High temperature hot plate

(14) Low temp hot plates

(7) Chill plates (CPL)

(4) Chilling Hot Plate (CHP) process station

(3) TRS Modules

TCP Module

HCP Module

Wafer Edge Exposure (WEE) Module

Wafer type: Notch, DUV type

Missing parts:

CSB motor I/O Board 2-0 PRA θ Motor driver

CSB Add on board

3-4 Panasonic motor

3-1 Out cup cylinder

3-1 Arm 1

3-1 Arm 2

PRB2 Chemical IO board

Temperature and humidity controller ((2) Cups)

2-0 PRA X Motor driver

4-0 IRA Z Motor drive

4-0 IRA UPS

WEE Theta driver

4-0 IRA Motor IO board

4-0 IRA IFB Add on board

Hard Disk Drive (HDD)

2000 vintage.

TEL / TOKYO ELECTRON ACT 8 is an industry-leading photoresist equipment developed by TEL, a Japanese company specializing in semiconductor equipment. The system, developed using advanced technology, offers users a cutting-edge, automated unit for processing wafers. The machine is notable for its high-precision and highly accurate results. It offers a superior etching process by exposing a substrate to light while maintaining a high degree of accuracy. The tool filters light to stabilise the image, reduce distortions, and improve line-width accuracy. With its high-speed process control, TEL ACT 8 is capable of handling over 300 wafers per hour. It also makes use of a built-in software asset that enables users to monitor process conditions, uncover abnormalities, and respond swiftly to changing process needs. The model is equipped with intelligent features, such as real-time data capture, which allows users to capture process data to analyze process trends and better manage production. It has a Clean Track cleaning mechanism to penetrate photoresists with cleaning solutions without causing damage to the wafers. The equipment produces high-quality, low-cost results by minimizing line-width variation and minimizing the need for aggressive descumming. It also supports sensitive applications, such as thin-film deposits. In addition, the system has automated testing and data analysis capabilities that enable users to diagnose problems and minimize downtime, freeing up production time and increasing efficiency. TOKYO ELECTRON ACT 8 delivers the industry's best photoresist unit at an affordable price point. Its precision and automation come together to provide reliable results for a variety of applications. Its versatility and flexibility allow users to tailor the machine to their specific needs in order to produce the highest quality of photoresist that meets their specific needs.

There are no reviews yet