Used TEL / TOKYO ELECTRON ACT 8 #9357239 for sale

URL successfully copied!

Tap to zoom

ID: 9357239

Wafer Size: 8"

Vintage: 2001

Coater / Developer system, 8"

Main frame with controller

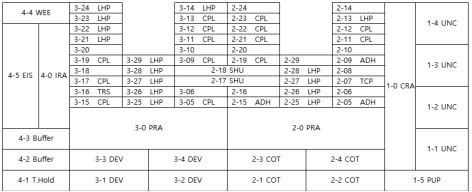

Carrier station:

Type: Normal uni-cassette

(4) Cassette stages

Pickup cassette

Coater:

(3) Dispense nozzle with temperature controller for etcher

RRC Pump

Rinse nozzle: Back / EBR / Solvent bath for etch unit

Rinse:

(2) Buffer tanks: 3 Liter

PR Suck-back valve

Direct drain

TARC Coater:

(2) Dispense nozzle with temperature controller for etcher

RRC Pump

Rinse nozzle: Back / EBR / Solvent bath

Rinse:

(2) Buffer tanks: 3 Liters

PR Suck-back valve

Direct drain

Developer:

SH Nozzle

(2) Stream nozzles for DI rinse

(2) Buffer tanks: 3 Liters

Temperature controller

Direct drain

(3) Adhesions:

100% Sealing closed chamber (Built-in hot plate)

HMDS Tank with float sensor

(15) Low Temperature Hot Plates (LHP)

(14) Chill Plates (CPL)

TCP Module

(3) TRS Modules

Wafer Edge Exposure (WEE) module:

Wafer type: Notch, DUV

Notch

DUV

Chemical cabinet 1: Solvent and developer

Chemical cabinet 2: PR and HMDS

(2) TEL OEM Temperature controllers

AC Power box

Interface

Missing parts:

2-1 COT Spin I/O Board

2-4 COT EBR Nozzle tip

2-4 COT EBR Nozzle valve

2-1 Nozzle changer motor

3-2 Shutter cylinder

(2) PRB YASUKAWA Spin motor drivers

2-0 PRA Z-Driver

3-0 PRA Z-Driver

Temperature and humidity controller (For 4 chu)

Hard Disk Drive (HDD)

2001 vintage.

TEL / TOKYO ELECTRON ACT 8 is a state-of-the-art photoresist equipment. It is designed to provide industry leading precision and accuracy in the photolithography process. Photolithography is a critical step in the manufacturing of many electronic components. TEL ACT 8 system utilizes a high precision mask aligner to accurately transfer a pattern to a photoresist material. The pattern is transferred to a substrate material with a high rate of speed and accuracy. TOKYO ELECTRON ACT 8 features a powerful stepper motor and a proprietary control unit. This allows for rapid and precise alignment of the mask with the substrate. The resolution of the mask aligner is 25 nanometres, which provides high accuracy and repeatability. The machine is also capable of image processing of the mask and can control the light dose of each layer based on the complexity of the pattern. ACT 8 is also equipped with a powerful cleanroom environment. The air is filtered and controlled to a very high degree. This ensures that even the most fragile and miniature components are not exposed to any contamination. The cleanroom also helps by controlling the humidity, which is important for controlling the rate of exposure of the photoresist. TOKYO ELECTRON ACT 8 is also equipped with advanced software that is used for controlling the entire tool. The software is able to control the light exposure in a wide range of patterns. It is also able to control the temperature of the substrate and the mask, which is important for controlling the shrinkage of the photoresist. TEL / TOKYO ELECTRON ACT 8 is a highly flexible and accurate photoresist asset. It is capable of producing high quality parts with high repeatability. The powerful motor and advanced software make it possible to produce precision parts with high throughput. The sophisticated environmental controls make sure that even the most delicate components are not contaminated. The model is designed for high volume production of small components.

There are no reviews yet