Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9106025 for sale

URL successfully copied!

Tap to zoom

ID: 9106025

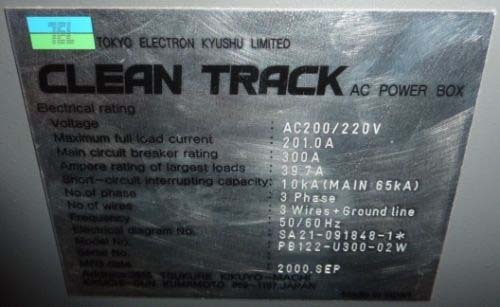

Vintage: 2000

AC Power Box

P/N: PB122-U300-02W

TDK back-up units: missing

AC control board: included

200/220V

Full Load Current 201.OA

300A

3 Phase, 3-Wires + Ground Line

50/60Hz

2000 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 12 is a photoresist equipment used to etch patterns on the surface of DUV semiconductor substrates. Photoresists are light-sensitive chemicals used in lithography to transfer a pattern from a mask or reticle to the substrate. This system helps to precisely define the pattern that will be etched onto the substrate. TEL Clean Track ACT 12 consists of three modules: the Corona Igniter, the Resolution Enhancement Technology (RET) and the Step and Repeat Unit (SRU). The Corona Igniter is the first step in the process. The Igniter introduces a special chemical called an initiator onto the surface of the substrate, activating the photoresist on the substrate in order to form a protective coat. This protective coat enables precise patterning of the photoresist after exposure to ultraviolet (UV) light. The RET module then takes the activated photoresist substrate to the next level. This module uses extremely advanced imaging techniques to create detailed and accurate patterns in the photoresist layer with a very high degree of resolution. It combines a number of technologies such as contact-level imaging, shrinking and dot-reduction to achieve this goal. The SRU is the third and last module of TOKYO ELECTRON Clean Track ACT 12. This module takes the photoresist pattern defined by the RET module and transfers it to a mask or a reticle. It then takes multiple exposures to a stepper in order to transfer the pattern onto the substrate. The stepper is a device that moves the reticle in an exact pattern with precise intervals so that each position is correctly exposed. Clean Track ACT 12 is a very reliable and precise photoresist unit. With its combination of the Corona Igniter, the RET module and the SRU, it can accurately and finely define the patterns to be etched onto substrates with a high degree of resolution and accuracy. This machine is used in many industries and is considered to be one of the most advanced photoresist systems available.

There are no reviews yet