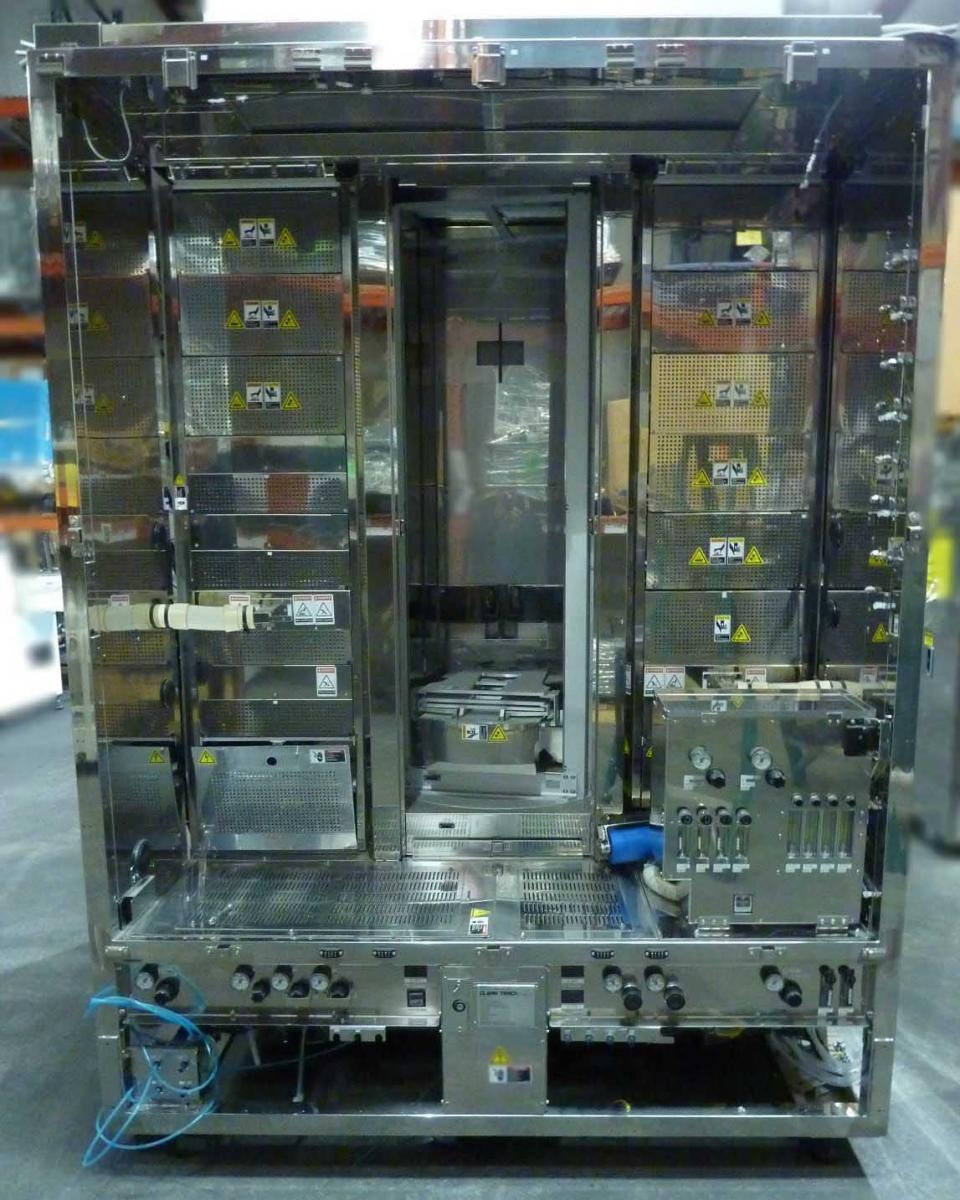

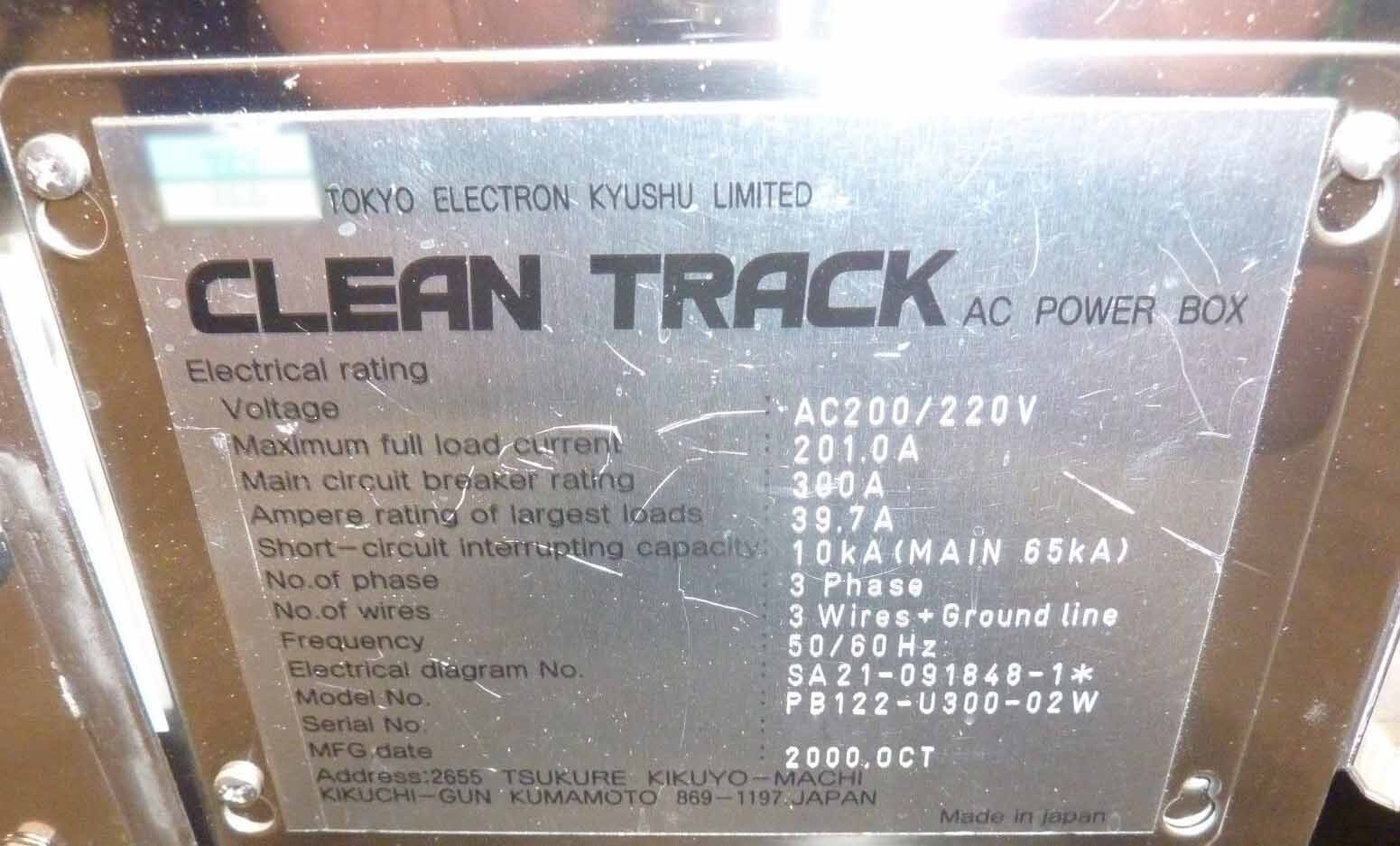

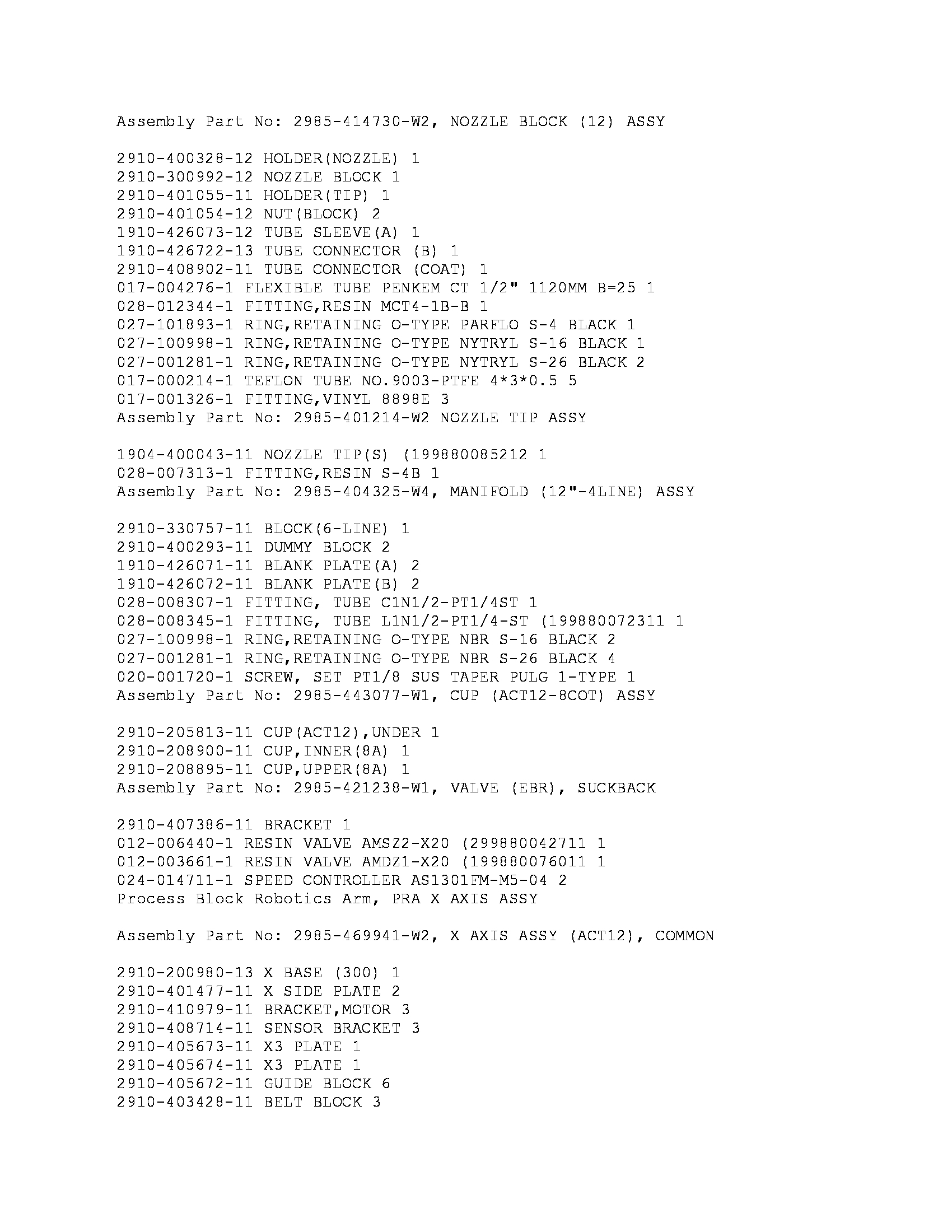

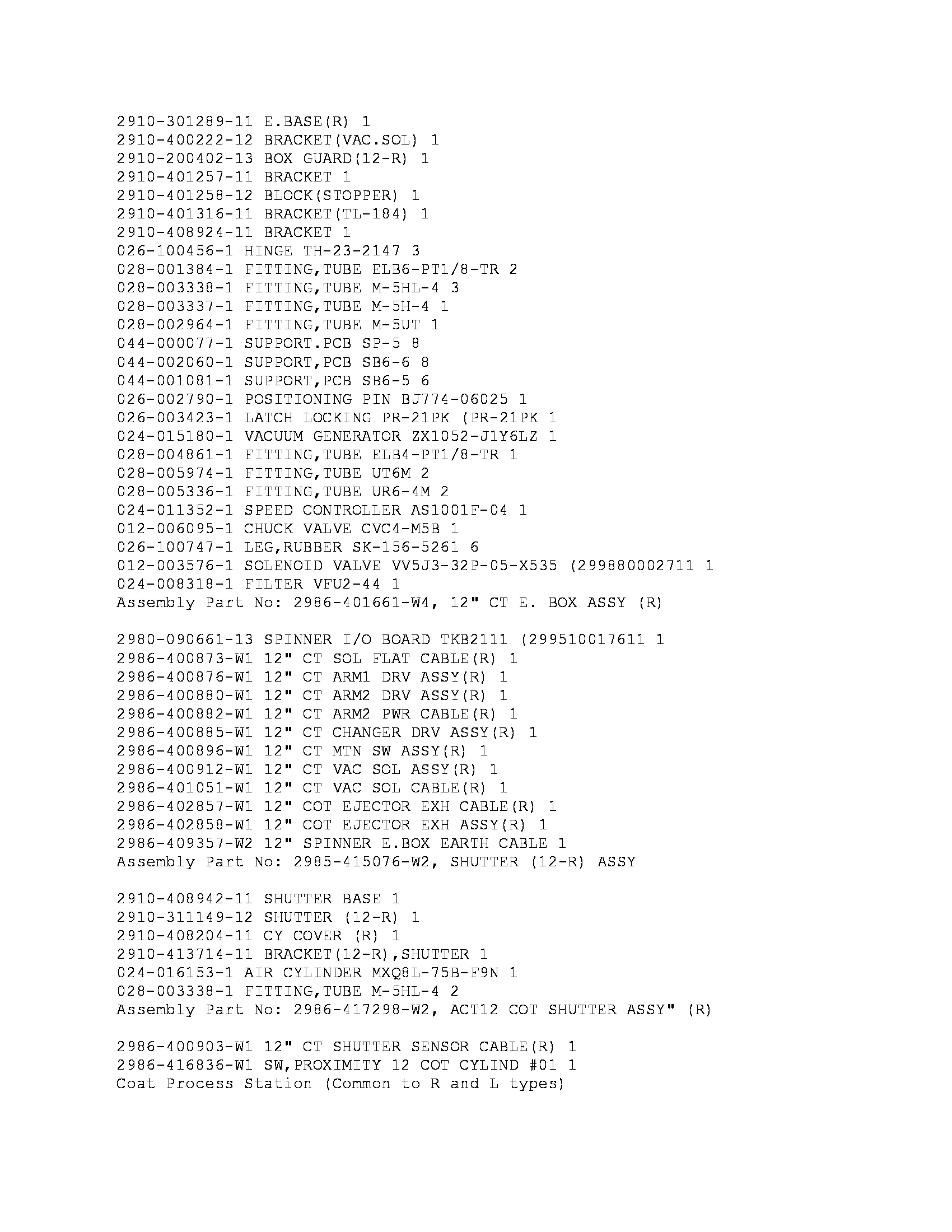

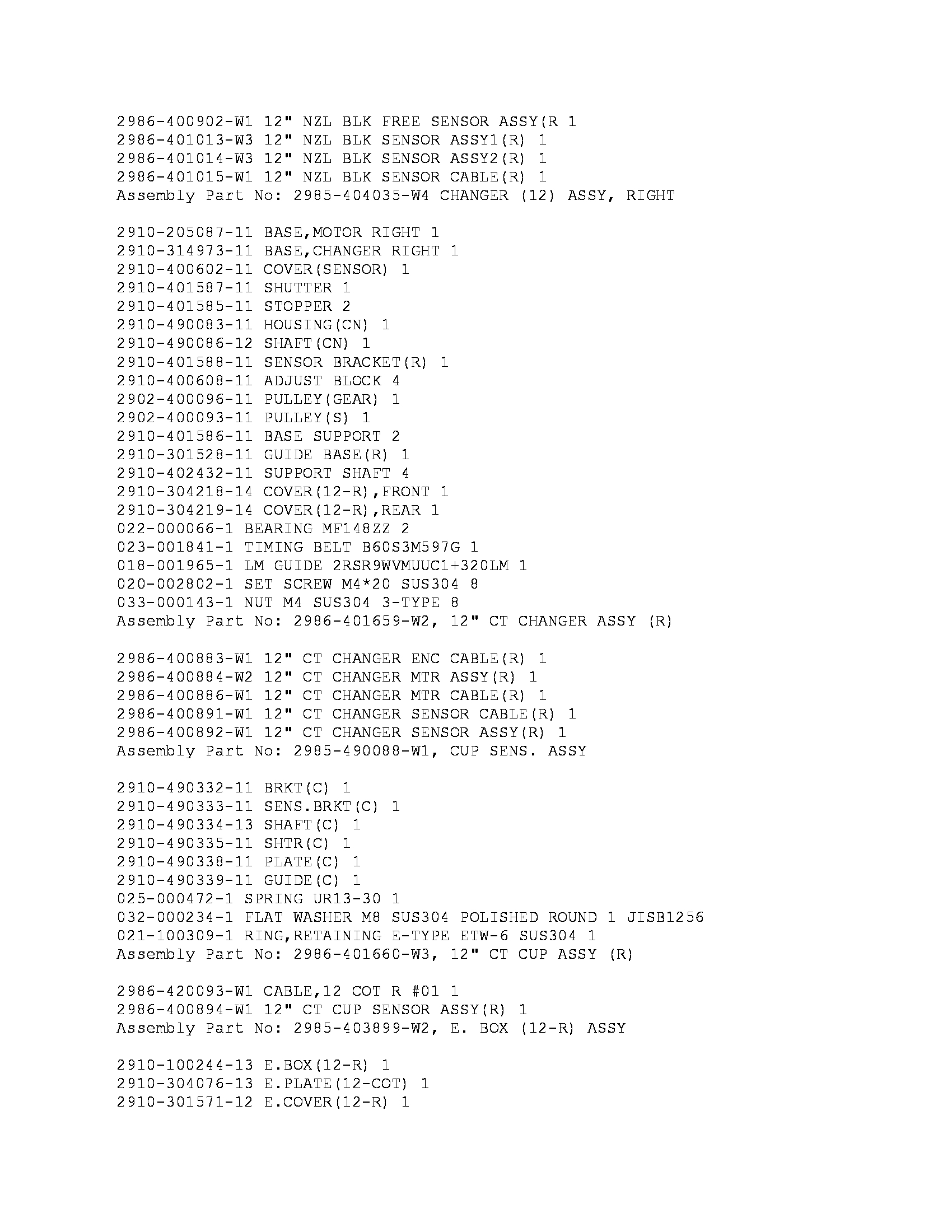

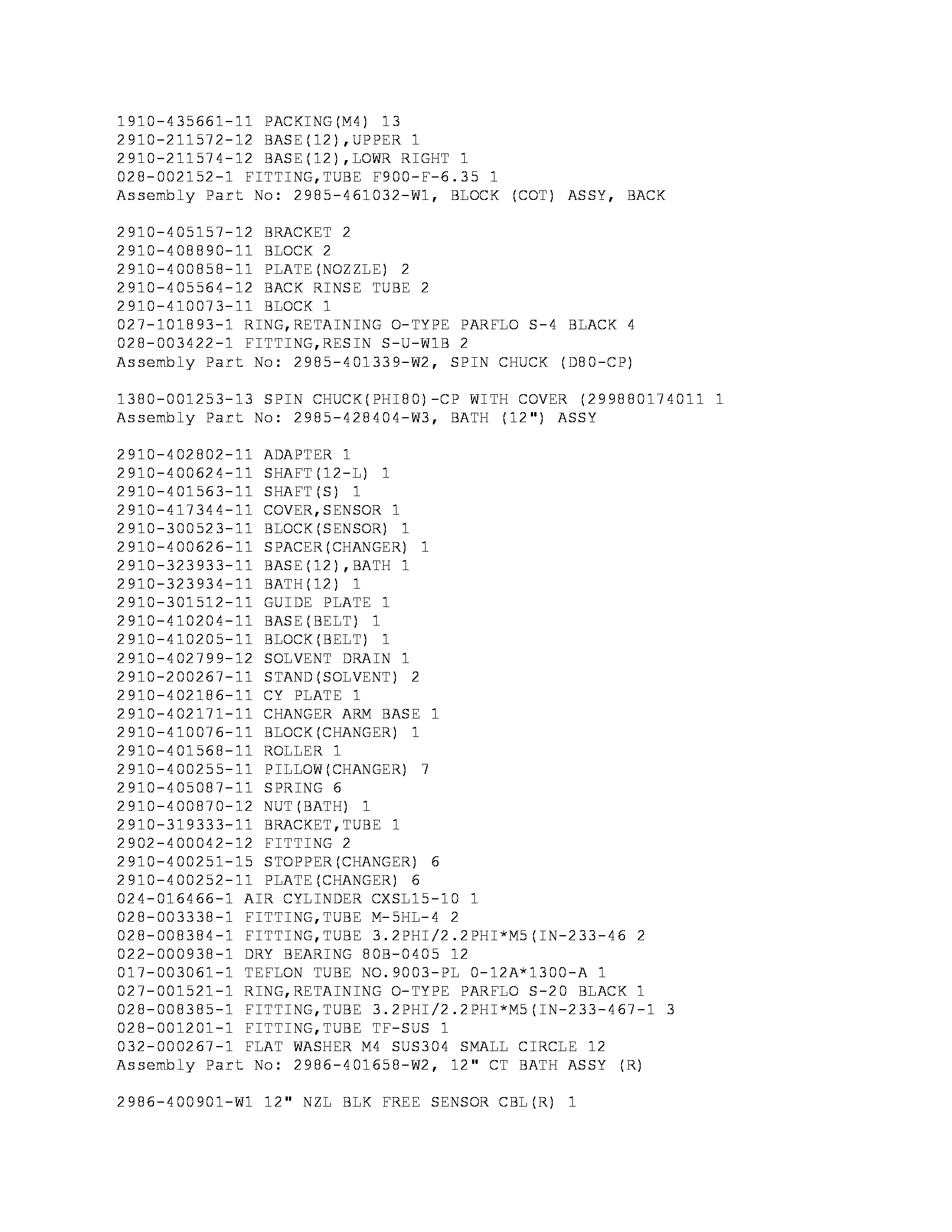

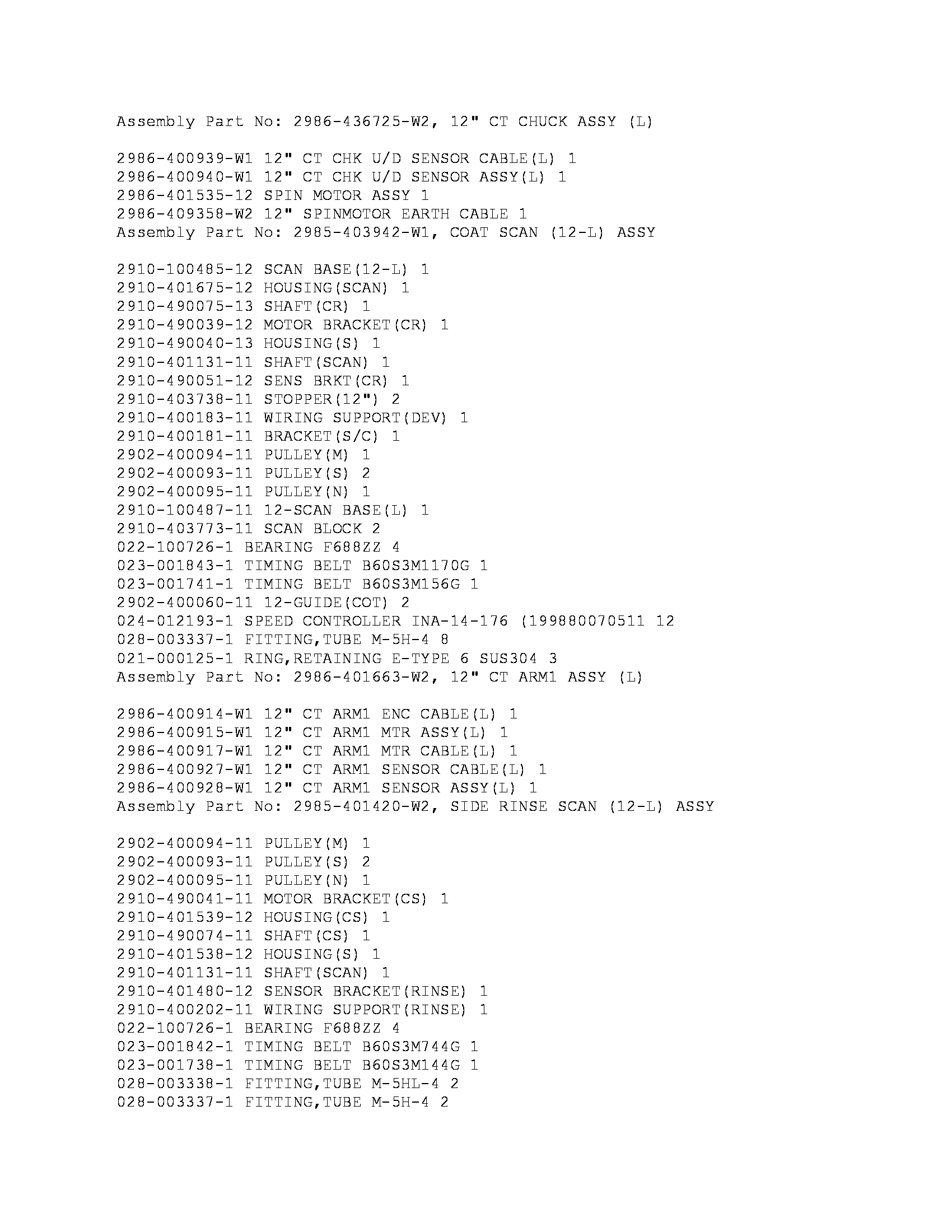

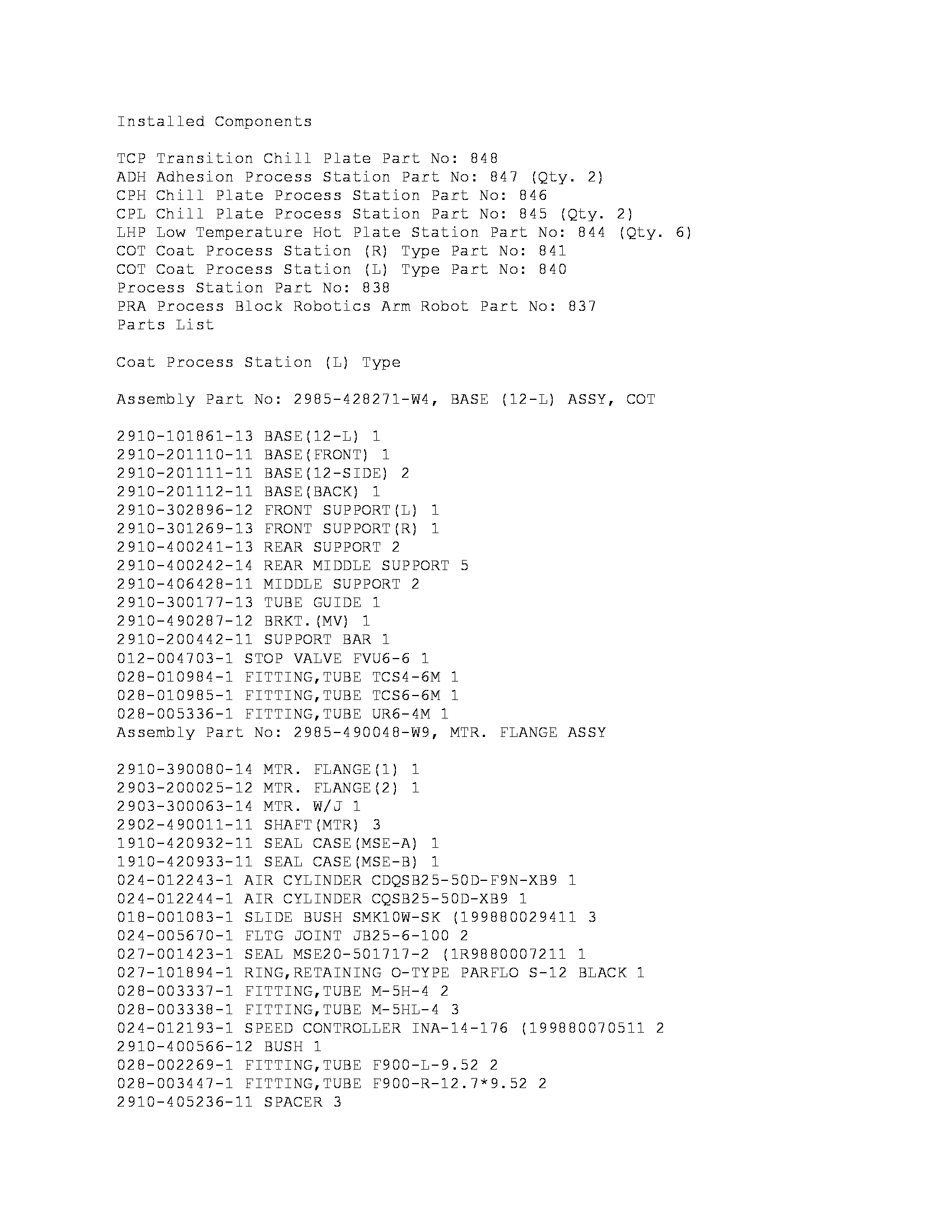

Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9186892 for sale

URL successfully copied!

Tap to zoom

ID: 9186892

Wafer Size: 8"

Vintage: 2000

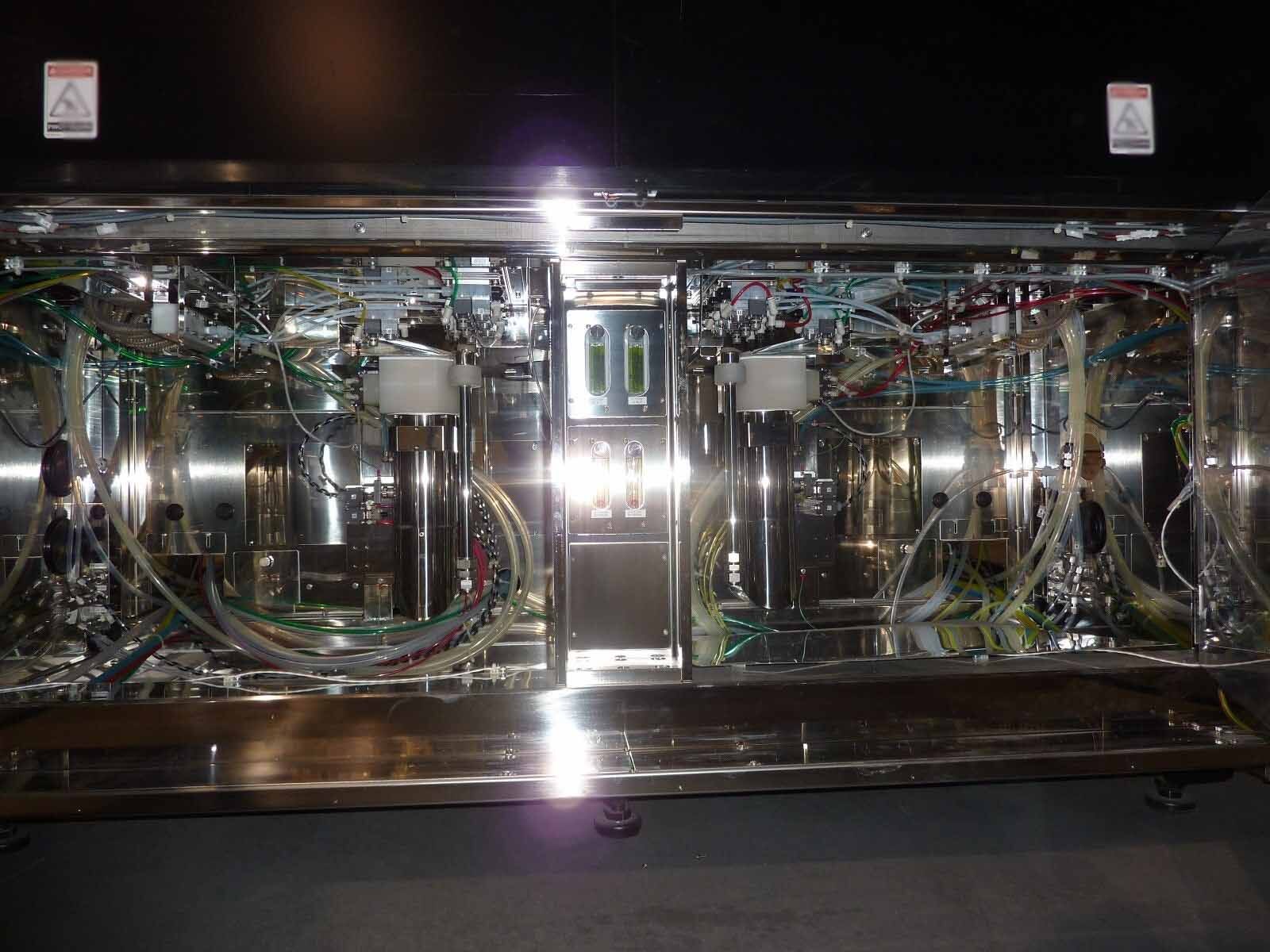

Coater process station, 8"

Model no: ACT12-200

(2) Plate process stations

CE Marked

2000 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 12 is a photoresist equipment used for precise patterning of printed circuit boards. It is a dry etching technology that utilizes advanced high-resolution mask alignment and precise photolithography to form precise and high-resolution printed circuit board (PCB) patterns. TEL Clean Track ACT 12 system is designed to provide organizations with a precise and high-resolution solution for advanced semiconductor patterning needs. The first step of TOKYO ELECTRON Clean Track ACT 12 process is to apply a high-resolution photoresist on the PCB. The photoresist is then exposed to UV light through a well-aligned high-resolution mask. After exposure, the photoresist is developed, and then cleaned, in order to remove any remaining photoresist not exposed to UV light. The exposed photoresist acts as an etch resistant layer, protecting the underlying substrate from the etching process. Once the photoresist is developed, the substrate is ready for dry etching. Clean Track ACT 12 unit uses reactive ion etching (RIE) technology to etch the pattern into the substrate. RIE uses high voltage and low pressure plasmas to remove material from the PCB in a precise and uniform manner. This allows for extremely precise patterning of the substrate. Once the etching process is complete, the etching protection layer is removed using a mixture of solvents. After the photoresist is removed and the etching is complete, the pattern is ready to be soldered and prepared for integration into the final product. TEL / TOKYO ELECTRON Clean Track ACT 12 machine is capable of producing high-resolution, highly precise prints on PCBs with minimum margins of error. Its fast and uniform etching method makes it ideal for high speed production runs of PCBs. Its affordability and ease of use also makes it an ideal choice for businesses looking to produce high-quality, cost-effective PCBs.

There are no reviews yet