Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9190227 for sale

URL successfully copied!

Tap to zoom

ID: 9190227

Wafer Size: 8"

Vintage: 2001

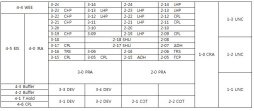

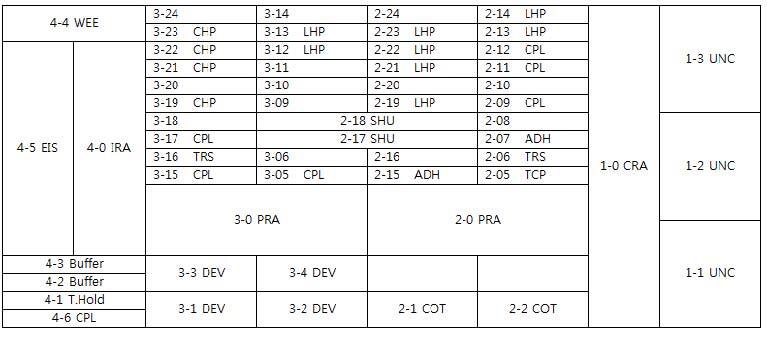

(2) Coaters / (4) Developers system, 8"

In-line

Right to left

Loading configuration: 3 Foup type

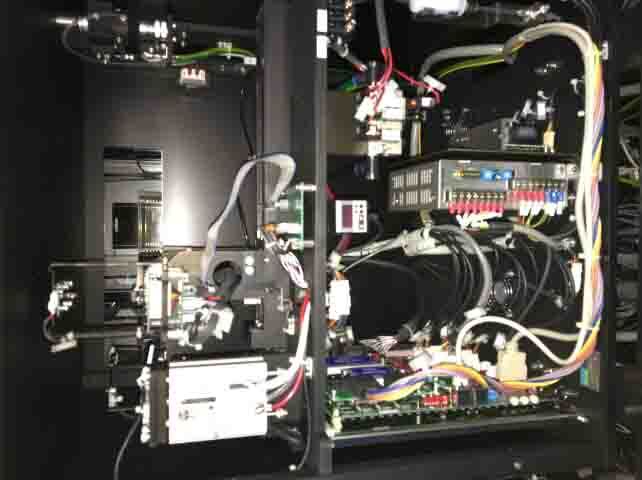

Main controller: 2nd Controller

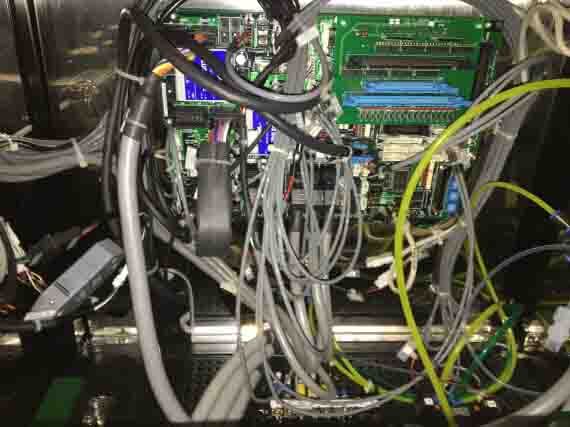

Main frame with system controller

CSB

PRB1

PRB2

IFB

Power box

T&H Controller

Chemical box

Thermo controller

(2) Mass flow controllers

Carrier station: 8" Foup type

(3) Cassettes / (25) Slots

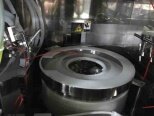

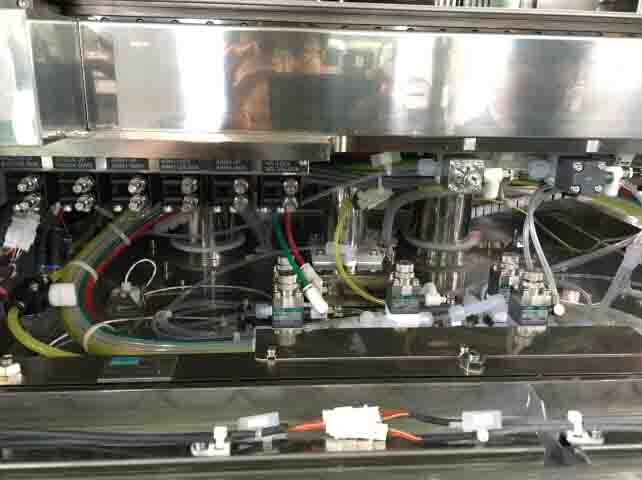

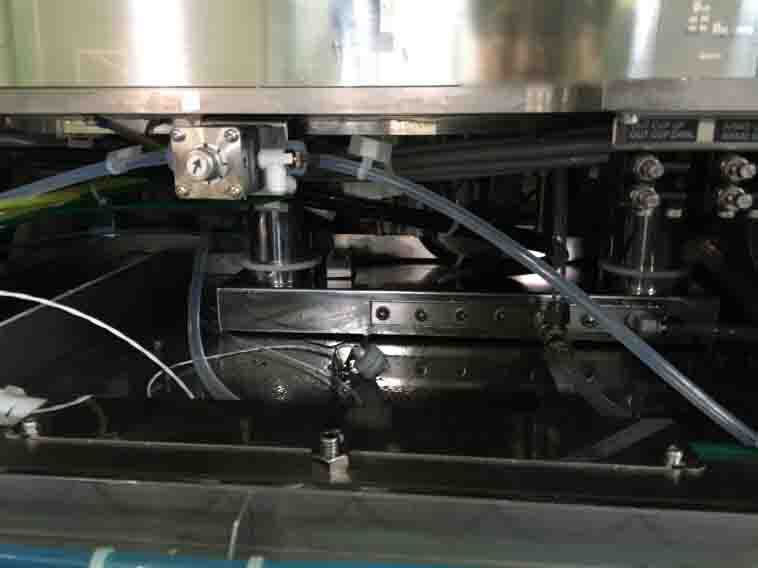

Coater unit (2-1, 2-2 Module):

(4) Dispense nozzles

With temperature controlled lines for etch unit

RRC Pump

PR Suck-back valve: (8) Air operation suck-back valves

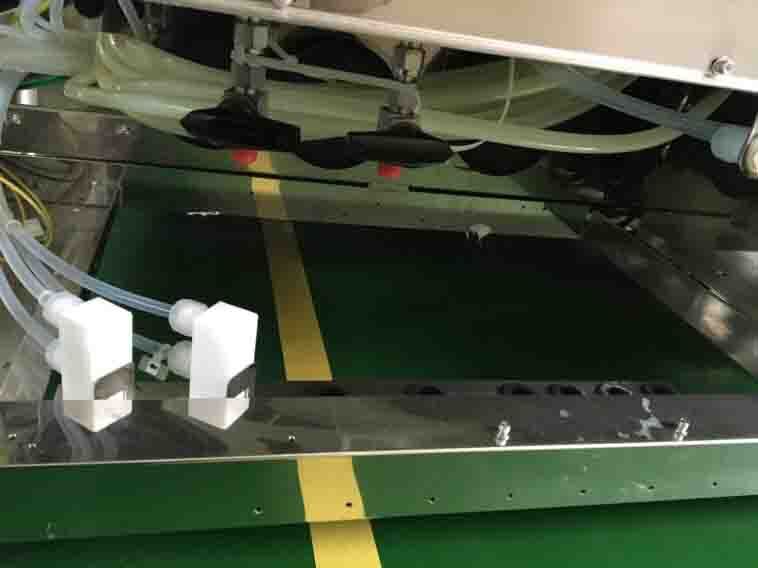

Rinse system:

(3) Liters

(2) Tanks

Buffer tank system

Programmable side rinse

(4) PR Nozzles

(8) Bottles

Thinner supply:

CCSS Supply

Local canister tank function

Photo resist temperature control system

Drain: Direct drain

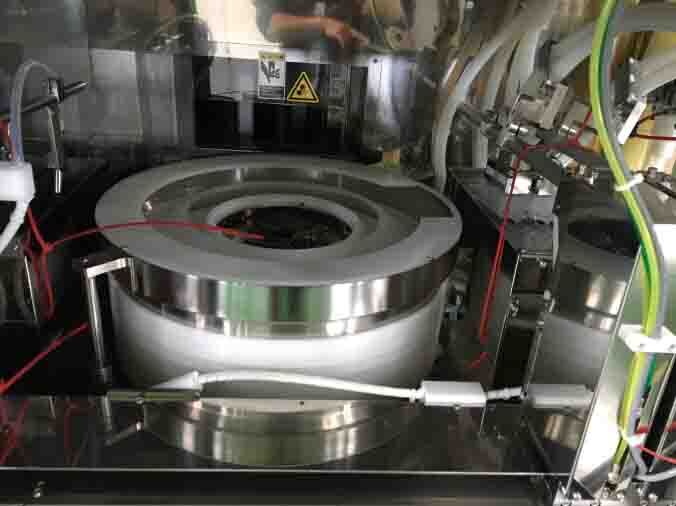

Developer unit (3-1, 3-2, 3-3, 3-4):

(2) H Nozzles for each unit

Stream nozzle for DI rinse

(2) Points for back side rinse on each unit

Developer temperature control system

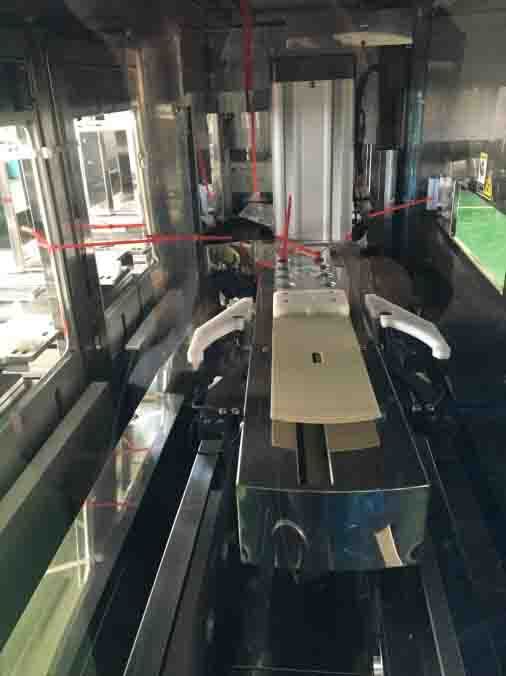

I/F Wafer stage type: NIKON (S204)

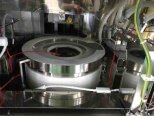

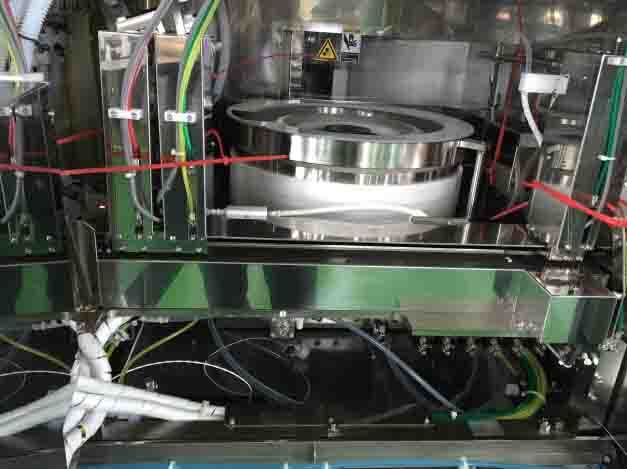

Adhesion unit:

100% Sealing closed chamber (Built-in hot plate)

HMDS Tank with float sensor in system

HMDS Supply: Local bottle

(8) Low temperature hot plates (LHP)

WEE Unit (Wafer edge exposure)

Type: DUV (UV254)

(7) Chill plates (CPL)

(4) Chilling hot plates (CHP)

TCP Unit

(2) TRS Units

SHU: (2) Shuttles

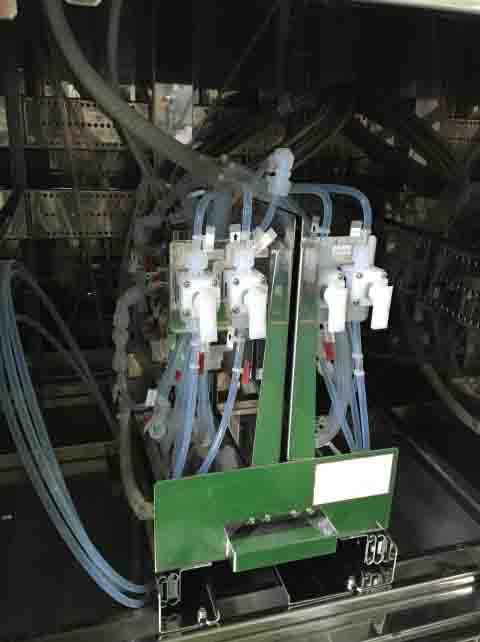

Chemical cabinet 1:

Solvent

Developer

HMDS Chemical cabinet

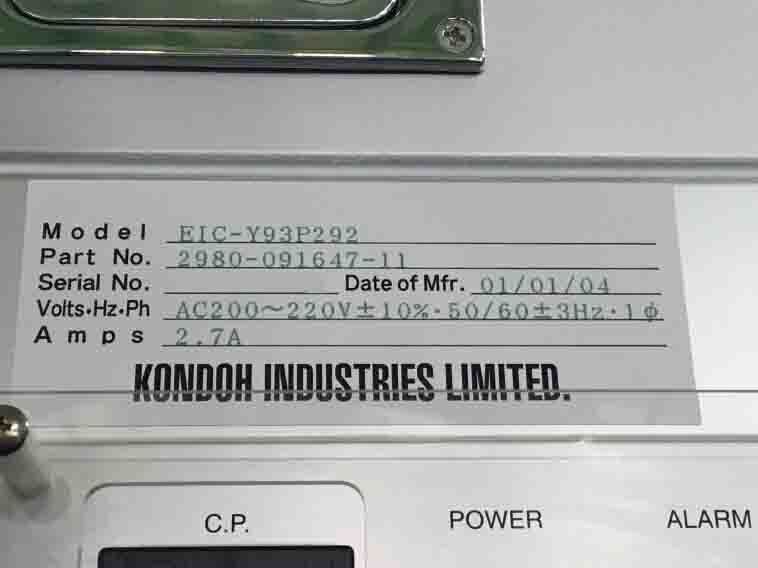

Temperature & humidity controller: Shinwa series (ESA-8)

Temperature control unit(TCU): TEL

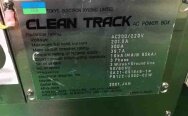

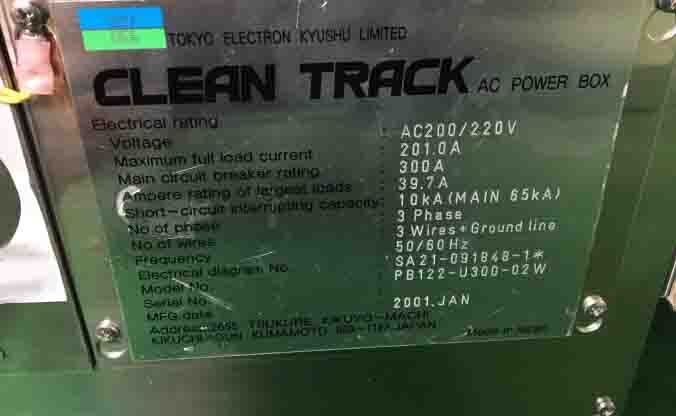

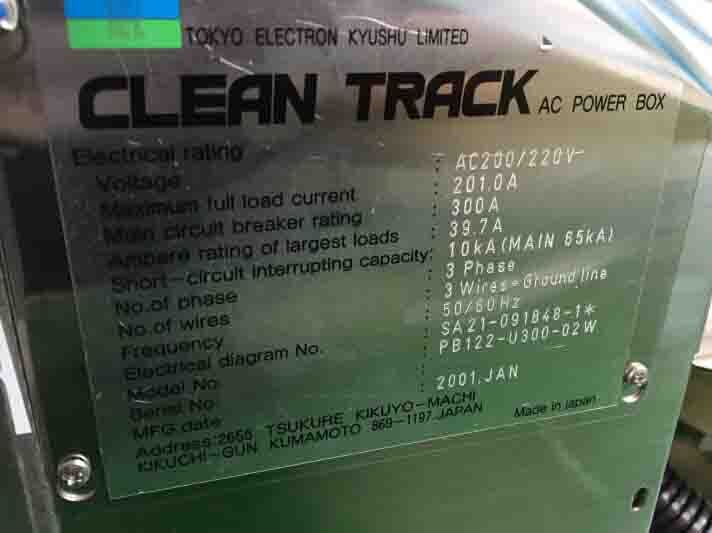

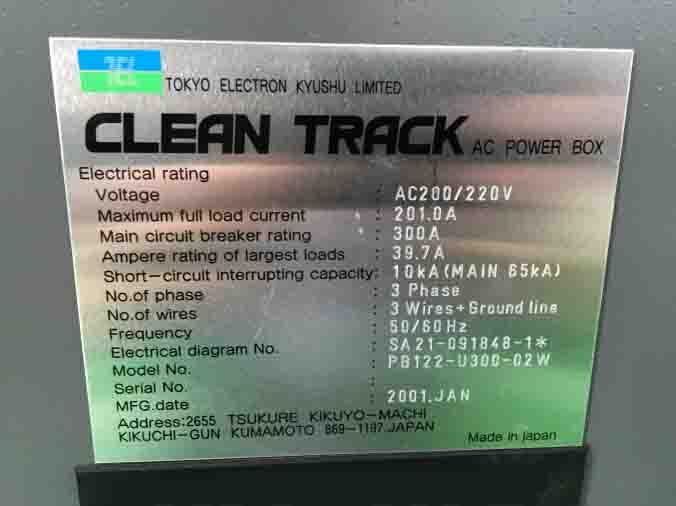

AC Power box:

AC200 / 220V

Full-load current: 300A

Power: AC 208V, 3 Phase, 300A (Maximum)

2001 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 12 is the latest and most advanced photoresist equipment available on the market. It is designed for ultra-low particle performance in the cleanroom environment. The system utilizes a unique combination of technologies including the proprietary Clean Track Auto Clean (CTAC) process which guarantee particle cleanliness, and advanced top-down scan tools for easy maintenance. The Clean Track Auto Clean (CTAC) process utilizes two sequential stages to ensure the highest particle free environment. Firstly, two separate activated brush modules are used to dislodge particles from any surface contours. These bristles are precisely tailored to the shape and size of the part or piece of equipment, ensuring that all contaminants are removed effectively. Secondly, a high airflow unit is used to extract the dislodged particles from the surface. The high air flow also applies an anti-static charge to the surface, further improving the particle-free environment. The machine also utilizes proprietary scan technology to detect any remaining particles. The scanning tool utilizes a 16-channel sensor array to detect particles as small as 1 micron. The sensors measure and compare particle characteristics including size, shape, and density, allowing for accurate identification of particle counts. Through this scanning process, the tool is able to detect and remove particle levels below the industry standard. TEL Clean Track ACT 12 asset also utilizes advanced temperature, humidity, and ozone monitoring techniques in order to ensure the cleanroom environment is consistently maintained. Temperature and humidity sensors monitor the environment in order to adjust the model as needed. Additionally, ozone sensors are used to detect the presence of any ozone-generating particles, and adjust the equipment's ozone production accordingly. The system provides complete control to the user, allowing for precise monitoring of the cleaning process. Additionally, both the dust and anti-static systems provide advanced statistical analysis tools, enabling users to monitor the cleaning thresholds and ensure optimal particle free performance. Overall, TOKYO ELECTRON Clean Track ACT 12 is a highly advanced photoresist unit, enabling users to achieve the highest levels of cleanliness in the cleanroom environment. The machine utilizes a combination of advanced technologies to allow for constant particle free performance, while providing complete control over the cleaning process.

There are no reviews yet