Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9216089 for sale

URL successfully copied!

Tap to zoom

ID: 9216089

Wafer Size: 12"

Vintage: 2008

Coater / (2) Developer system, 12"

With system controller

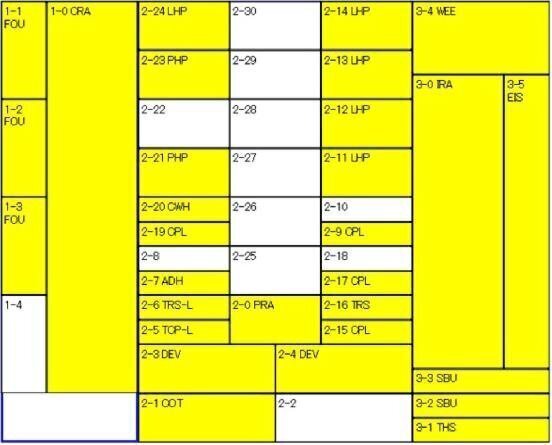

Left to right

I/F Wafer stage type: NIKON Type (SFl3)

Carrier station:

Foup cassette

Uni-cassette

(3) Cassettes

Coater unit:

(6) Dispense nozzles with temperature controlled lines

MILLIPORE RDS Pump

Rinse nozzle: Back / EBR / Solvent bath

Rinse system: 3 Liters (2) buffer tanks

Degassing system

Programmable side rinse:

PR Nozzles (1-6): (36) Bottles

Thinner supply (Bottle / Nozzle): CCSS

AMC Suck-back valve

Direct drain

Developer unit:

H-Nozzle

Stream nozzle for DI rinse

Developer system:

(2) 3 Liters buffer tanks

Developer supply: CCSS

Degassing system

Developer temperature control system

Direct drain

Adhesion unit:

Sealing closed chamber

HMDS Tank with float sensor

HMDS Supply: Local bottle

(5) Low temperature hot plates (LHP)

(4) Chill plates (CPL)

(4) Precision chilling hot plates (CHP)

TCP Unit

(2) TRS Units

WEE Unit (Wafer edge exposure)

UV Sensor: I-line

Chemical cabinet:

Solvent

HMDS

DEV Chemical cabinet

SHINWA ESA-8 Series Temperature / Humidity controller

Temperature Control Unit (TCU)

AC Power box

2008 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 12 is a photoresist equipment that is used in semiconductor fabrication. It consists of a photoresist processing system and a stepper track combined in one integrated unit to provide a low-particulate environment. The photoresist unit is the first step in semiconductor device fabrication and is used to create small patterns on the substrate. The photoresist is exposed to light, either from a photomask or a beam of electrons, depending on the pattern being created. The exposed photoresist is then developed and the resulting pattern is transferred to the substrate. TEL Clean Track ACT 12 is designed to be as efficient, clean, and low-particulate as possible. This is achieved through its advanced stepper track machine, which works in conjunction with the photoresist processing tool. The stepper-track asset is designed to reduce the number of particles created by the photomask during the exposure process. It does this by capturing the particles and isolating them between the track and the photomask during the processing. The particles are then safely removed and disposed of. TOKYO ELECTRON Clean Track ACT 12 also features an advanced temperature tracking model that can directly enforce temperature control by correlating electron beam temperatures with process times and dose. This reduces the chances of defects caused by changes in temperature during processing. Clean Track ACT 12 is an invaluable tool in the rapidly growing field of semiconductor fabrication. Its combination of advanced photoresist processing, stepper-track equipment, and temperature tracking capabilities provide precise results in a low-particulate environment. It is becoming increasingly popular amongst device manufacturers due to its efficiency and effectiveness.

There are no reviews yet