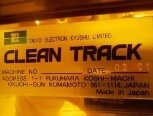

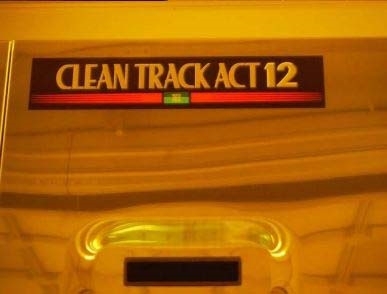

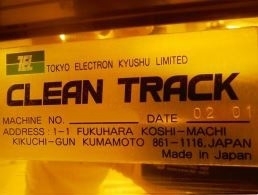

Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9259917 for sale

URL successfully copied!

Tap to zoom

ID: 9259917

Wafer Size: 12"

Vintage: 2002

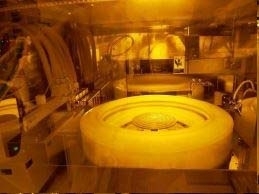

Resist coater / Developer system, 12"

Single block

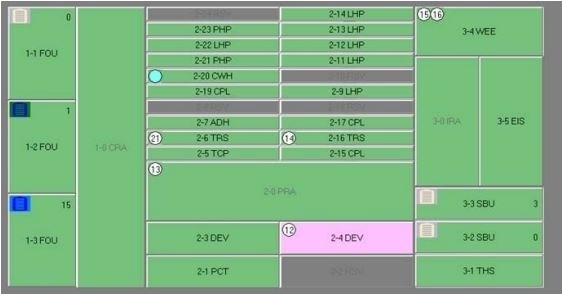

Track 1:

PI Coater cup

(2) Developer cups

ADH

Track 2:

Resist reduction:

Developer: H Nozzle

Resist pump:

SHV 15 ml (Line 1)

RDS 10 ml (Line 2~6)

Oven configuration:

(2) PHP

(3) CPL

(4) Standard LHP

(2) High EXH LHP

Track chemicals:

Resist supply:

Gallon bottle

Coat bottle

Thinner: OK73

2002 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 12 is a photoresist processing equipment designed for use in wafer and mask fabrication. The system provides superior performance, reliable results, and a compact footprint for industrial lithography operations. The unit features an ultraviolet laser scanner for direct imaging of photoresist with excellent image quality and resolution. The laser creates accurate exposure patterns in photoresist with minimal resist ash residue or energy losses. The advanced scanner design also allows for high speed processing and easy operation. The machine also features automated process control to ensure repeatable and stable results. It is equipped with laser intensity control, temperature and motion control, resist patterning, resist thickness control and process tracking functions. The integrated tool can perform multiple exposure processes with concurrent tracking of each process. In addition to improved performance, TEL Clean Track ACT 12 also features an improved environmental footprint. The asset uses an optimized design for reduced water and power consumption, as well as improved maintenance with fewer parts. It also features a quieter operation. TOKYO ELECTRON Clean Track ACT 12 is an ideal choice for wafer and mask fabrication operations that require precision control and performance from large-scale production to small production runs. The model provides superior performance in a small footprint, making it a cost-effective solution for industrial lithography operations.

There are no reviews yet