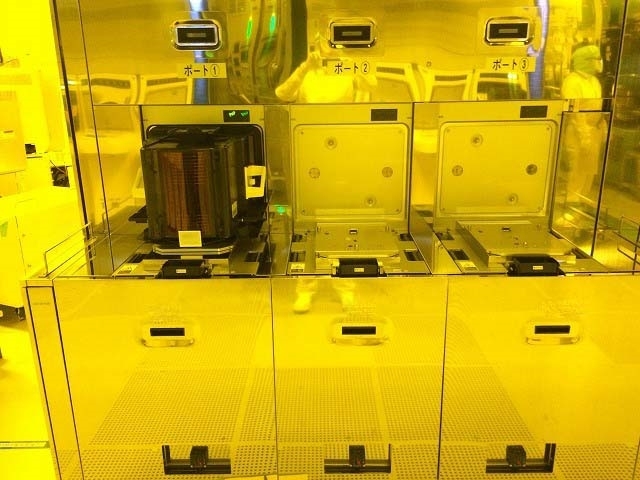

Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9265669 for sale

URL successfully copied!

Tap to zoom

ID: 9265669

Wafer Size: 12"

Vintage: 2006

Resist coater / Developer system, 12"

Single block

Track 1:

(2) Coater cups

(2) Developer cups

ADH

Track 2:

Resist reduction: RRC

Developer: SH Nozzle

Resist pump: RDS 10 ml

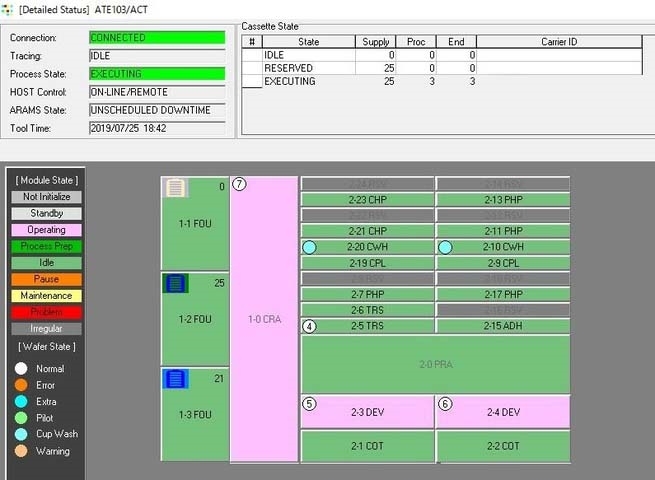

Oven configuration:

(4) PHP

(2) CHP

(2) CWH

(2) CPL

Track chemicals:

Resist supply: Gallon bottle

Thinner: OK73

2006 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 12 is a fully automated photoresist equipment designed to improve the efficiency of mask making processes used in large-scale electronics assembly. Its advanced design utilizes an array of patterned cleaning technologies including spray, develop, and rinse systems to ensure the highest quality cleaning results. The system offers unparalleled cleaning performance and can process up to 1,000 wafers per hour. TEL Clean Track ACT 12 utilizes a dual-arm design consisting of a movable cleaning arm and a stationary arm to optimize the cleaning process. This ensures that the solution is evenly dispensed over the entire surface of the wafer for uniform results. The unit is equipped with a six-nozzle sprayer that optimizes pattern accuracy and covers up to three times the area of a conventional sprayer. TOKYO ELECTRON Clean Track ACT 12 also features a comprehensive develop module that includes a pressurization chamber to ensure consistent and reproducible results. The module reduces solution evaporation and drive off, resulting in precise and reliable development and etching processes. The machine also utilizes rinse technologies that minimize cross contamination and improve performance. Clean Track ACT 12 also provides a number of user-friendly options such as the ability to monitor and adjust the distance between the cleaning arm and the wafer, and the ability to control the composition of the cleaning solution. The tool is designed for ease of use and can be quickly setup and configured by operators with minimal training. Furthermore, the asset is designed to minimize maintenance needs, with a full-size fan filter model that ensures clean air is circulated throughout the chamber without requiring frequent cleaning or replacement. In conclusion, TEL / TOKYO ELECTRON Clean Track ACT 12 provides a reliable, automated photoresist equipment that is designed for efficient mask making processes. Its advanced design combines a comprehensive array of patterned cleaning technologies with user-friendly options that enable operators to quickly and accurately control the cleaning process. This ensures the highest levels of performance with minimal maintenance needs.

There are no reviews yet