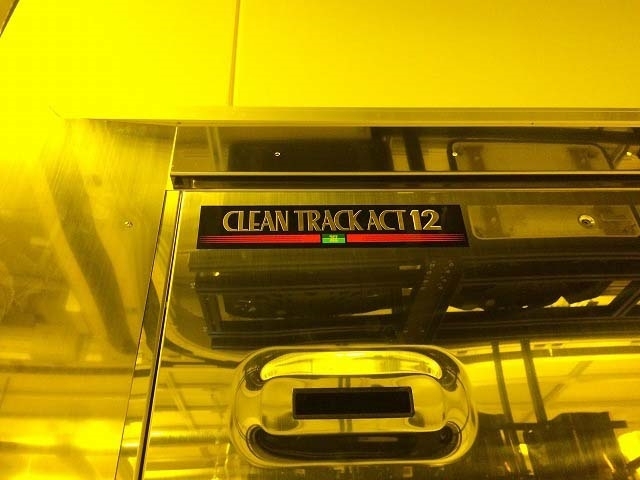

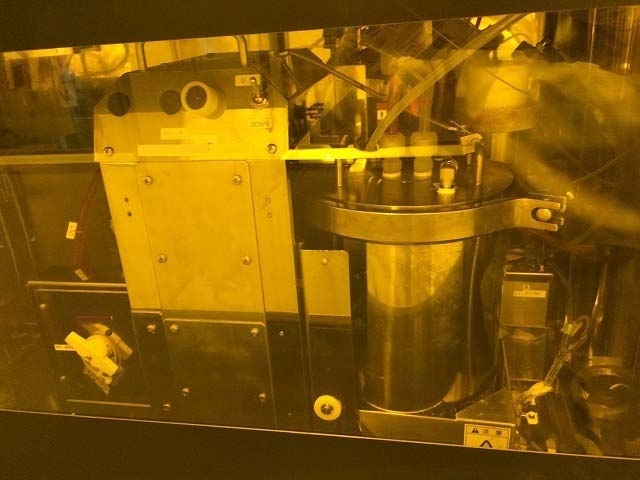

Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9265670 for sale

URL successfully copied!

Tap to zoom

ID: 9265670

Wafer Size: 12"

Vintage: 2002

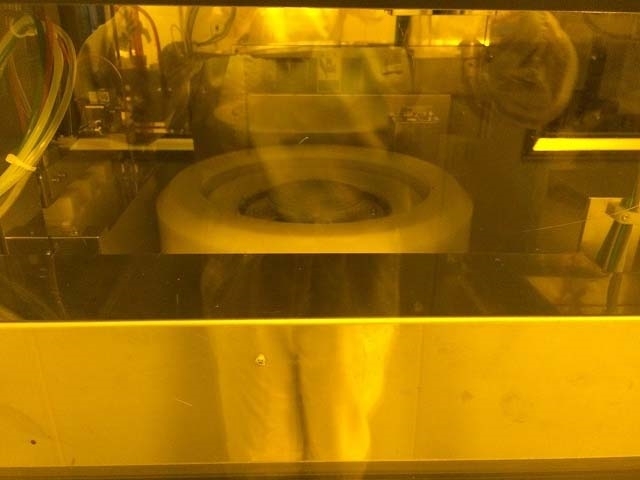

Polyimide coater / Developer system, 12"

Single block

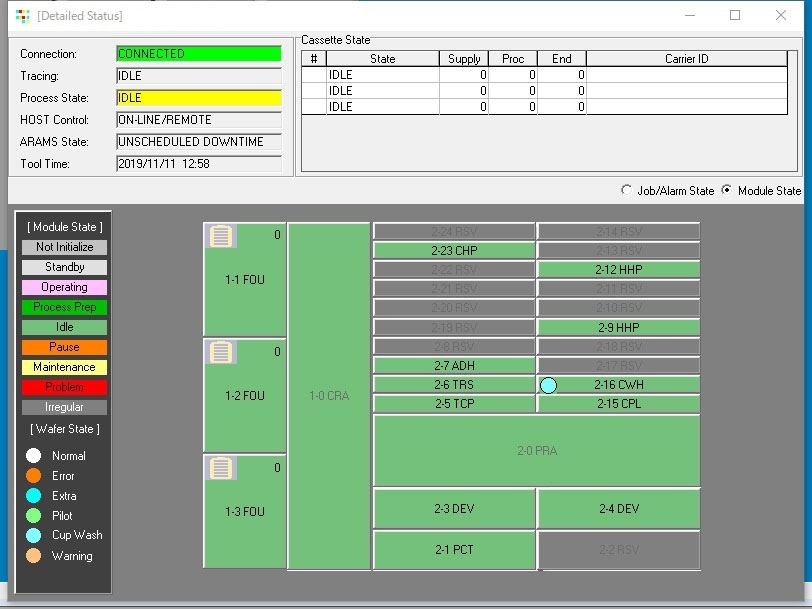

Track 1:

PIC Cup: 1

Developer cup: 2

ADH:1

Track 2:

Dev nozzle: SH

PI Pump: ENCOMPASS

Oven:

PIC: CHP

Dehyd: HHP

Track chemicals:

PI Supply: Gallon bottle

PM Thinner

Option:

PRA Arm: Vacuum pincet

2002 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 12 is a photoresist equipment built for the semiconductor industry. It is designed to provide cleaner environments for lithography applications. The system uses a unique multi-stage cleaning design to provide maximum cleanliness. The device cleans the photoresist from the surface of the substrate by using an array of nozzles and pumps. For cleaning, the nozzles are able to generate an optimal cleaning flow by using a precision slit-nozzle design. The slit nozzle creates a turbulent airflow that breaks large particles into small pieces for easier removal. In addition, the nozzles can also create an array of suctioning channels for efficient extraction of particles from the surface. The cleaning operation is further enhanced by the addition of extra nozzles that inject high-pressure gas, which serves to break up adhered particles and encapsulated bubbles. The pumps used by the unit are of a diaphragm design which create a vacuum inside the tank. This vacuum allows the user to customize the cleaning process for different applications. There are three sizes of pumps, ranging from small to largest, which accommodate different combinations of pressure and volume. Each pump also includes an efficient pressure control machine which ensures that the pressure is always within an optimal range. Additionally, TEL Clean Track ACT 12 is equipped with a water purification tool that ensures the tank is clean by removing chemicals, dirt, and other impurities from the tap water. This not only reduces contamination of the photoresist but also enhances the performance of the cleaning operation. TOKYO ELECTRON Clean Track ACT 12 also utilizes a visual inspection asset to monitor the quality of the substrate surface. This model consists of three cameras placed inside the unit that capture an image of the substrate before, during, and after the cleaning process. This helps the user ensure the photoresist has been effectively removed and the surface is still smooth and free of defects. Overall, Clean Track ACT 12 is a highly advanced photoresist equipment that provides better cleaning performance and greater control over the lithography process. The system's efficient cleaning design combined with its robust water purification and visual inspection systems helps to ensure a successful cleanroom operation.

There are no reviews yet