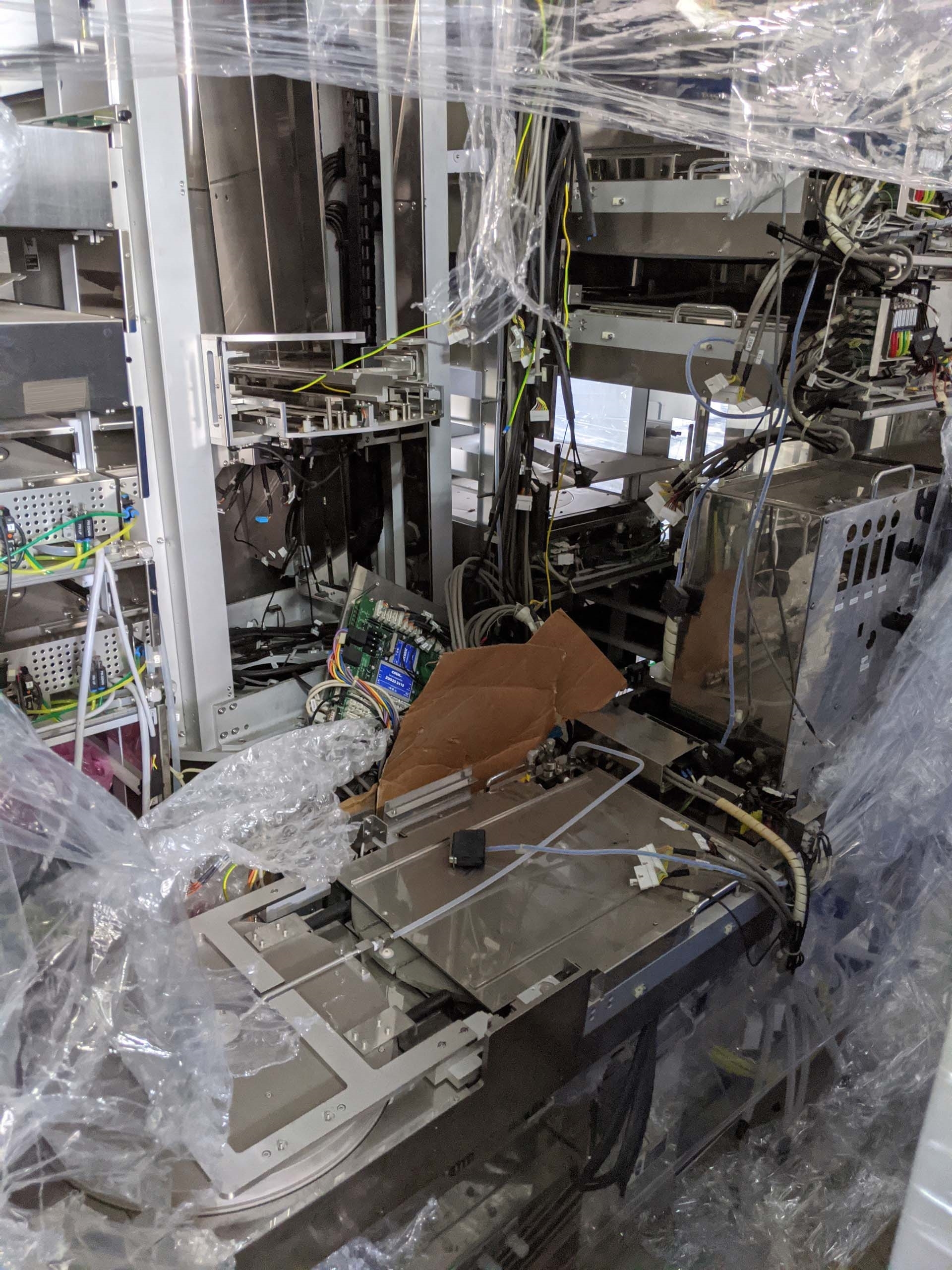

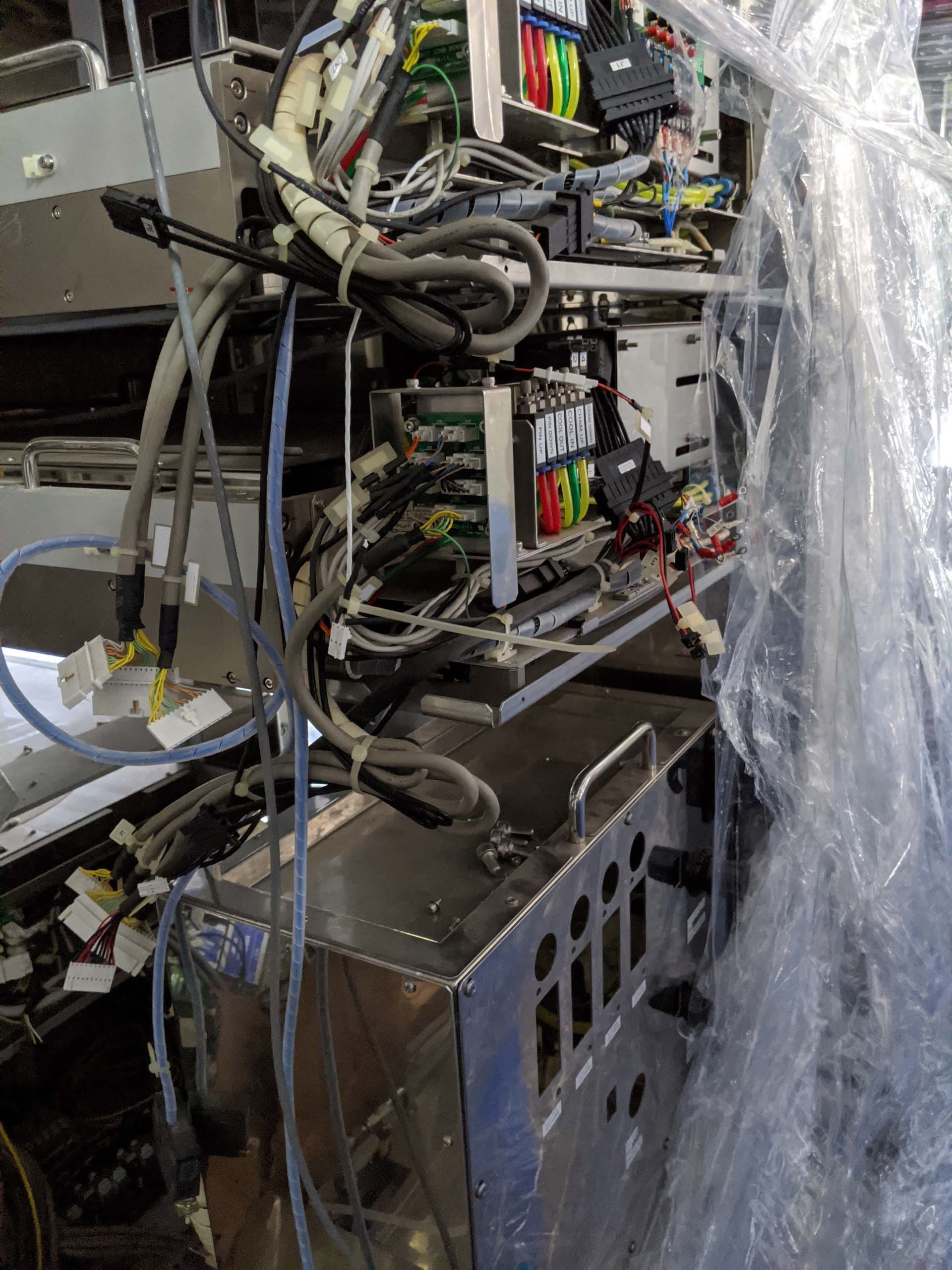

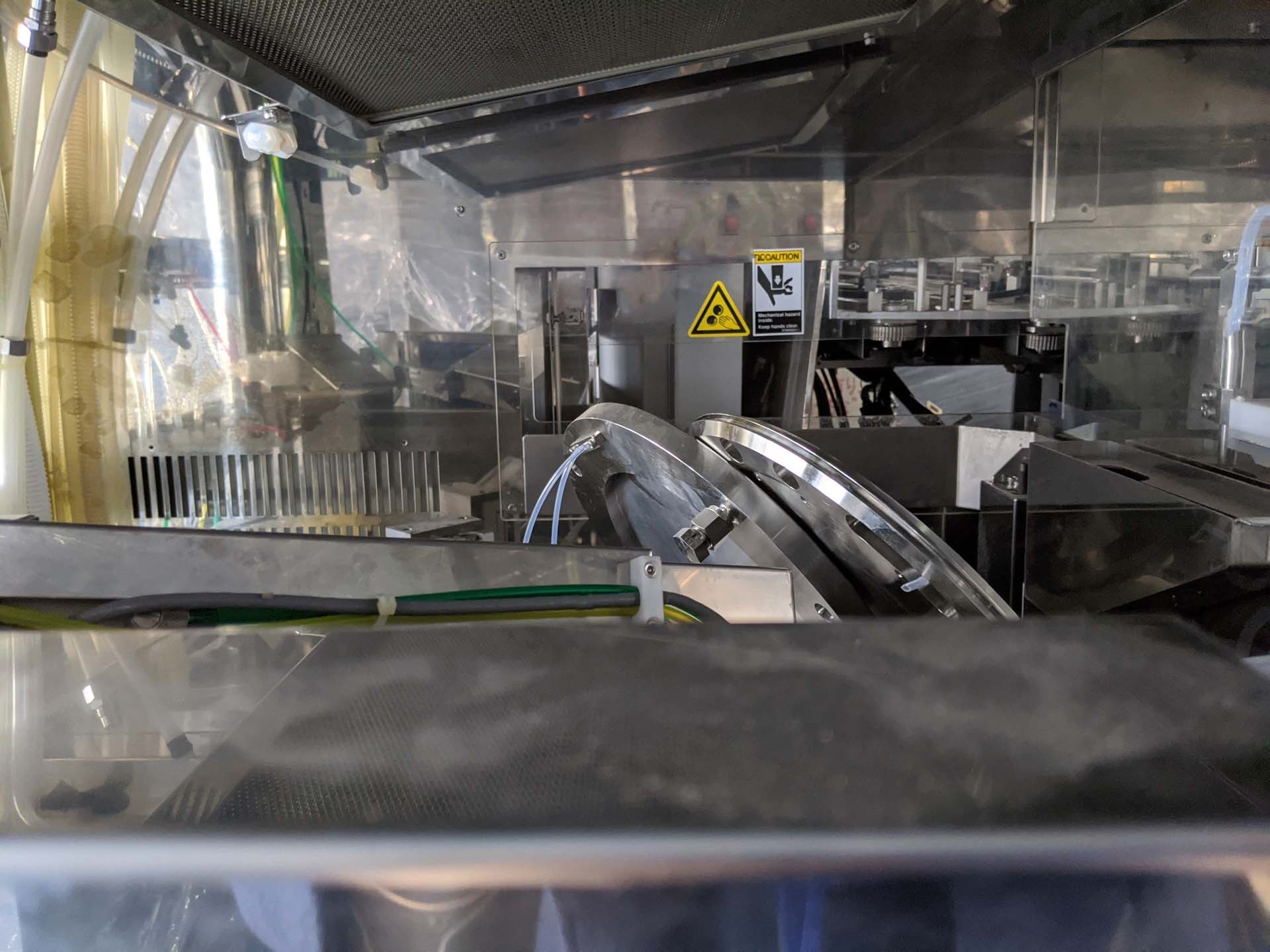

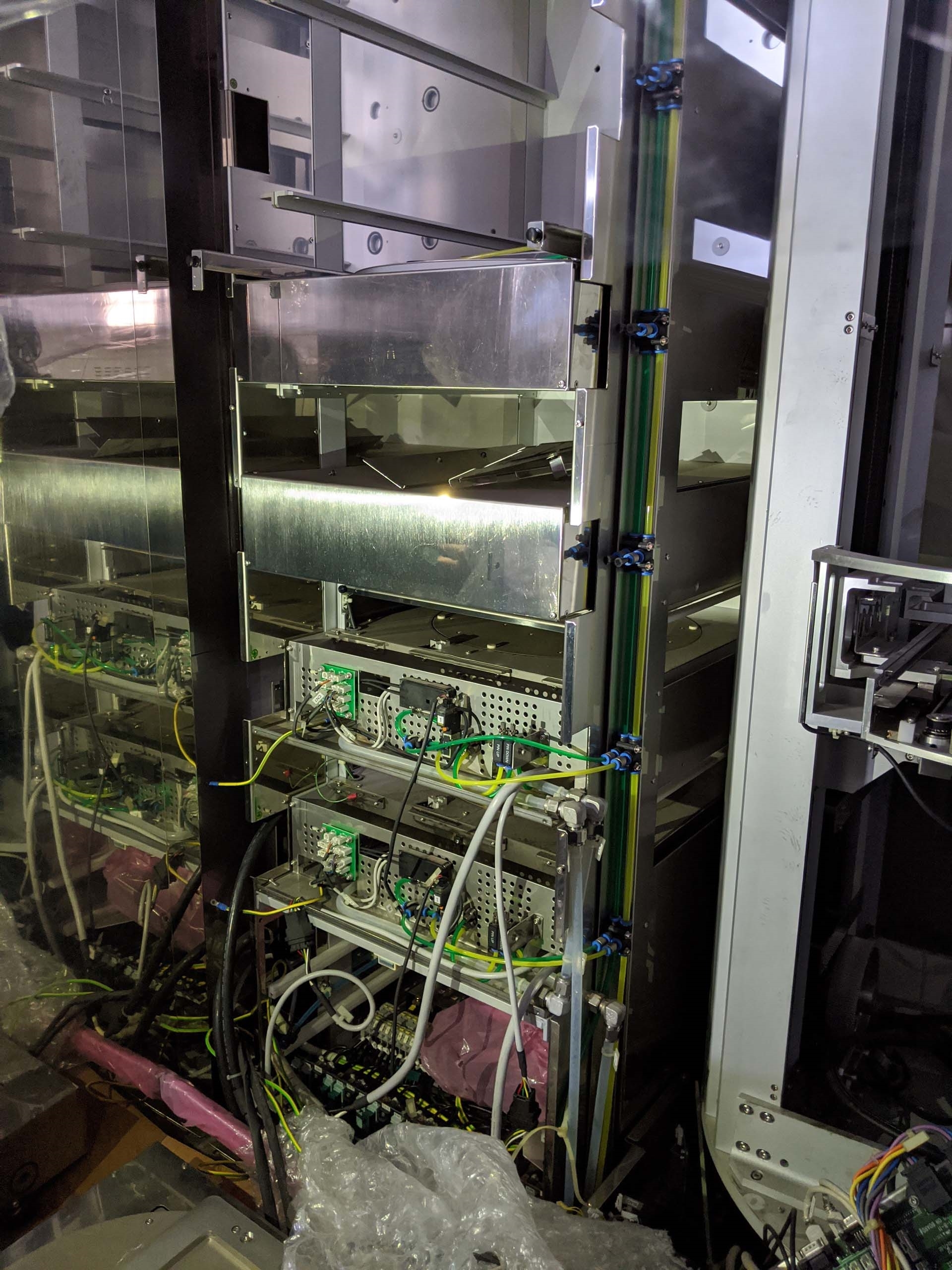

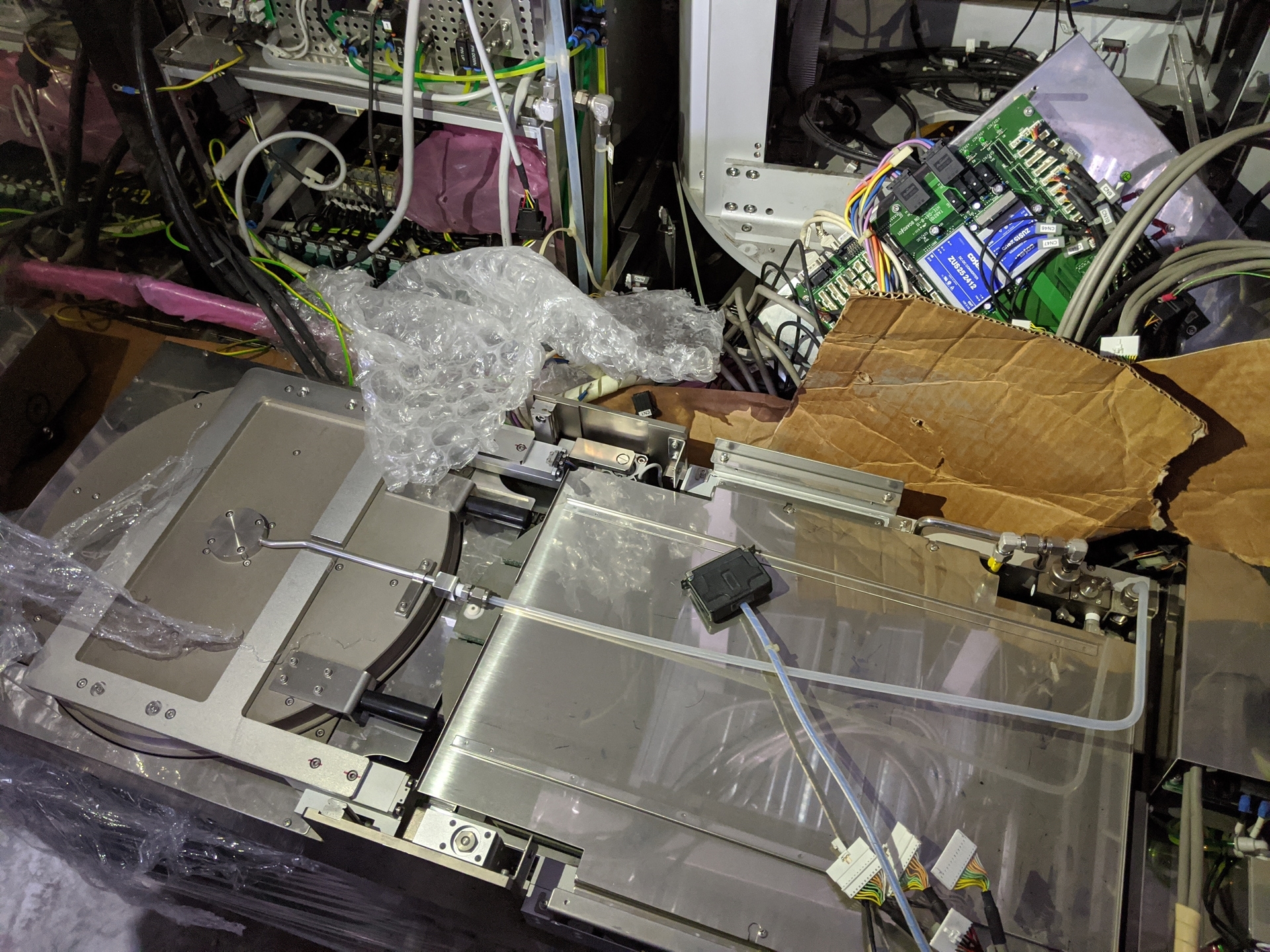

Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9269256 for sale

URL successfully copied!

Tap to zoom

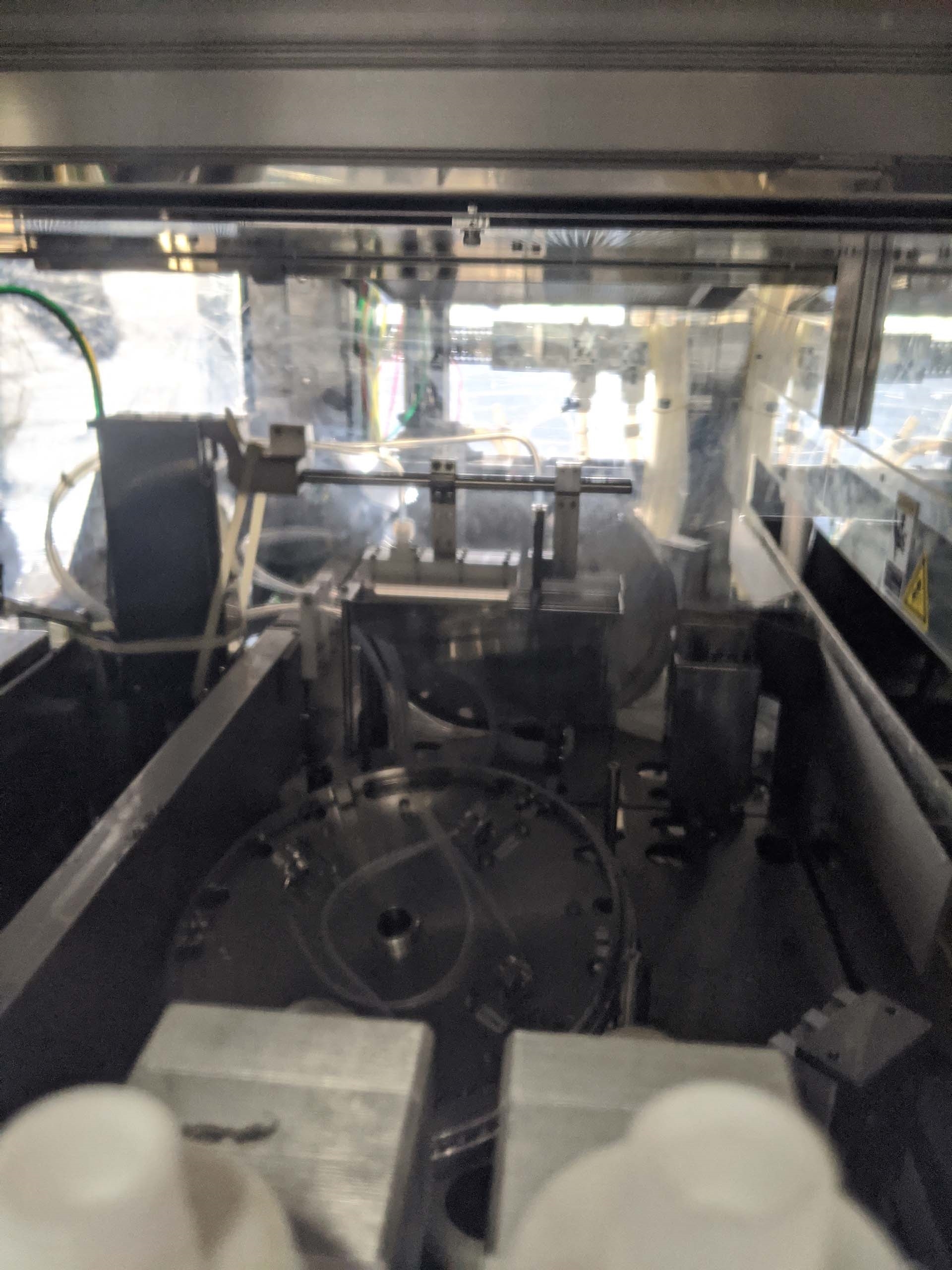

TEL / TOKYO ELECTRON Clean Track ACT 12 is a photoresist system designed for use in semiconductor fabrication. It provides consistent, high-quality results with superior cleanliness and superior handling of substrates. This system is a highly versatile platform for developing photoresists for various deposition applications, including electrostatic deposition, chemical-mechanical planarization (CMP) and other specialty applications. TEL Clean Track ACT 12 consists of three main components: the mainframe, the main processor and the associated software packages. The mainframe houses the two-axis turning table, which is required to hold the target substrates during processing. The main processor contains all the components required to run the software required during the photoresist process. This includes the calculations to control the speed and accuracy of the application, as well as the actual software that is necessary to create the desired pattern. In addition, the processor also contains all the components required to operate the microprocessor-based touch screen that allows the operator to precisely control the process parameters. TOKYO ELECTRON Clean Track ACT 12 includes various tools for optimal deposition of photoresist on the substrate. These include mask plates for the application of the photoresist, as well as an auxiliary tool that is used to transfer the photosensitive material from the mask plate to the substrate. The system also includes a laser-based heating tool to create a uniform coating on the substrate, and a vacuum attachment for clean-up after completion of the process. The cleaning and processing of the substrate is done through a specialized machine that utilizes a combination of chemical cleaners, abrasive cleaners and etching solutions to remove contaminants from the substrate. After the contamination has been eliminated, a chemical primer is applied and then allowed to dry before the application of photoresist. The deposition of photoresist is then done using a series of rectangular pulses of a specified width and frequency. Additional treatments can be used to enhance the adherence of the photoresist to the substrate, if necessary. Clean Track ACT 12 provides consistent, high-quality results with superior cleanliness and superior handling of substrates. It is an ideal platform for developing photoresists for various deposition applications and specializes in electrostatic deposition, chemical-mechanical planarization and other specialty applications.

There are no reviews yet