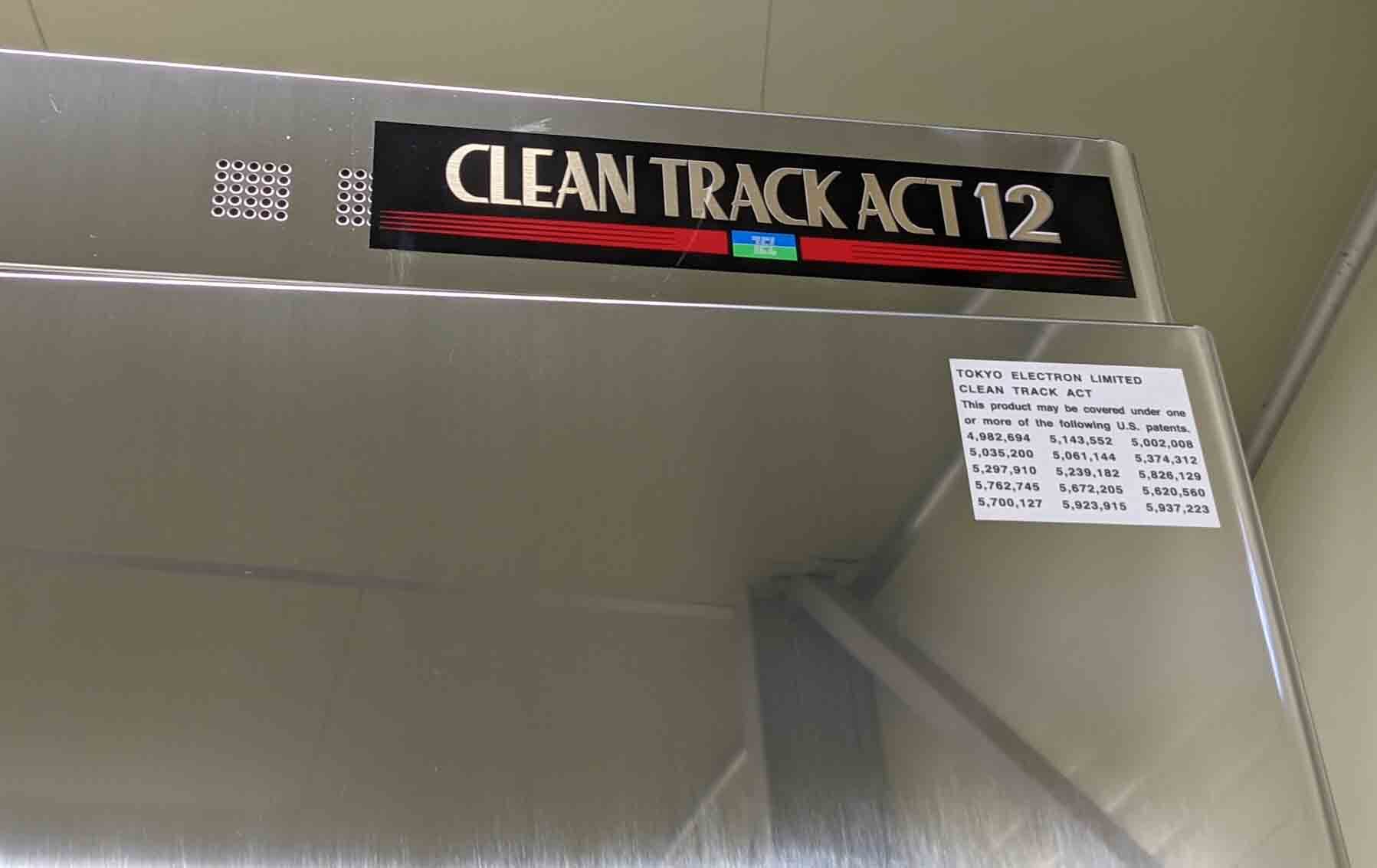

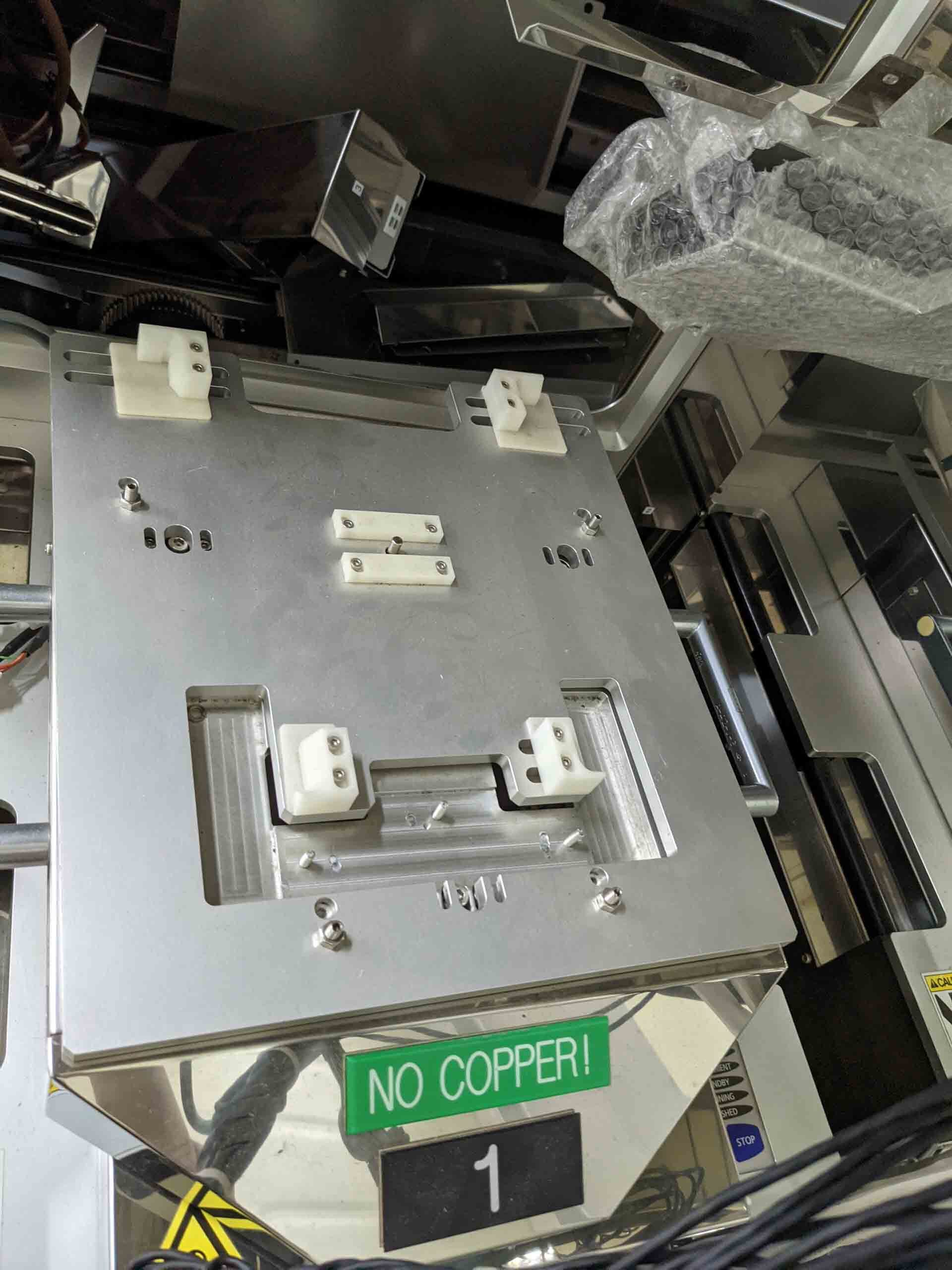

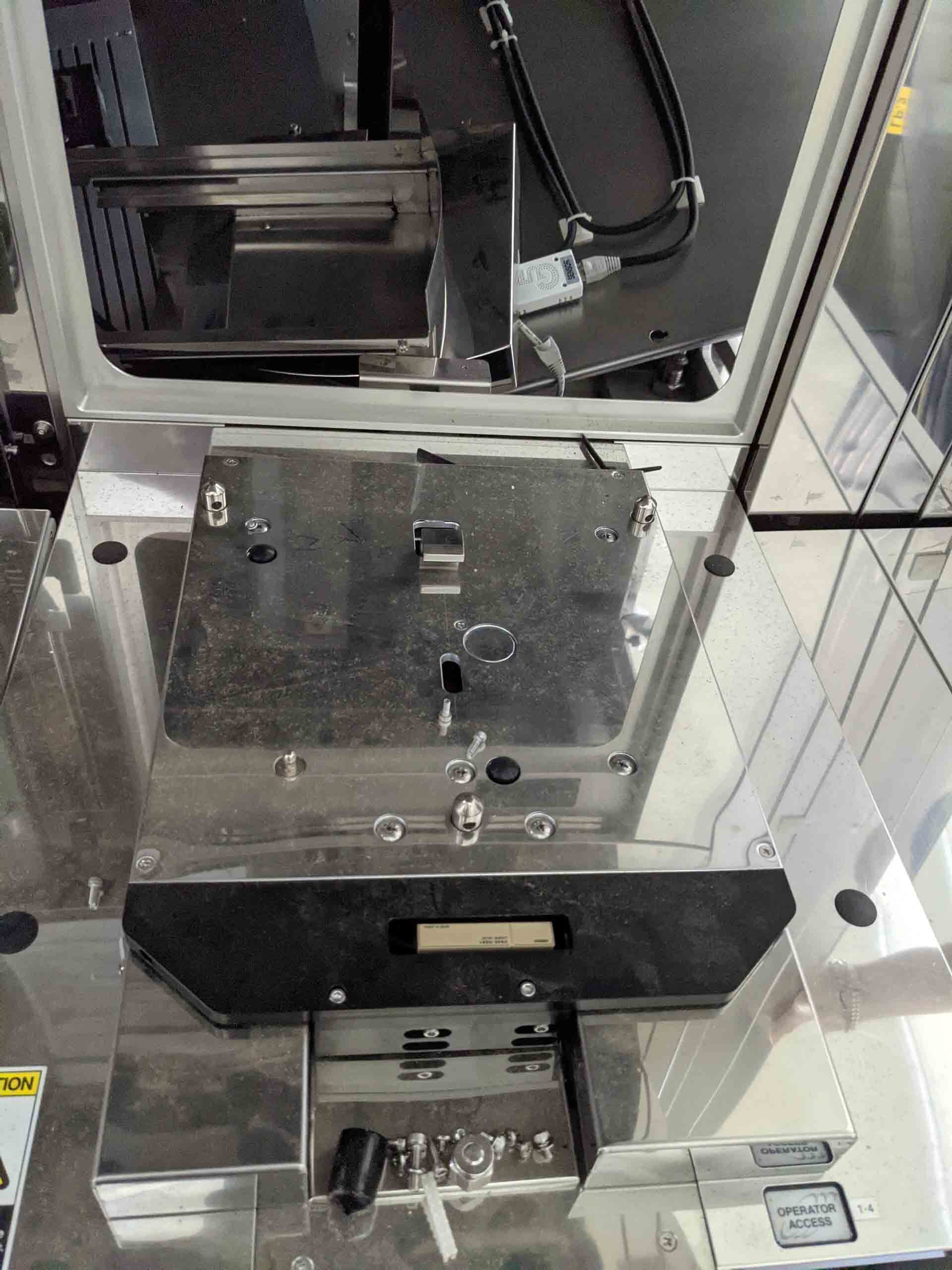

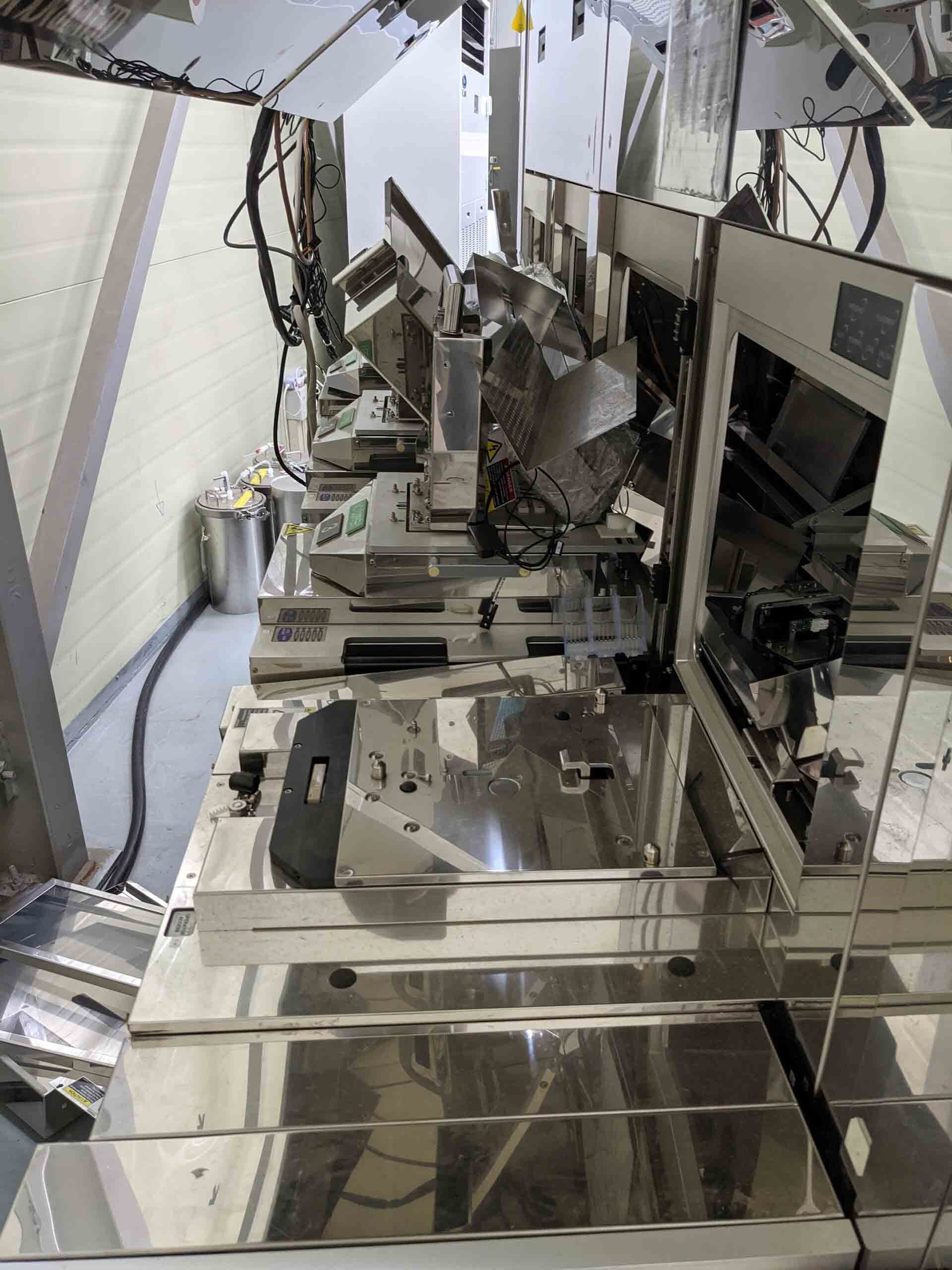

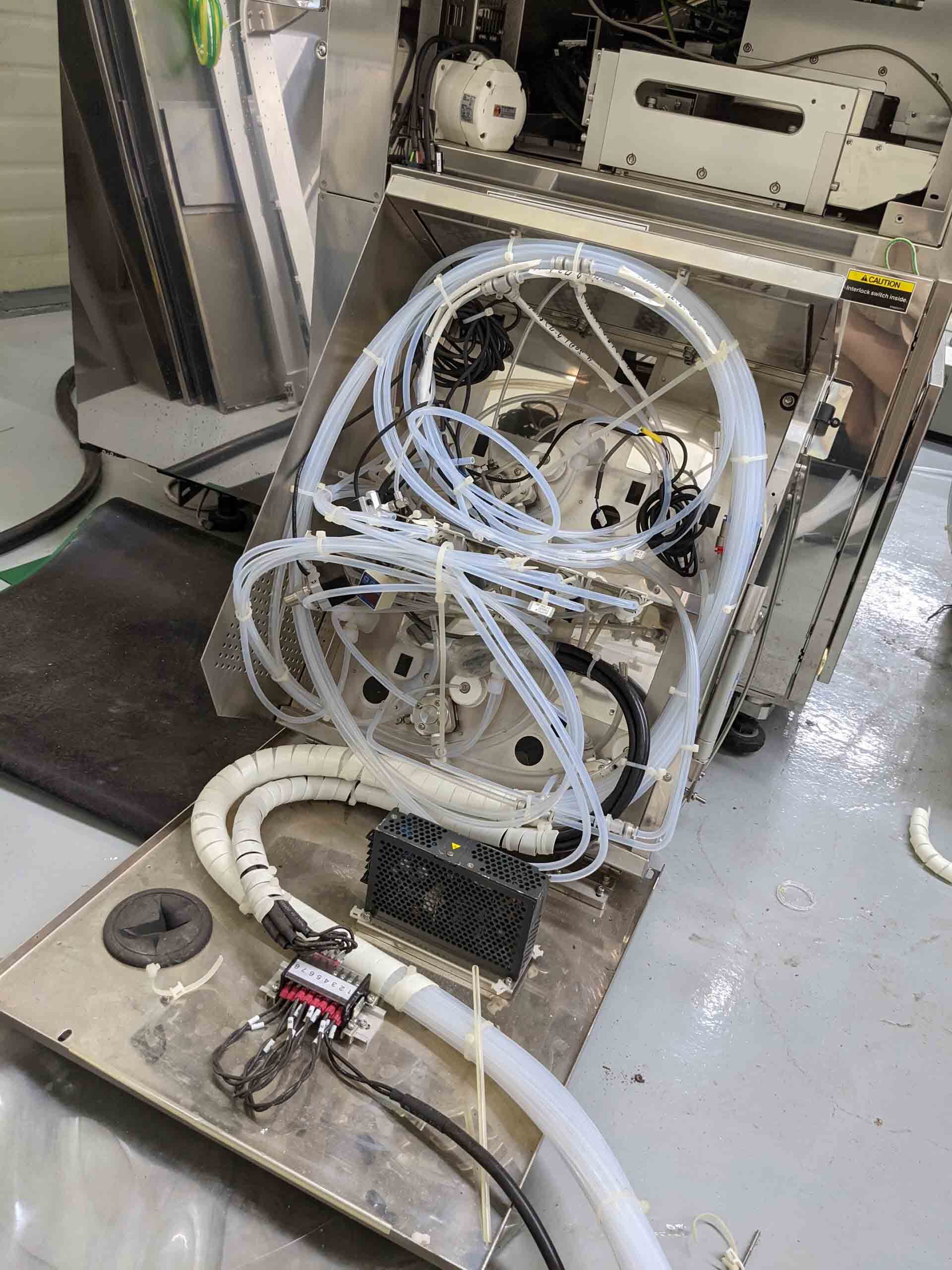

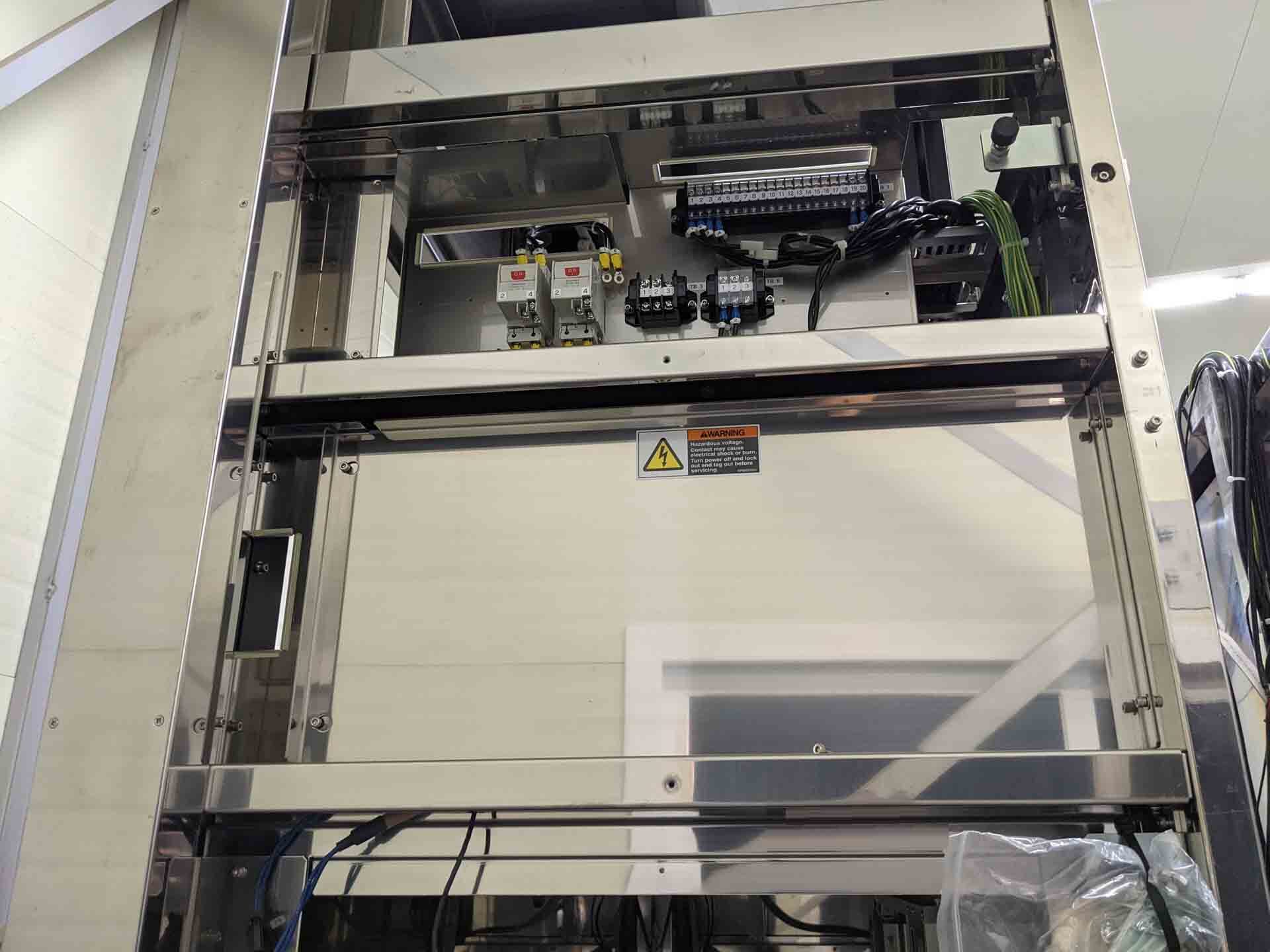

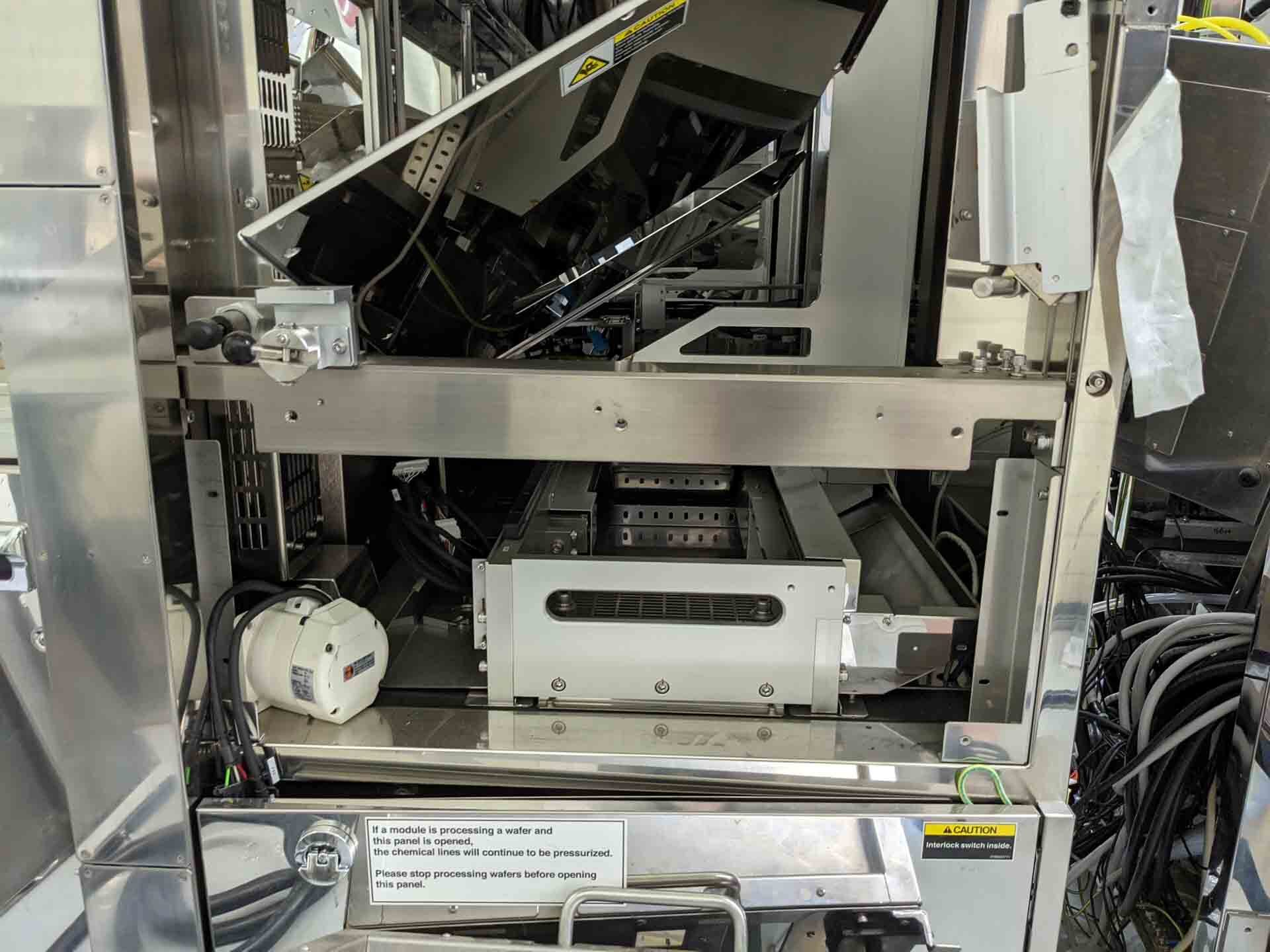

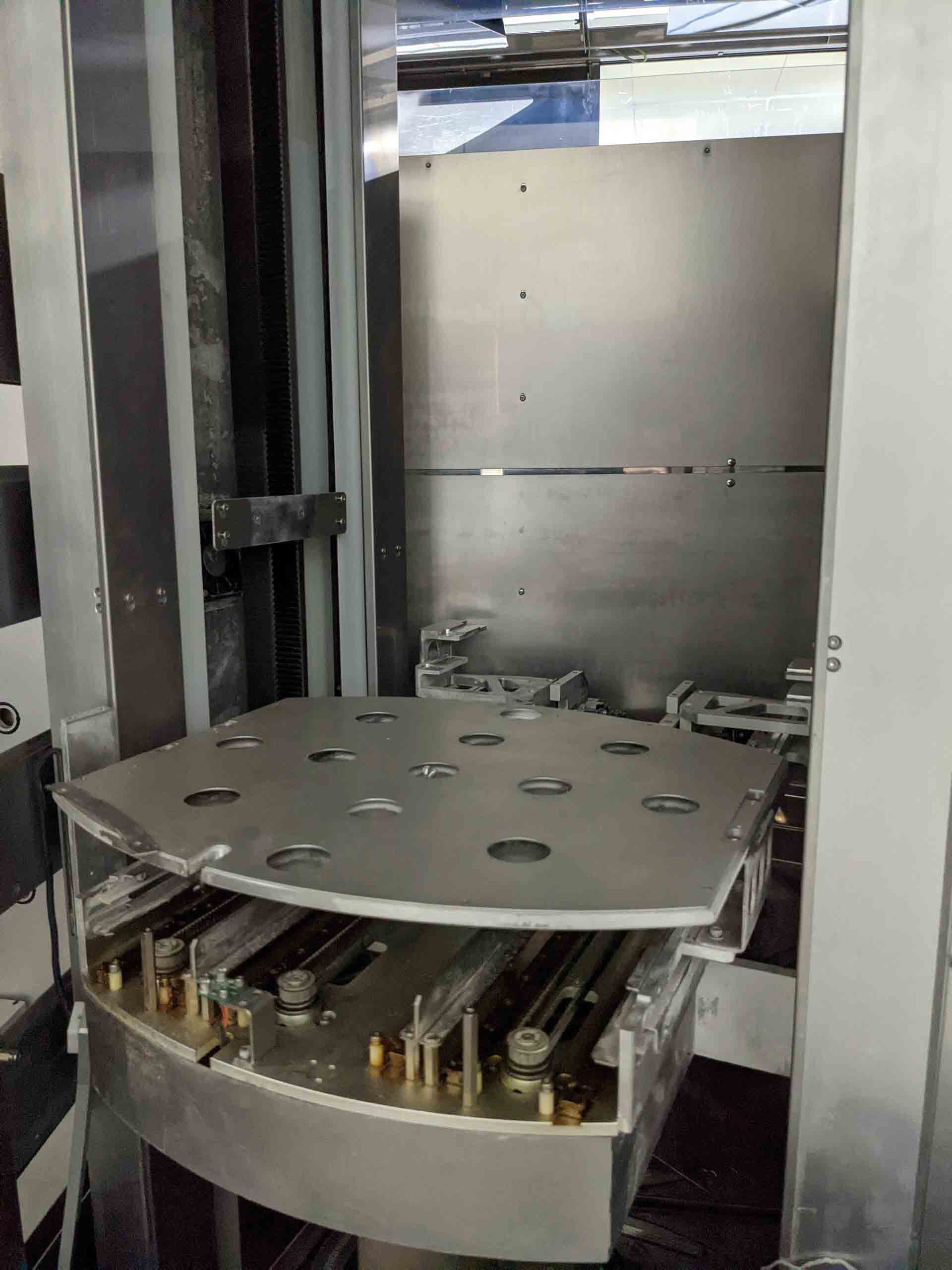

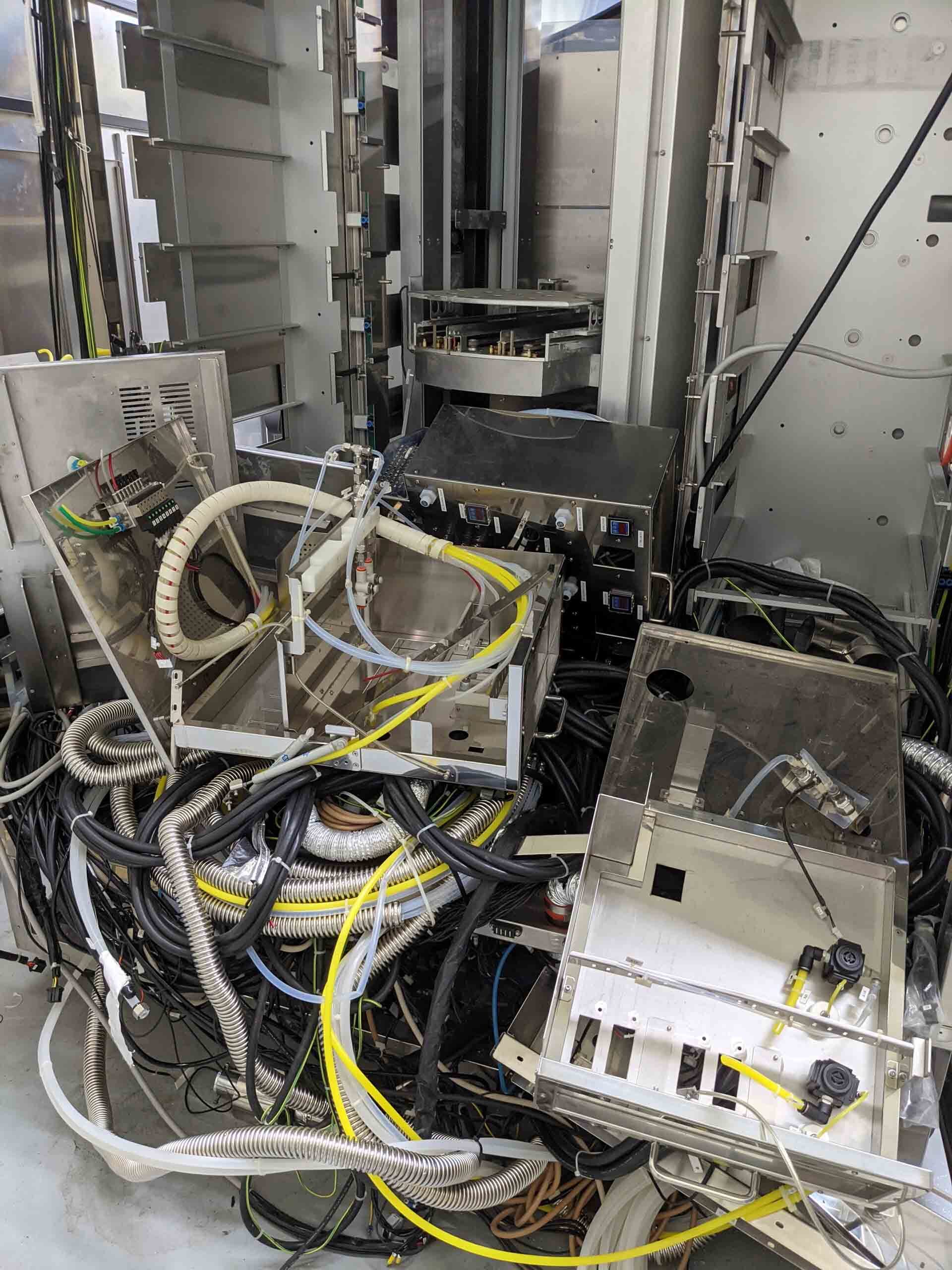

Used TEL / TOKYO ELECTRON Clean Track ACT 12 #9395682 for sale

URL successfully copied!

Tap to zoom

ID: 9395682

Wafer Size: 12"

System, 12"

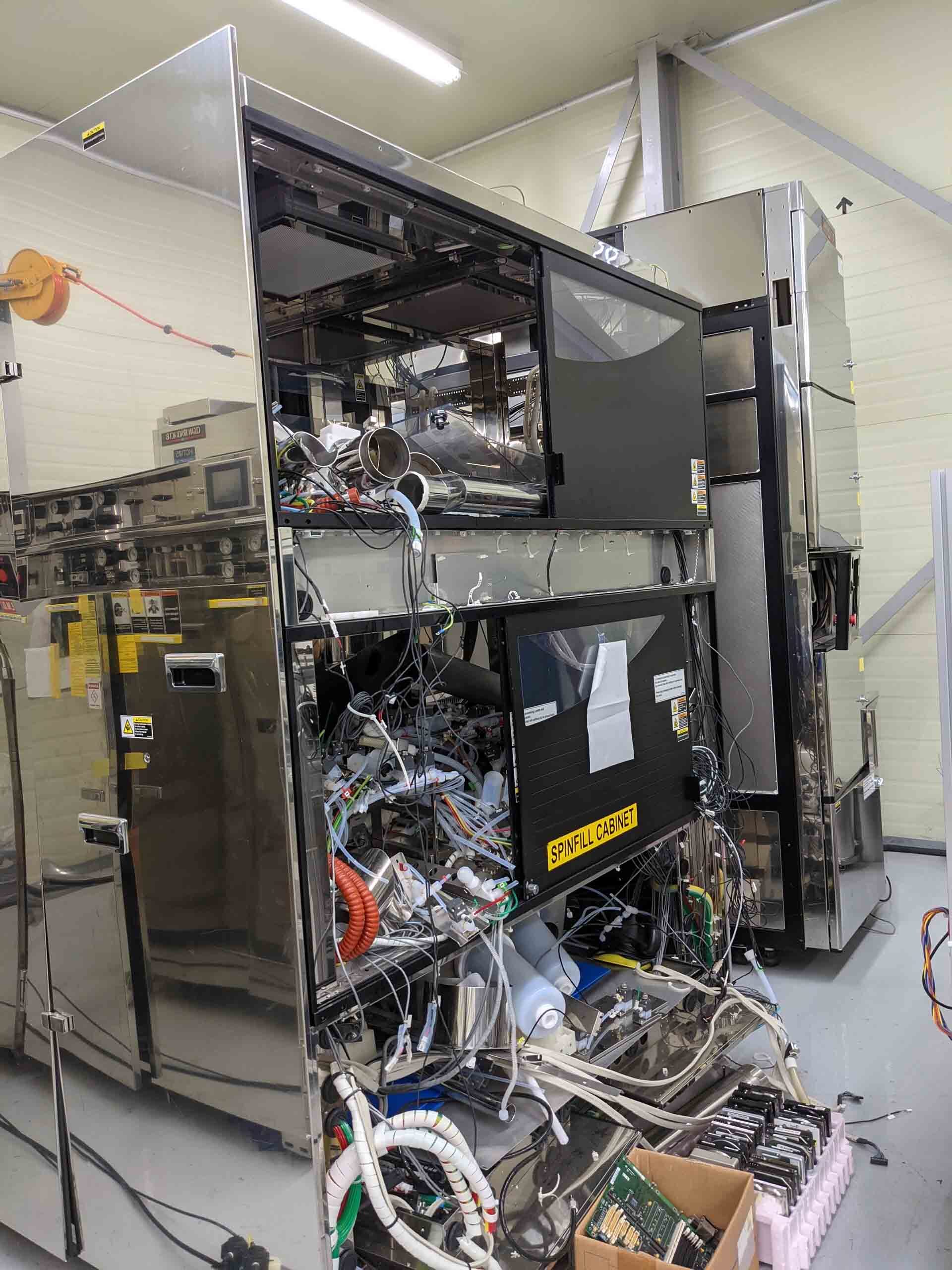

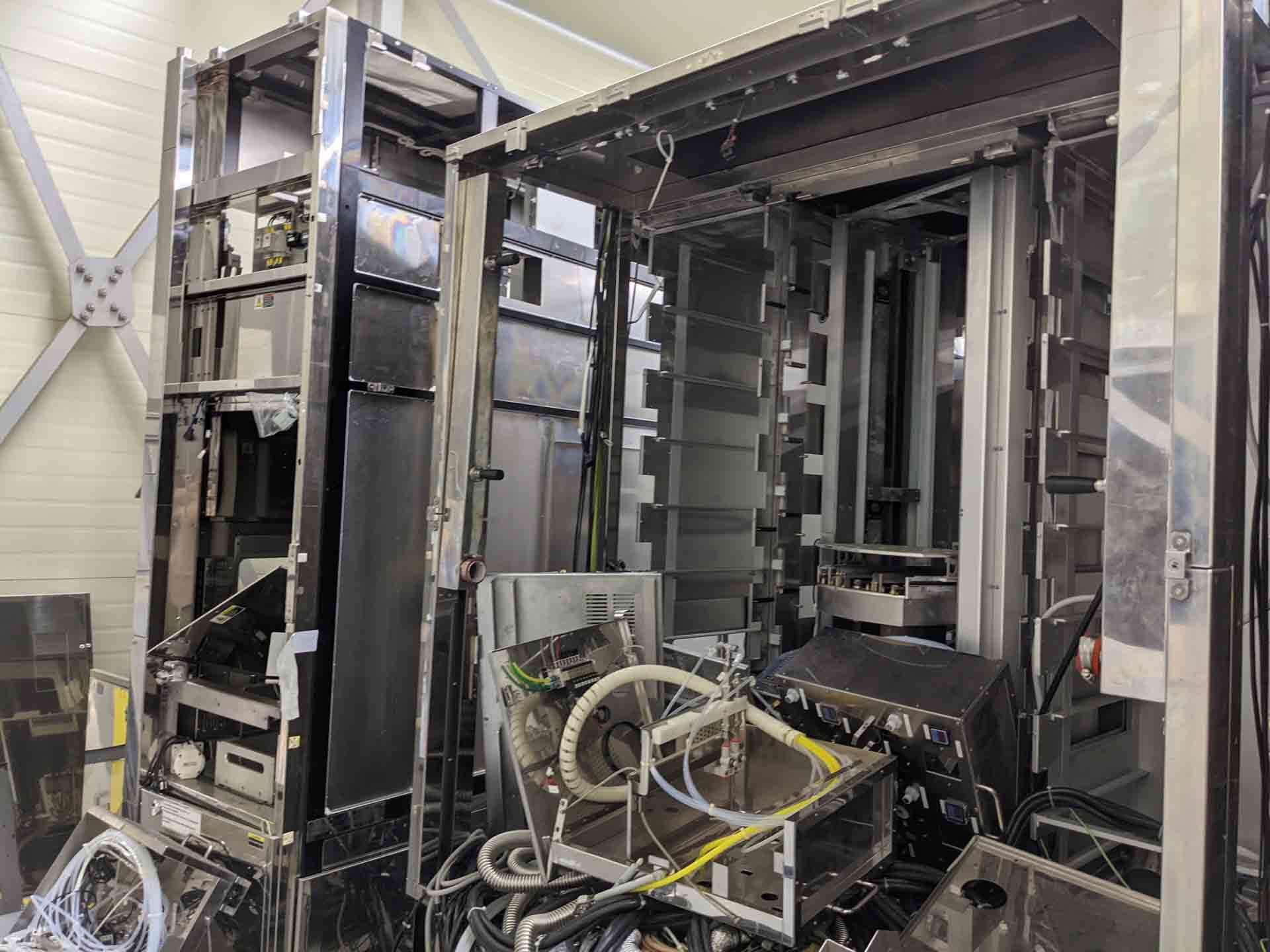

Single block

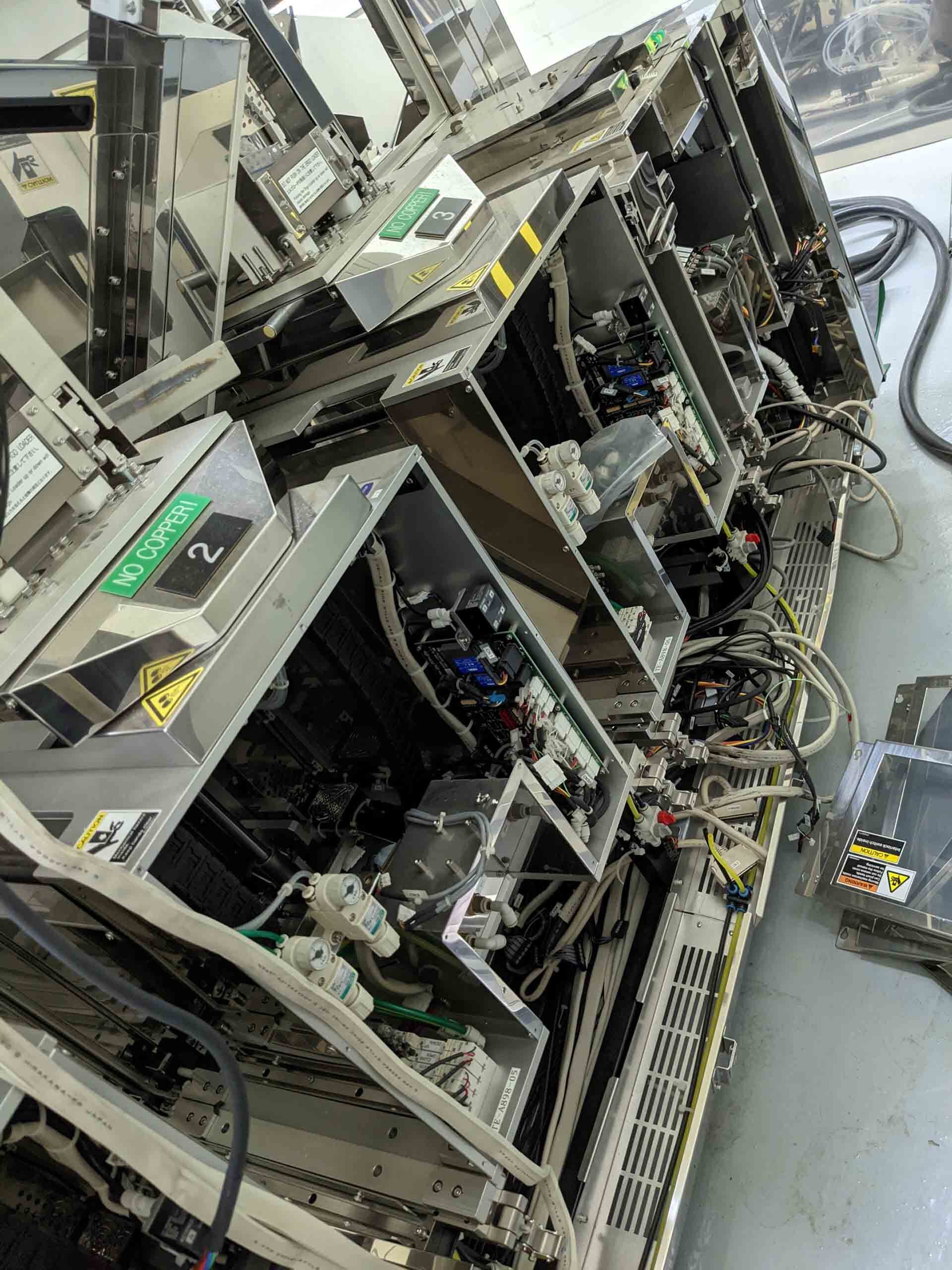

FOUP Open cassette

No nozzles

No Stepper / Scanner interface

No hot / chill / transfer plates and types

No chemical cabinet

No T&H (Temperature and Humidity)

No power distribution box and AC transformer

No IDI and RRC pumps

No DEV and EBR systems

No HDD.

TEL / TOKYO ELECTRON Clean Track ACT 12 photoresist equipment is a high-precision, automated photolithography machine equipped with advanced features designed to reduce contamination and improve performance. The system is capable of processing a variety of substrates and producing highly accurate structures with minimum distortion and precision. TEL Clean Track ACT 12 utilizes a state-of-the-art vacuum process designed to remove air bubbles, dust, and other contaminants from the substrate prior to processing. Substrate contamination is further minimized through the use of a specialized high temperature, high pressure cleaning process. The unit also includes an automatic, optical alignment machine which increases accuracy by precisely aligning substrate and mask pattern for each step of the photolithography process. The tool utilizes high-performance, 12-zone exposure lamps to precisely expose the substrate to light, with each zone independently controlled by a computer controlled asset. The total exposure time can be precisely controlled in order to ensure accurate patterning without any excess exposure. TOKYO ELECTRON Clean Track ACT 12 utilizes a specialized mask table assembly, designed to maintain high levels of vibration control and reduce thermal distortion. Additionally, the model is equipped with multiple controllers and feedback sensors which monitor pressure, temperature and vibration of the table to keep these levels within specification. The equipment also includes an advanced chemical dispense system which ensures accurate chemical coating, as well as a specialized chemical recovery unit which recovers the photoresist for reuse. Following the photolithography process, the machine is equipped with a special post-processing unit which can accurately measure the profile of the substrate in order to verify accuracy and detect any defects. The post-processing unit is also used to aid in the cleaning process, removing chemical residue and any remaining contaminants. In summary, Clean Track ACT 12 photoresist tool is a highly advanced, automated lithography machine designed to produce high-precision structures with minimal distortion and precision. The asset utilizes several advanced features to minimize contamination and improve accuracy and performance.

There are no reviews yet