Used TEL / TOKYO ELECTRON Clean Track ACT 8 #9106750 for sale

URL successfully copied!

Tap to zoom

ID: 9106750

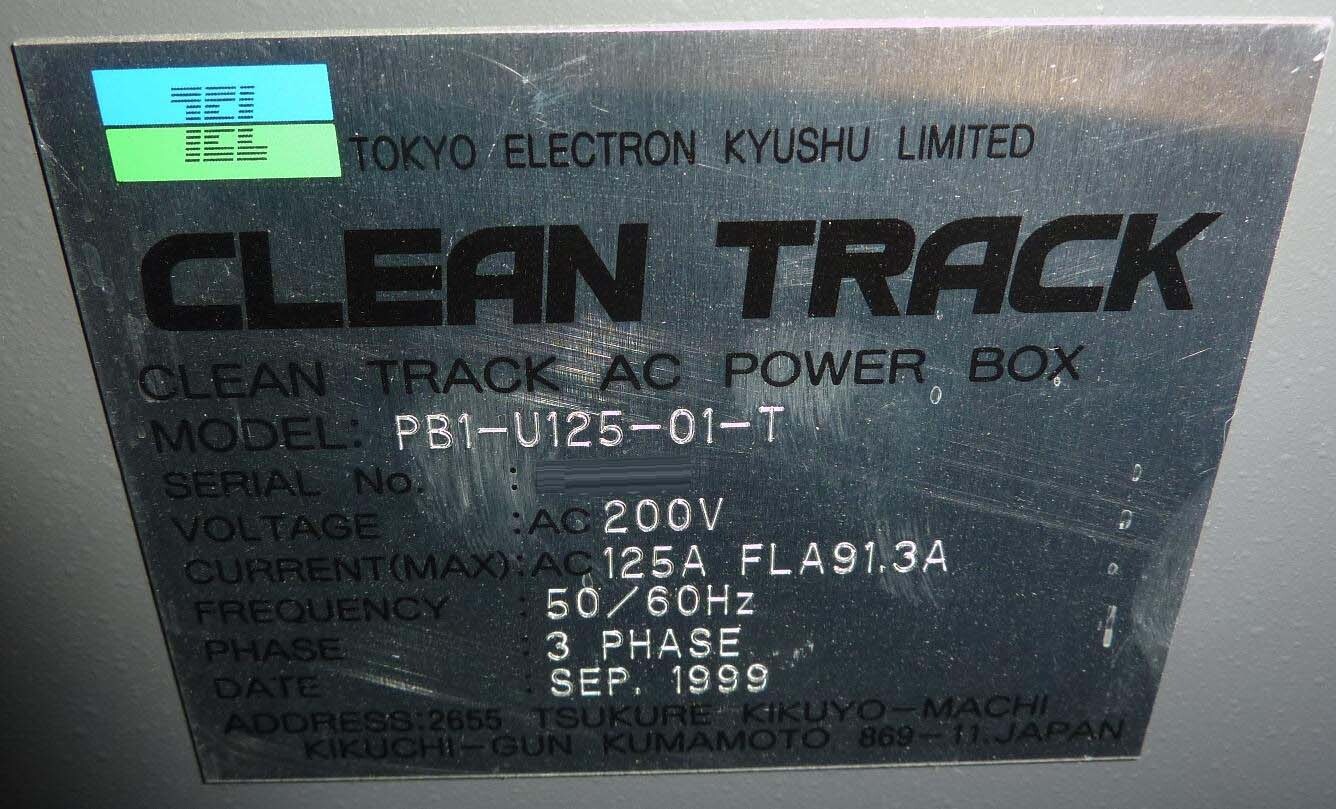

Vintage: 1999

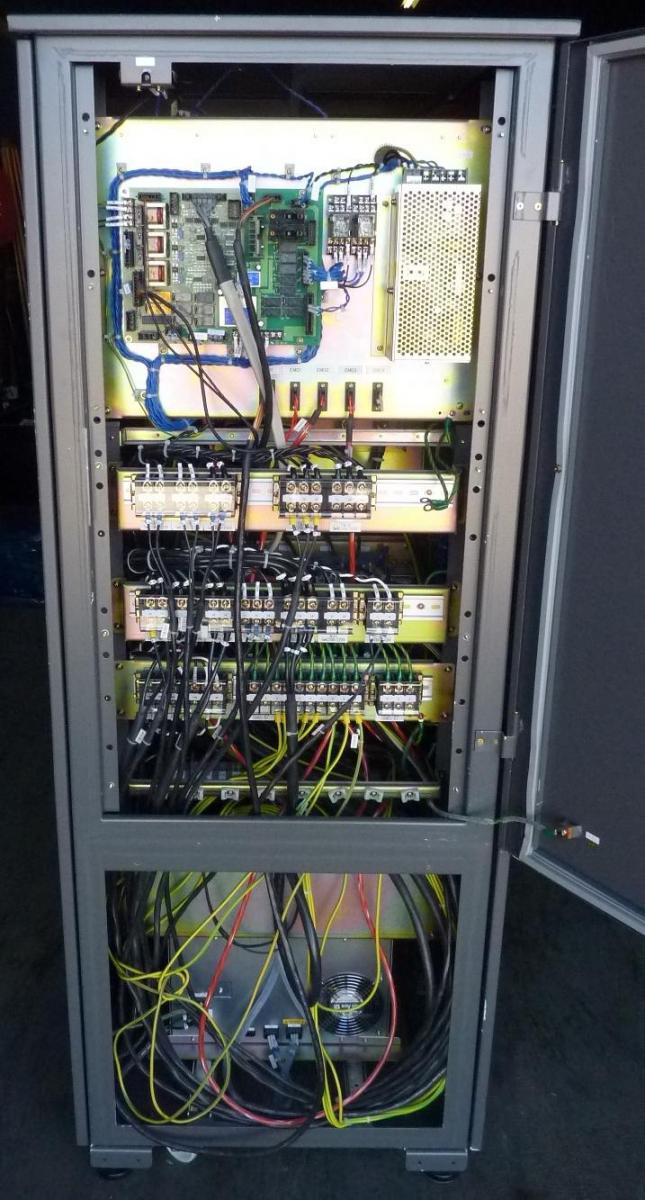

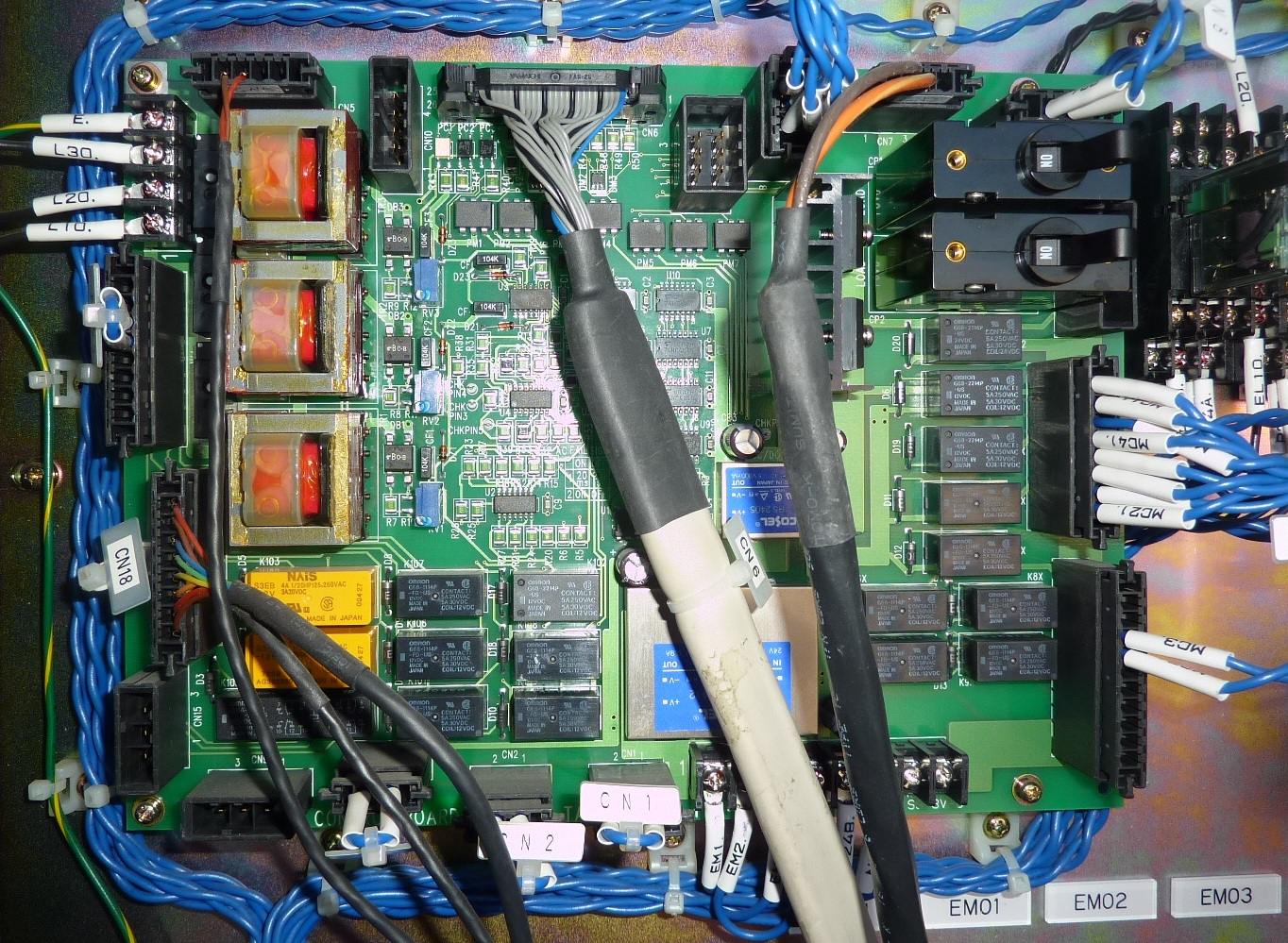

AC Power Box, P/N: PB1-U125-01-T

Includes Control Board

200V, 125A FLA91.3A, 50/60Hz, 3 Phase

1999 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 8 is a photoresist equipment designed to improve the cleanliness of the exposure process and reduce the amount of chemical waste. The system consists of two components: a Clean Track mask aligner and a custom cleaning solution. The Clean Track mask aligner is a precision alignment unit that precisely places a mask with UV-sensitive material onto a photomask. This mask is then used to expose photoresist to UV light. The material on the mask is a special transfer material that allows it to be repositioned accurately with minimal waste. The machine also includes an automated vacuum tool to ensure that the mask is held in place and that the exposure process produces clean, accurate, and repeatable exposure results. The custom cleaning solution is designed specifically for use with the Clean Track mask aligner. This proprietary cleaning solution is composed of both aqueous and organic components, as well as surfactants and solvents, to ensure that the photomask is thoroughly cleaned before and after exposure. This fiber-free solution breaks down polymers that are commonly found on photomasks and helps prevent image blur during the exposure process. The combination of the Clean Track mask aligner and the custom cleaning solution provides an effective way to clean photoresists and improve the exposure process, while reducing both the amount of time and waste associated with the exposure process. The Clean Track asset is also designed to be compact and easy to use, while ensuring the highest levels of cleanliness. Furthermore, the model meets the industry's most stringent standards for cleanliness and safety. By providing a comprehensive solution for photoresist cleaning and exposure process, TEL Clean Track ACT 8 can help to improve yields and reduce costs in photolithography processes.

There are no reviews yet