Used TEL / TOKYO ELECTRON Clean Track ACT 8 #9182601 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9182601

Wafer Size: 8"

Vintage: 2004

(3) Coaters / (3) Developers, 8"

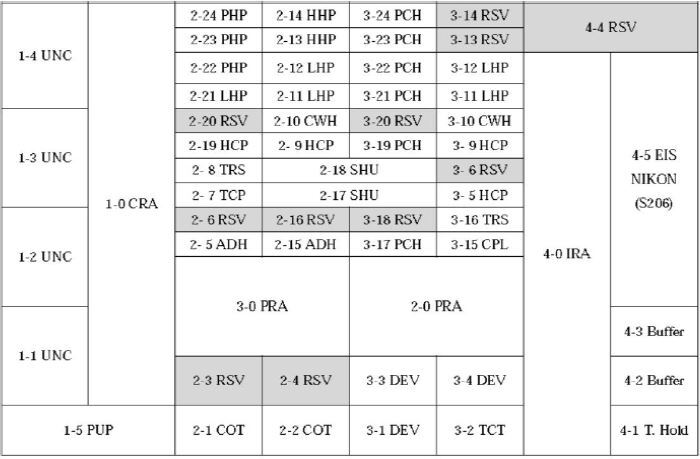

General system configuration:

Left to right

Carrier type: Notch type, (25) Slots

System power rating: AC 208V, 3-Phase for system, 173A (Max)

Loading configuration:

(4) Loaders

Uni-cassette

Software version: 3.04.130

(3) Main controllers

Main system details:

Main frame with system controller

Carrier station

Type: Normal cassette type

Cassette: (25) Slots

Coater unit details (2-1, 2-2 module):

(8) Dispense nozzles

with temperature controlled lines for etch unit

(16) RRC Pumps

PR Suck-back valve: (16) AMC Suck-back valves

Rinse nozzle: Back / EBR / Solvent bath for etch unit

Rinse system: 3-Liter 2-tank buffer tank system

Programmable side rinse

PR Supply (1, 2, 3, 4, 5, 6, 7, 8): (8)Bottles (1-Bottle / 2-Nozzle)

Solvent Supply

CCSS Supply

E.B.R Flow system: CCD Type

Drain type: Direct drain system (Including a pump)

TCT Unit details (3-2 Module):

(3) Dispense nozzles with temperature controlled

Resist 1, 2 RRC pump (F-T201-1)

Resist 3 RDS pump (R GEN tm-01)

PR Suck-back valve: (3) AMC Suck-back valves

Rinse nozzle: Back / EBR / Solvent bath for etch unit

Rinse system: 3-Liter 2-tank buffer tank system

Programmable side rinse

PR Supply (1, 2, 3): (3) Bottles (1-Bottle/1-Nozzle)

Solvent supply: CCSS Supply

E.B.R Flow system: CCD Type

Drain type: Direct drain system (Including a pump)

Developer unit details (3-1, 3-2, 3-4 Module):

(1) LD Nozzle for each unit

(3) Dispense nozzles with temperature controlled

(1) Stream nozzle for DI rinse

2-Point for back side rinse on each unit

Developer system: (3) 3-Liter 2-tank buffer tank system

Developer supply: CCSS Supply

Developer temperature control system

Drain: Direct drain

I/F Wafer stage type: NIKON Type (S206)

(2) Adhesion units details:

HMDS Tank with float sensor in system

HMDS Supply: Local canister supply

(3) Precision hot plate stations (PHP)

(6) Precision chilling hot plate stations (PCH)

(2) Cup washer holders (CWH)

(4) High chill plate stations (HCP)

(1) Chill plate station (CPL)

(2) High temp hot plate stations (HHP)

(5) Low temp hot plate stations (LHP)

(2) Transition stages (TRS)

(1) Transition chill plate (TCP)

Chemical cabinet #1: PR Bottle & 2-1, 2-2 COT pump

HMDS Buffer tank assembly

Solvent buffer tank

Solvent filter assembly

Developer buffer tank & developer / DI filter assembly

Chemical cabinet #2: HMDS Canister tank

Temperature & humidity controller:

Type: SHINWA ESA-8Series (TEL OEM)

Temperature control unit (TCU):

Type: TEL OEM

AC Power box:

AC 200/220V

Full load current: 173A

System configuration:

(1) UNC: Uni-cassette stage

(1) TCT: TARC Process station

(2) ADH: Adhesion process stations

(3) PHP: Precision hot plate stations

(6) PCH: Precision chilling hot plate stations

(2) CWH: Cup washer holders

(2) SHU: Shuttles

(2) COT: Coat process stations

(3) DEV: Develop process stations

(4) HCP: High speed chill plate stations

(1)CPL: Chill plate station

(2) HHP: High temperature hot plate stations

(5) LHP: Low temperature hot plate stations

(2) TRS: Transition stages

(1) TCP: Transition chill plate

Other system details:

In-Line

CSB, PRB1, PRB2, IFB

Power box, T&H Controller 1

Chemical box 1, 2

Thermo-controller 1

2004 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 8 is a photoresist equipment designed specifically for LCD panel production lines. Photoresist systems use ultraviolet light (UV) to expose photoresist material coated onto the surface of a substrate, usually glass. If the substrate is exposed to light of appropriate wavelength, the resist decomposes, leaving a pattern of exposed and unexposed areas. This photoresist technology is used in LCD panel production lines to create an ultra-fine pattern of electrodes on the LCD panel. TEL Clean Track ACT 8 provides reliable pattern formation for LCD production lines. It is a modular system consisting of an exposure unit, a focus and alignment unit, a substrate stage module, a measurement and control unit, and a supporting control machine. The exposure unit utilises a powerful UV-LED light source and a variety of optics and galvanometers to provide superior exposure stability with highly precise alignment and aberrations control. The focus and alignment tool allows for precise and repeatable pattern positioning, allowing for accurate and precise electrode pattern formation. The substrate stage module provides precise motion speed and precision, allowing for extremely precise pattern formation. The measurement and control unit automatically adjusts and controls the exposure levels of each exposure unit. The supporting control asset synchronizes the hardware components and provides a user-friendly interface that allows users to monitor, adjust, and analyze the exposure levels of each exposure unit on the production line. TOKYO ELECTRON Clean Track ACT 8 is designed to maximize productivity while offering superior resist definition and pattern accuracy. It offers high-resolution patterns with a minimum line width of 0.1 microns and a uniformity of ±2%. It also provides fast exposure times to meet the high demands of LCD production lines. With its superior exposure uniformity and high precision, Clean Track ACT 8 is an excellent choice for LCD panel production lines.

There are no reviews yet