Used TEL / TOKYO ELECTRON Clean Track ACT 8 #9245118 for sale

URL successfully copied!

Tap to zoom

ID: 9245118

Wafer Size: 8"

Vintage: 2002

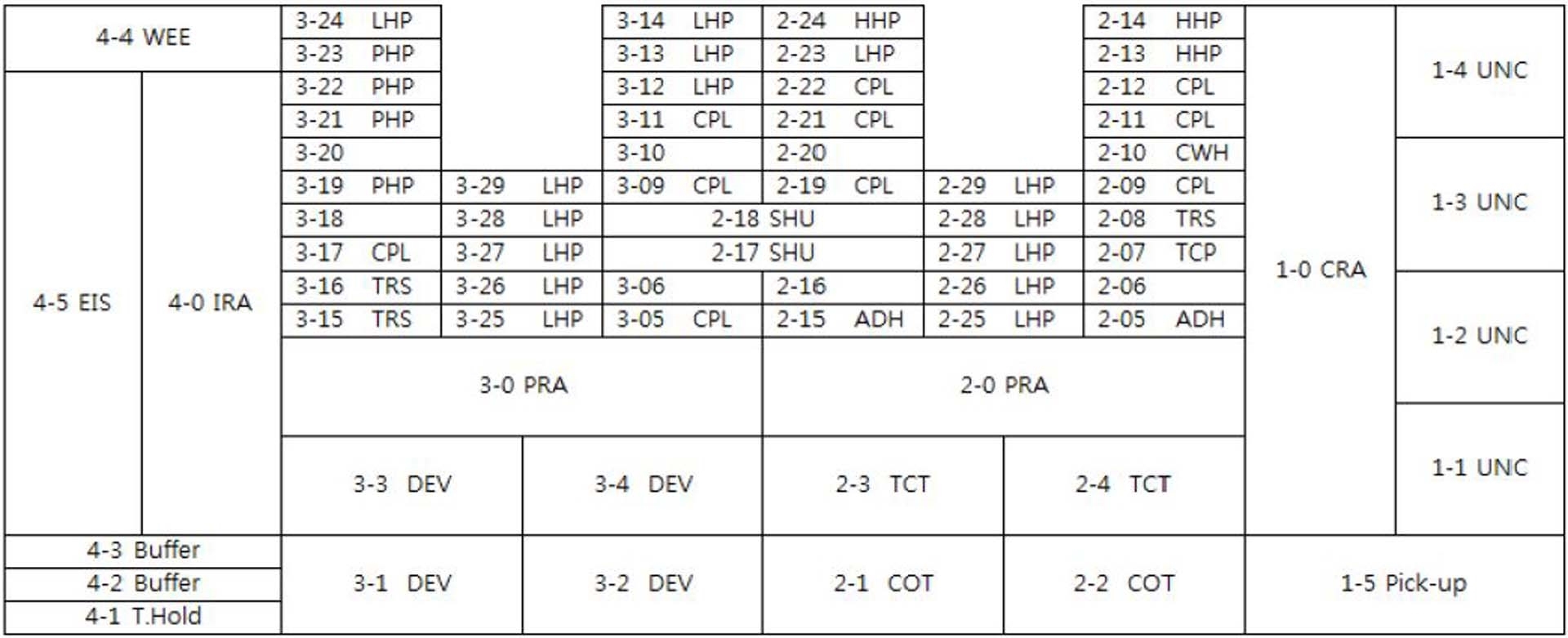

(4) Coater / (4) Developer system, 8"

(2) Chemical cabinets: Solvent and developer

(2) SMC Thermo controllers: HMDS, PR

YEST YIB-TP23 T and H Controller

AC Power box

MFC: 4-Ports

Right to left

Wafer type: Notch, DUV type

DUV Type

25-Slots

Loading configuration: (4) Loader uni-cassettes

Carrier station:

Type: Normal uni-cassette

(4) Cassette stages

Pick-up cassette

Uni-cassette system

Coater unit (2-1, 2-2, 2-3, 2-4 Module):

(4) Dispense nozzles

With temperature controlled lines

RDS Pump

Rinse nozzle: Back / EBR / Solvent bath

Rinse system: 3 Liters (2) buffer tank systems

PR Such-back valve type: AMC Suck-back valve

Programmable side rinse

Direct drain

Developer unit (3-1, 3-2, 3-3, 3-4 Module):

H Nozzle

(2) Stream nozzles for DI rinse

2-Points for back side rinse / Unit

Developer system: 3 Liters (2) buffer tank systems

Developer temperature control system

Direct drain

(2) Adhesion units:

100% Sealing closed chamber (Built-in hot plate)

HMDS Tank with float sensor

Interface type: ASML

(3) High temperature hot plates

(15) Low temp hot plates

(10) Chill plates (CPL)

(4) Precision Hot Plate (PHP) process station

(3) TRS Modules

TCP Module

Wafer Edge Exposure (WEE) module

(2) TEL / TOKYO ELECTRON Temperature control units

Main controller missing

Power: AC 208 V, 3-Phase

2002 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 8 is a complete photoresist equipment designed to provide precision lithography part processing capabilities with high productivity, outstanding overlay accuracy, and excellent repeatability. The system features a SIMOX process module for dry development of resist layers, as well as modular additions for larger-scale wafer and semiconductor processing needs. The unit is designed as a single-layer, single-chamber process, which enables simple and effective resist handling. It features a precision-controlled X-Y stage, combined with an innovative resist monitor to reduce noise and improve performance. The machine also features a Triple-Exposure treatment module that provides improved edge definition and edge precision as it applies a series of exposures with adjustable interval times. The tool utilizes advanced process control techniques to ensure maximum accuracy at low photoresist consumption levels. Its proprietary La Ra Revolution process monitor also monitors the run on a real-time basis, allowing quick corrective solutions if needed. This helps ensure uniformity in results even when the process conditions vary. The asset also features proprietary PROM (photo resist optimization module) software for use in SEM windowing and OPC. This software enables precise calculations of optimal conditions for each structure type, thereby enabling higher resolution parts to be manufactured with fewer mistakes. The model also adds extra convenience with flexible equipment configuration and installation on the clean track. This makes it easy to tailor it to a range of production needs. In summary, TEL Clean Track ACT 8 is a complete photoresist system that provides users with outstanding overlay accuracy and excellent repeatability, while providing easy installation and flexible unit customization. The machine offers advanced process control, improved edge definition, and software-assisted part optimization for improved resolution-all while keeping photoresist consumption levels low.

There are no reviews yet