Used TEL / TOKYO ELECTRON Clean Track ACT 8 #9269229 for sale

URL successfully copied!

Tap to zoom

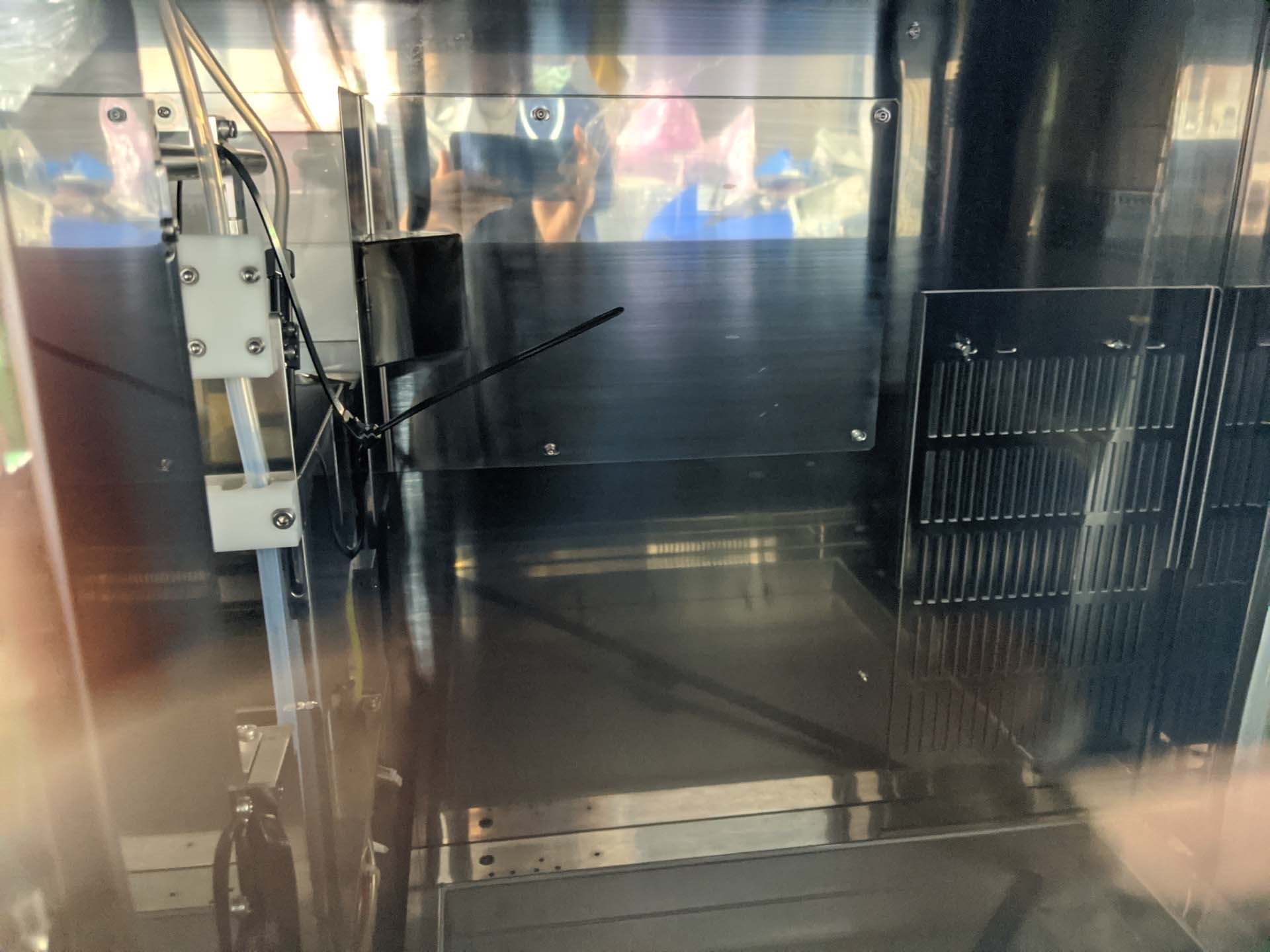

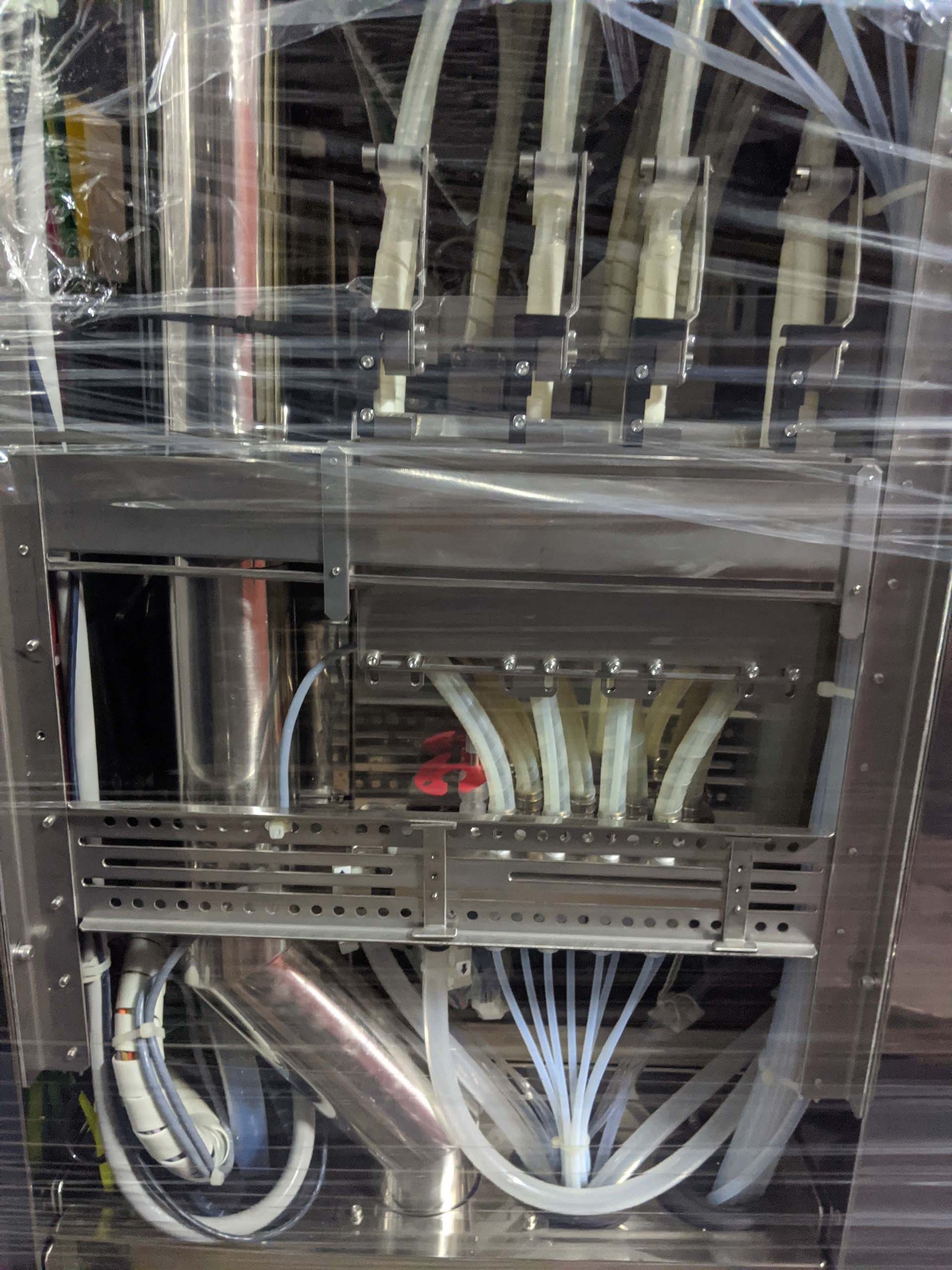

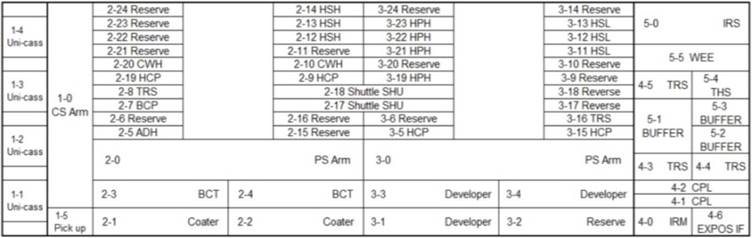

TEL / TOKYO ELECTRON Clean Track ACT 8 is a state-of-the-art photoresist equipment designed for use in semiconductor processing. This system features an advanced surface cleaning technology that is capable of removing extra dust and particles from the substrate before it is exposed to photoresist. This reduces the chances of contamination and defect formation, which can lead to inferior performance or product failure. TEL Clean Track ACT 8 utilizes an advanced Optical State Profiler, or OSP, which can detect sub-micron sized particles on the top surface of a substrate. Once detected, the OSP automatically adjusts the surface cleaning parameters to ensure an optimal removal of particles, which can then be confirmed using Defect Density Imaging (DDI). This sophisticated technology delivers a great deal of precision and accuracy when it comes to achieving a clean substrate for further processing. TOKYO ELECTRON Clean Track ACT 8 also features a synchronized coating unit, which allows for uniform coating throughout the entire substrate. This machine employs a precision wafer stage positioning tool to deliver consistent substrate contact during the coating process, ensuring optimal uniformity of photoresist deposition. Moreover, this asset also utilizes a novel auto-focus module to maximize the accuracy of alignment and optical image acquisition during inspection. This module not only improves image quality but also facilitates the process of evaluating defects on the wafer with increased accuracy. Clean Track ACT 8 also includes an integrated exposure condition database (ECDB) that allows for a greater degree of customization according to the specific requirements of each job. This ECDB helps to ensure that the exposure conditions are optimized for each substrate, further improving the overall quality of the photoresist layer. Ultimately, TEL / TOKYO ELECTRON Clean Track ACT 8 is a sophisticated photoresist model with many advanced features designed to deliver superior performance. Utilizing cutting-edge surface cleaning technology, precision wafer staging, an innovative auto-focus equipment, and an integrated exposure condition database, this system is perfectly suited for a wide range of semiconductor processing applications.

There are no reviews yet