Used TEL / TOKYO ELECTRON Clean Track ACT 8 #9382447 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9382447

Wafer Size: 8"

Vintage: 2003

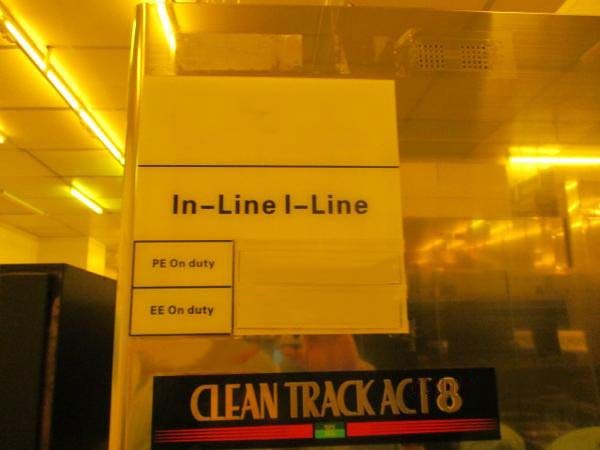

(2) Coaters / (2) Developers system, 8"

2003 vintage.

TEL / TOKYO ELECTRON Clean Track ACT 8 is a state-of-the-art photoresist etching process equipment used in the semiconductor manufacturing industry for ultra-fine pattern formation with high fidelity. Its key feature is the advanced "Act In/Out" system that processes the wafer surface with two different types of laser light within the same chamber, allowing for higher uniformity of etching compared to single-ingested processes. TEL Clean Track ACT 8 unit employs a two-step etching method. First, a pumpless light-restricted depyrogenation (LRD) process uses focussed laser light to vaporize deposited impurities on the wafer surface. Second, a low-power pass-through laser is employed at very low temperatures to deposit the photoresist in a single pass. This two-step process produces extremely thin and uniform photo-resist patterns and a highly controlled edge profile without the need for wet-processing. The machine also features high accuracy indexing, resulting in high fidelity photoresist placement that is critical to the etching process. This is enabled by the use of precision stage motion control and integrated pattern recognition algorithms. The tool also employs a patented "adaptive lighting pattern," which ensures that light intensity is always uniform across the wafer, and the "mirror-and-glass" optics to consistently focus the laser and maintain image resolution even in extreme temperatures. Additionally, the asset features an optimized photoresist etching process. Rather than a single applicator, this process uses a dual simullaser workstation for maximum uniformity and high-resolution imaging. Finally, TOKYO ELECTRON Clean Track ACT 8 is equipped with sophisticated software that keeps track of all the parameters and processes for extremely precise etching and excellent yields. In summary, Clean Track ACT 8 is a next-generation photoresist etching process model designed to achieve extremely precise pattern formation and ultra-fine edges with high accuracy. It utilizes a two-stage process which vaporizes contaminants and applies photoresist in one pass, and also features advanced laser light manipulation systems, unique "adaptive lighting pattern," and a powerful software platform for precise control of the etching process.

There are no reviews yet