Used TEL / TOKYO ELECTRON Clean Track ACT 8 #9402762 for sale

URL successfully copied!

Tap to zoom

ID: 9402762

Vintage: 2013

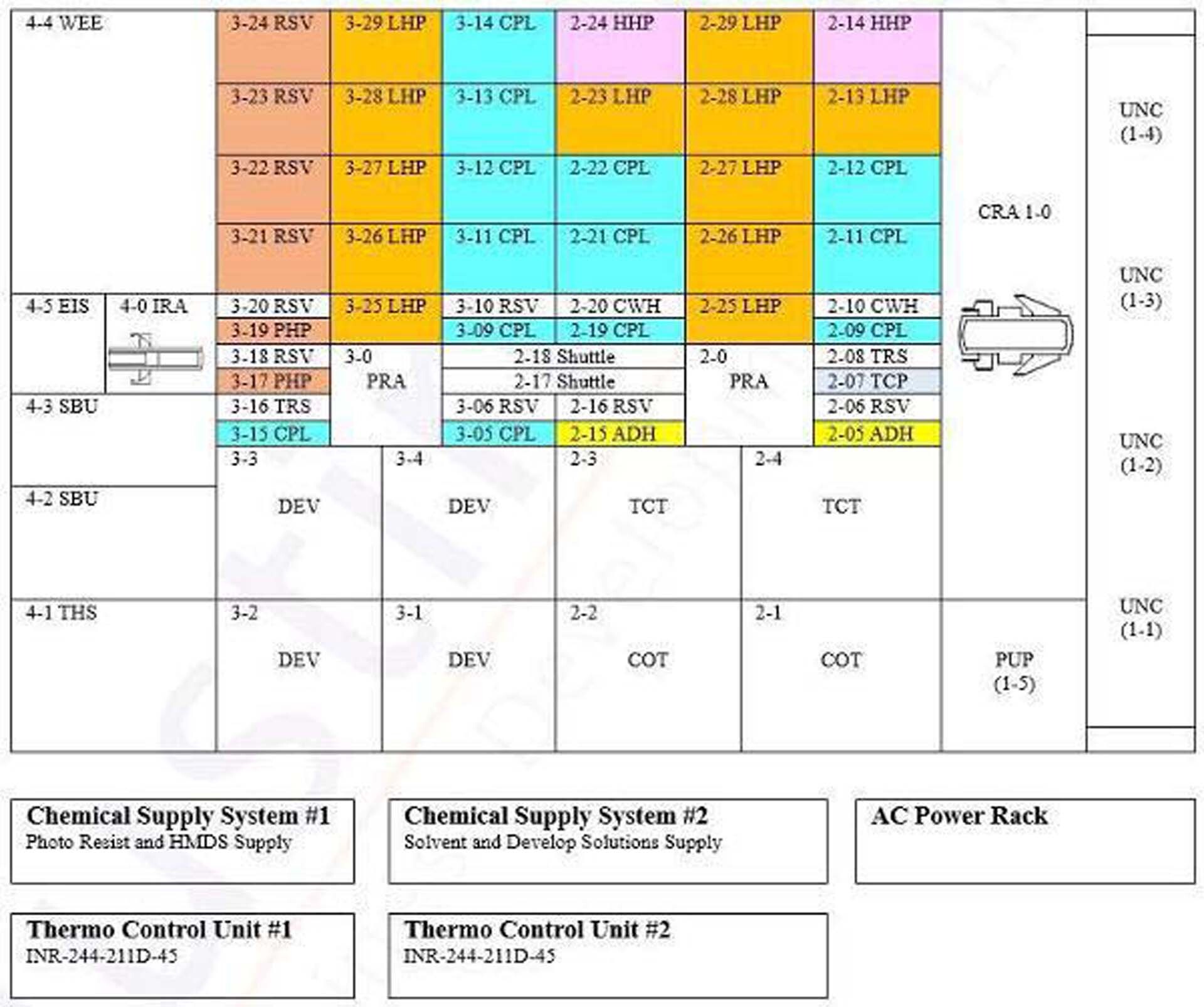

(4) Coater / (4) Developer system

Type: Dual

Inline type

Right to left

RDS Pump

SH Nozzle

Open cassette

(3) Main controllers

(2) PHP

Does not include :

T and H

HDD

Missing parts:

COT:

Spin motor driver

Arm1 driver

Spin motor driver

Arm1 Up / Down sol valve

Spin motor driver

(2) TCT Coater cups

(2) PHP TC Control boards

(4) COT EBR Flow meters 30ml/min

(4) COT EBR Flow meters CCD Sensor PCS-1

IRA Z Unit kit XY-HRS 055ZM109

IRA Pincette, 8"

IRA Z IRA Z MU-D015 Axis motor driver

IRA X MU-M008 Axis motor assembly

IRA Y IRA Y M-ESA-LYA2AF8 Axis motor driver

IRA M-ESA-J1003AF9-20 Theta axis motor driver

WEE TKB2251 CCD Board

WEE SMC Vacuum solenoid

Chemical cabinet

HTK270-M Sub operation panel

2013 vintage.

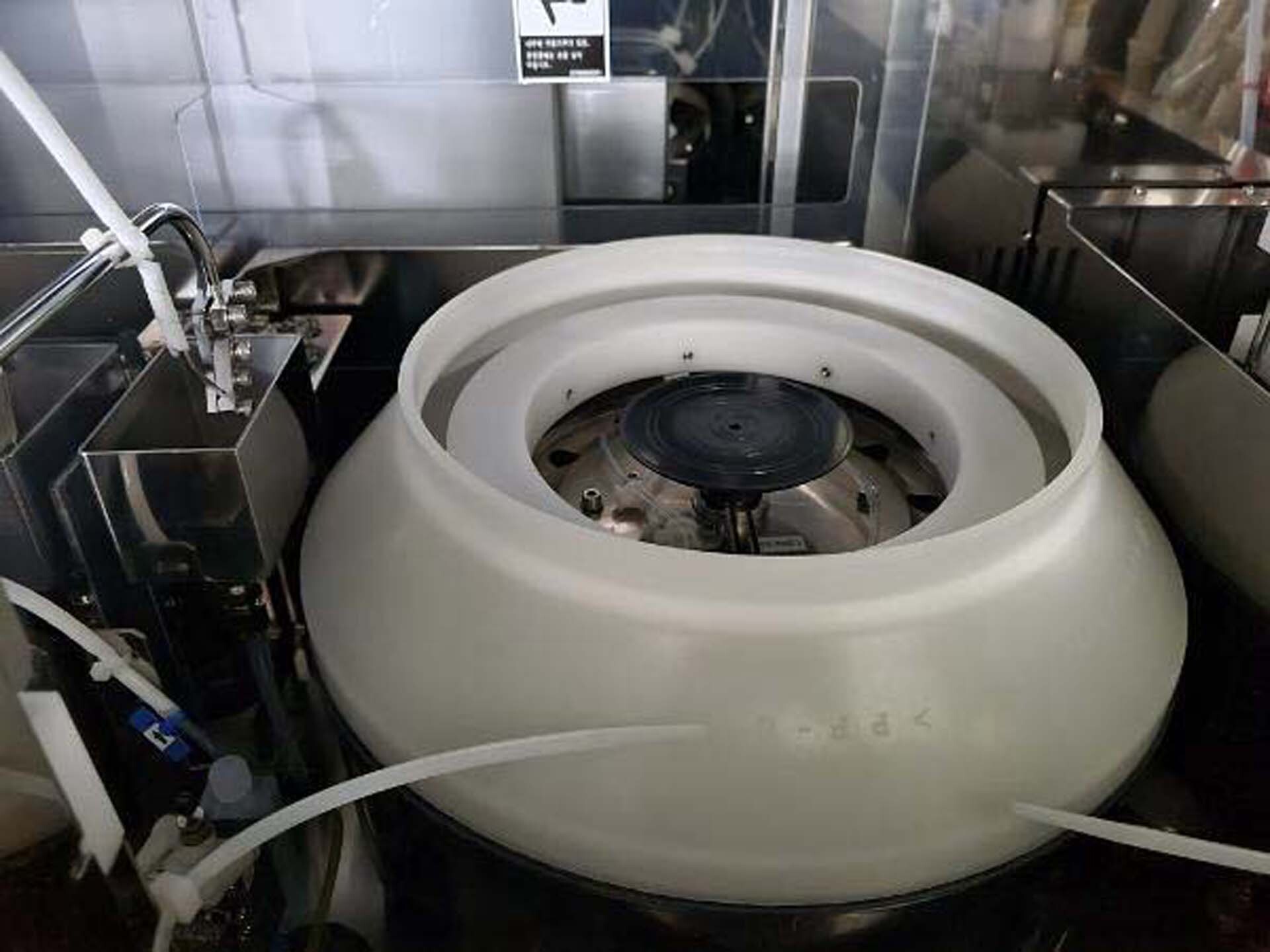

TEL / TOKYO ELECTRON Clean Track ACT 8 is a photoresist equipment designed for the cleaning and surface preparation of semiconductor materials. It utilizes a patented robotic arm assembly to automatically dispense cleaning liquid directly onto the surface of the material. The liquid is then vacuumed off, leaving behind a uniform and clean coating on the surface. TEL Clean Track ACT 8 consists of a controller, a digital camera, a manipulator arm and a vapor barrier system. The controller provides interface with the process recipe, device safety, and programmable operation. The digital camera is used to detect the motion of the robotic arm assembly, providing the necessary feedback for accurate cleaning and coating. The manipulator arm is designed to provide smooth, precise motion of the cleaning liquid. The vapor barrier unit is designed to minimize the escape of volatile fumes generated during the cleaning process. All of these components come together to create a complete and dependable photoresist machine. TOKYO ELECTRON Clean Track ACT 8 is equipped with a vision subsystem which allows it to accurately detect material defects that could be missed by a manual inspection process. This tool also includes an intelligent material handling module that can easily recognize different materials and adjust its parameters appropriately. The cleaning process is initiated by the introduction of a cleaning liquid, followed by the deposition of a photoresist material. The deposition process is performed using a shortwave UV light source and is followed by photo exposure and development. Following the cleaning and coating processes, the device is then rinsed with water or an appropriate solvent to remove excess photoresist material. Clean Track ACT 8 is an easy to use, reliable and cost-effective photoresist asset capable of providing consistent cleaning and coating results. It is designed to streamline the entire process of semiconductor material cleaning and coating, making it the ideal choice for companies seeking an efficient solution.

There are no reviews yet