Used TEL / TOKYO ELECTRON Clean Track Lithius #293595689 for sale

URL successfully copied!

Tap to zoom

ID: 293595689

Wafer Size: 12"

Vintage: 2004

Coater / Developer system, 12"

In-line with CANON ES6

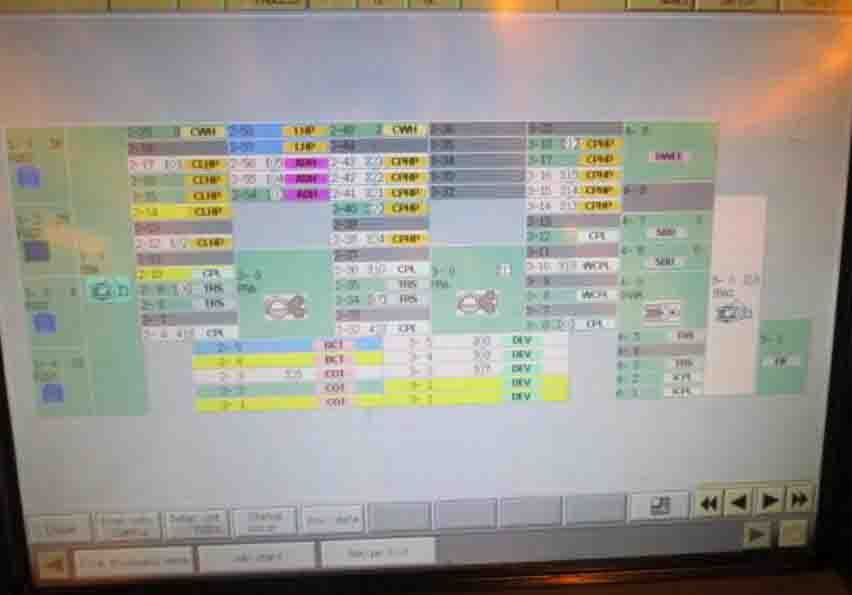

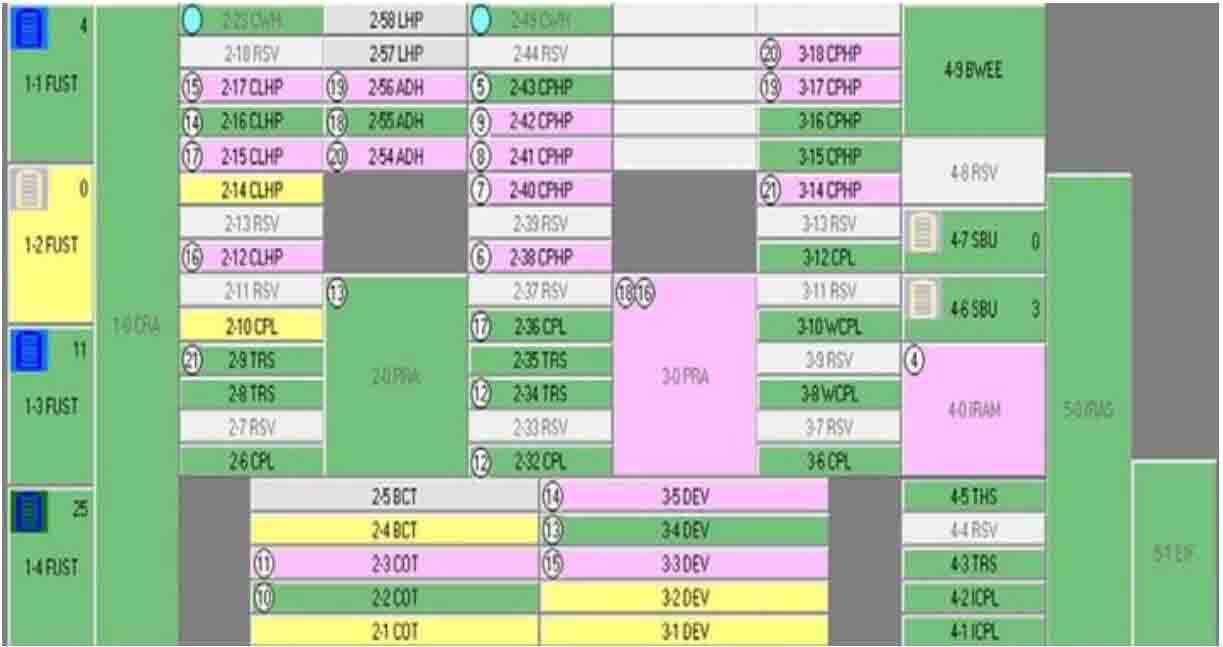

(4) Loaders

TEL Photoresist processing system

FOUP Carrier station: 4 Side loading

(2) Process station blocks

Wafer edge with inline thickness measurement system

CAR Capable

DEV Solution supply system

FIRM Supply system

NH3 Monitor ports specification

CANON Interface station

Online communication (GJG)

S2-0302 Safety compliance

(3) P.Resist coater units

(2) BARC Resist coater units

(5) Developer units

LD Nozzle

(3) Adhesion process units

(6) Chill Plates (CPL)

(2) Water Controlled Chilling Plates (WCPL)

(5) Chilling Low Temperature Hot Plates (CLHP)

(10) Chilling High Precision Hot Plates (CPHP)

(2) External chemical cabinets

T and H controller cup

AC Power box

HPT Pump:

(4) Nozzles per cup

(6) Nozzles per cup

Direct drain:

COT

BCT

DEV

Solvent supply system:

COT

BCT Unit

Power supply: 208 VAC, 3 Phase

2004 vintage.

TEL / TOKYO ELECTRON Clean Track Lithius is a photoresist equipment designed to improve the production of integrated circuits in semiconductor fabrication. The system consists of two components that, when used in tandem, enable a cleaner and more accurate development of microcircuits. The unit consists of a Lithius cleaning agent, and a Clean Track chamber, both components designed by TEL. The Lithius cleaning agent uses a solvent to strip away impurities and residues on the wafer surface. This enables the clean and accurate processing of photoresists onto the wafer. When the cleaning agent is applied, it bonds with the contaminants, removing them in a single application. Although the Lithius is able to clean a wide variety of residues, it is suitable for use with most photoresist systems, including those developed by TOKYO ELECTRON. The Clean Track chamber is a sealed chamber with a unique wafer holder. The wafer is placed onto the holder in the sealed space and is used to introduce the Lithius cleaning agent. The wafer is then exposed to ultra-violet light, which acts to catalyze the clean-up process of the lithography photoresist machine. This takes place in a closed space, preventing environmental contamination, such as dust and humidity, which could impede the development process. The combined application of the Lithius cleaning agent and the Clean Track chamber enables the safe and efficient exacting of detailed structures into wafers. This allows greater levels of integration and accuracy when manufacturing integrated circuits, and increases yield and throughput rate. In conclusion, TEL Clean Track Lithius is an effective and highly efficient photoresist tool, ideal for the fabrication of integrated circuits. The inherently clean environment of the Clean Track chamber as well as the quick clean-up solvent enables detailed and accurate structure processing, increasing yield and throughput rate for a wide range of applications.

There are no reviews yet