Used TEL / TOKYO ELECTRON Clean Track Lithius #9217452 for sale

URL successfully copied!

Tap to zoom

ID: 9217452

Interface block

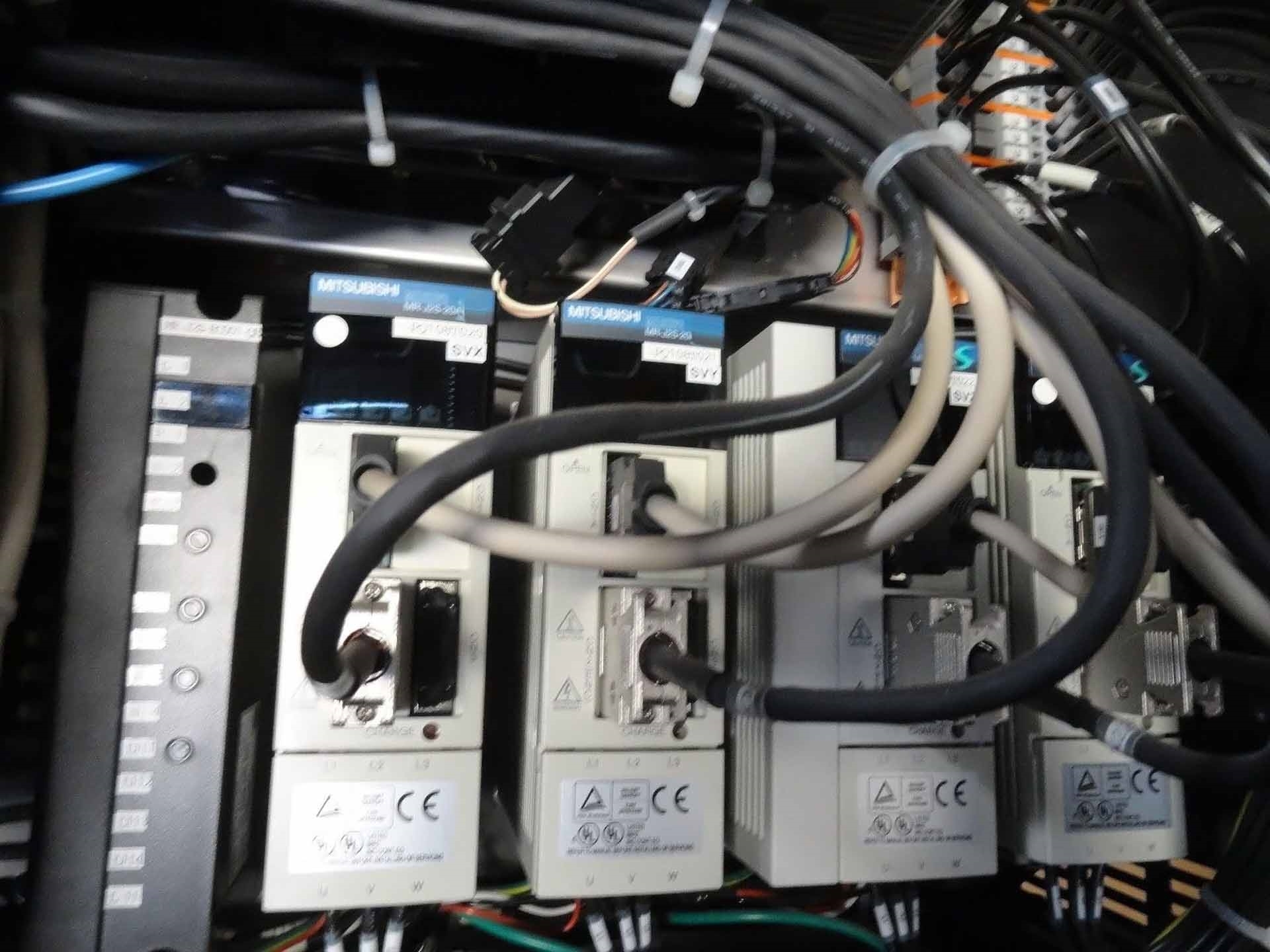

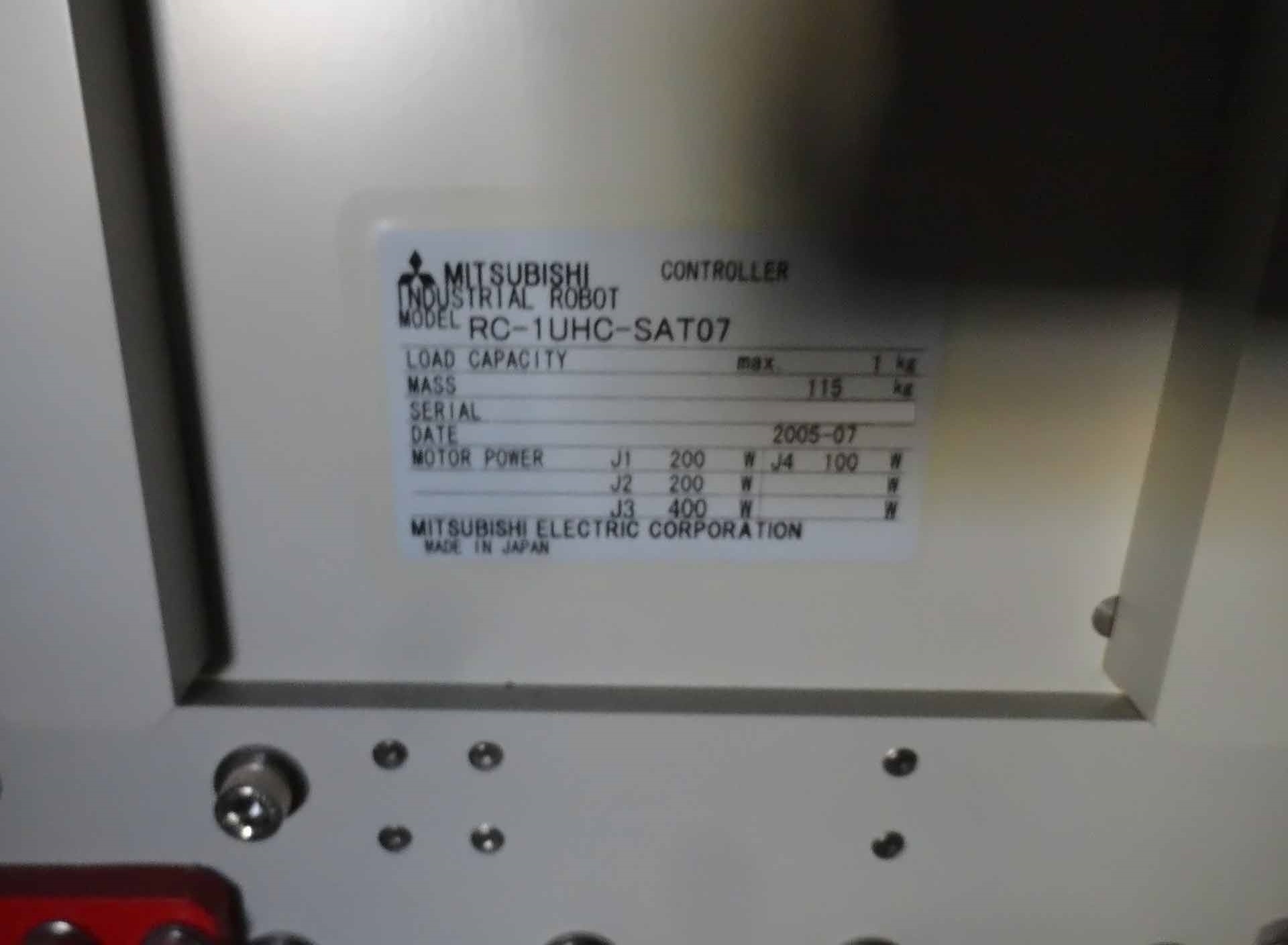

MITSUBISHI P/N: RC-1UHC-SAT07

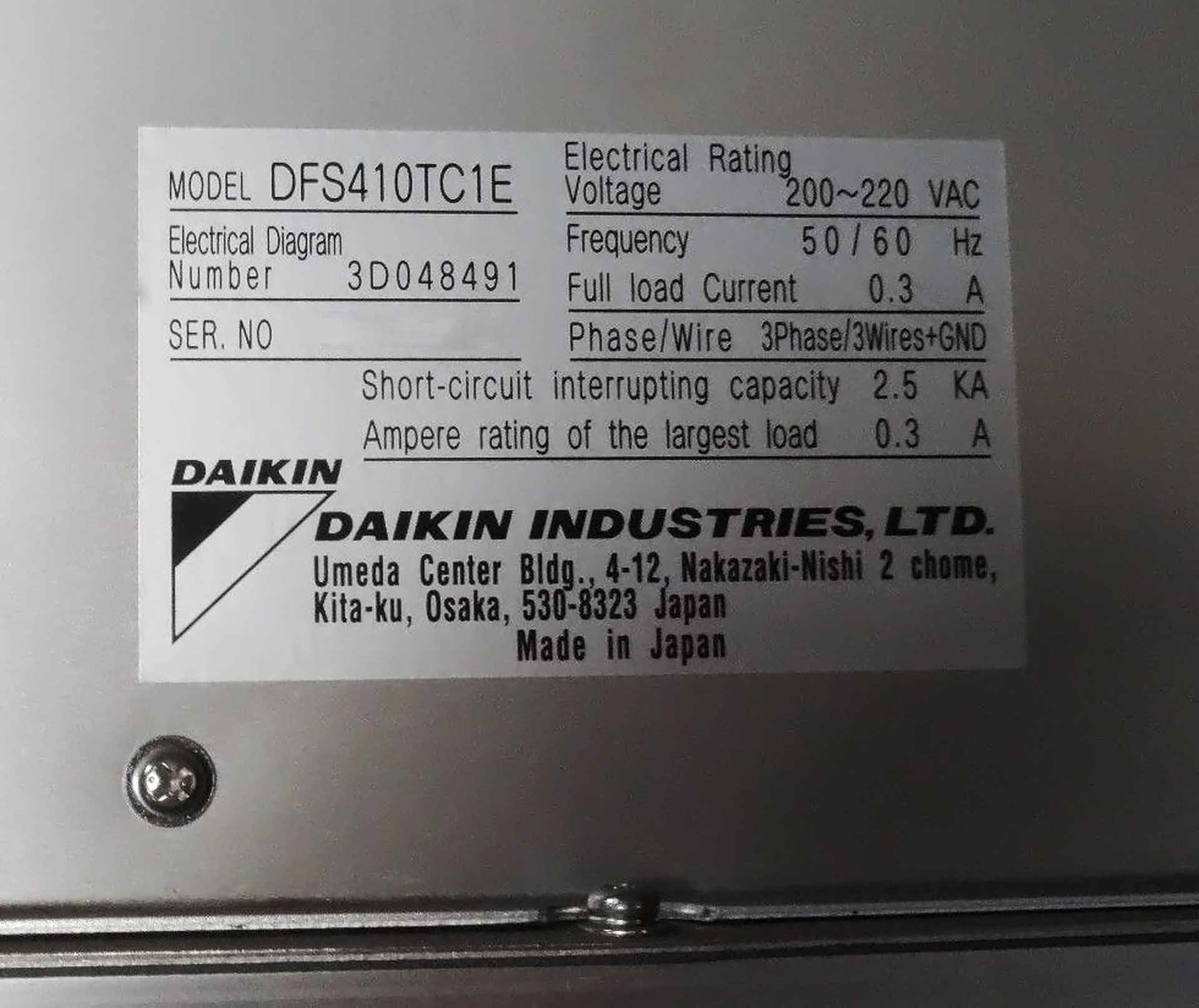

DAIKIN P/N: DFS410TC1B

Additional P/N:

(1) DFS410TC1E

(1) MR-JS2-BC001-QE

(2) MR-JS2-20A

(1) MR-JS2-40A

(1) MR-JS2-10A

(1) MR-T0059A-117B.

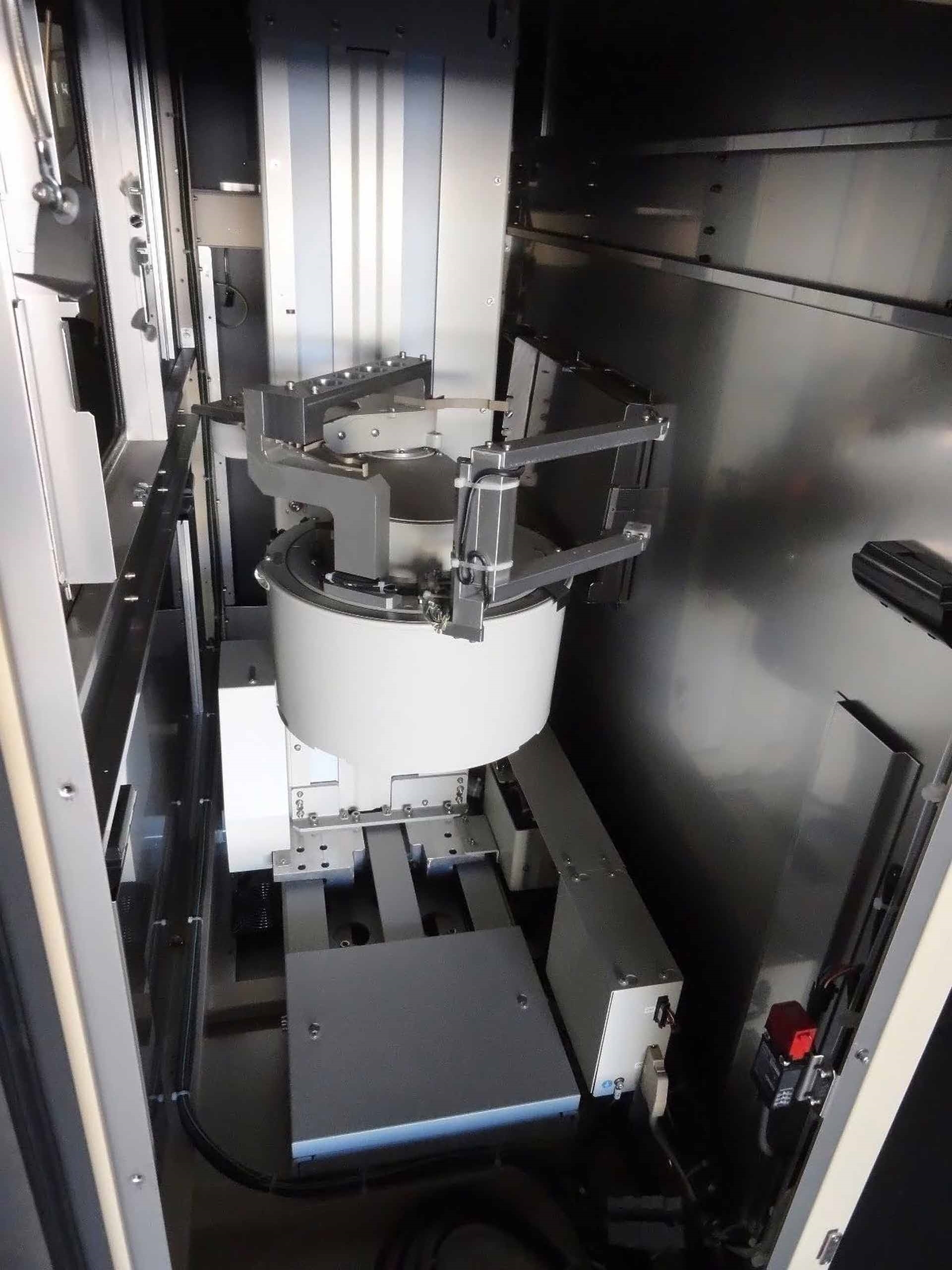

TEL / TOKYO ELECTRON Clean Track Lithius is a completely automated photoresist equipment designed to provide precise, clean, and consistent results in all lithography applications. Using advanced imaging and processing software, this system produces consistent results for various types of photoresist materials including photoresist, acrylic, PMMA, or polyimide. The unit uses a combination of advanced optical components such as lenses, diffractive optical elements, mirrors, and wavelength filters to create a uniform beam that is applied to the photoresist material. This application processes the beam in such a way that it completely encapsulates the substrate and creates a uniform coverage layer in only a fraction of a second. This ensures that the exposed material has accurate and even coverage for maximum quality and performance. The machine's advanced air bearing stage tool offers precise and repeatable motions with a maximum scanning speed of 0.5mm/s. It also offers real-time monitoring of the substrate temperature to ensure consistent, repeatable results. This feature further reduces the time required for the desired substrate to be consistently processed. In addition, this asset is also equipped with automatic cleaning features. The model's nozzle cleaning and nozzle leak detection systems ensure that the air delivery systems and the nozzles are delivering a consistent spray, eliminating any potential for air or material delivery errors. Overall, TEL Clean Track Lithius is an advanced precision photoresist equipment designed to provide consistent, repeatable results in all lithography applications. Its combination of advanced optical components, scanning speed, and temperature control offer a complete solution suited to any lithographic task. Furthermore, its automated cleaning features provide assurance of consistent, uniform beam coverage, and reliable substrate temperature levels.

There are no reviews yet