Used TEL / TOKYO ELECTRON Clean Track Mark 8 #27547 for sale

URL successfully copied!

Tap to zoom

ID: 27547

Wafer Size: 8"

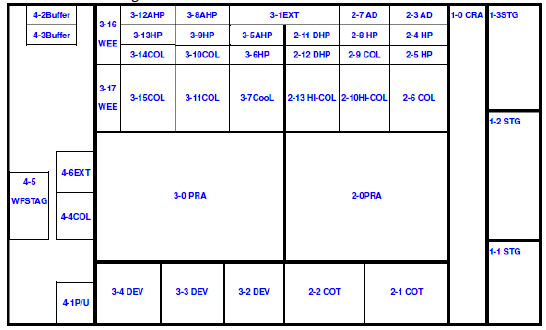

(2) Coater / (3) Developer systems, 8"

Double block + IFB

Right to left

2C2D 1IFB

2C3D 1IFB

SMIF - 3SUC.

TEL / TOKYO ELECTRON Clean Track Mark 8 is a photoresist equipment used in the manufacturing of electronic components such as semiconductors. It is a unique manufacturing tool that uses intense ultraviolet radiation and a masking process to etch intricate patterns onto wafers of semiconductor material. A photoresist is applied to the wafer which shields the desired areas of the chip from being exposed to the UV radiation. The non-shielded areas are then exposed to the UV radiation which causes a chemical reaction in the remaining photoresist and the exposed area is etched away, leaving behind the desired pattern. TEL Clean Track Mark 8 uses advanced photoresist technology to ensure a high quality finish and accurate etching. It allows for adjustable etching parameters, such as UV exposure time, distance between wafer and mask, intensity of radiation, and mask design. This allows for a wide range of designs to be etched onto the semiconductor material. The system also features a sophisticated cooling unit with air jets and temperature sensors to ensure that the temperature of the photoresist remains at a consistent level throughout the etching process. This allows for precise etching and ensures that the design of the pattern is replicated accurately. The cooling machine also helps to reduce waste and damage to the photoresist and wafer. TOKYO ELECTRON Clean Track Mark 8 also uses advanced software to control the parameters of the photoresist, mask and etching process. The software is user-friendly and can be easily programmed to allow for flexible settings and designs. Overall, Clean Track Mark 8 is an innovative photoresist tool that is used in the manufacturing of electronic components. It provides a high quality finish and accurate etching through the adjustable settings and its advanced cooling asset. It also has advanced software for controlling the parameters of the process. This makes it an essential tool for the manufacturing industry.

There are no reviews yet