Used TEL / TOKYO ELECTRON Clean Track Mark 8 #9158015 for sale

URL successfully copied!

Tap to zoom

ID: 9158015

Wafer Size: 8"

Vintage: 1997

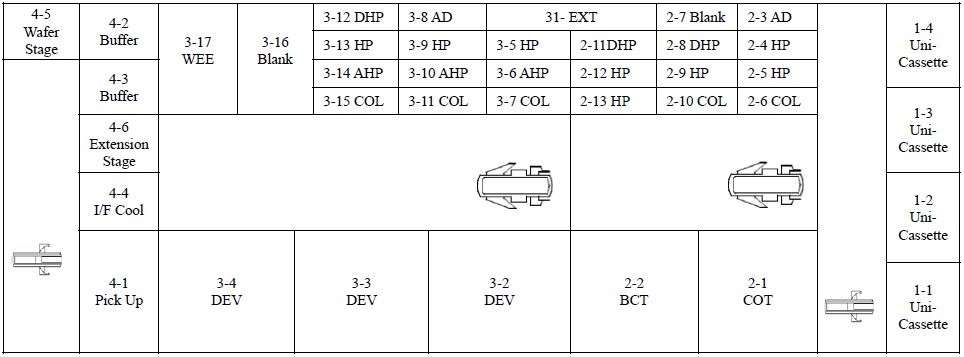

(2) Coater / (3) Developer system, 8"

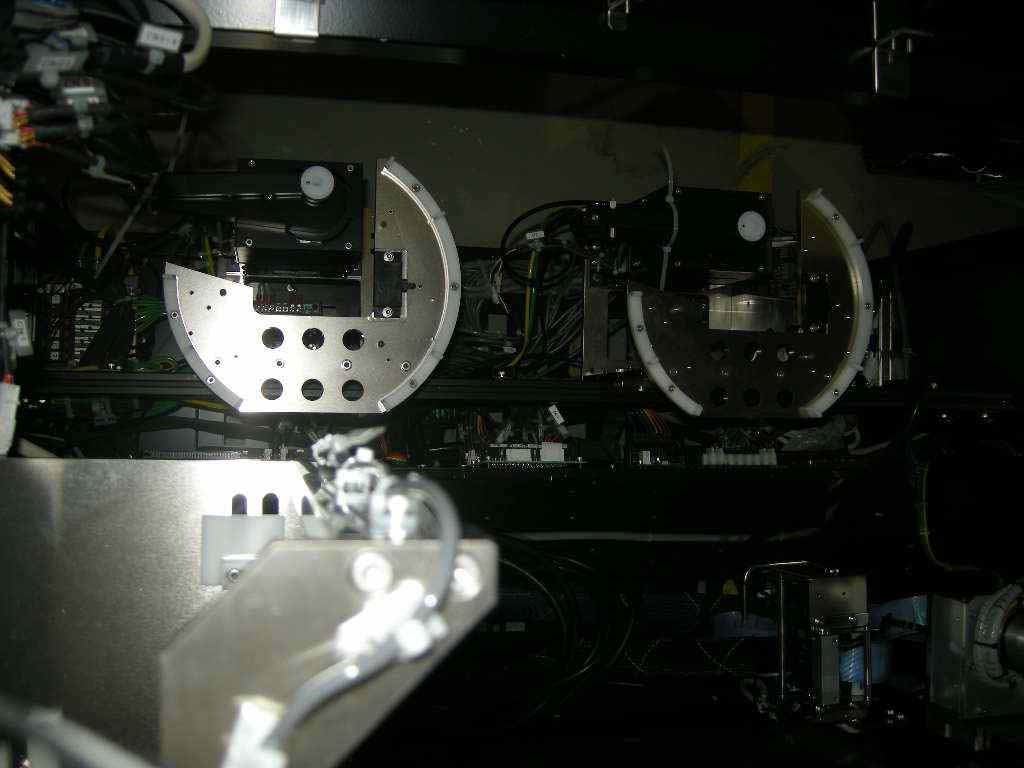

Dual block

Silicon substrate wafer

Wafer flow: Right to left

CSB Unit at right

Interface station unit at left

(2) Process blocks:

Cassette station block (CSB):

FC-9801F Controller

Stage / Indexer:

Non SMIF / Open uni-cassette

Cassette station (CS)

Cassette station arm (CSA)

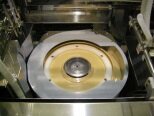

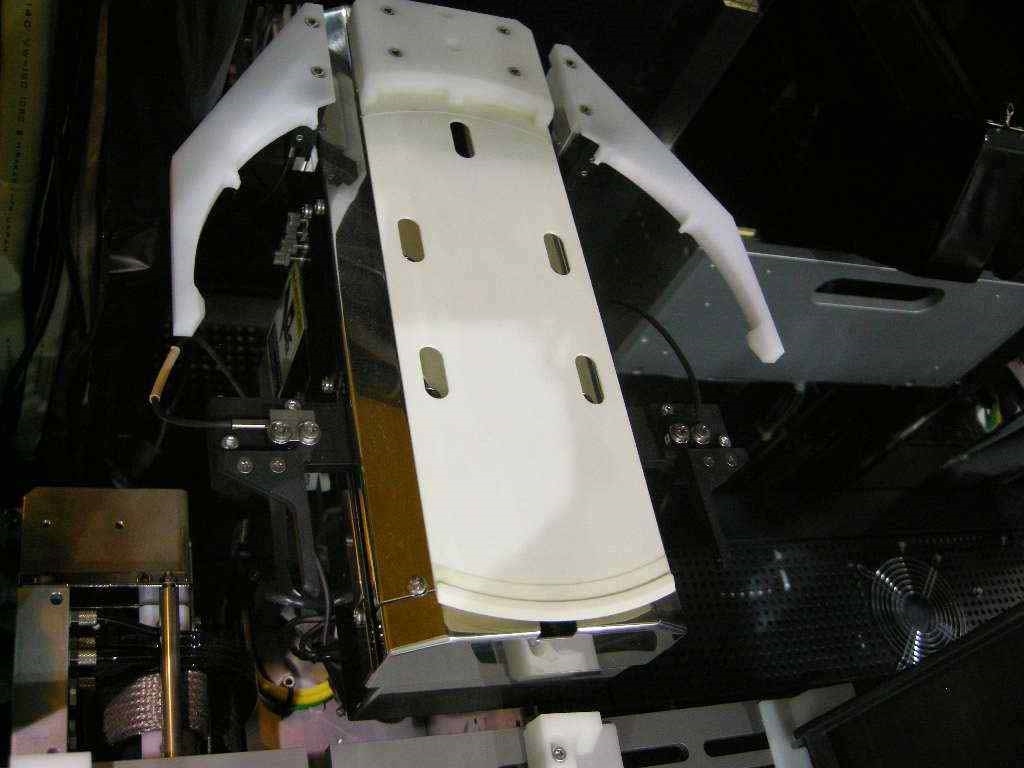

PSB / Process station block (Spin units):

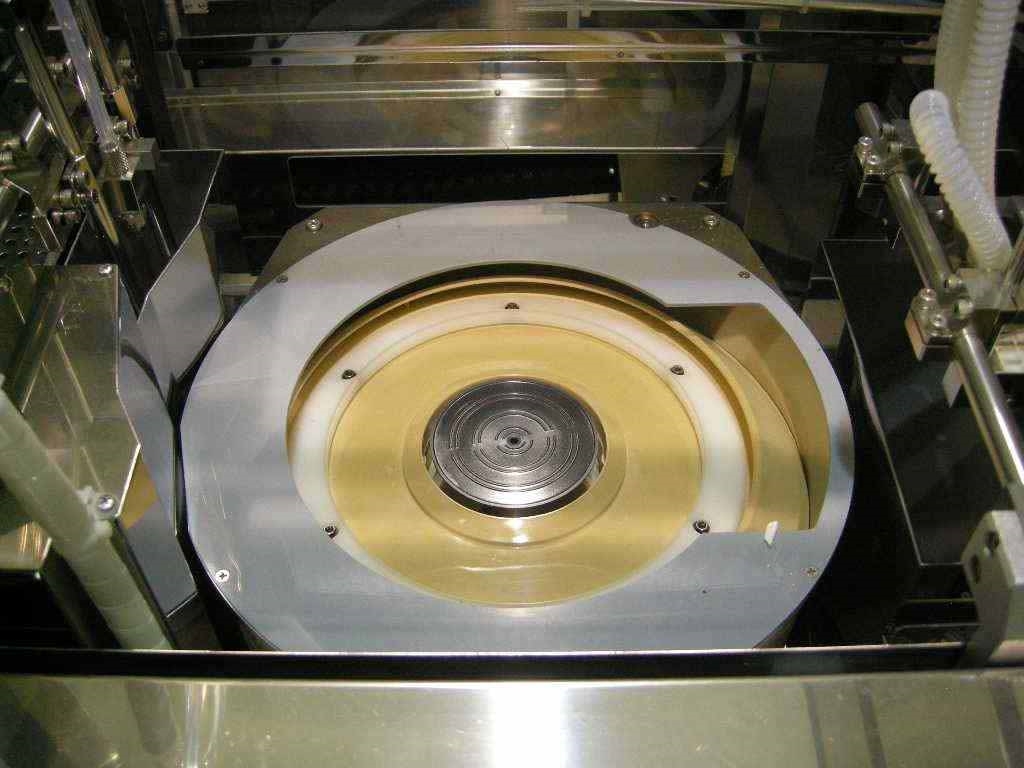

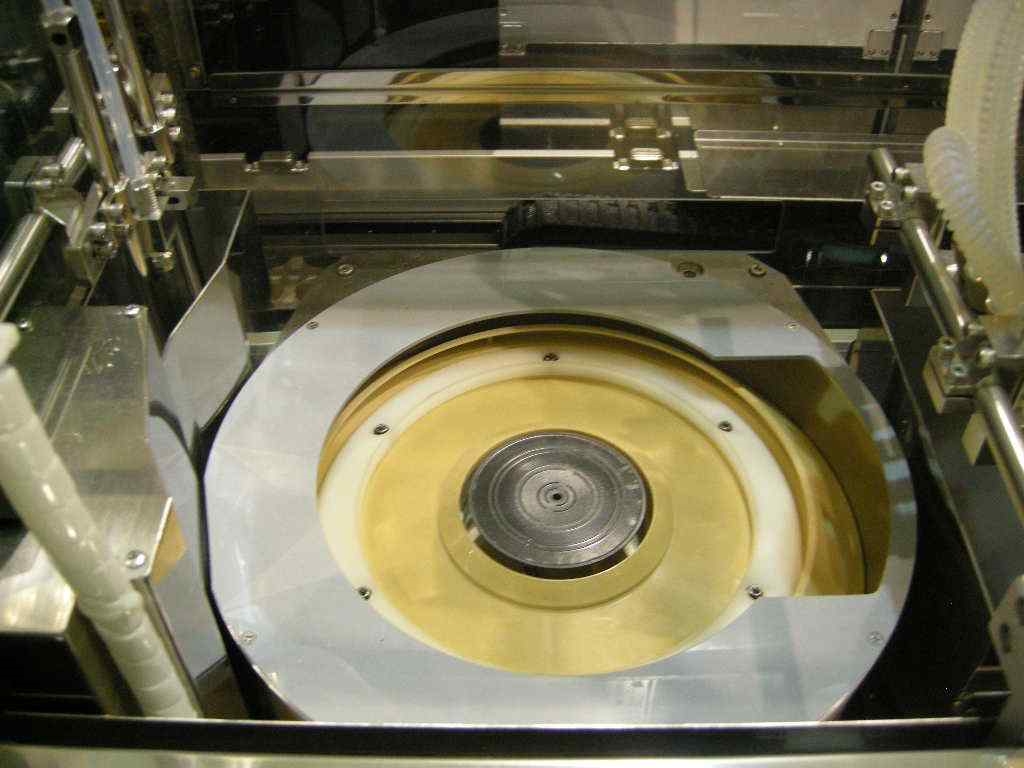

2-1 Standard photo resist coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

(6) Photo resist bottles in external chemical supply systems

Photo resist auto exchange

Auto dummy dispense system

2-2 Bottom layer coat (BCT) unit:

(3) Bottom layer coat (BCT) dispense nozzles

(3) IWAKI Bellows photo resist pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzle

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Photo resist bottle: (6) External photo resist supply system

Photo resist auto exchange

Auto dummy dispense system

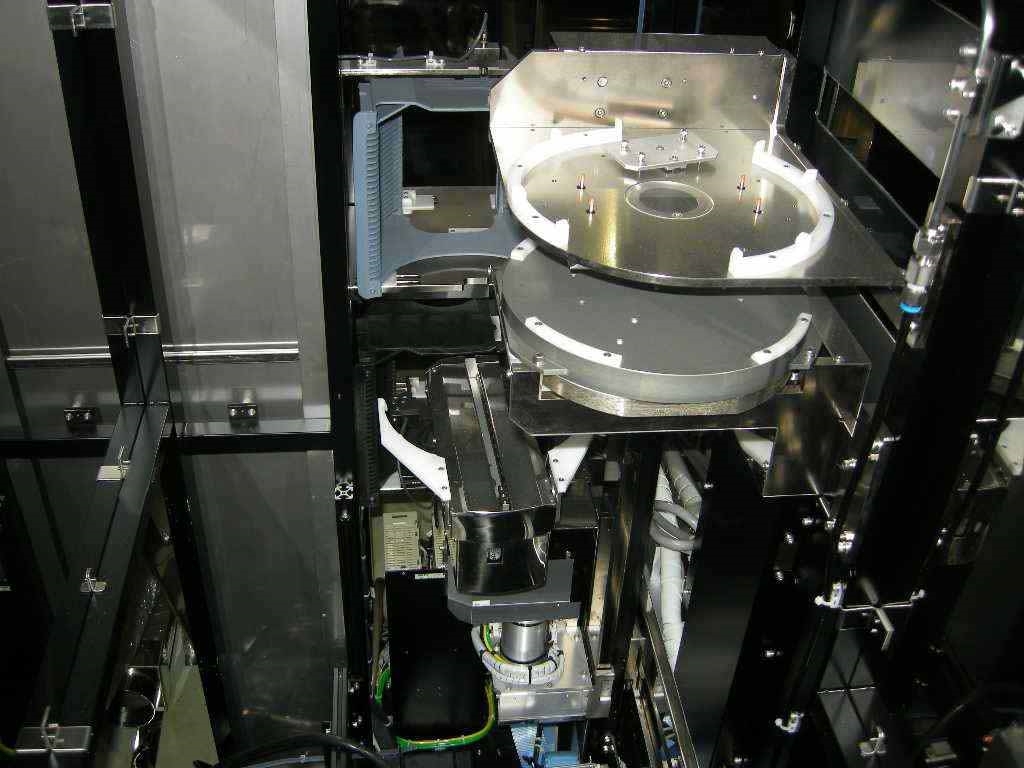

Process block robotics arm (PRA)

Adhesion unit (AD)

(5) Hot plate oven units

(2) Dehydration hot plate (DHP) oven units

(2) Cool plate units

Process station block (Spin units):

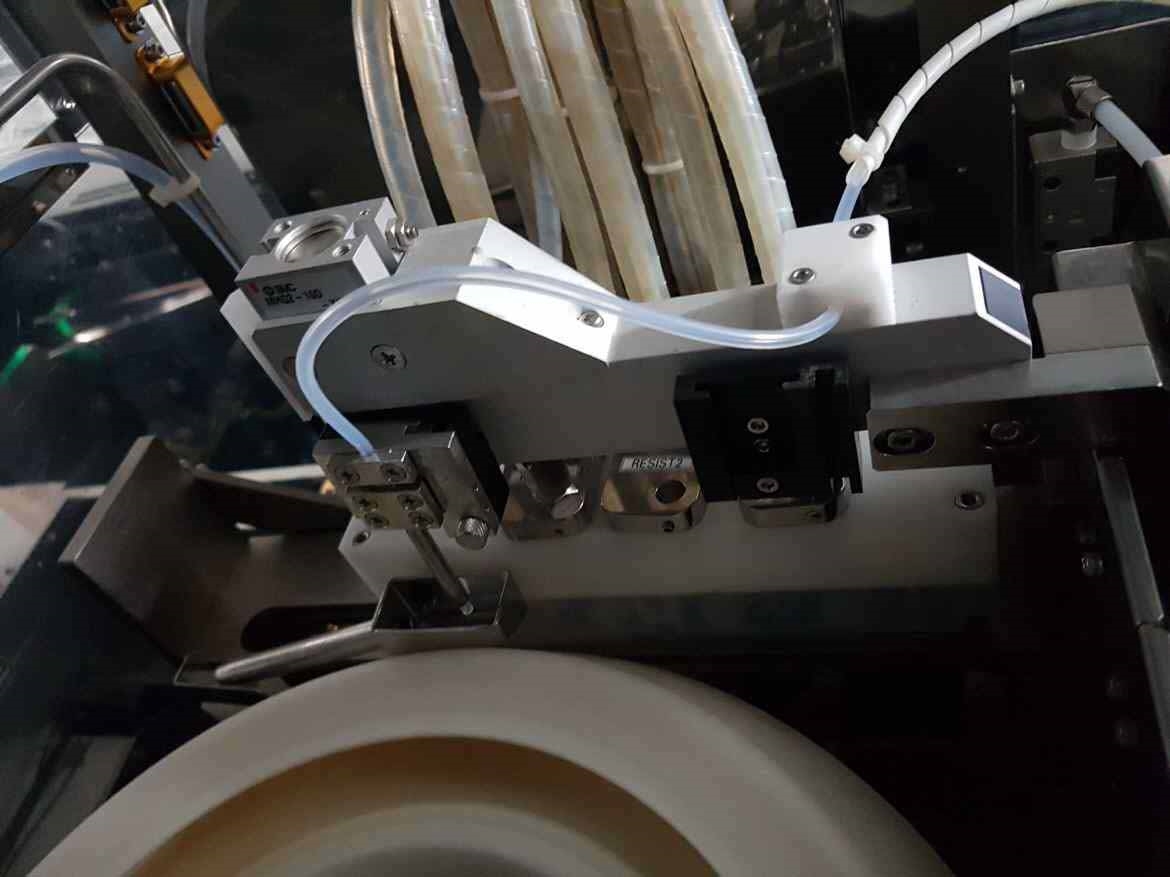

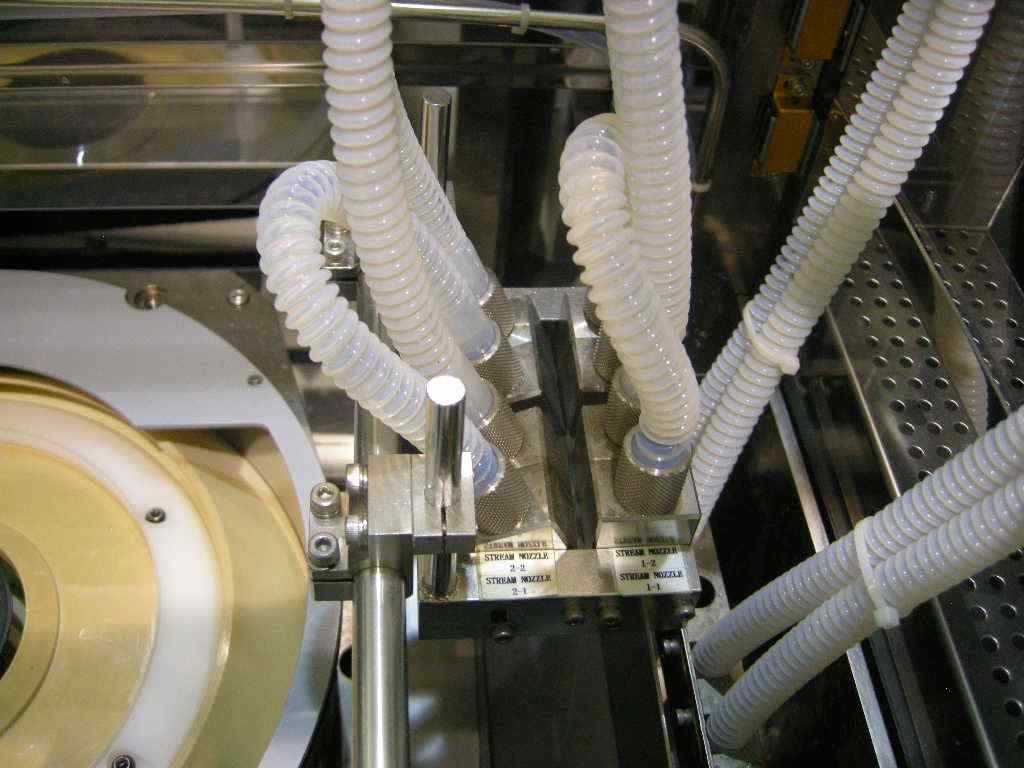

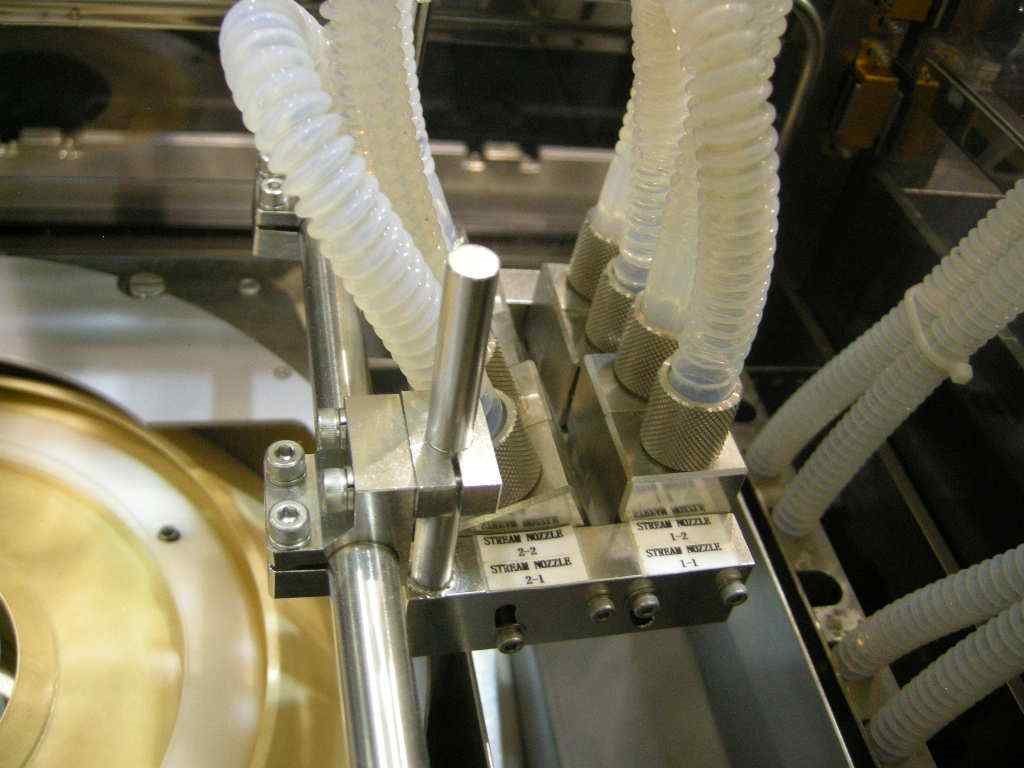

3-2, 3-3, 3-4 Develop units:

(4) Stream nozzles at (4) Stream nozzle blocks

Rinse nozzles:

(2) Stream type

Spray type

Dual back rinse nozzles

Develop temperature control

Motor flange temperature control

Drain type: Direct gravity drain type

Auto damper

Auto dummy dispense system

Process block robotics (PRA) Arm

Adhesion unit

(3) Hot plate oven units

Dehydration hot plate (DHP) oven unit

(3) Air-purge hot plate (AHP) oven units

(3) Cool plate units

Extension unit

Wafer edge exposure (WEE) unit

Interface station block (IFB):

Interface arm (IFA)

Interface for ASML PAS Series Stepper

(2) Buffers

Pick-up system

Interface cool

Extension stage

Wafer stage

Temperature and humidity controller:

TEAM KOREA TK-TH8T4

2-Cup control capacity for 2 Coat units

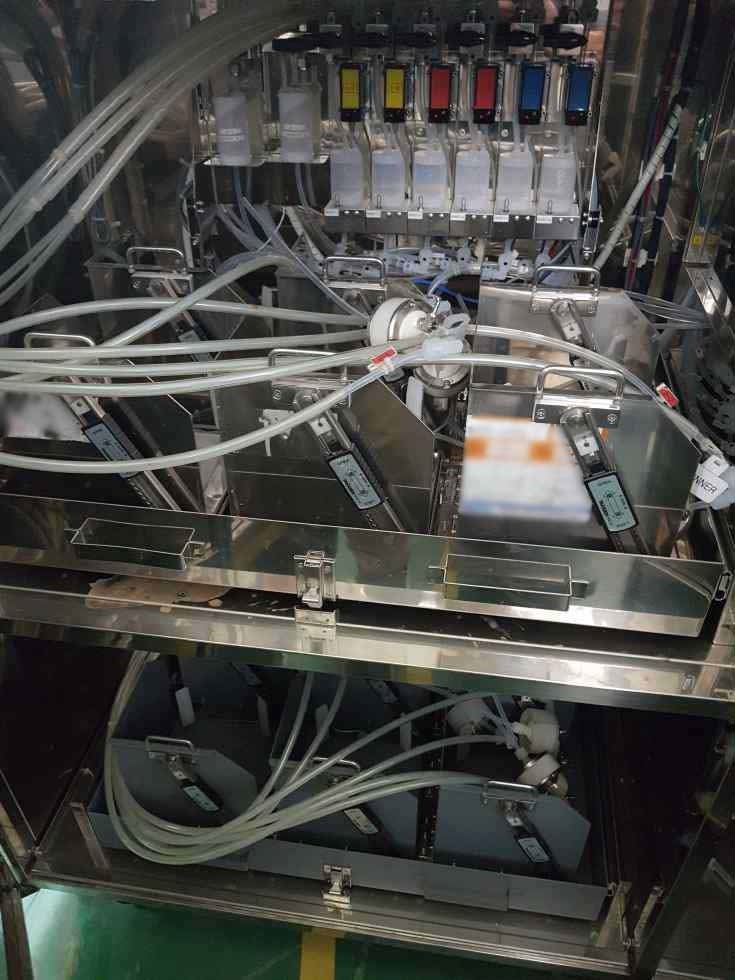

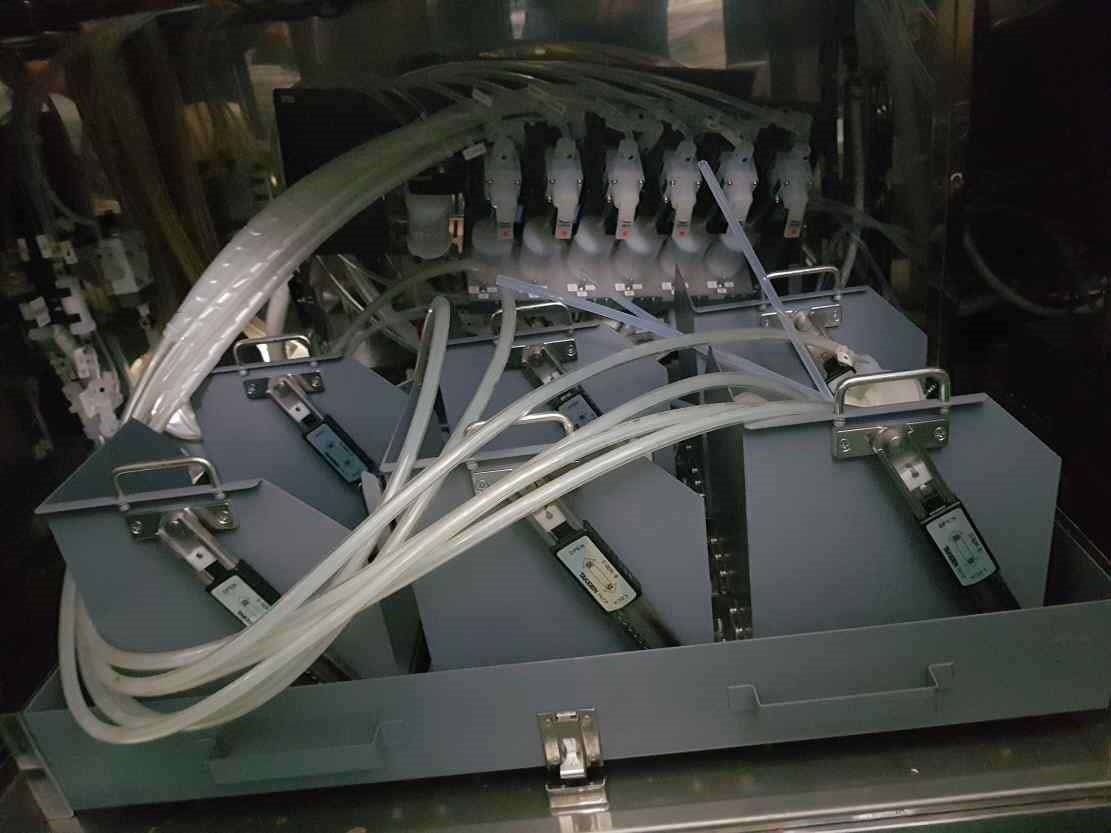

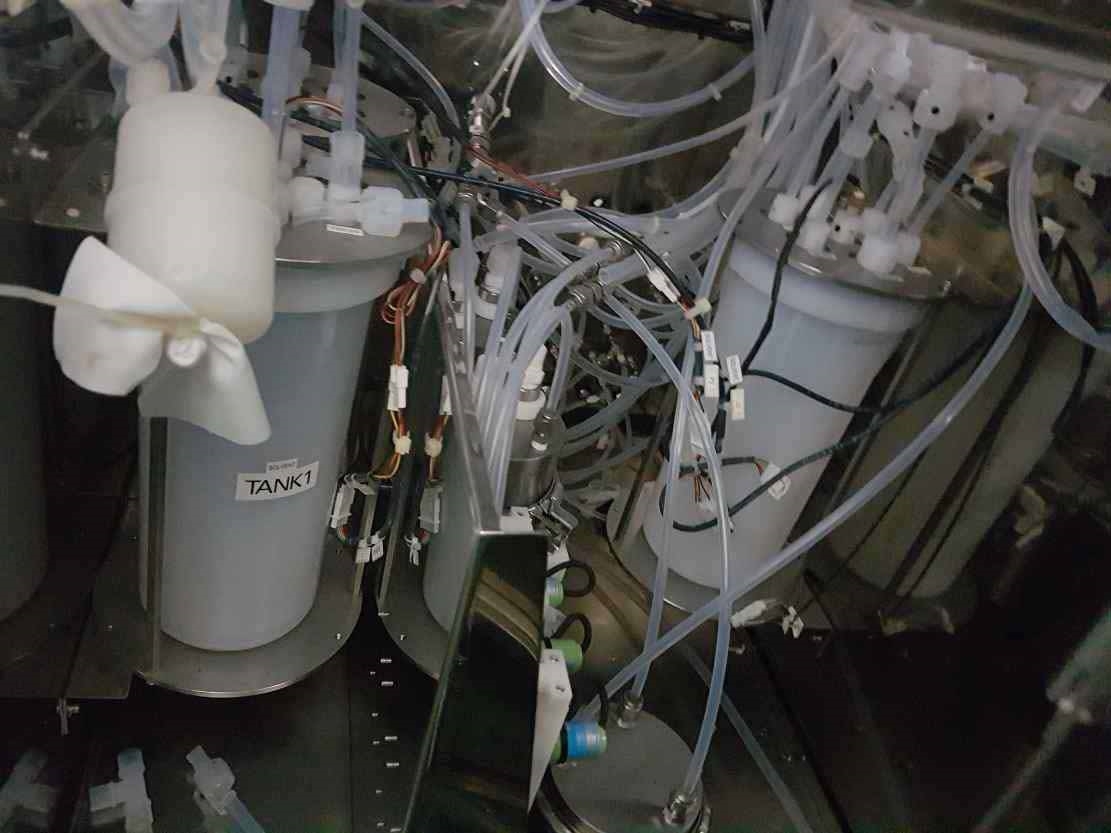

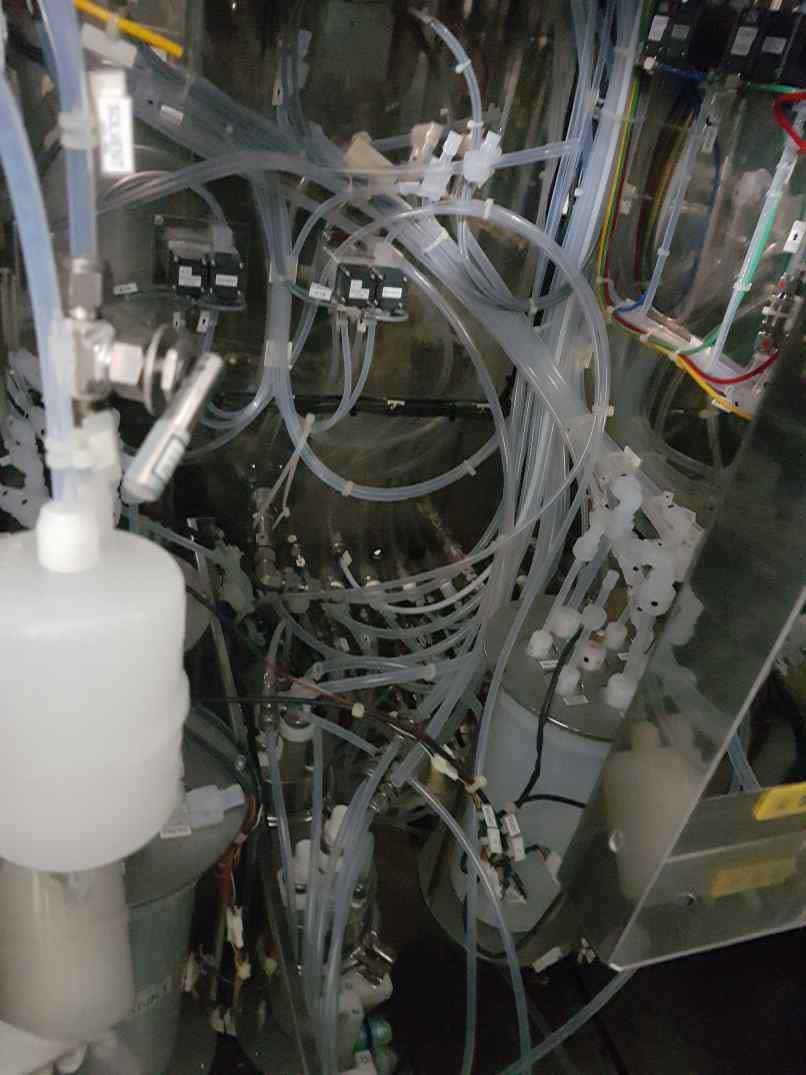

External chemical supply system:

Solvent supply system:

Solvent chemical type

CSS Bulk-fill to auto supply system

With (2) Buffer tanks: Auto switch-off / Exchange

Develop supply system:

Develop solution chemical type

CSS Bulk-fill to auto supply system

With (2) Buffer tanks: Auto switch-off / Exchange

Photo resist supply system for 2-1 Coat and 2-2 BCT

6-Bottles of manual supply type

Auto exchange system

HMDS Supply system:

HMDS Chemical type

CSS Bulk-fill to auto supply system with bubbling jar

HMDS Supply system

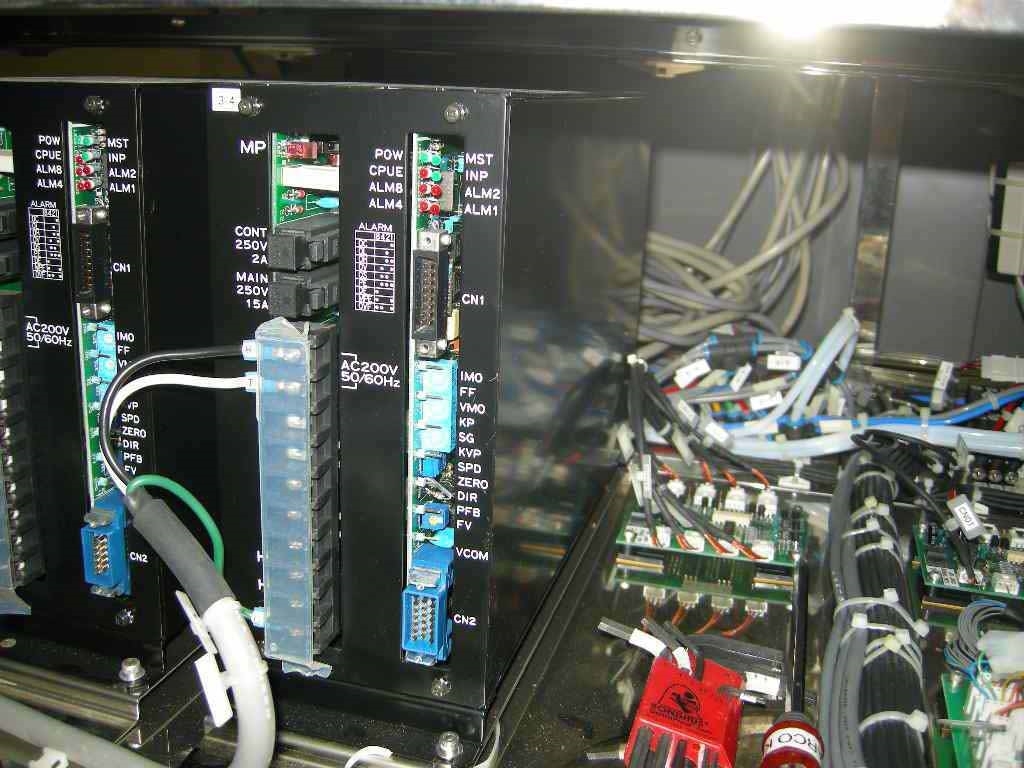

Themo controller:

External chemical supply system: (2) TEL / TOKYO ELECTRON SMC Multi controller

MAX 16 Channel capacity: 12-Channels for (2) Process

SMC Multi thermo controllers:

(6) SMC Circulators: Chilling channels

2-1 COT Unit

2-2 BCT Unit

Stream nozzle block:

Block 1 and 3: 3-2, 3-3 DEV

Block 2 and 4: 3-4 DEV

(5) Motor flanges

(6) SMC Thermo controllers: Chilling channels

2-9 COL

2-10 COL

3-7 COL

3-11 COL

3-15 COL

4-4 I/F COL

(4) Robots:

CS Arm

(2) Main arm robots

Interface arm

Power transformer AC cabinet: 208 VAC, 3-Phase, 50/60 Hz

1997 vintage.

TEL (TOKYO ELECTRON) TEL / TOKYO ELECTRON Clean Track Mark 8 is a photoresist equipment used in the fabrication of circuit boards. The system is capable of a variety of photoresist processes including spin-coating, soft-baking, mask aligning, spray-coating, and hard-baking. The clean track enables repeatable and accurate results that help create high yields. TEL Clean Track Mark 8 is designed to help reduce cleanroom downtime and improve productivity. It features a durable and reliable antistatic chassis and a "no-ccd" aligning unit that cuts alignment time in half. Furthermore, the machine is equipped with a touch panel LCD display, which makes navigating the tool's functions easier. The asset includes two unique and advanced baking technologies for improved cleanliness and process accuracy. The first is the split bake, which separates the baking process into two parts to decrease the risk of contaminations and optimize the temperature stability. The second is the hybrid bake, which can completely bake the wafer without separating the substrate into tasks. TOKYO ELECTRON Clean Track Mark 8 utilizes specially designed nozzles and cleaners that can rapidly remove resist residue, which results in cleaner wafers while significantly reducing chemical waste production. Special coating capabilities reduce chemical usage and cleaning time by as much as 70%, ceramic head nozzles help reduce total particle counts, and high-precision contact-less tracking helps improve the alignment accuracy. Furthermore, the model is retrofittable, which allows for compatibility with a variety of photoresist systems. Overall, Clean Track Mark 8 uses advanced technologies to enable users to get repeatable and top-notch results while minimizing the use of chemicals, energy, and downtime. It is designed to be an efficient and effective photoresist equipment that helps users attain maximum yields while keeping a cost-effective production.

There are no reviews yet