Used TEL / TOKYO ELECTRON Clean Track Mark 8 #9165442 for sale

URL successfully copied!

Tap to zoom

ID: 9165442

Wafer Size: 8"

Vintage: 1997

(2) Coater / (2) Developer system, 8"

Single block

Open cassette

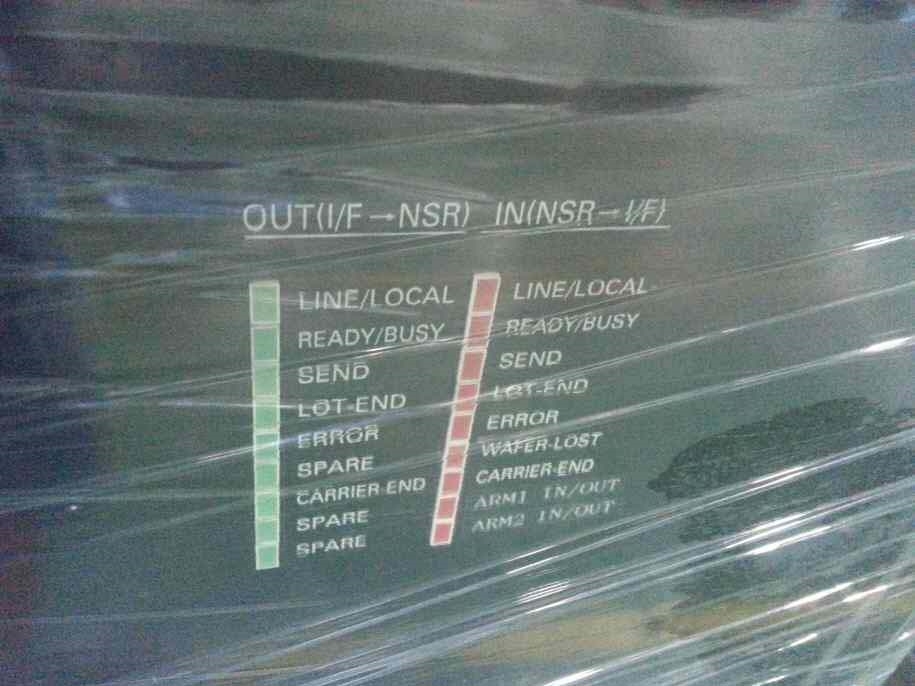

Interface for NIKON NSR 2205 EX14C

Silicon substrate wafer

Wafer flow: Left to right

CSB Unit at right

Interface station unit at left

(2) Process blocks: Single block system

Cassette station block (CSB):

FC-9821KE Controller

Stage / Indexer:

Non SMIF / Open uni-cassette

Cassette station (CS)

Cassette station arm (CSA)

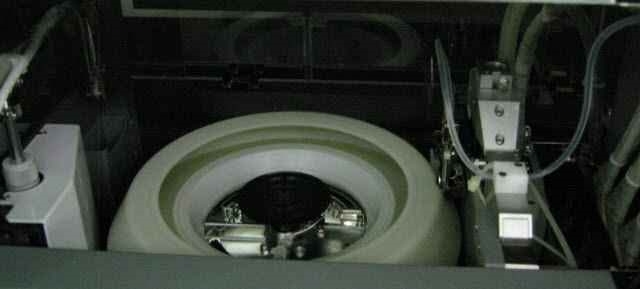

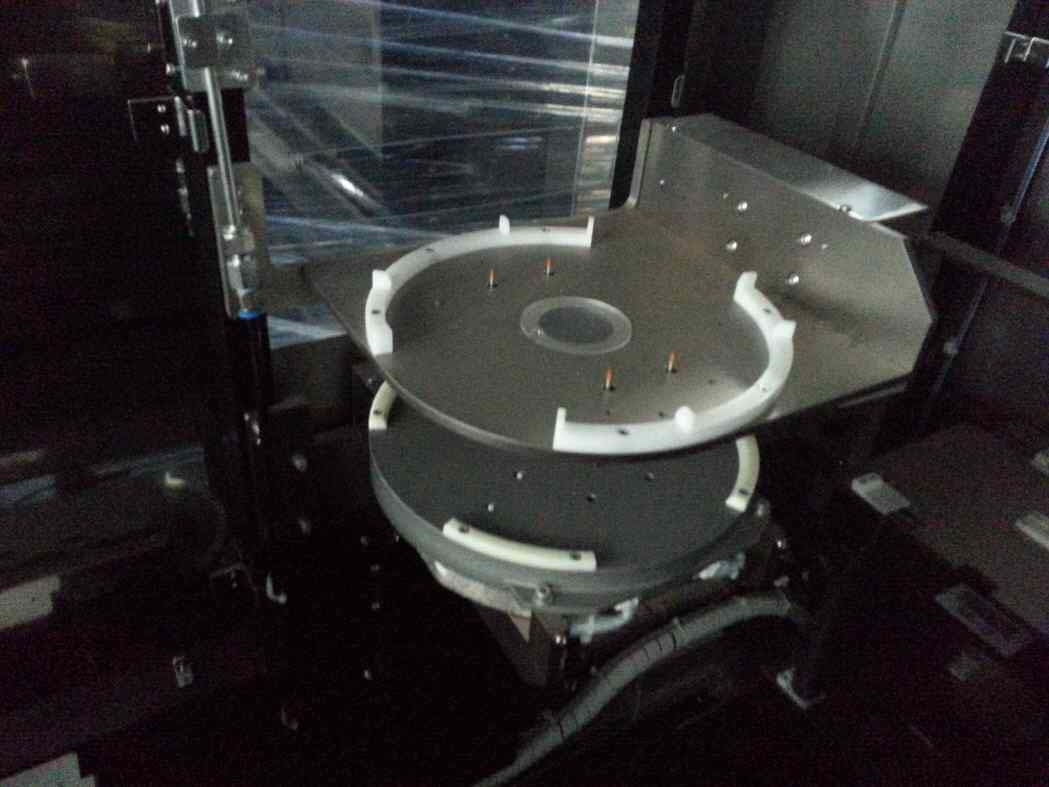

Process station block (Spin units):

2-1 Standard photo resist coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Auto dummy dispense system installed

Photo resist bottle: (6) External chemical supply system

2-2 Anti-reflection coat unit:

(3) Photo resist dispense nozzles

(3) IWAKI Bellows photo resist pumps

Solvent pre-wet reduced resist coat (RRC) nozzle

Side rinse nozzle (Programmable side rinse EBR)

Dual back rinse nozzles

Photo resist temperature control

Motor flange temperature control

Photo resist drain type: Direct gravity drain type

Auto dummy dispense system installed

Photo resist bottle: (6) External chemical supply system

2-3 and 2-4 Develop units:

(4) Stream nozzle blocks

(4) Stream nozzles

(2) Rinse nozzles: Stream type

Dual back rinse nozzles

Develop temperature control

Motor flange temperature control

Drain type: Direct gravity drain type

Auto damper

Auto dummy dispense system

Process block robotics arm (PRA)

Adhesion unit

(10) Hot plate oven units

(2) Air-purge hot plate (AHP) oven units

(7) Cool plate units

Wafer edge exposure (WEE) unit

Interface station block (IFB):

Interface arm (IFA)

(2) Buffers

Pick-up system

Interface cool

Extension stage

Wafer stage

Temperature and humidity controller:

SHINWA T&H-CPC

2-Cup control capacity for (2) Coat units

External chemical supply system:

Solvent supply system for (2-1) COT and (2-2) ARC:

Solvent chemical type

Bulk-fill central chemical supply (CSS) type

With (2) 3-Liter teflon buffer tanks

Develop supply system for 2-3 and 2-4 Develop units:

Develop solution chemical type

Bulk-fill central chemical supply (CSS) type

With (2) 3-Liter teflon buffer tanks

(2) Photo resist supply systems:

6-Bottles of manual supply type

Auto switch-off / Exchange installed

HMDS Supply system:

HMDS Chemical type

Bulk-fill central chemical supply (CSS) type

With 3-Liter teflon buffer tanks for AD unit

External chemical supply system / Cabinet: (2) SMC Multi thermo controller units

SMC Circulator pumps and thermo controller

With 7-Channels:

2-1 COT

2-2 ARC

Motor flanges: 2-1 COT and 2-2 ARC

2-8 COL

2-12 COL

2-16 COL

2-19 COL

SMC Circulator pumps and thermo controller

With 7-Channels:

1 and 3 Stream nozzle blocks: 2-3

2 and 4 Stream nozzle blocks: 2-4

(2) Motor flanges at 2-3 and 2-4 DEV

2-20 COL

2-23 COL

2-24 COL

3-4 I/F COL

(3) Robots:

CS Arm

Main arm robots

Interface arm

Power transformer AC cabinet: 208 VAC, 3-Phase, 50/60 Hz

1997 vintage.

TEL / TOKYO ELECTRON Clean Track Mark 8 is a photoresist system developed to satisfy the requirements of today's ultra-high reliability and high-precision circuit board boards. The Mark 8 utilizes an advanced Ultrasonic Contact Cleansing (UCC) method, equipped with a two-step "Airblow Cleaning and Sweep Cleaning" process. The Airblow Cleaning process uses a high-speed air flow to remove dust, dirt, and contaminates up to a certain size. It utilizes forced air flow to clean the surface without causing any damage or stress to the substrate. The Sweep Cleaning process employs a reciprocating cleaning method using a rotating brush. This removes the small contaminants remaining after the Airblow Cleaning process. The Mark 8 also incorporates several additional features for improved performance and output. These include the use of Specific Density Cleaner (SDC), CCD Camera for Defect Inspection, Temperature Control of Board and Chambers, Hardware and Software Alarm Monitoring, Shimura/Kitta Defect Inspection, Automatic Chemical Level Control, and Roll/Belt type Chip Viscosity Control. The Mark 8 also features an additional level of flexibility with a customizable board base stage, allowing it to process both high and low strain sensor substrates, as well as standardized and non-standardized substrates. Additionally, a height-sensing sensor is integrated into the tool, reducing the chance of particle contamination during processing and increasing performance. In today's era of high-accuracy circuit board boards, TEL Clean Track Mark 8 photoresist system provides the performance and reliability customers' need. It's advanced UCC capabilities combined with several added features help provide customers with consistently clean, high-quality substrates. With the Mark 8's versatility and advanced capabilities, it is designed to meet the most demanding requirements, ensuring unsurpassed performance.

There are no reviews yet