Used TEL / TOKYO ELECTRON Clean Track Mark 8 #9184205 for sale

URL successfully copied!

Tap to zoom

ID: 9184205

Wafer Size: 8"

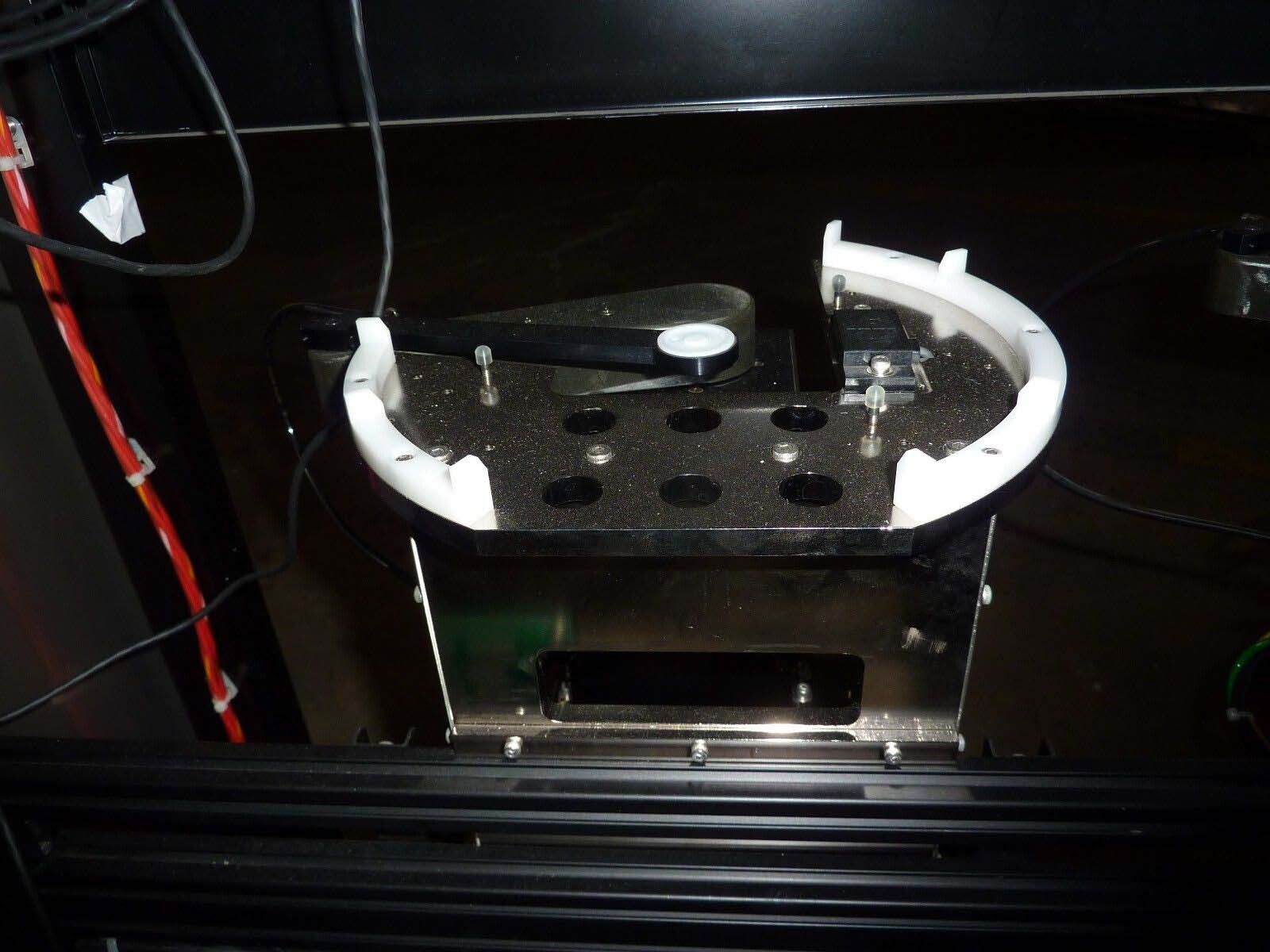

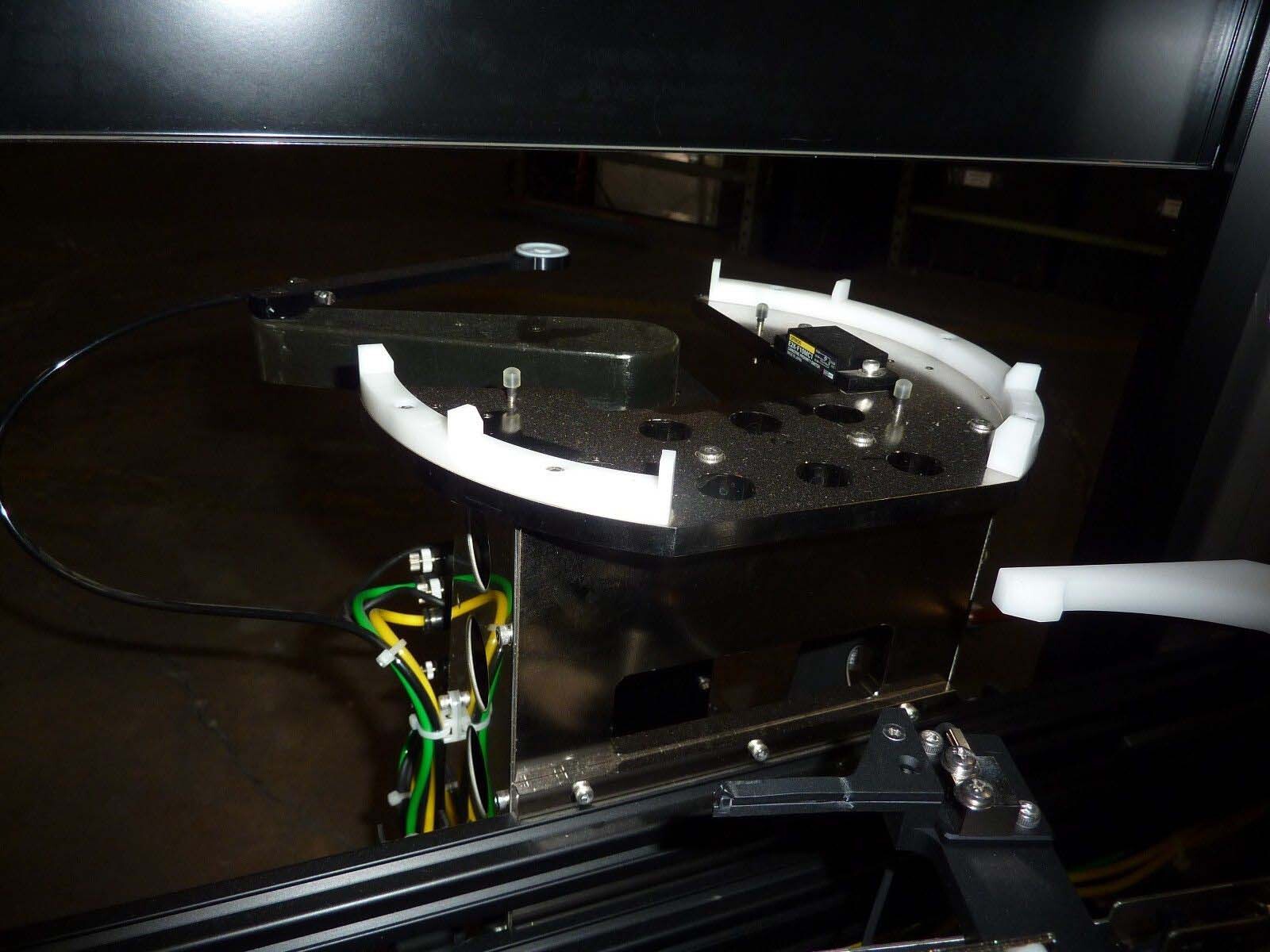

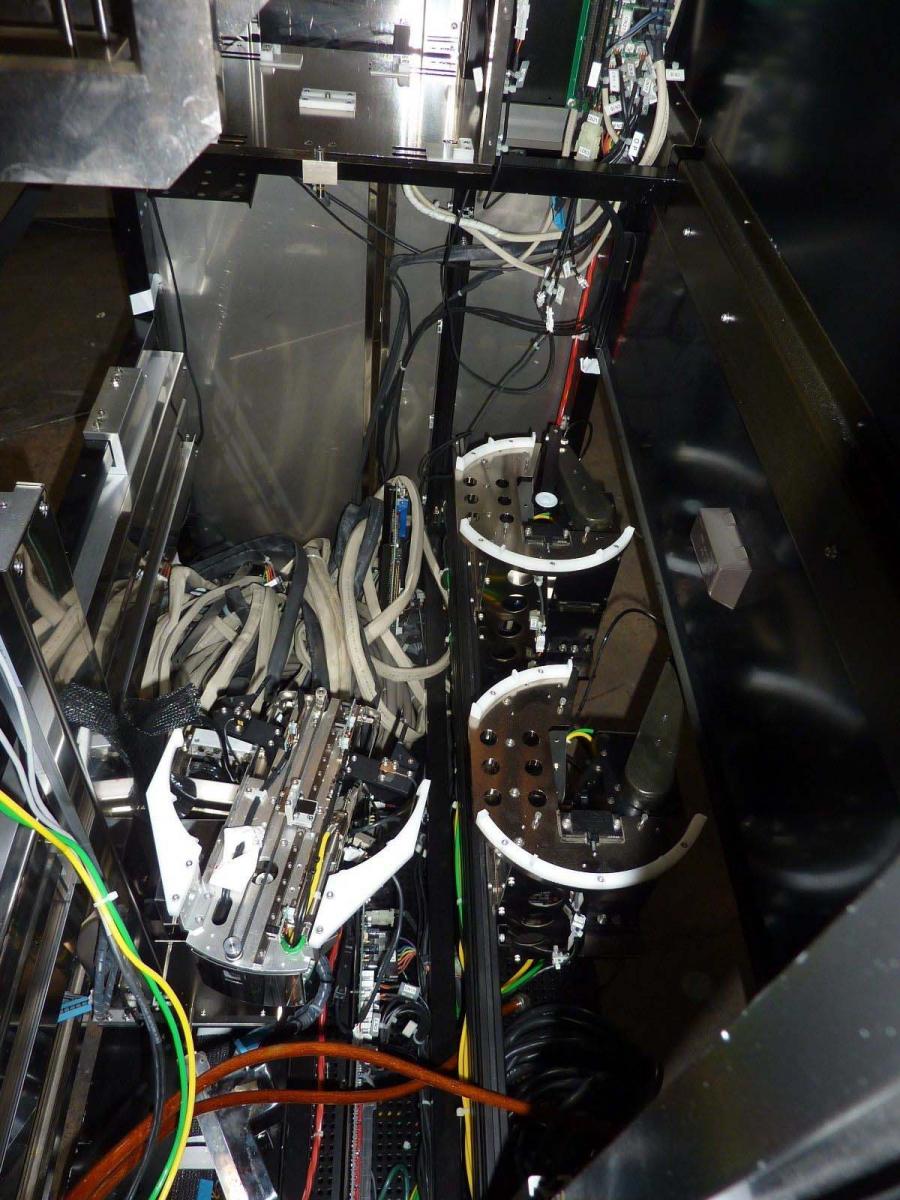

IRAM Interface block, 8"

Includes:

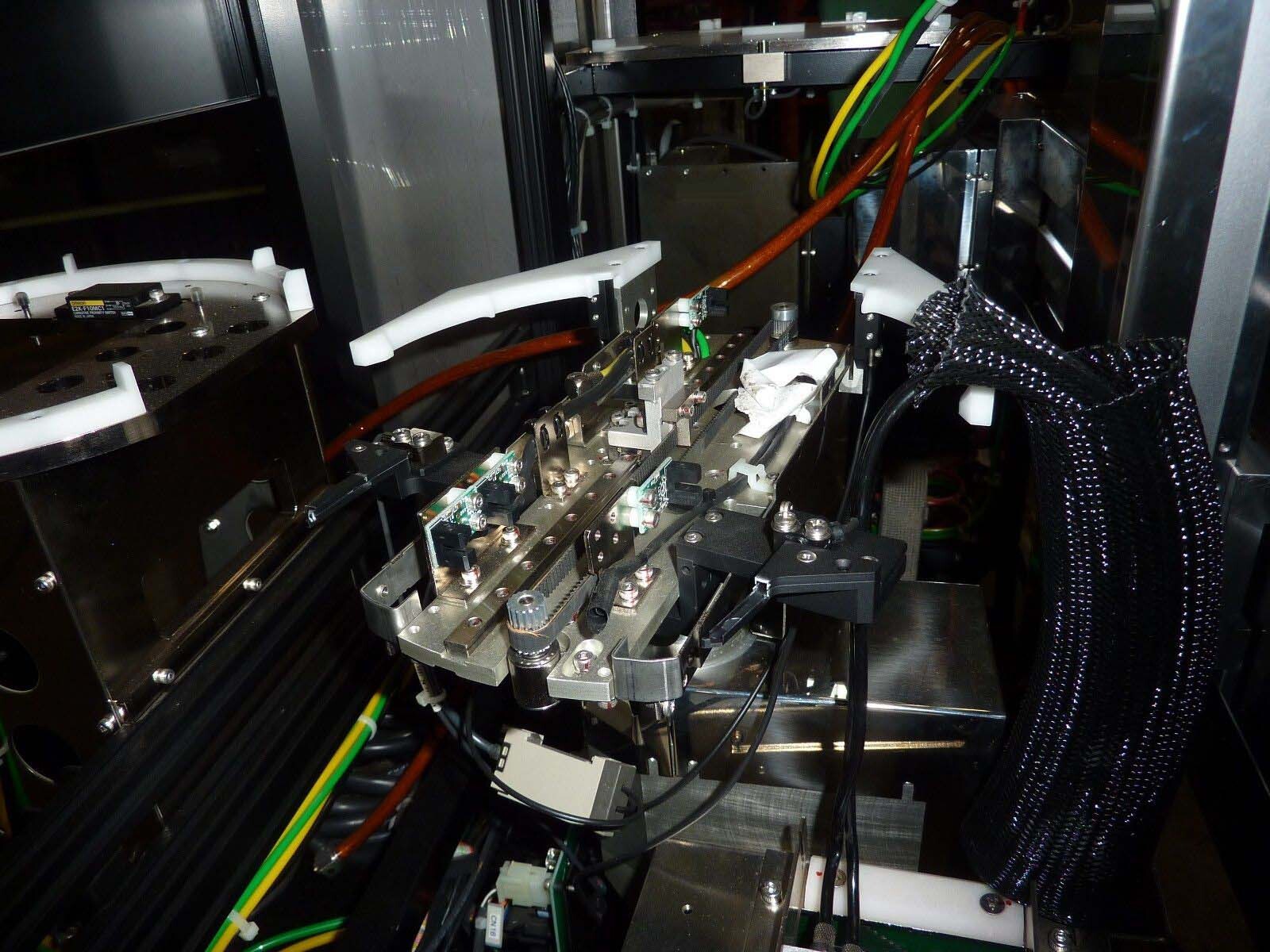

(2) KOGANEL Robots P/N: CR1131W-D

(2) OLYMPUS Servo drivers

TAIYO PCB Part no: CN-BASE

TEL Wafer robot

STP I/F & ELV Board:

PCB Part no: 381-639388-8

I/F Board:

PCB Part no: 381-643319-5.

TEL / TOKYO ELECTRON Clean Track Mark 8 is an advanced photoresist equipment designed for semiconductor fabrication processes. It is capable of performing the crucial steps of developing, exposing and post-treating with high precision and efficiency. This allows it to create a variety of devices with optimized characteristics and improved performance. At the heart of the system is a powerful Deep UV exposure source. This provides uniform irradiation across the whole wafer surface and enables accurate control over the pattern resolution and line/space widths. The exposure time can be tuned for smaller feature sizes and higher aspect ratios, allowing for more intricate patterns involving closely spaced lines and more complex geometries. The unit is equipped with a chemical dispense machine that uses highly accurate peristaltic pumps to apply the developer chemicals onto the wafer at a controlled rate. This ensures that the photoresist is developed with the required intensity and in a uniform manner. The post-treatment process is optimized with a Static & Dynamic Balancing function, which can fine-tune the developer pad tilt and speed, as well as the chemical dispense rate. The Mark 8 is designed for maximum operator safety. It has a built-in fume extraction tool that automatically filters airborne chemicals and lab contaminates to protect the user from exposure. In addition, the asset is designed to meet or exceed the stringent regulations covering corrosive chemical handling and the storage and disposal of toxic materials. In order to ensure the highest levels of performance and reliability, the model is rigorously tested and calibrated before being delivered. This includes running various simulations to simulate the effects of defect levels in the photoresist layer, in order to determine the optimal settings for any given application. TEL Clean Track Mark 8 has been developed to enable flexible and cost-effective photoresist processing. Its precise control over light energy levels, precise dispense of chemicals, dynamic balancing and automated safety features make it an ideal tool for semiconductor fabrication.

There are no reviews yet