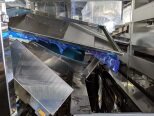

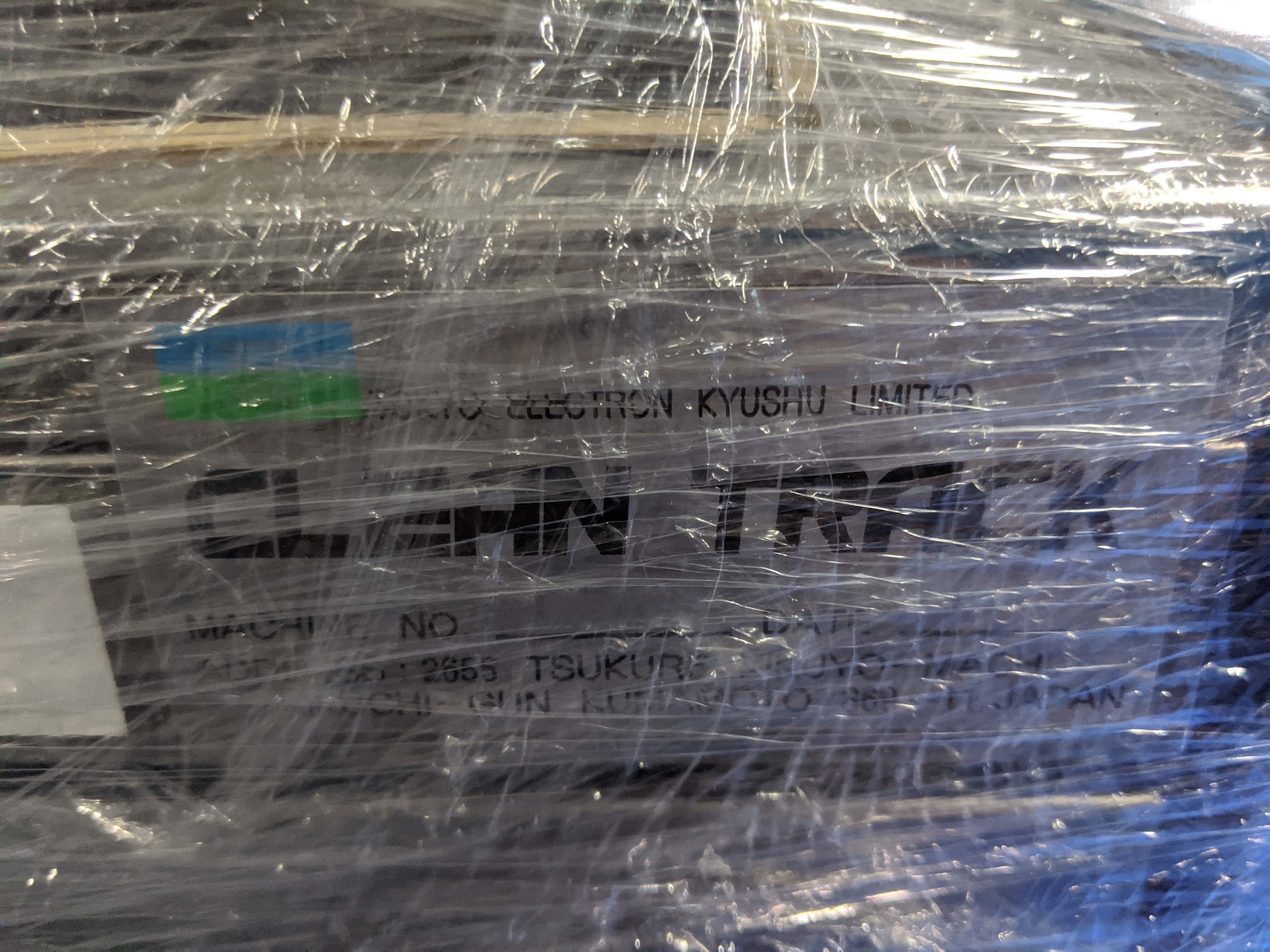

Used TEL / TOKYO ELECTRON Clean Track Mark 8 #9269233 for sale

URL successfully copied!

Tap to zoom

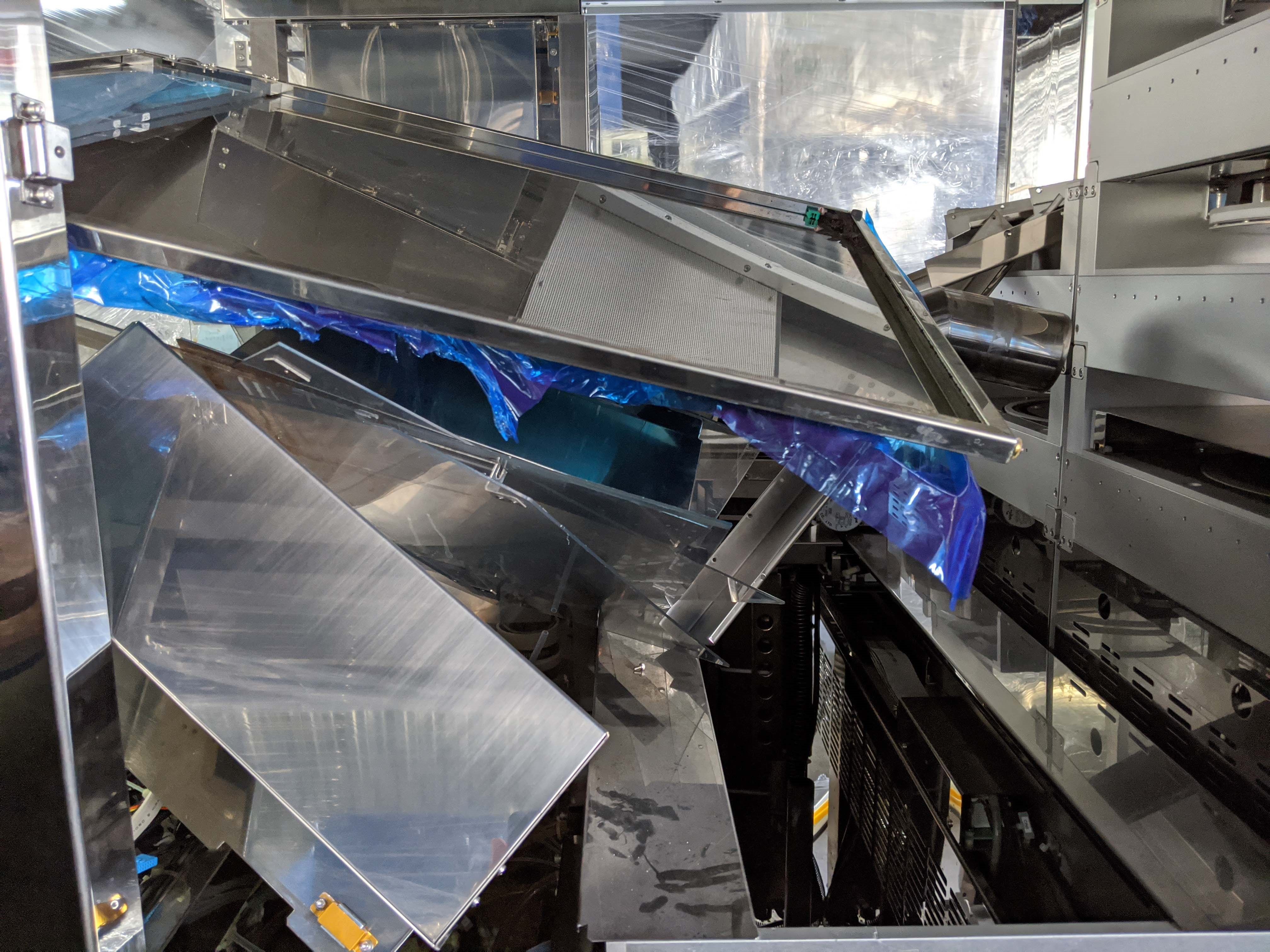

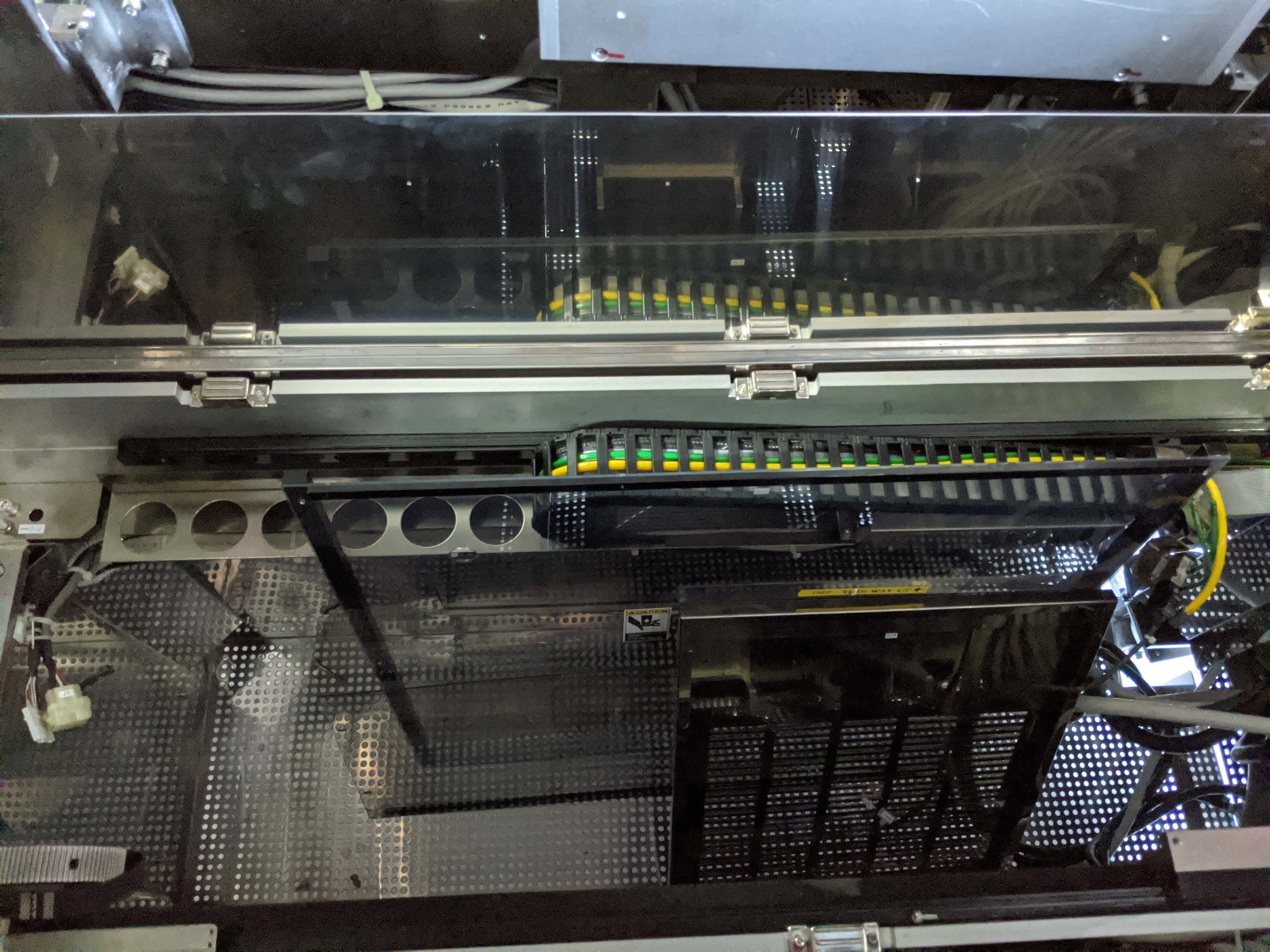

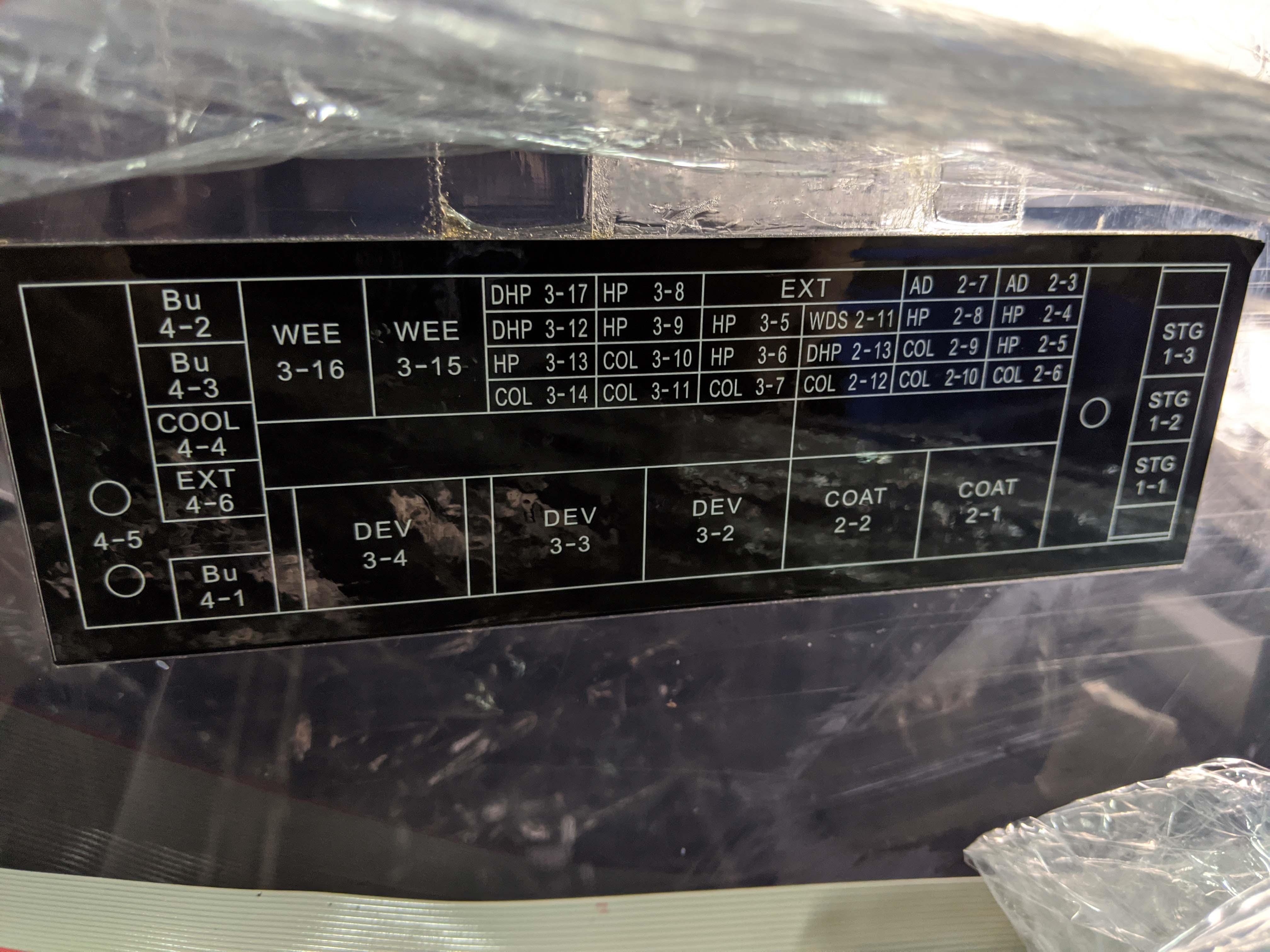

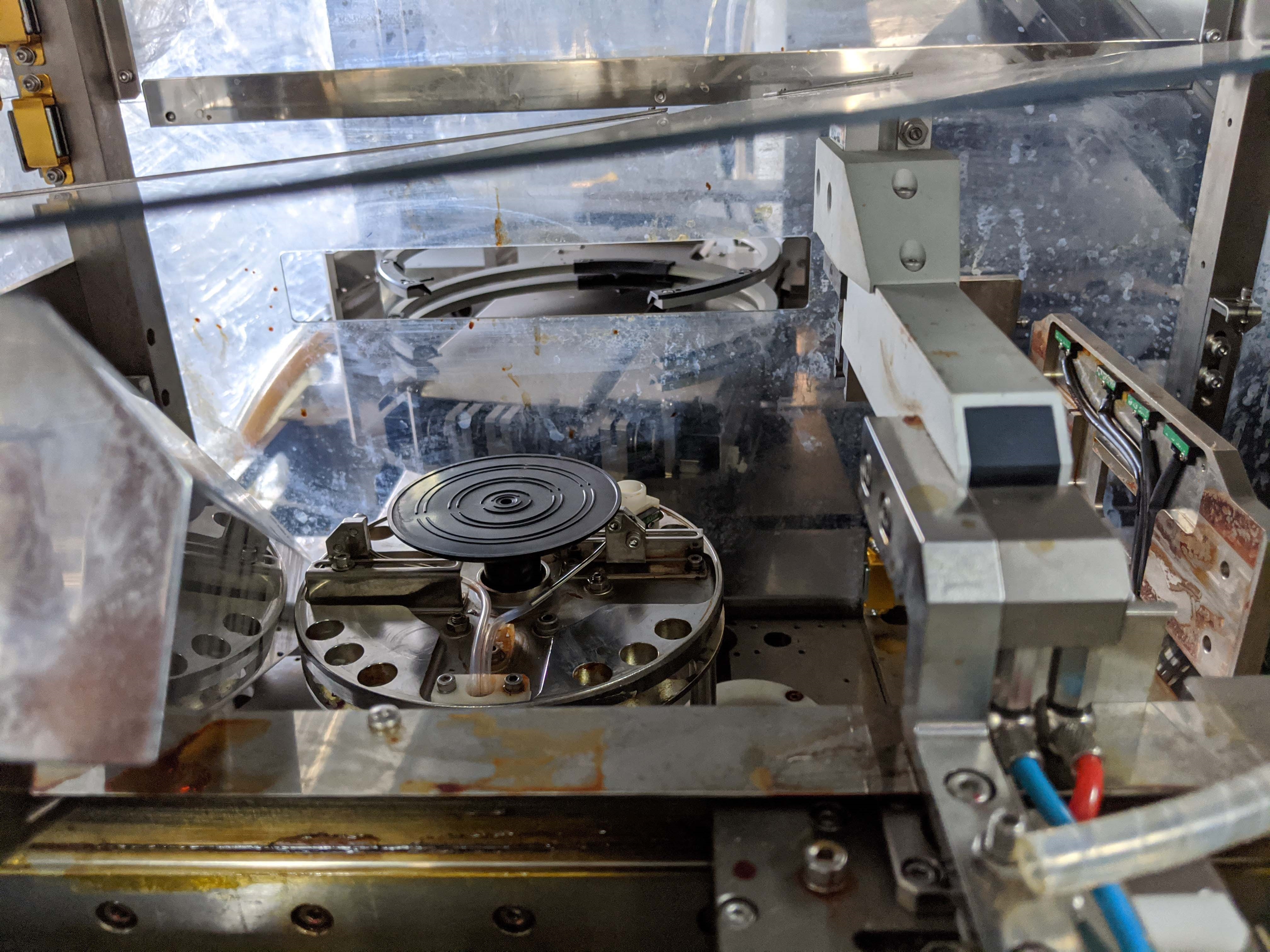

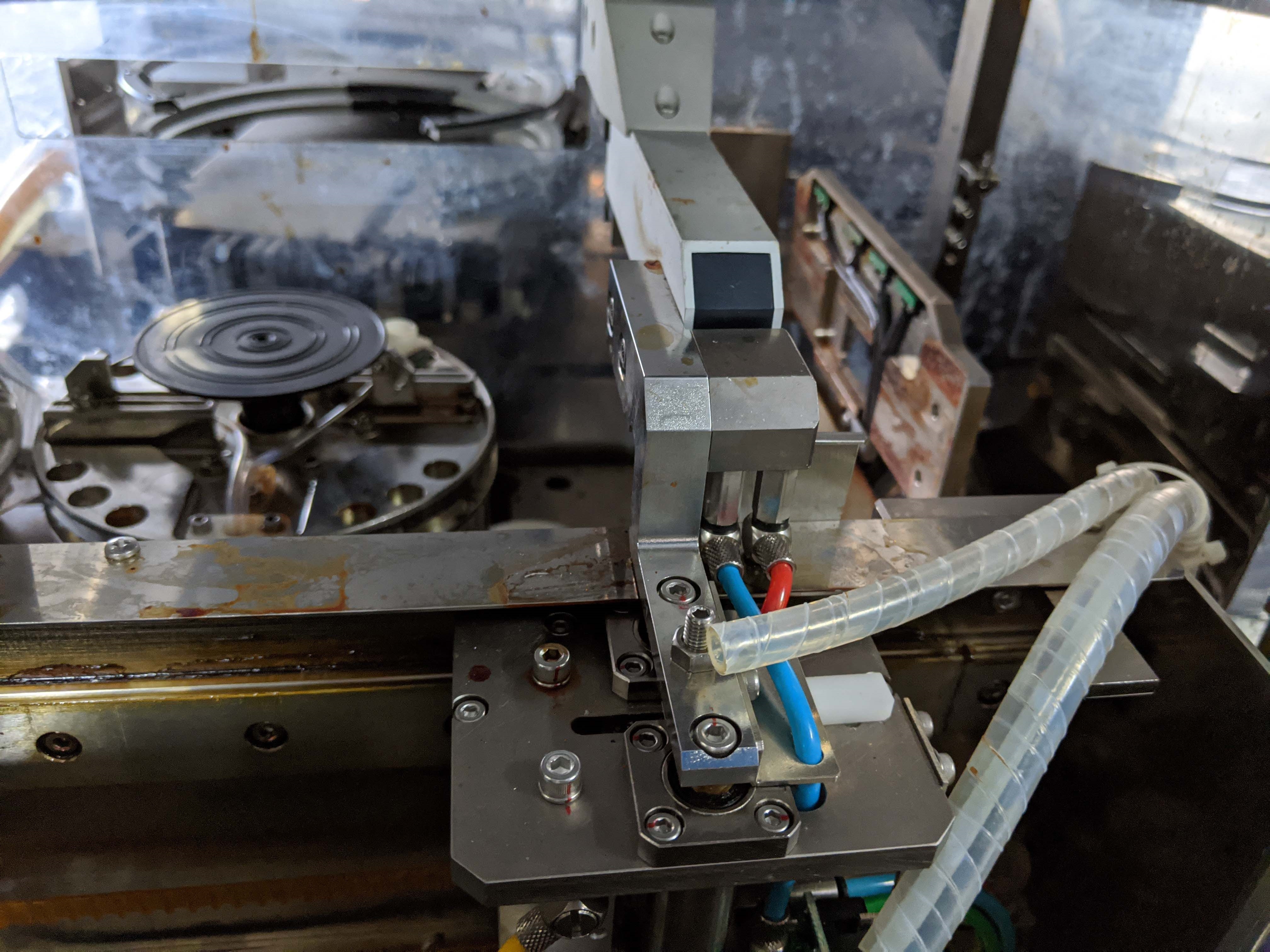

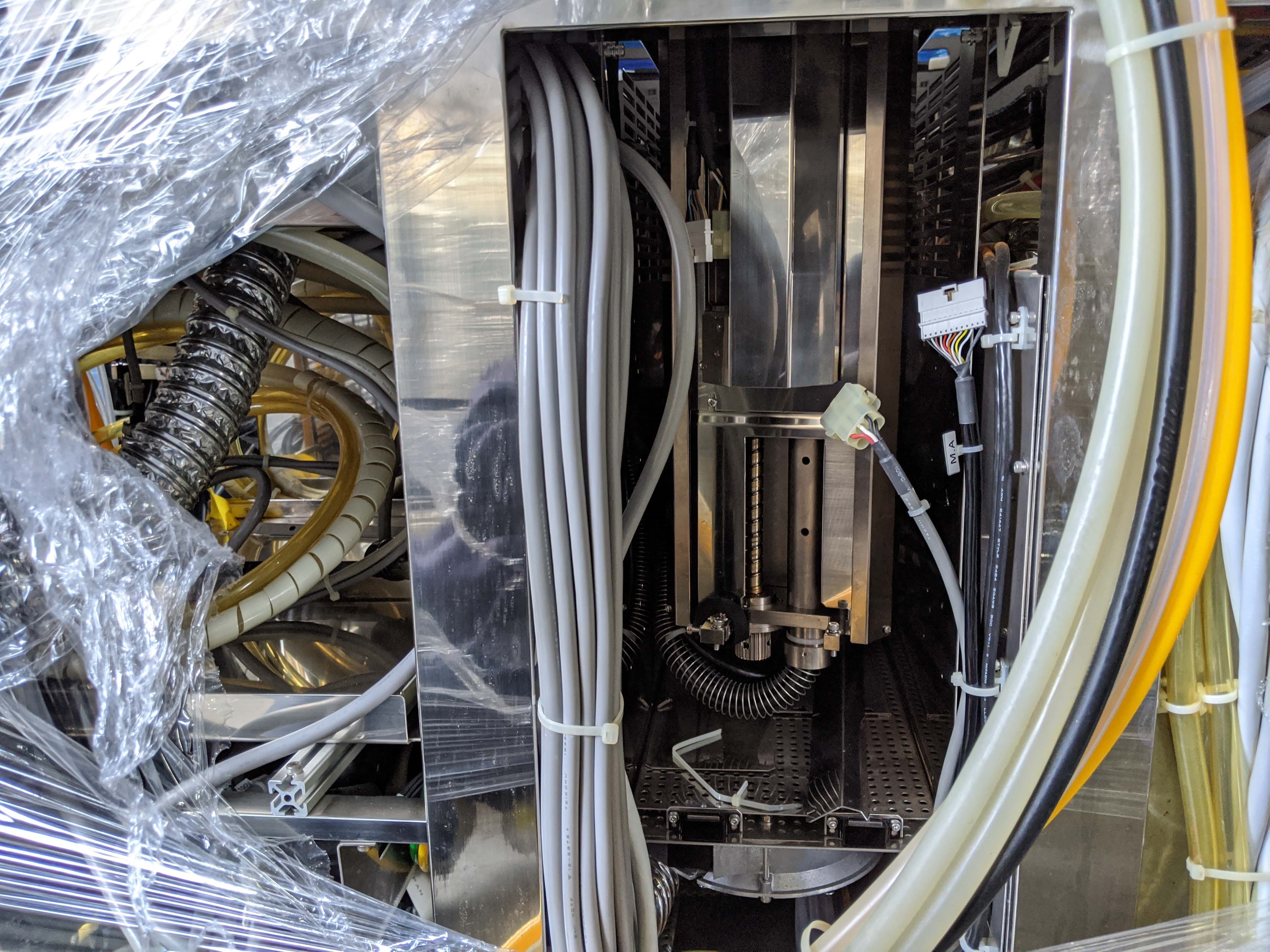

TEL / TOKYO ELECTRON Clean Track Mark 8 photoresist equipment is an efficient and versatile tool for photolithography in the semiconductor industry. It is a fully automated system designed to precisely deposit photoresist on wafers, as well as remove unwanted photoresist. Its compact design and user-friendly operation ensures maximum productivity with minimum waste. TEL Clean Track Mark 8 is a solvent-based spray photoresist device. Originally designed for 200 mm wafers, the unit offers high throughput for up to 6-inch wafers. It has a high degree of flexibility in terms of wafer loading, application parameters, and programmable function settings. Its advanced chemical delivery machine provides uniform, large-area coverage, while the automated cleaning modules offer superior residue removal. The tool has a built-in thermal spray module that provides stable and uniform coating of photoresist onto the substrate. It also contains an automated wafer chucking asset that facilitates the transfer of the wafer during lithographic processing. Its four integrated modules provide for even dispensing of photoresist, as well as efficient wash, rinse, and collection of the dispensed photoresist. To ensure high-quality performance, TOKYO ELECTRON Clean Track Mark 8 photoresist model is equipped with an advanced optical inspection equipment. This system helps identify defects or contamination on the wafer before photoresist application, as well as detect non-standard areas or defects on the wafer after the process. Clean Track Mark 8 is designed to be a cost-effective solution for all types of photoresist processes. It is also highly efficient, reducing wasted time and resources. With its user-friendly operation, comprehensive set of functions, and superior cleaning modules, TEL / TOKYO ELECTRON Clean Track Mark 8 is an invaluable tool for achieving high-quality results.

There are no reviews yet