Used TEL / TOKYO ELECTRON Clean Track Mark 8 #9269235 for sale

URL successfully copied!

Tap to zoom

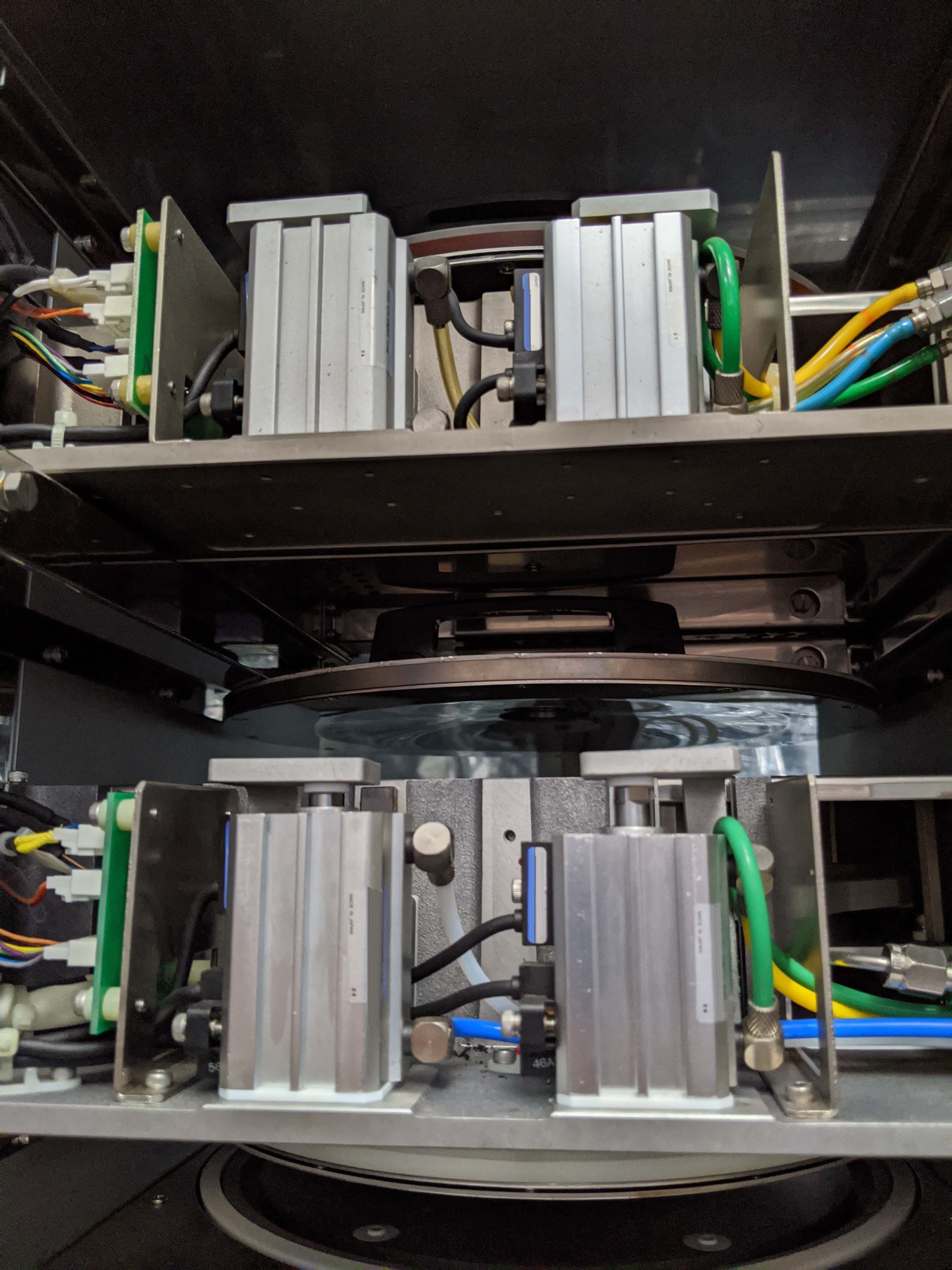

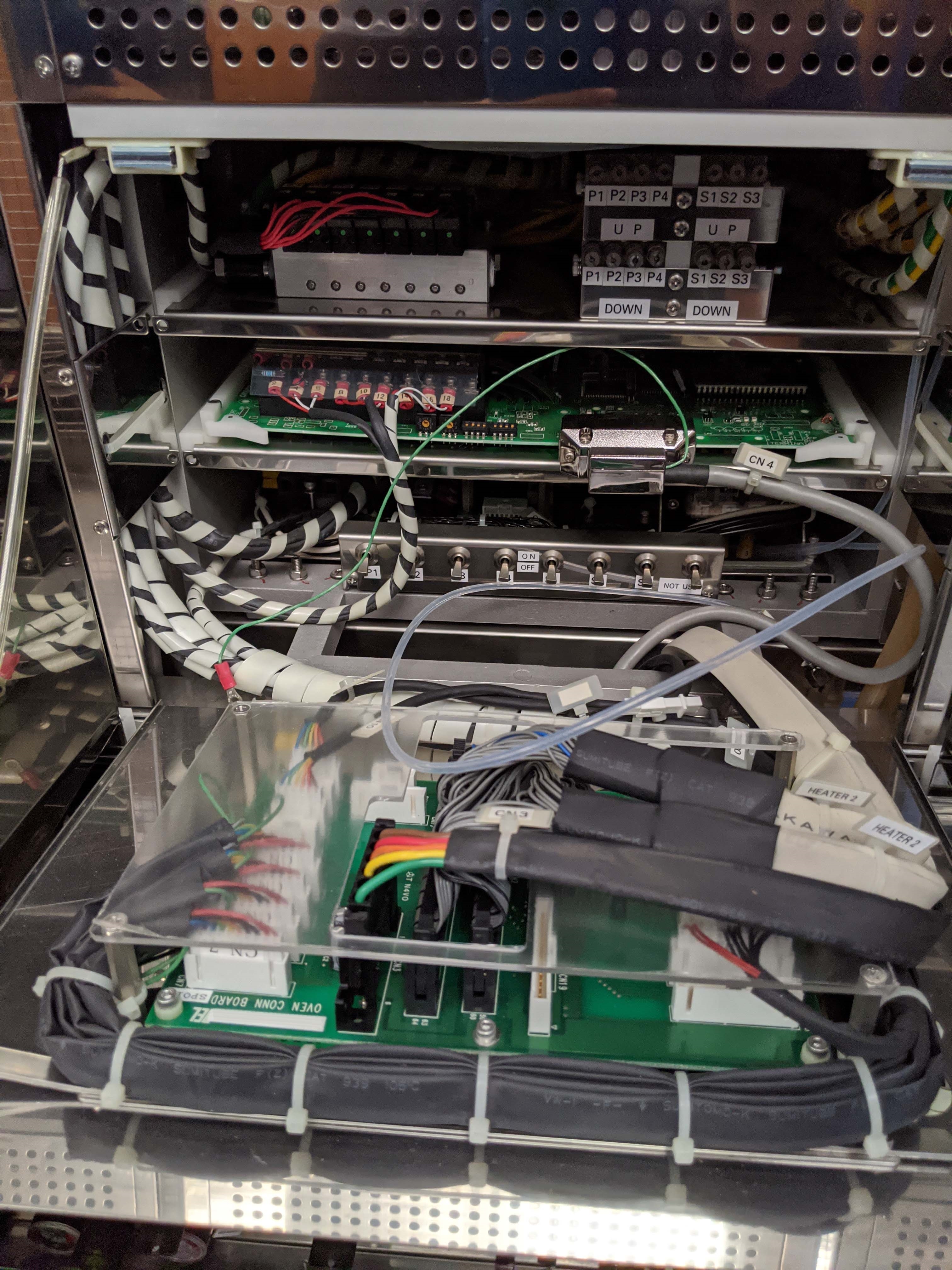

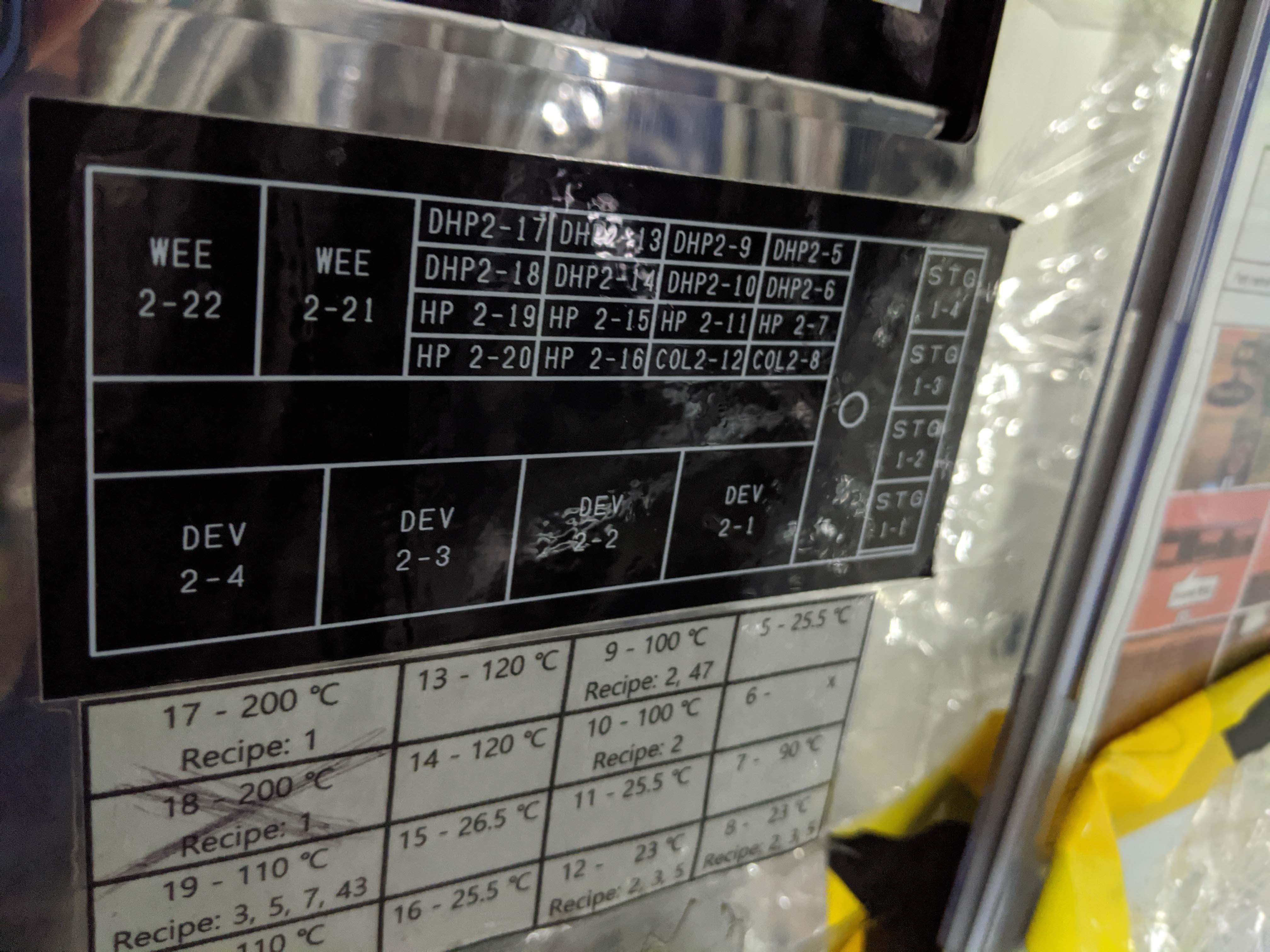

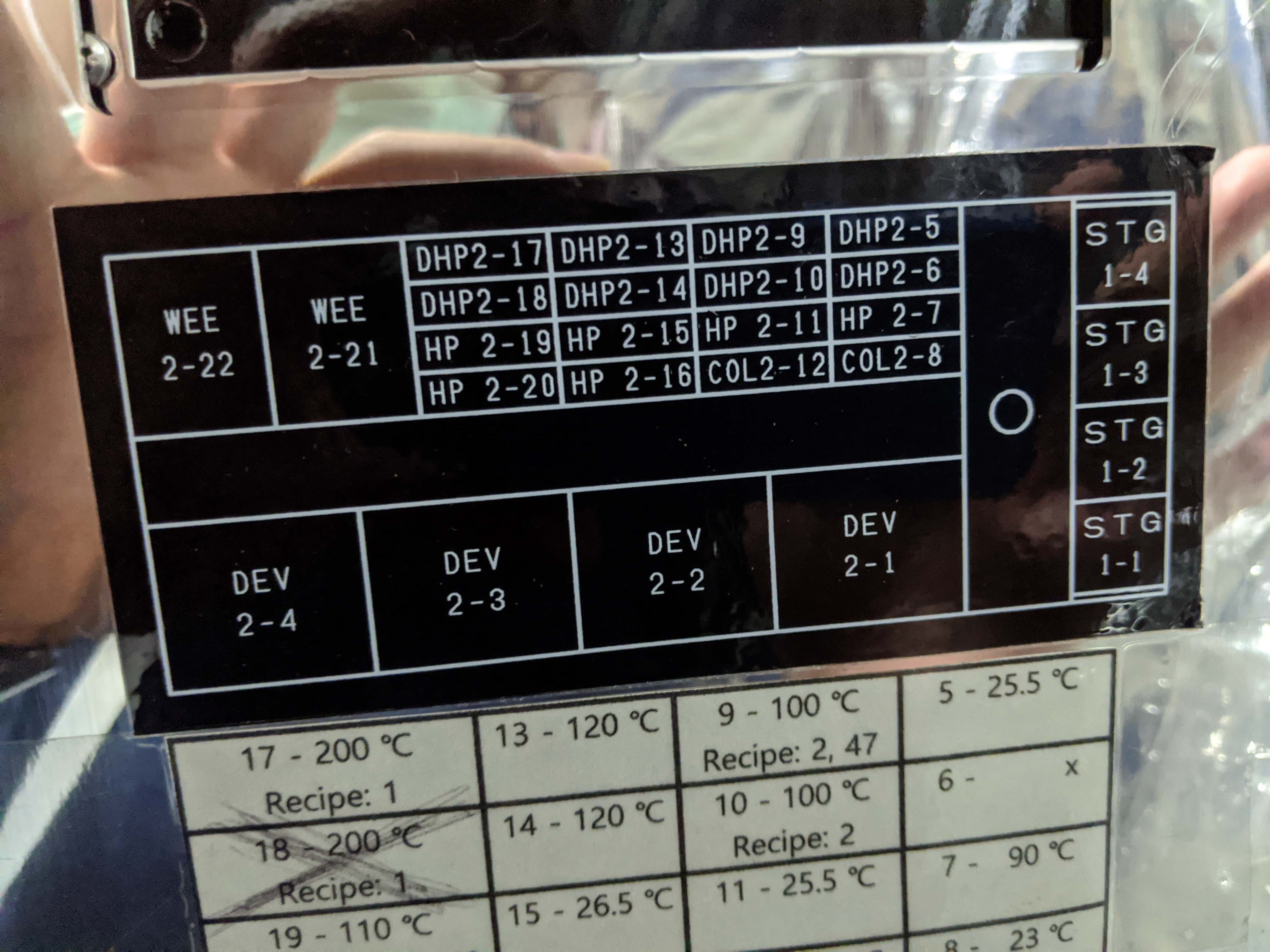

TEL / TOKYO ELECTRON Clean Track Mark 8 is a state-of-the-art photoresist equipment used in semiconductor device fabrication. It is a highly versatile and reliable system that has been designed to support a broad range of process applications. The unit includes a vision machine, a fully automatic track, a spin-rinse dryer, and a clean room. The vision tool is responsible for recognizing and identifying features such as wafer and photomask patterns, which are then used to match and align additional features as required by the particular process. The vision asset is integrated with a digital imaging model, allowing for effective and precise operation. TEL Clean Track Mark 8 automatically processes wafers, photomask, and other materials within a clean room environment. It is equipped with a single thick-film track, allowing for uniform and controlled development processes. The track is also equipped with a high-speed spin-rinse dryer, which enables lot-to-lot optimization and forecasting. TOKYO ELECTRON Clean Track Mark 8 is engineered with superior features, such as fast processing cycles, precise alignment of components, and 100% clean room capability. Additionally, the equipment offers an advanced, automated maintenance system which allows for true single-level operation and fast unit set up. Clean Track Mark 8 utilizes a modular design and modern automation machine incorporated into an ergonomic track that enables maximum production efficiency with superior throughput. TEL / TOKYO ELECTRON Clean Track Mark 8 is an ideal solution for any facility that requires a reliable, high-performance and efficient photoresist (PR) tool. Its integrated vision asset, high-speed track, and efficient spin-rinse dryer offering the ability to match even the most stringent requirements and process sequences. Moreover, its superior maintenance model increases the equipment lifetime and thereby significantly reduces total cost of ownership and sensitivity to maintenance-related production delays.

There are no reviews yet