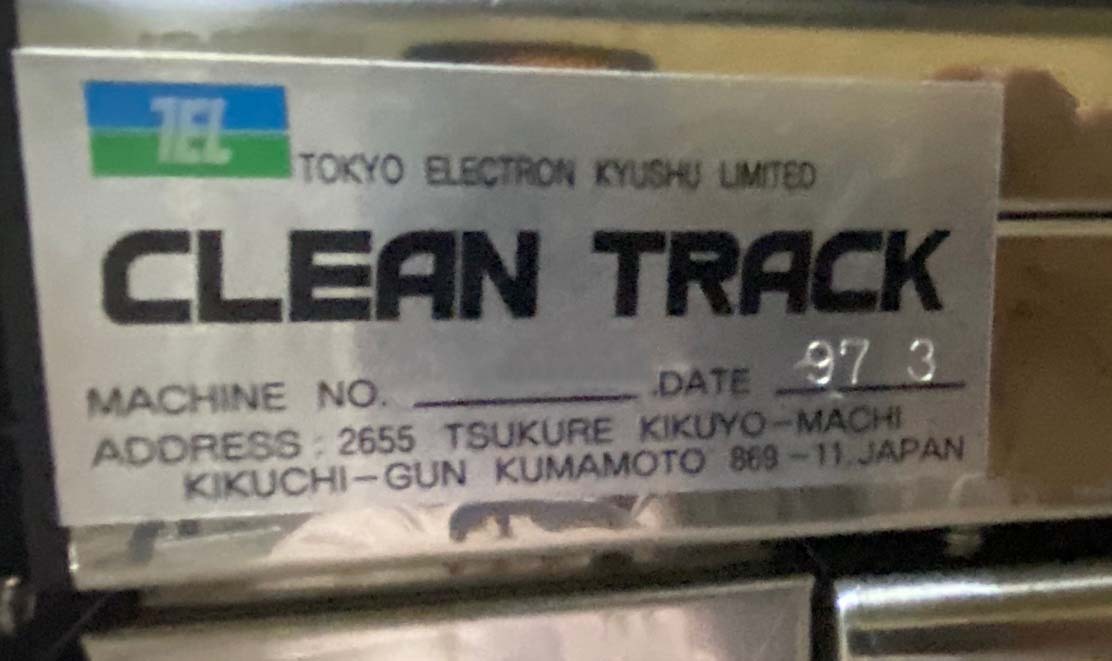

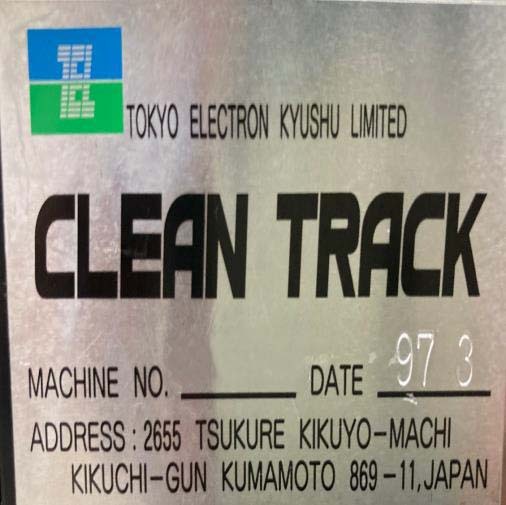

Used TEL / TOKYO ELECTRON Clean Track Mark 8 #9375656 for sale

URL successfully copied!

Tap to zoom

ID: 9375656

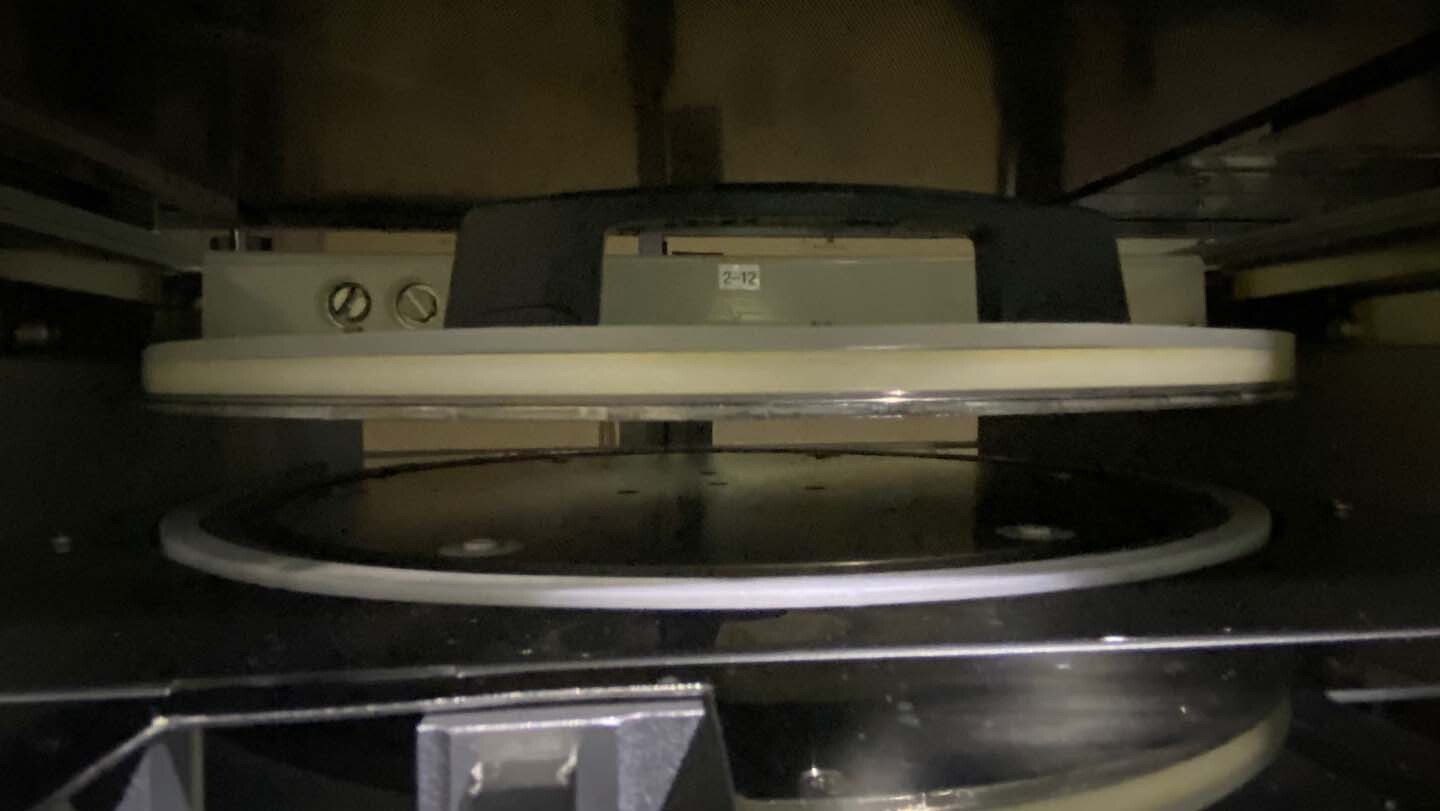

Wafer Size: 8"

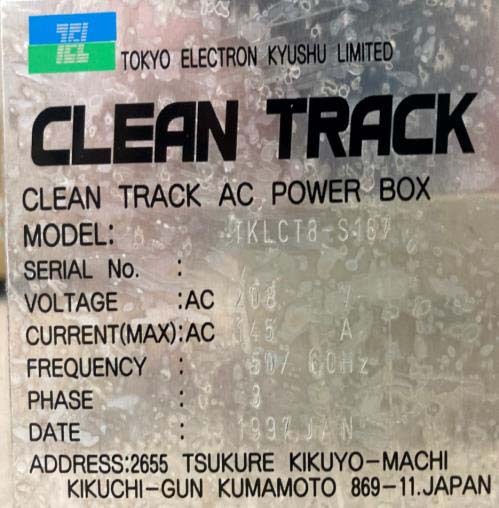

Vintage: 1997

System, 8"

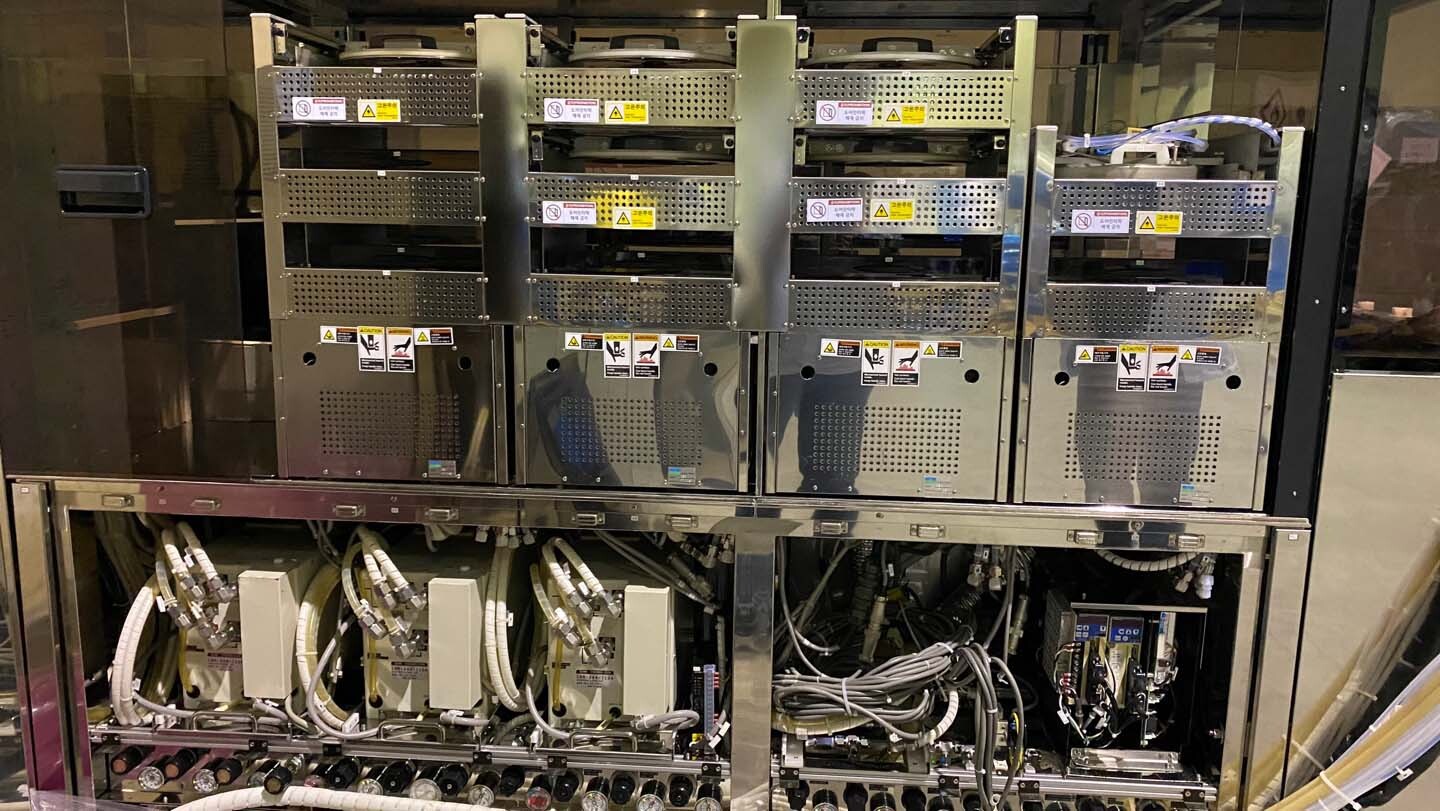

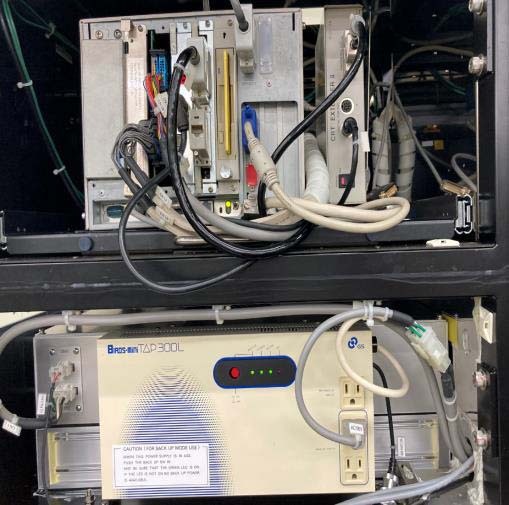

SMC INR-244-110D Thermo controller

(3) SMC INR-244-112A Chillers

(5) SMC INR-244-113B Thermo controllers

SHINWA T&H-CPC-1-NL THC Unit

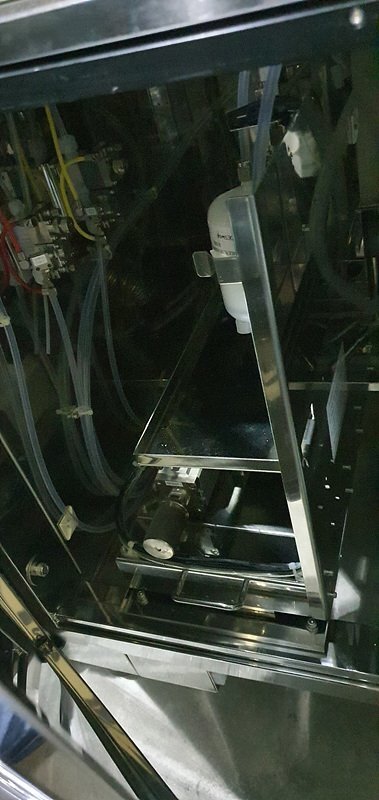

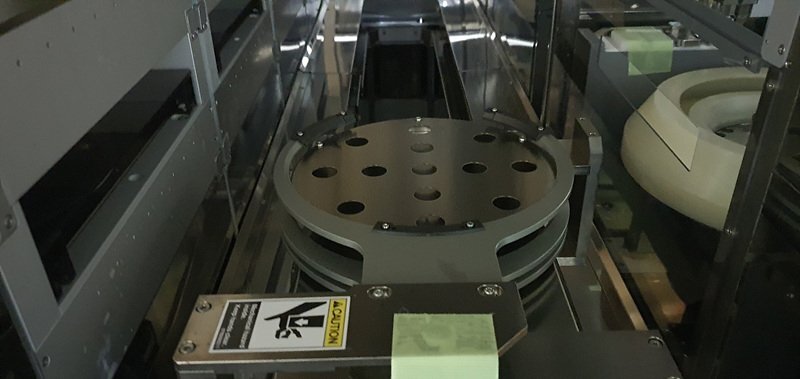

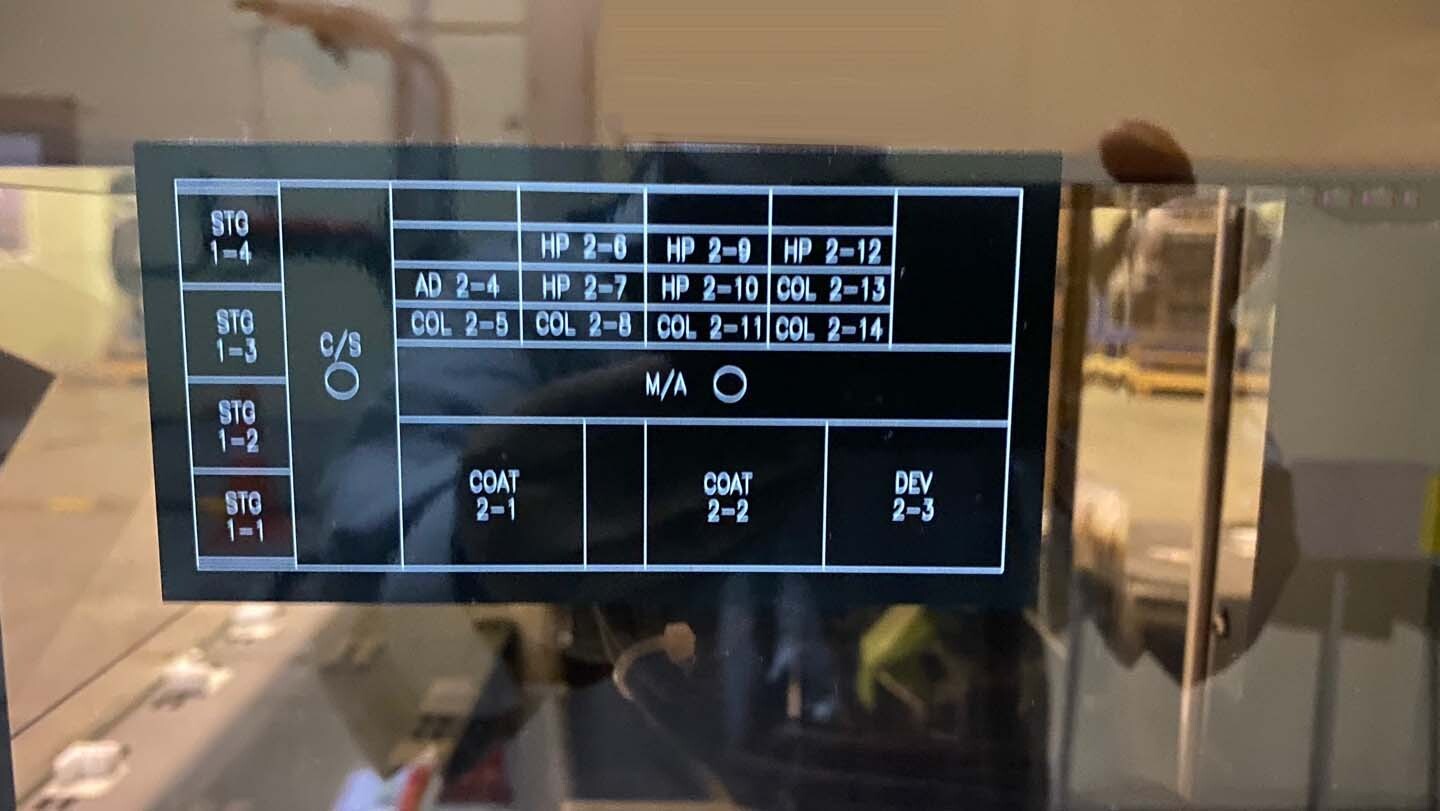

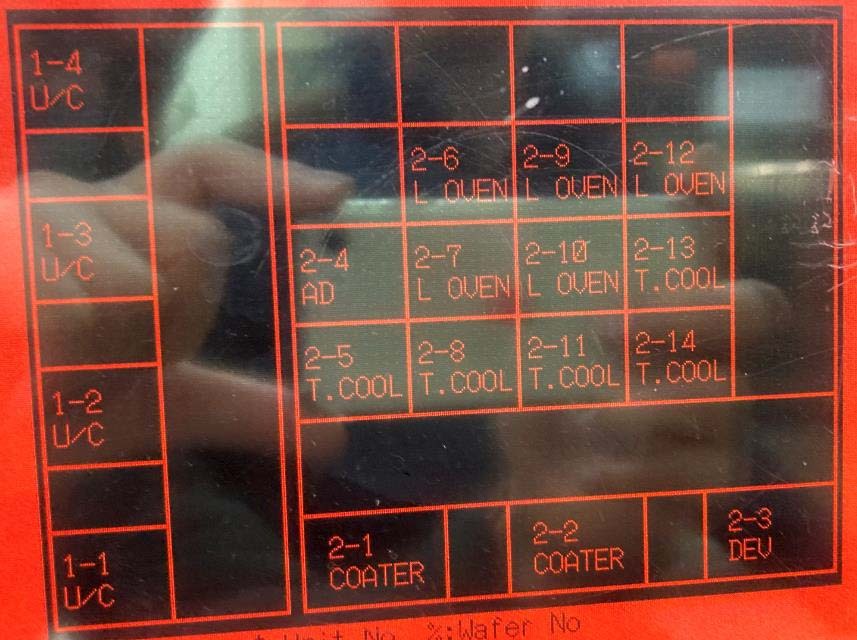

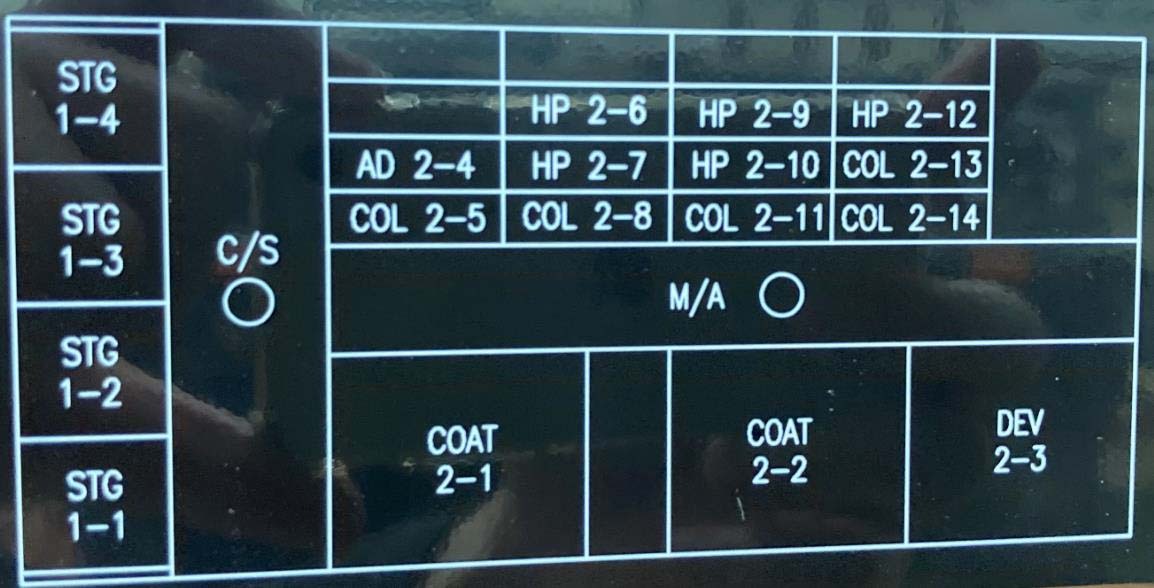

Wafer transfer robot

Process robot

(5) Ovens

(5) Coolers

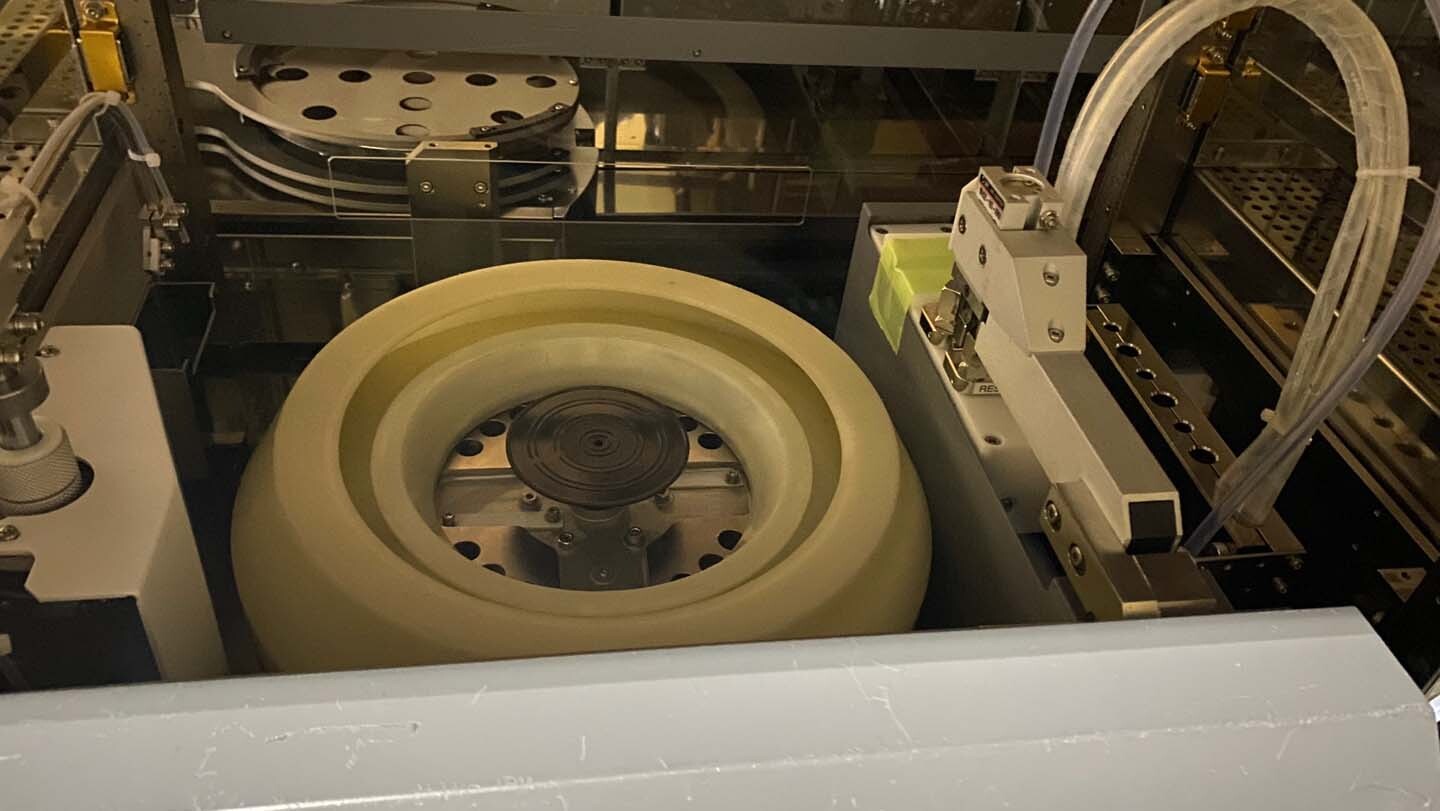

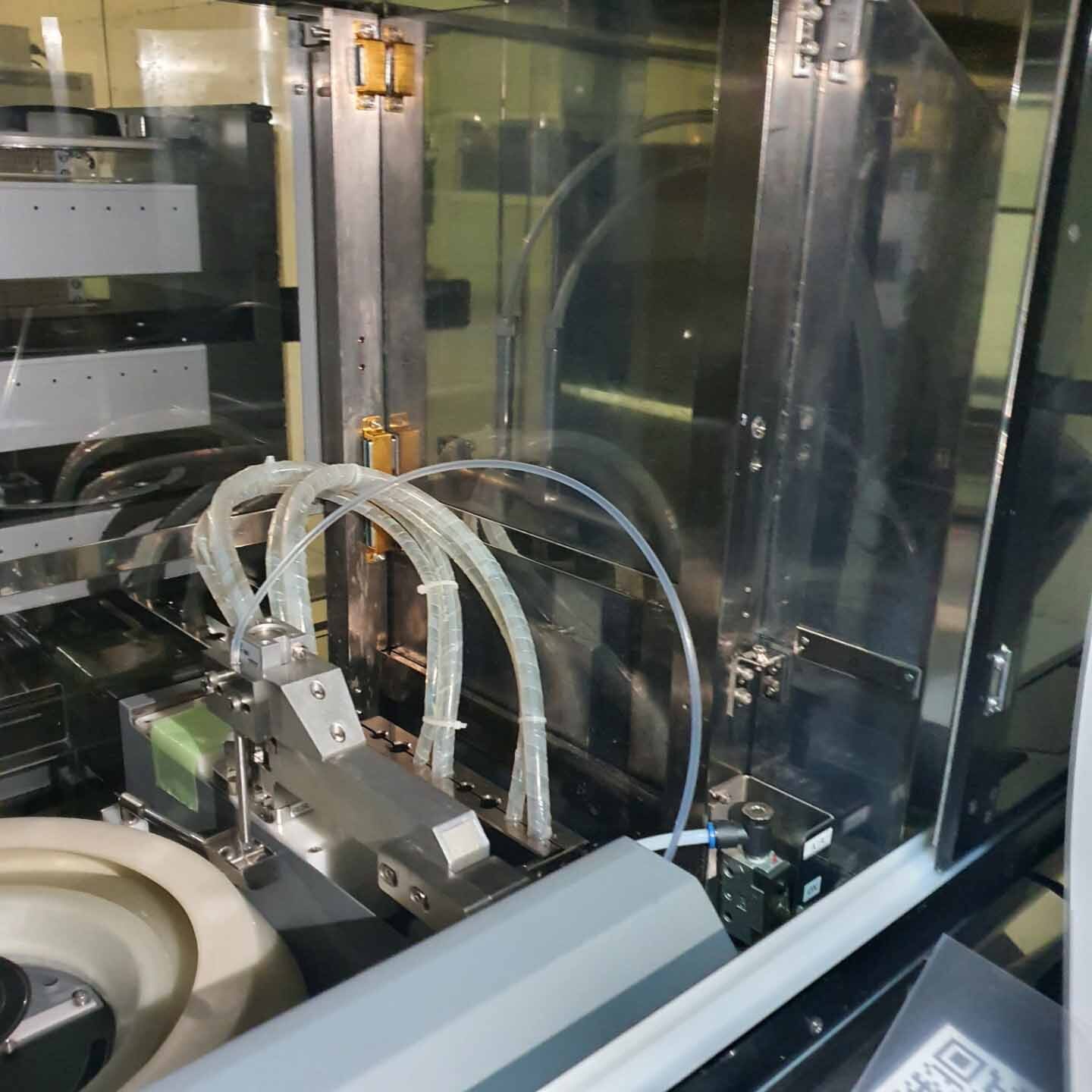

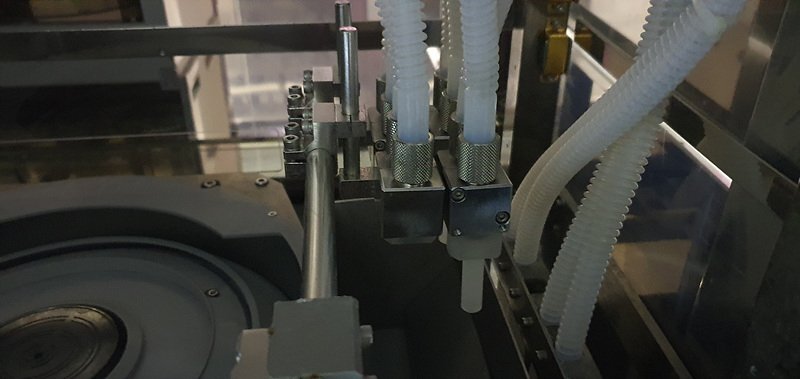

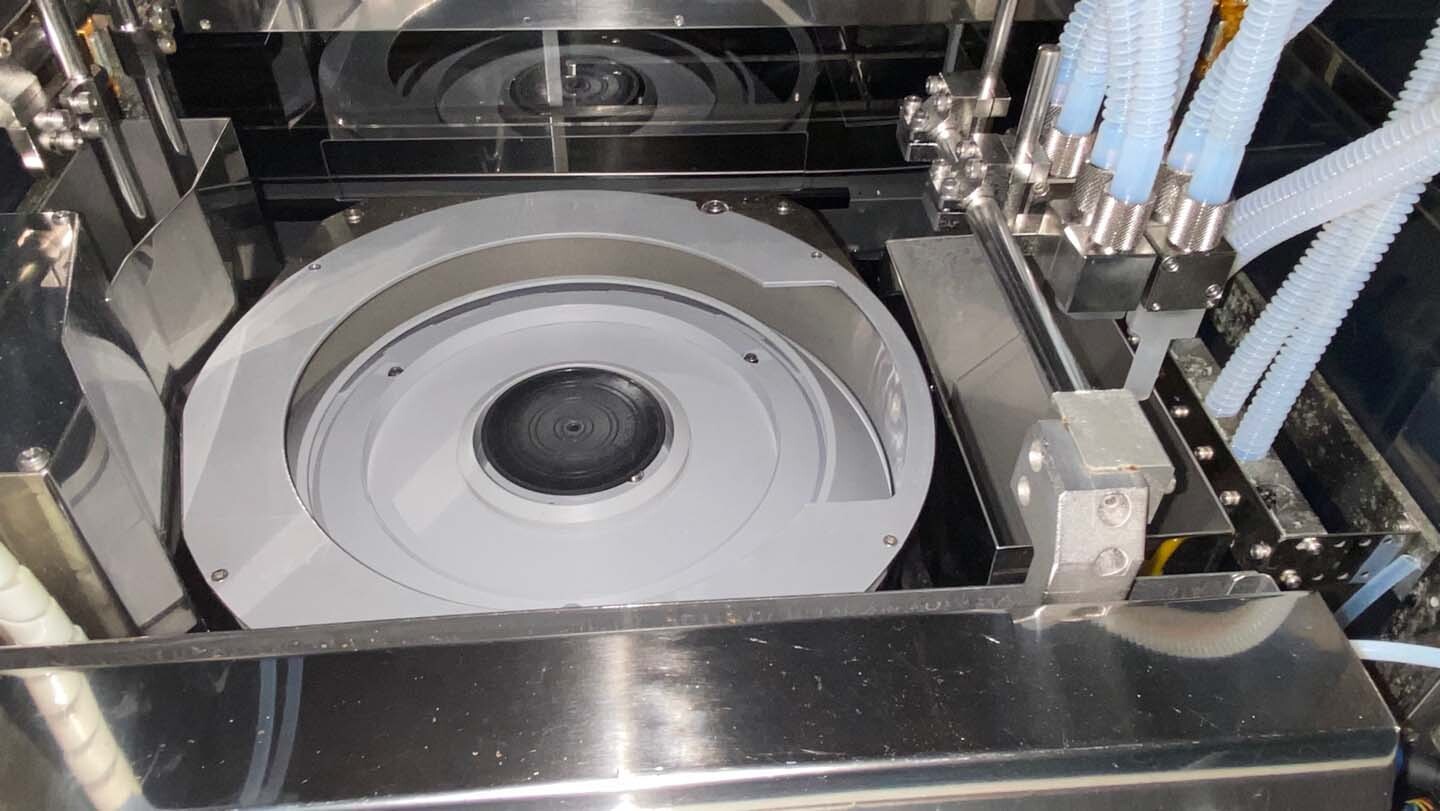

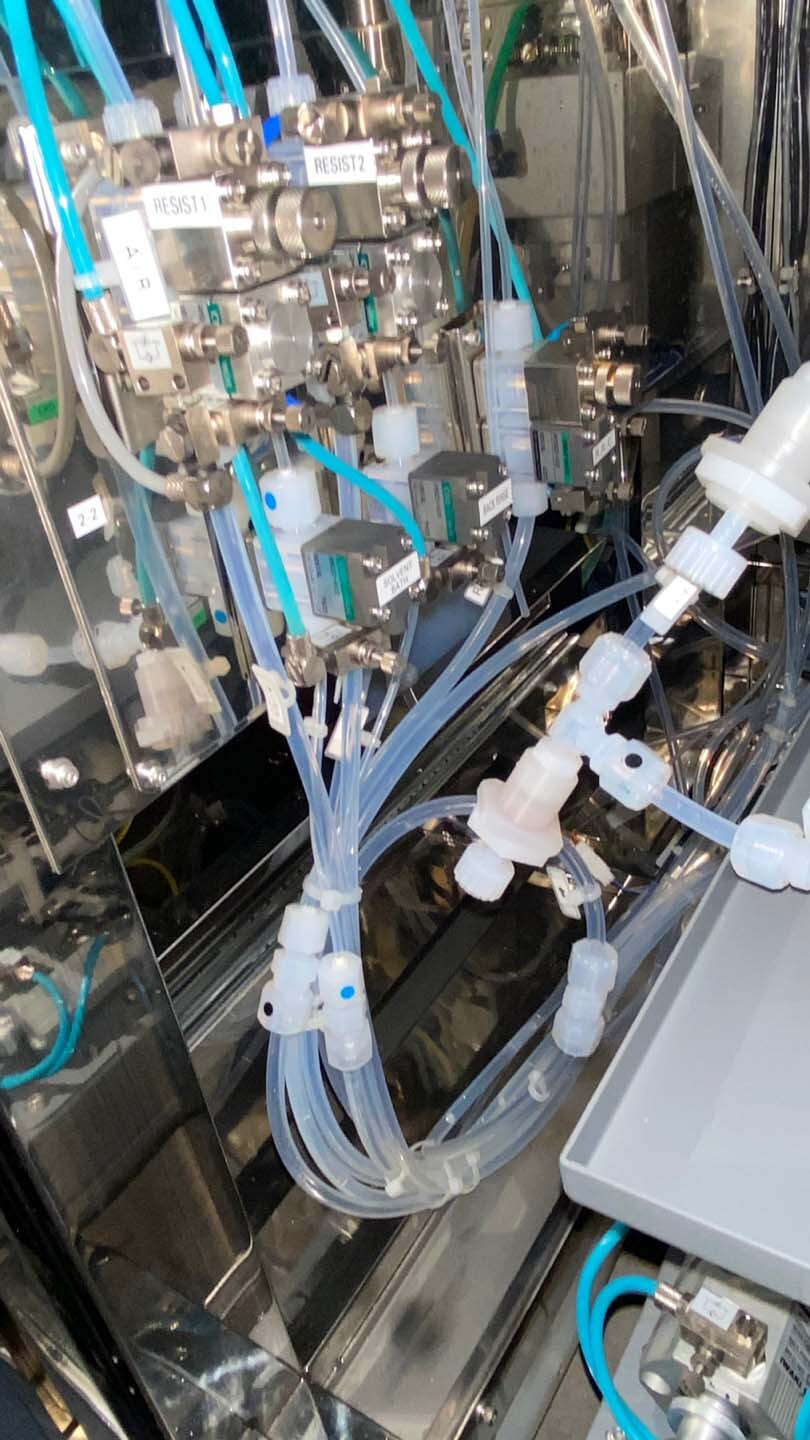

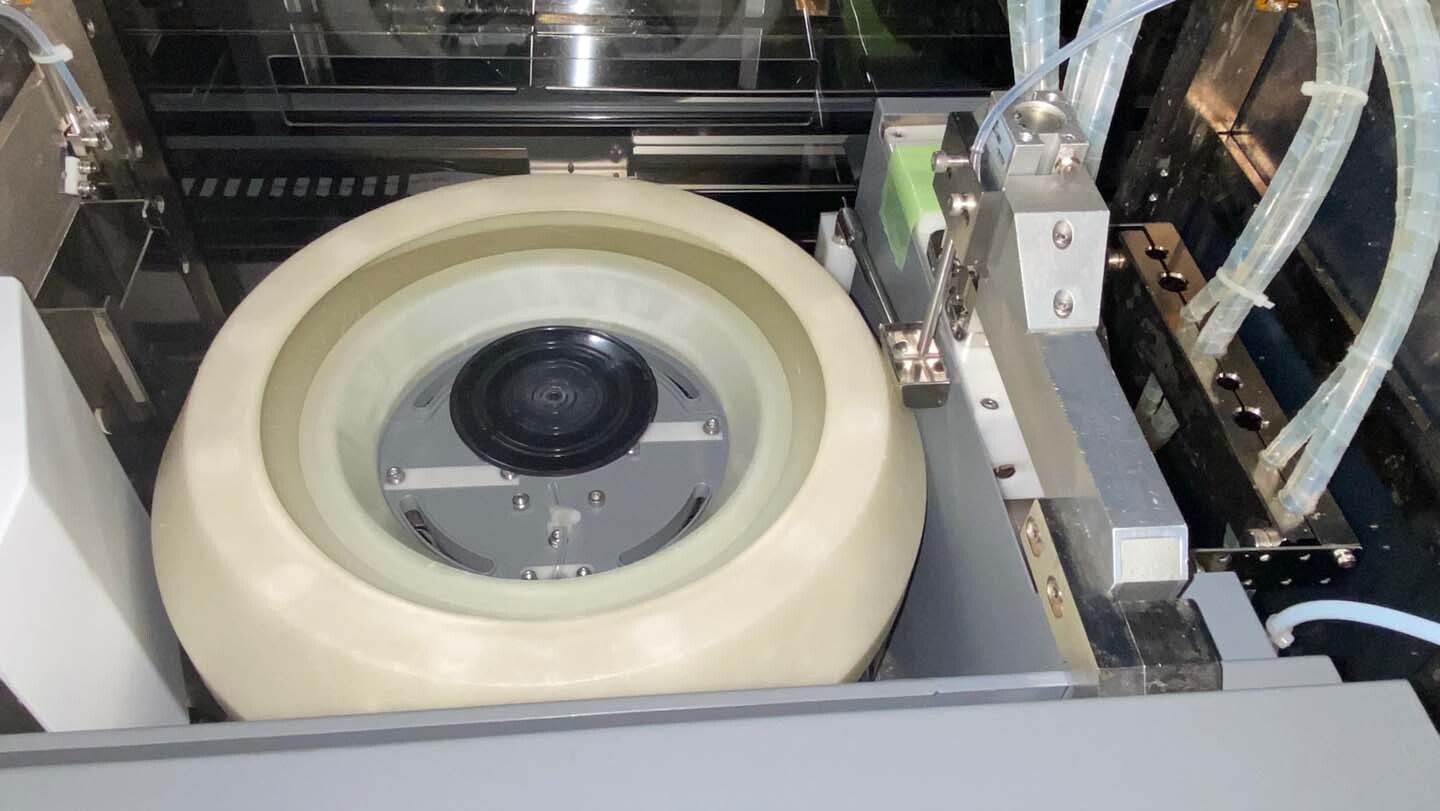

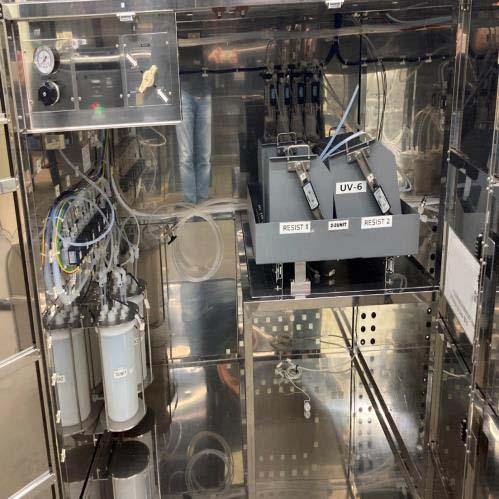

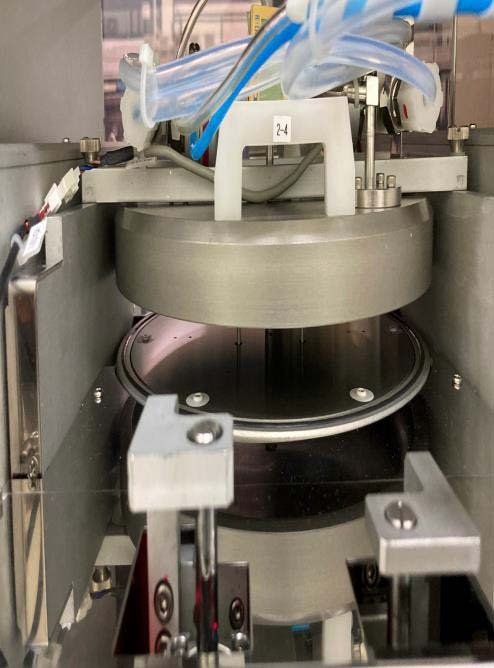

(2) Coater units

DEV Unit

Adhesion unit

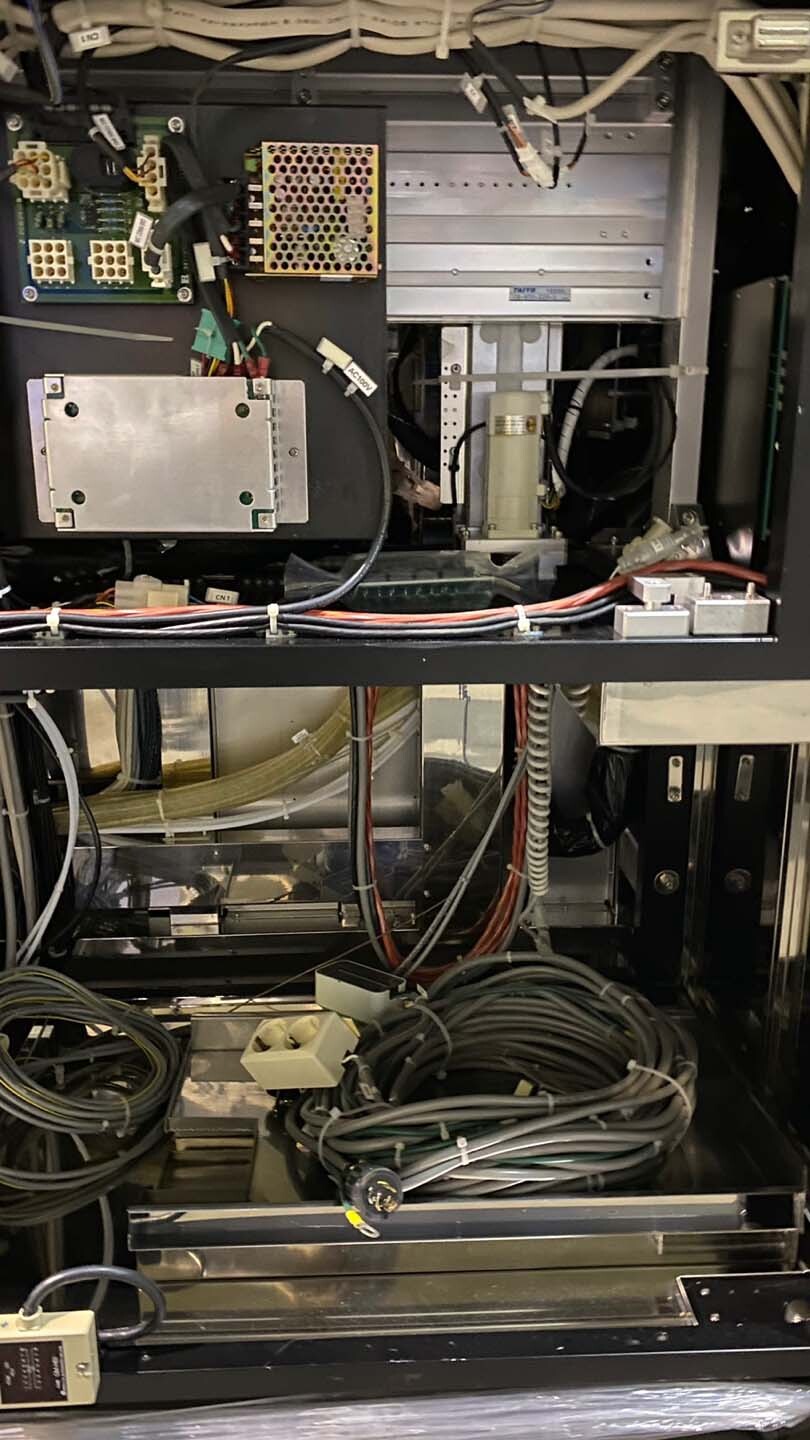

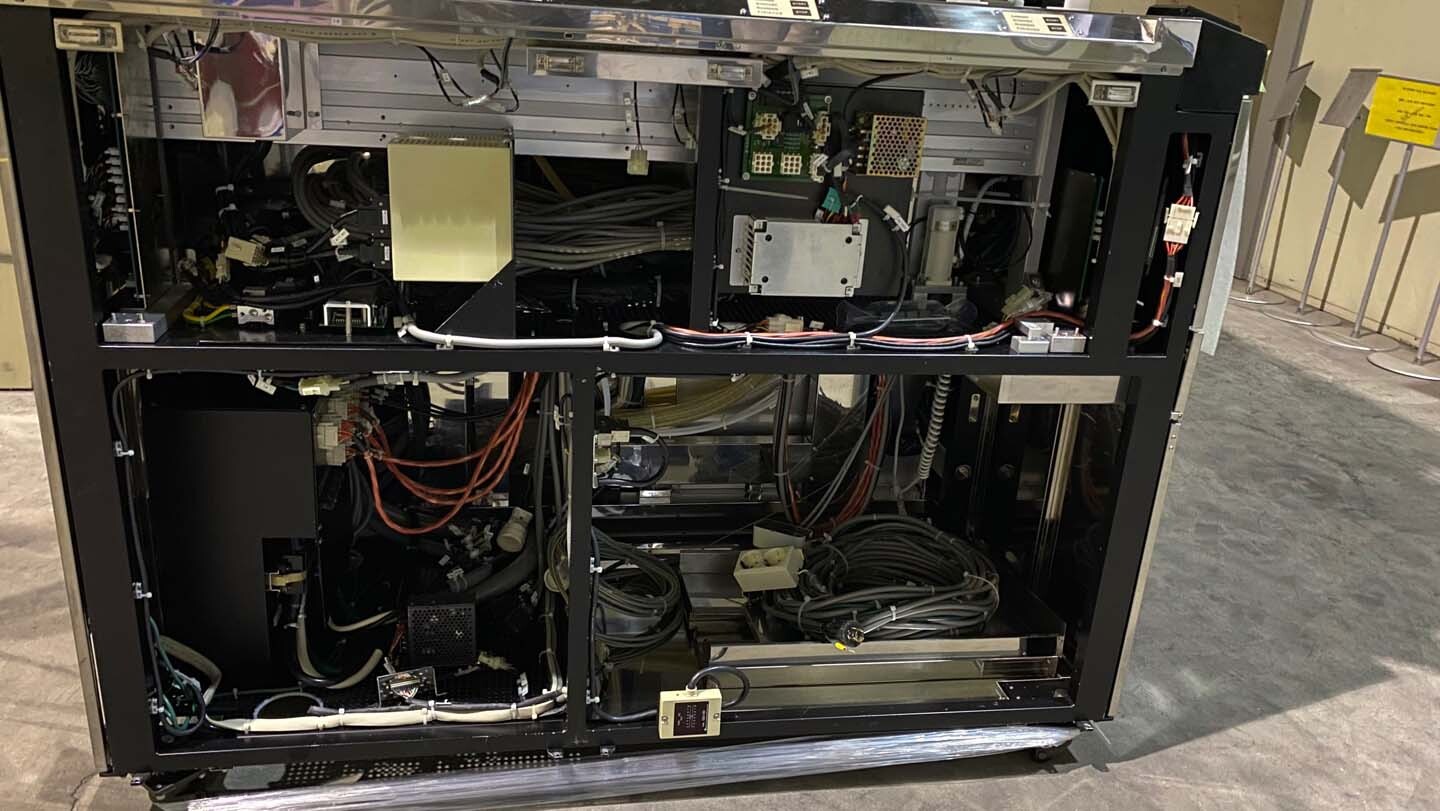

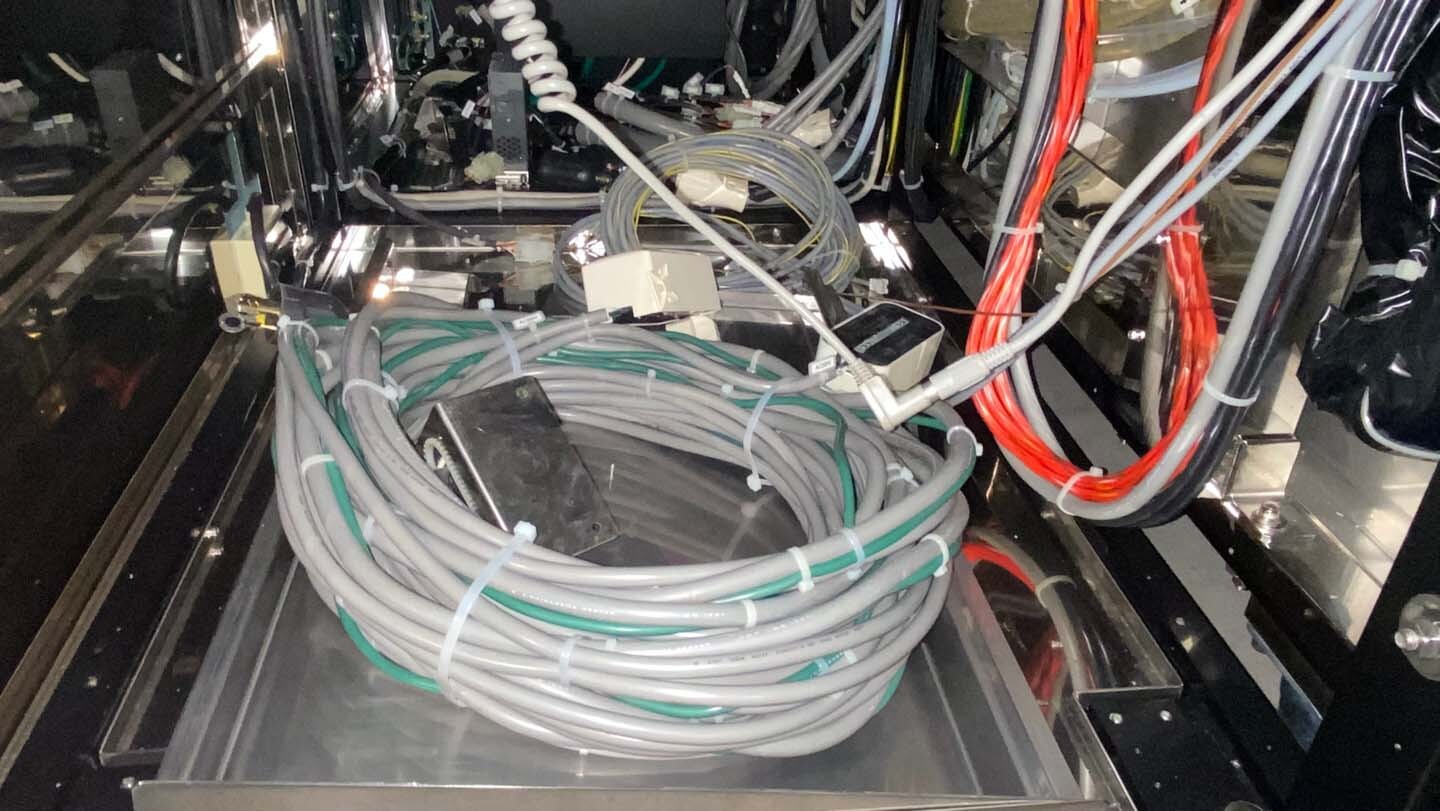

Board set

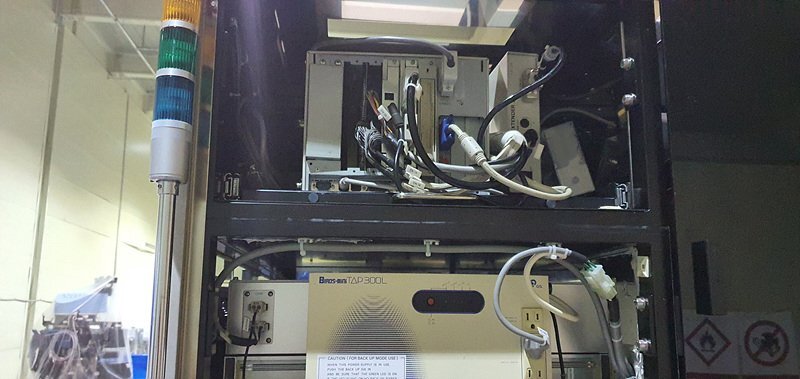

PC

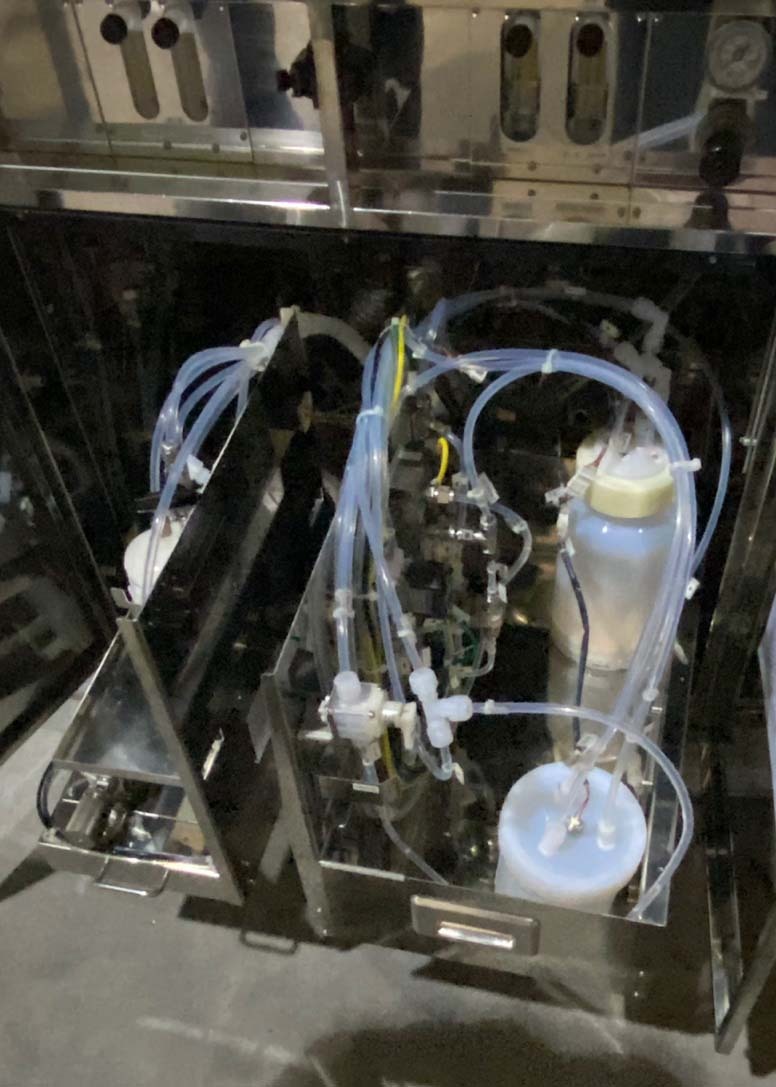

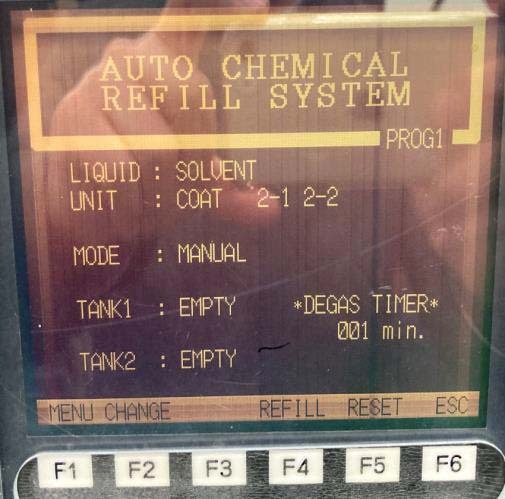

Chemical tank

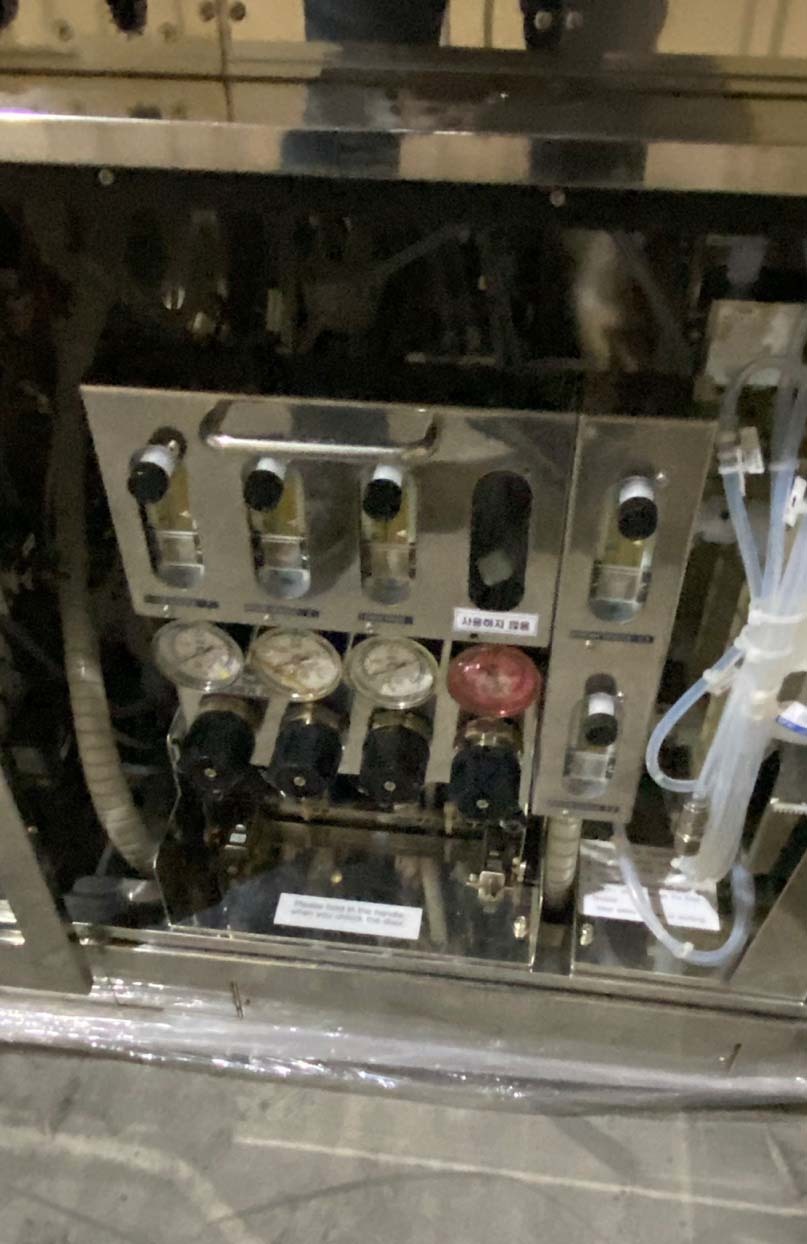

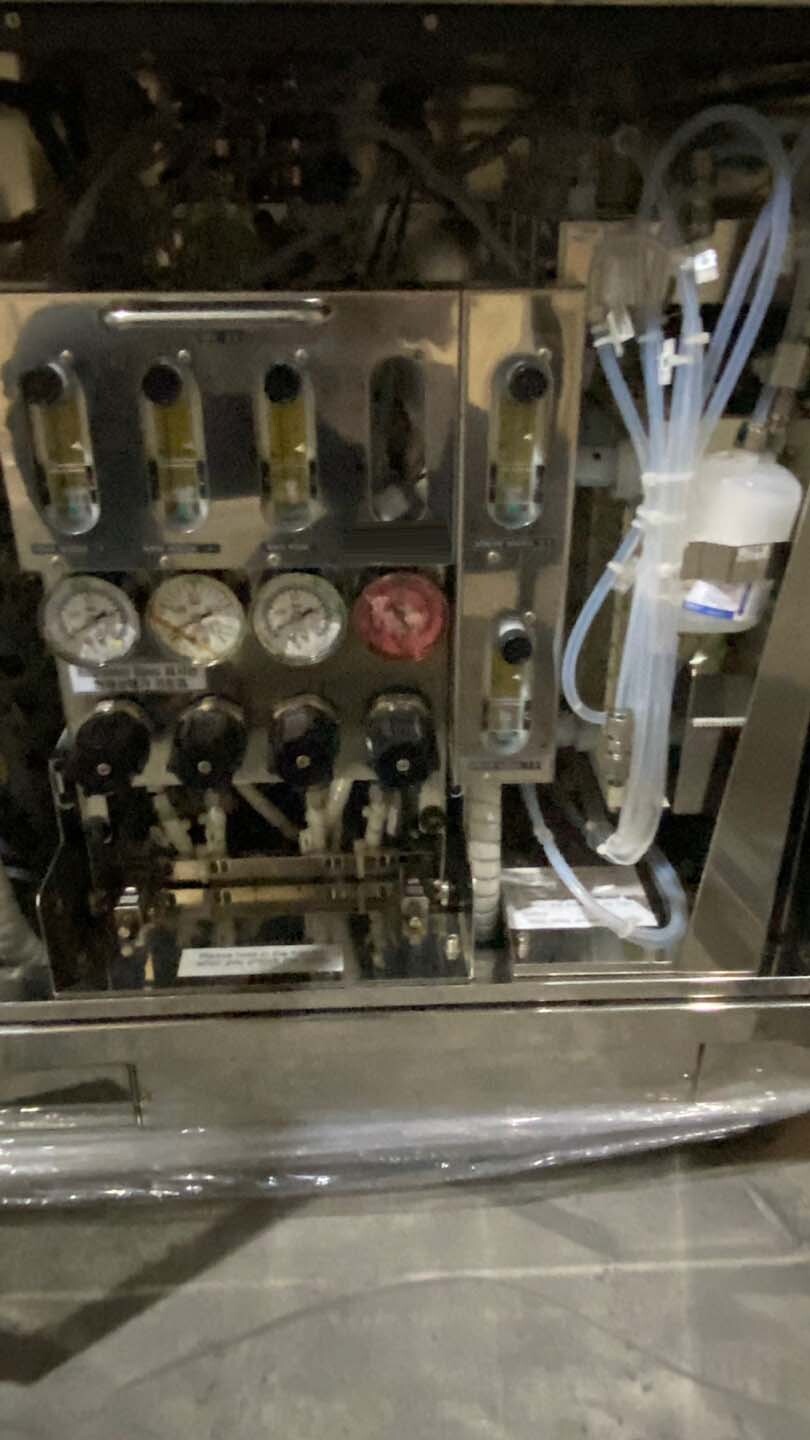

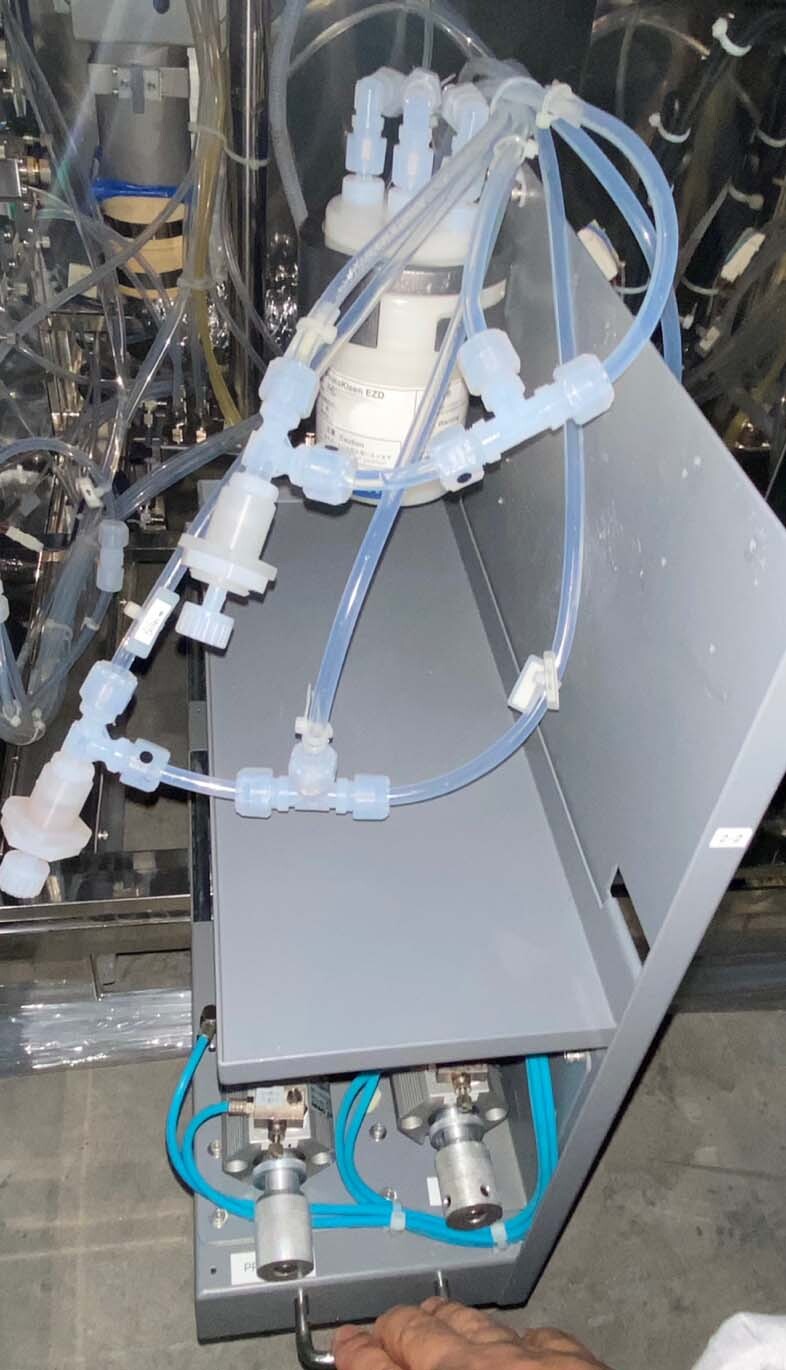

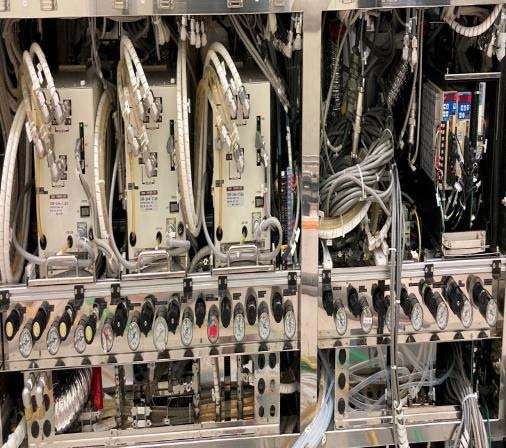

Mass flow control

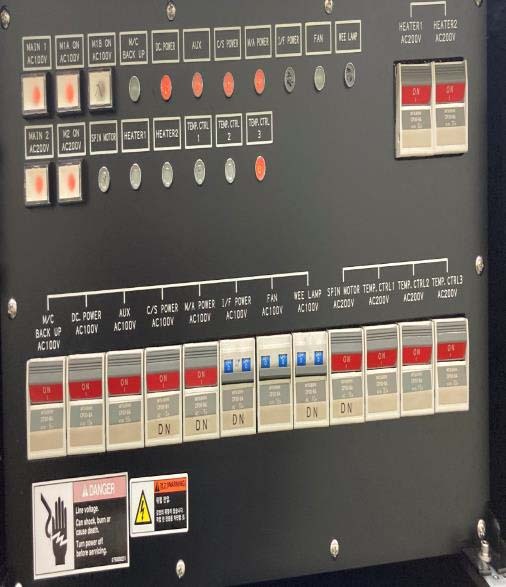

AC Rack

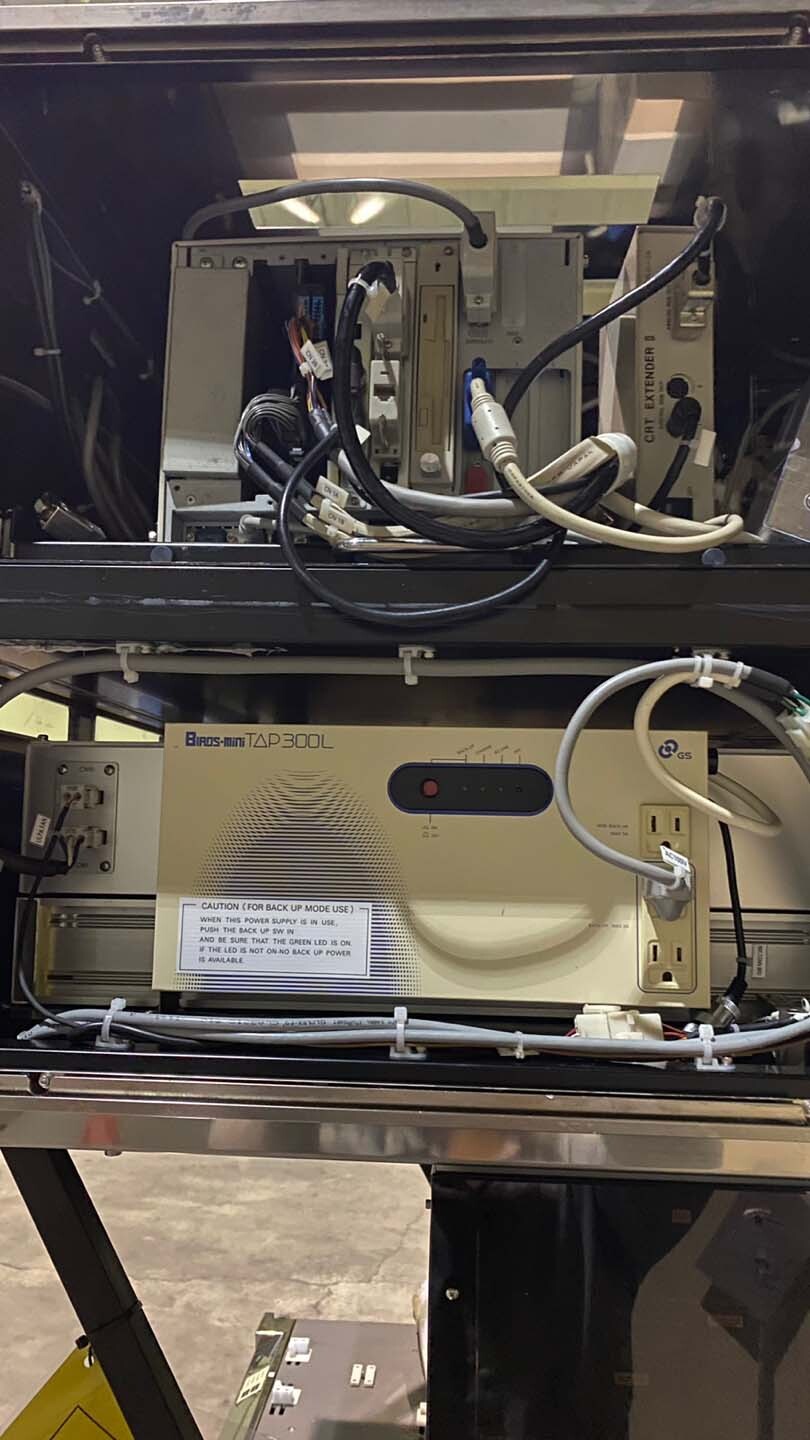

(2) UPS

SMIF Module:

INTERNOVA INC ICLS-RTX

Main controller

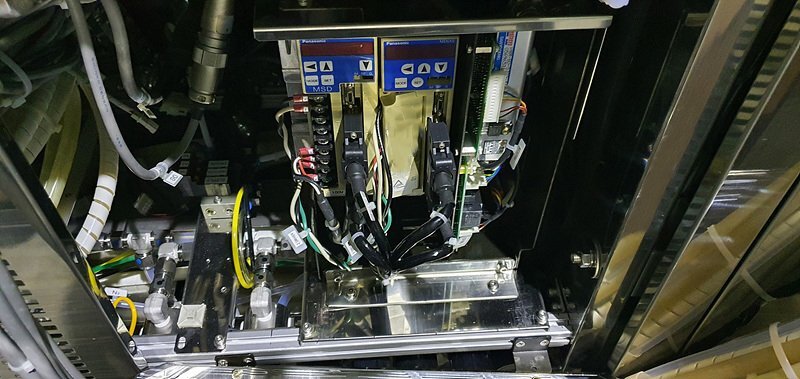

Driver part

1997 vintage.

TEL / TOKYO ELECTRON Clean Track Mark 8 is a photoresist equipment designed for premier lithography applications. This system uses a new type of resist technology called cationic resist and provides a high degree of accuracy and precision, with unparalleled ability for monitoring, trimming, and controlling the exposure of the lithography process. The unit consists of four major components: the control center, the wafer exposure/processing unit, the aligner, and the power source. The control center allows the user to set exposure parameters, monitor exposure levels, and control the motion of the aligner. The user can also communicate with the machine and modify exposure process parameters. The wafer exposure/processing unit includes a quartz table that is movable in two directions, as well as a chamber that allows the user to run different substrates and resist types at different temperatures. The aligner is used to precisely control the wafer's alignment and expose each wafer to the correct laser beam to achieve the desired process results. The tool is also equipped with an advanced power source to support the application of high-precision, repeatable exposures. TEL Clean Track Mark 8 incorporates a number of advanced features. It is equipped with an advanced process control asset that offers consistent and repeatable performance, with improved process stability and accuracy. This model is also able to monitor and analyze the process data to improve the lithographic process and achieve better results. The wafer exposure/processing unit is designed for improved uniformity, and can accommodate a variety of substrates and resists. The equipment also equipped with an advanced graphic user interface, providing a convenient way to monitor and control the system. TOKYO ELECTRON Clean Track Mark 8 is ideal for applications such as advanced semiconductor fabrication and microelectronic device manufacturing. It provides ultra-precise optical control by leveraging the features of cationic resist, and offers precise control and repeatability of exposure. By providing users with a reliable and efficient way to monitor and control the lithography process, Clean Track Mark 8 ensures higher quality results that can enable shorter development time and faster product time-to-market.

There are no reviews yet