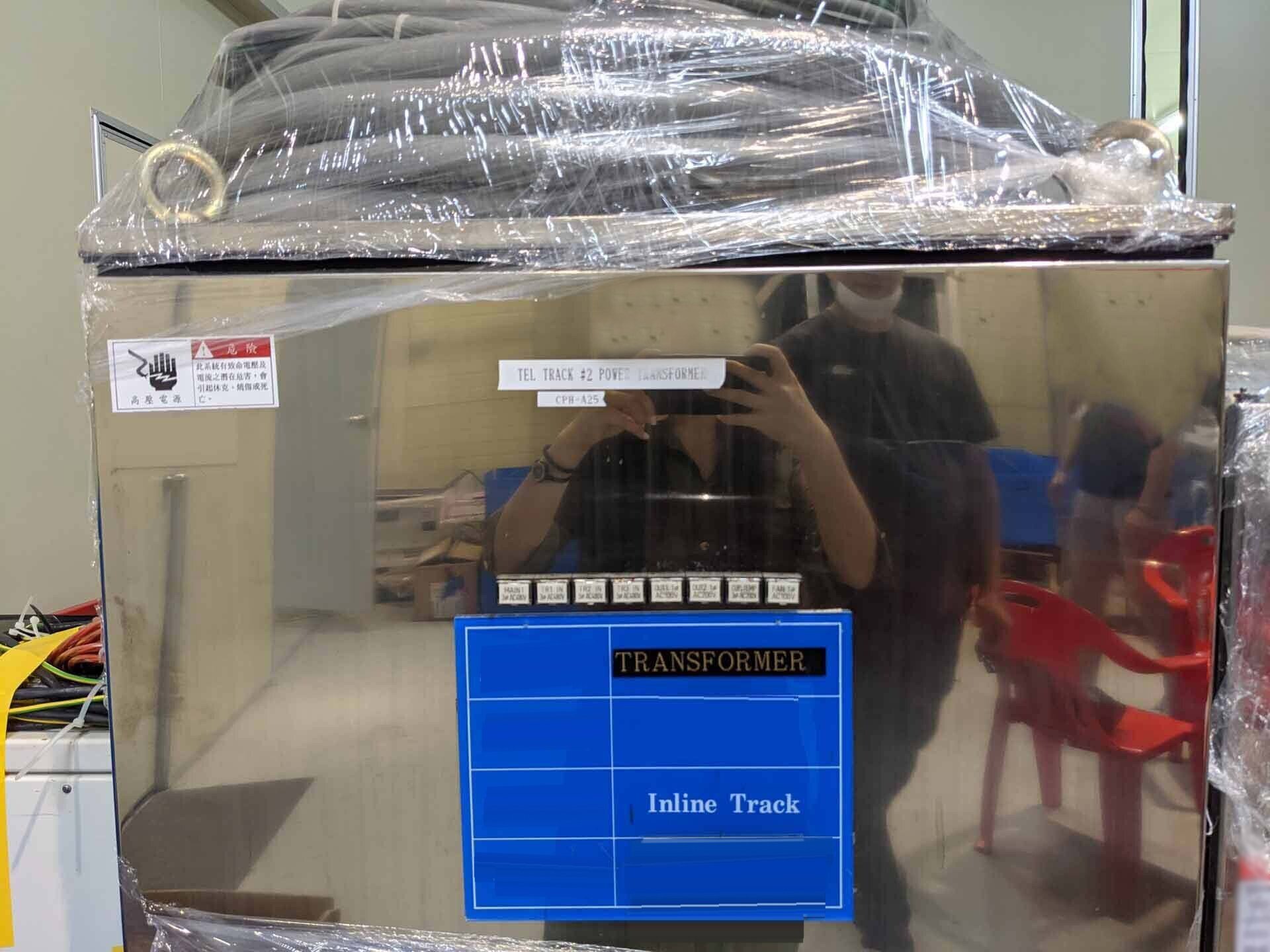

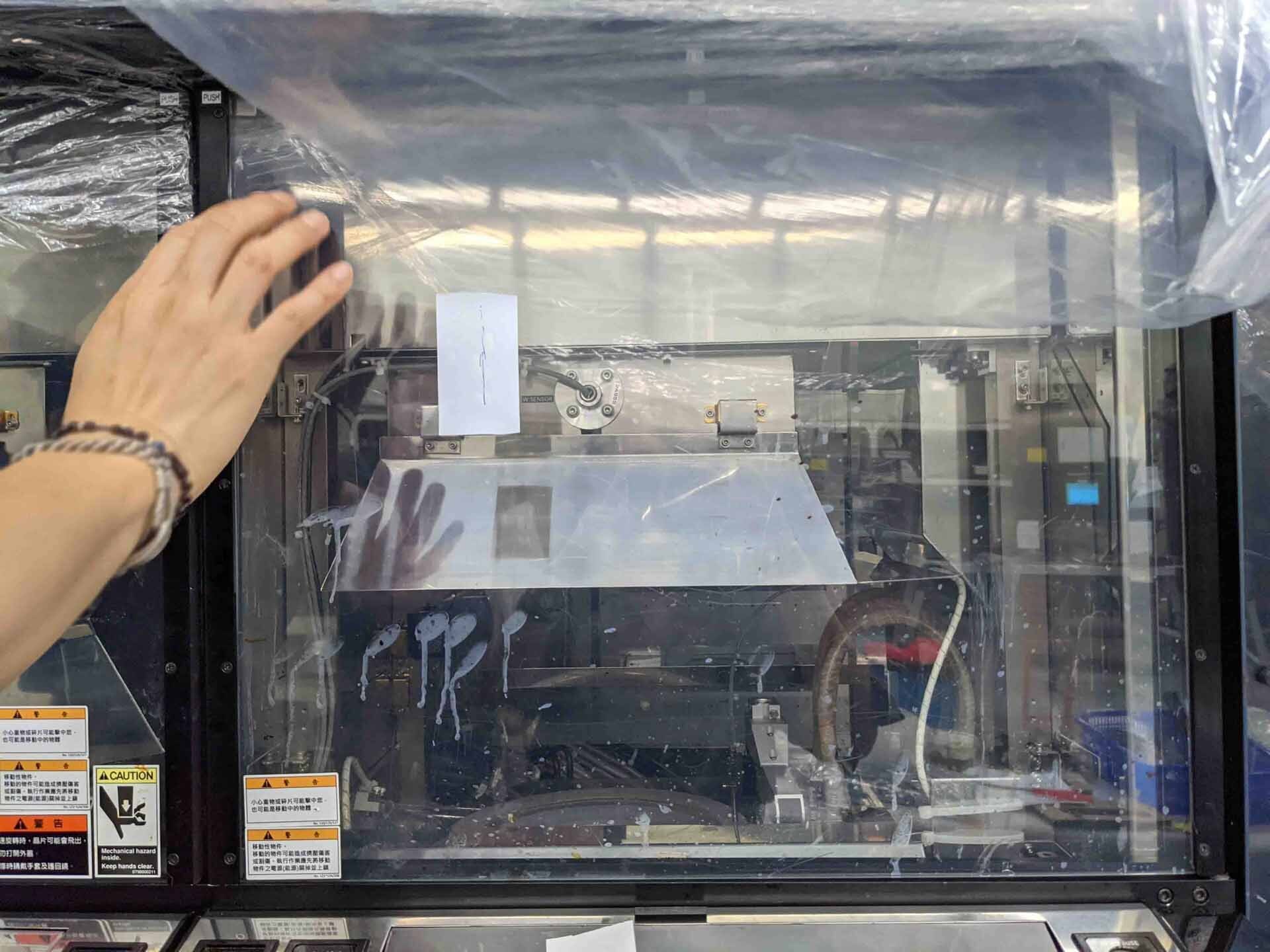

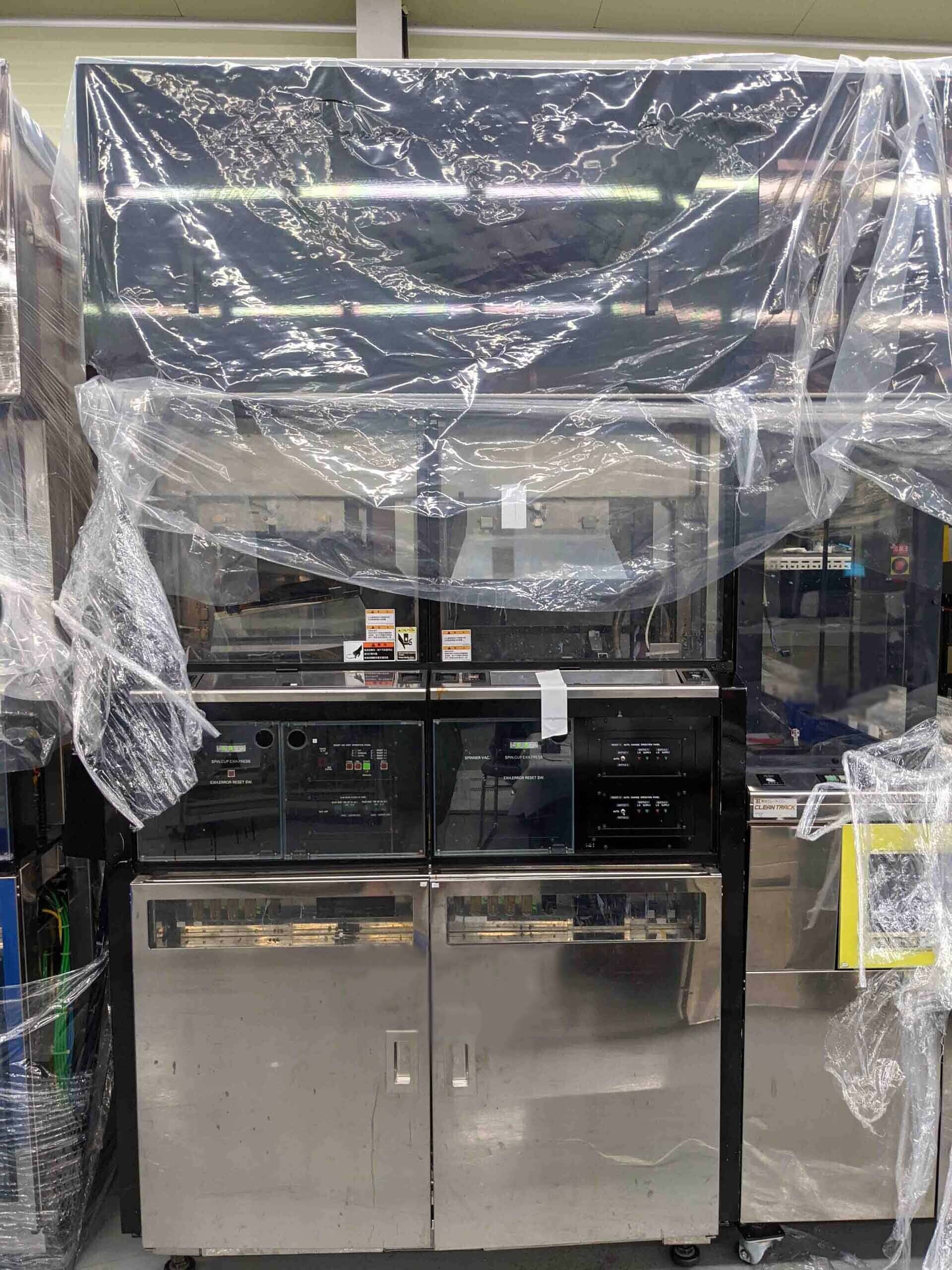

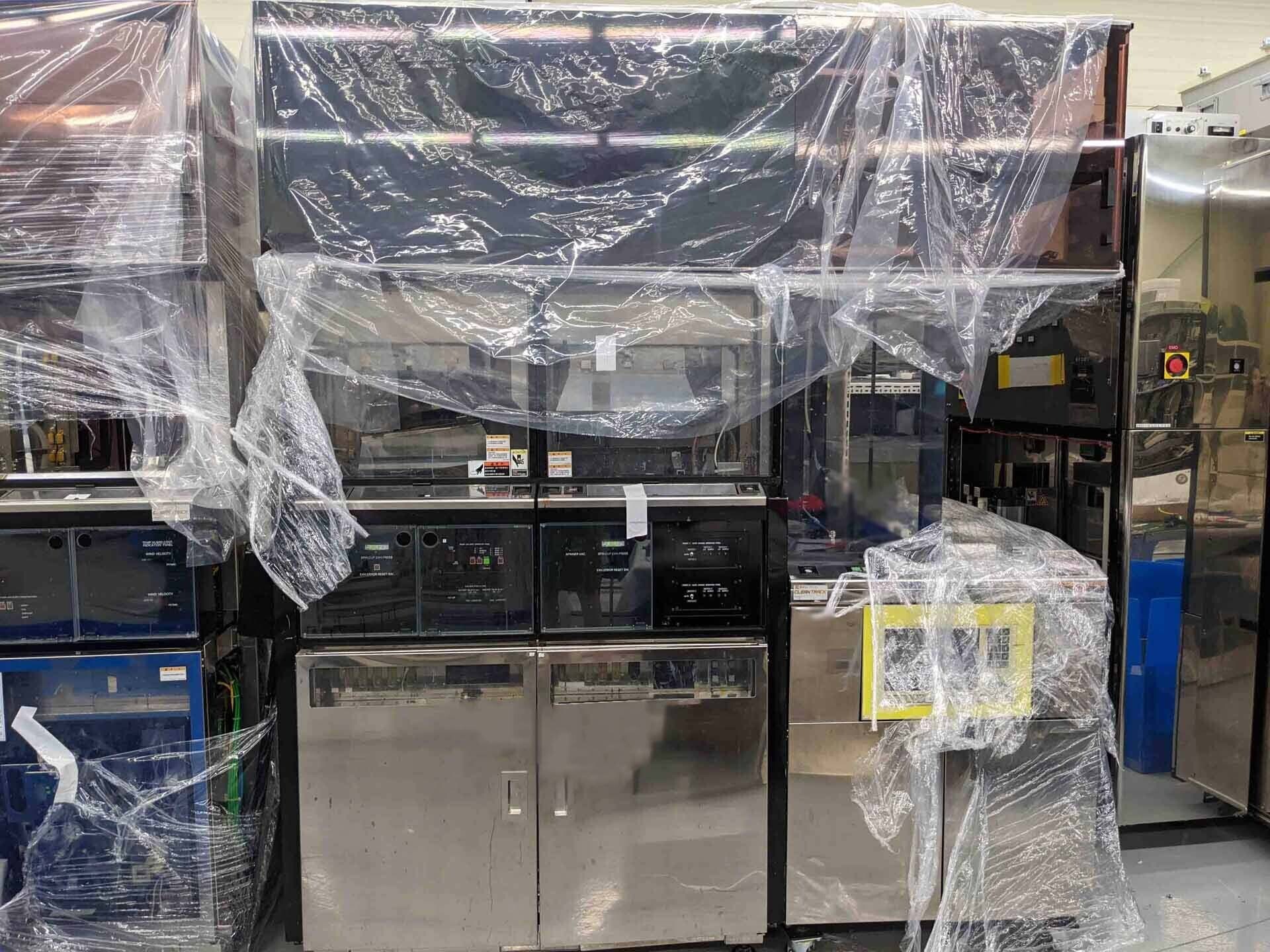

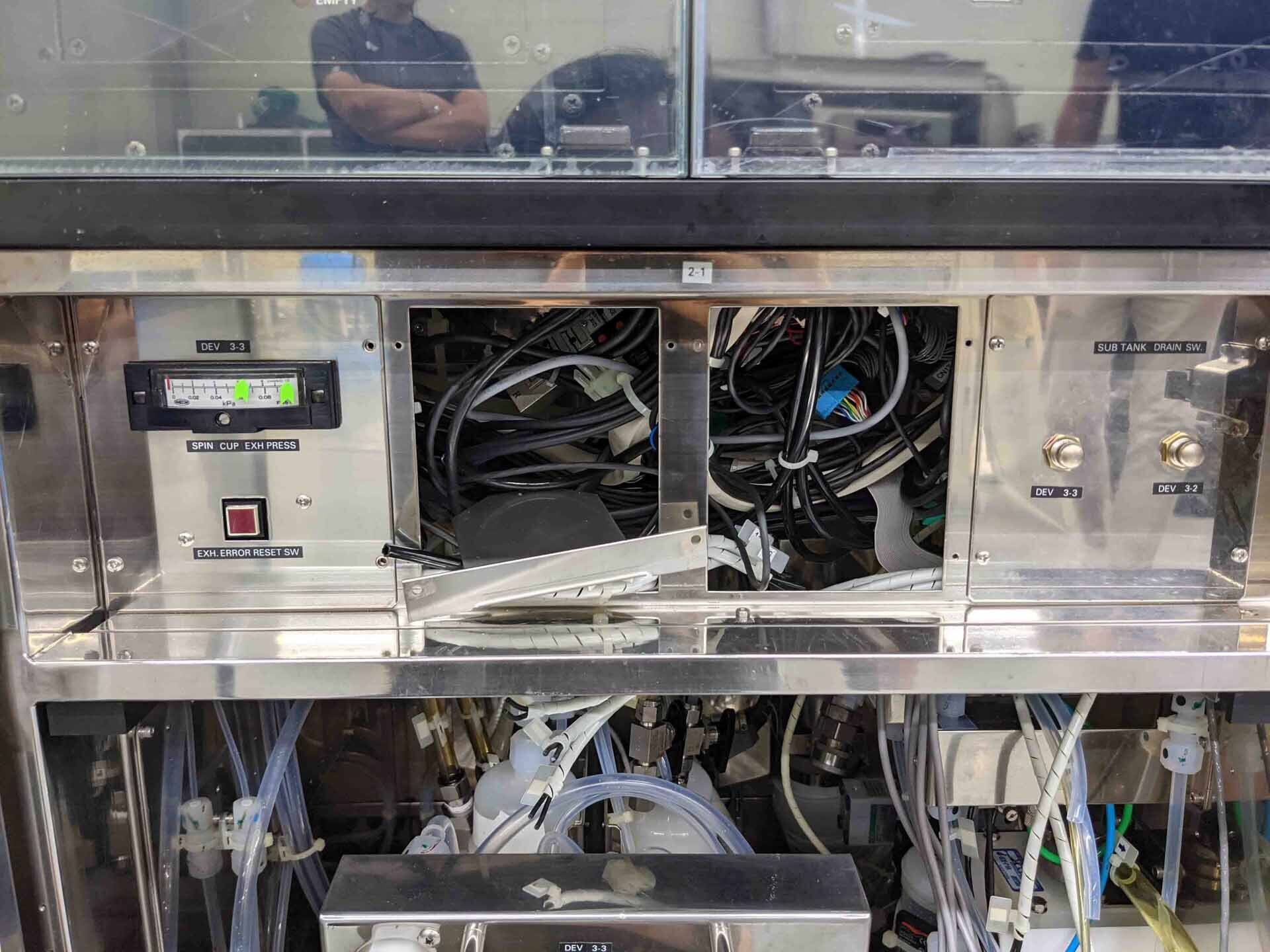

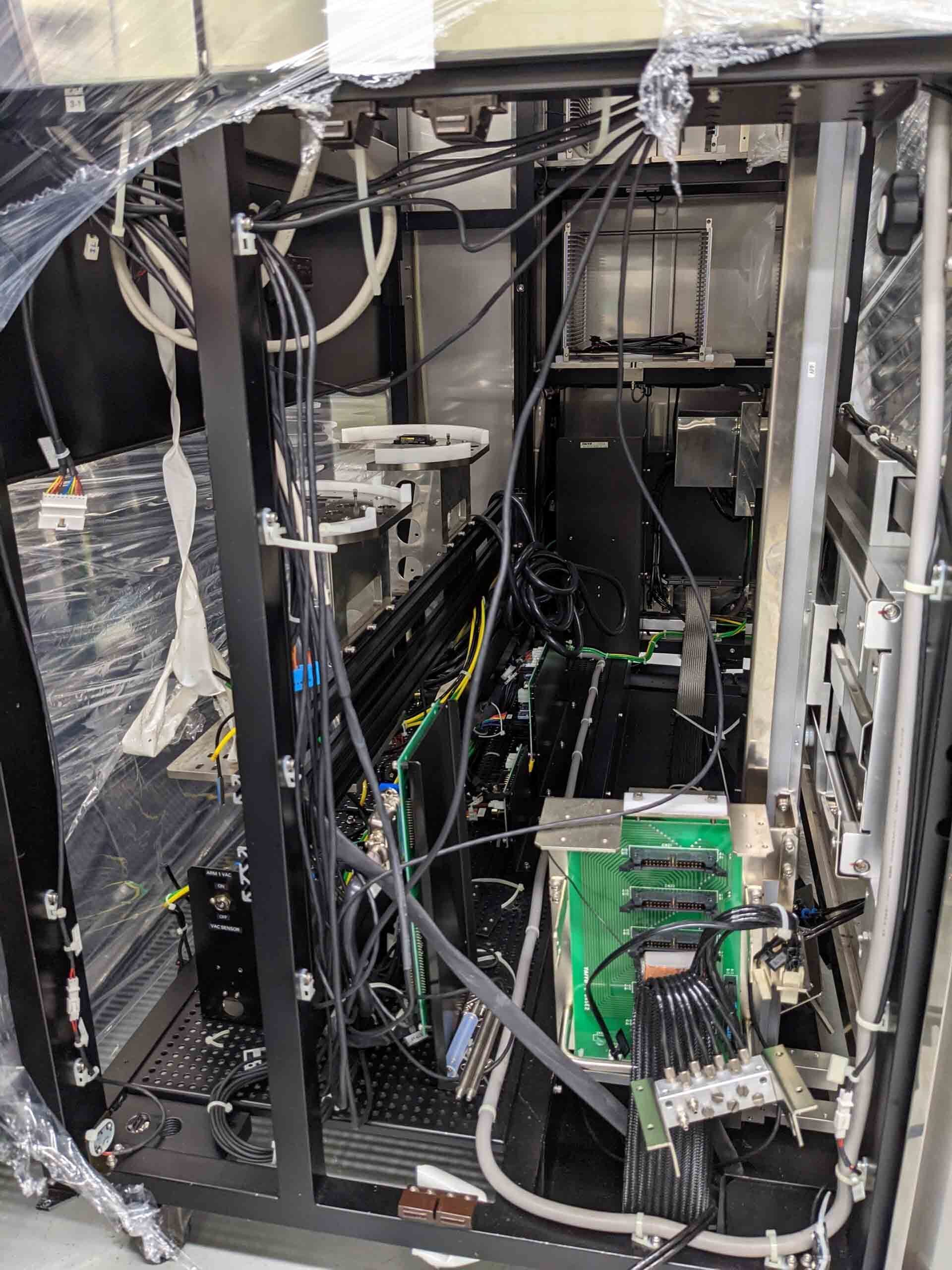

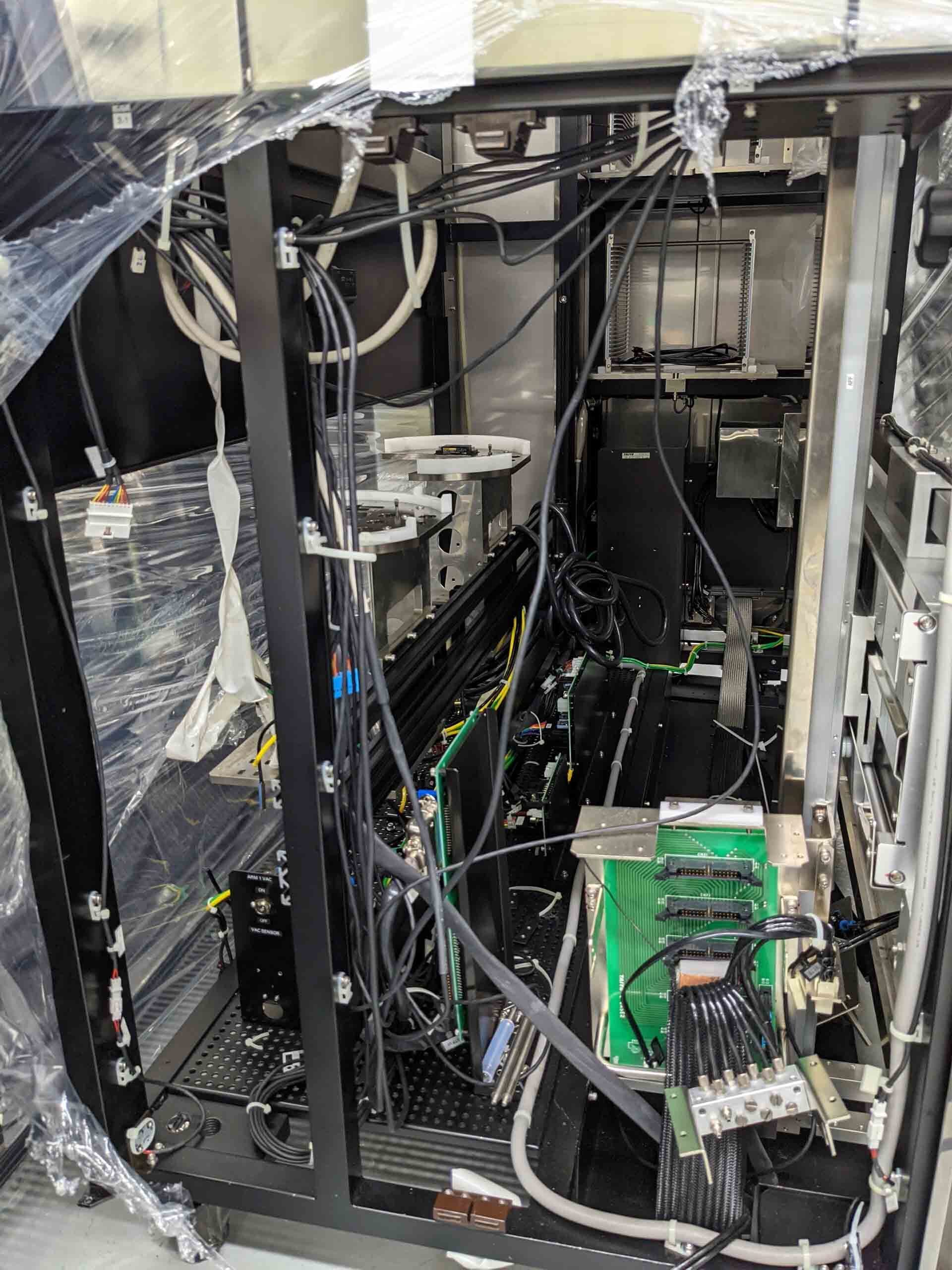

Used TEL / TOKYO ELECTRON Clean Track Mark 8 #9392817 for sale

URL successfully copied!

Tap to zoom

ID: 9392817

Wafer Size: 8"

Vintage: 1995

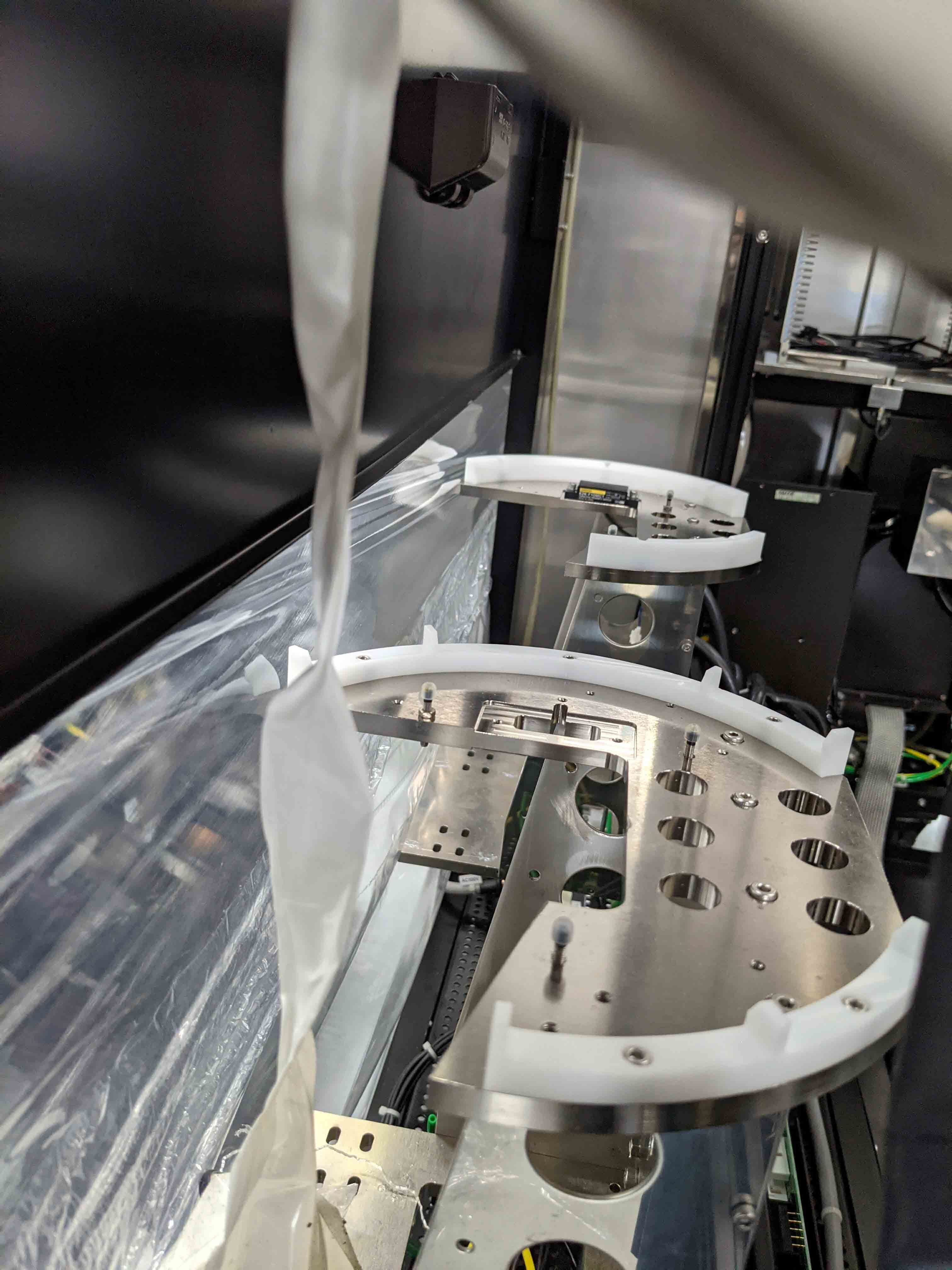

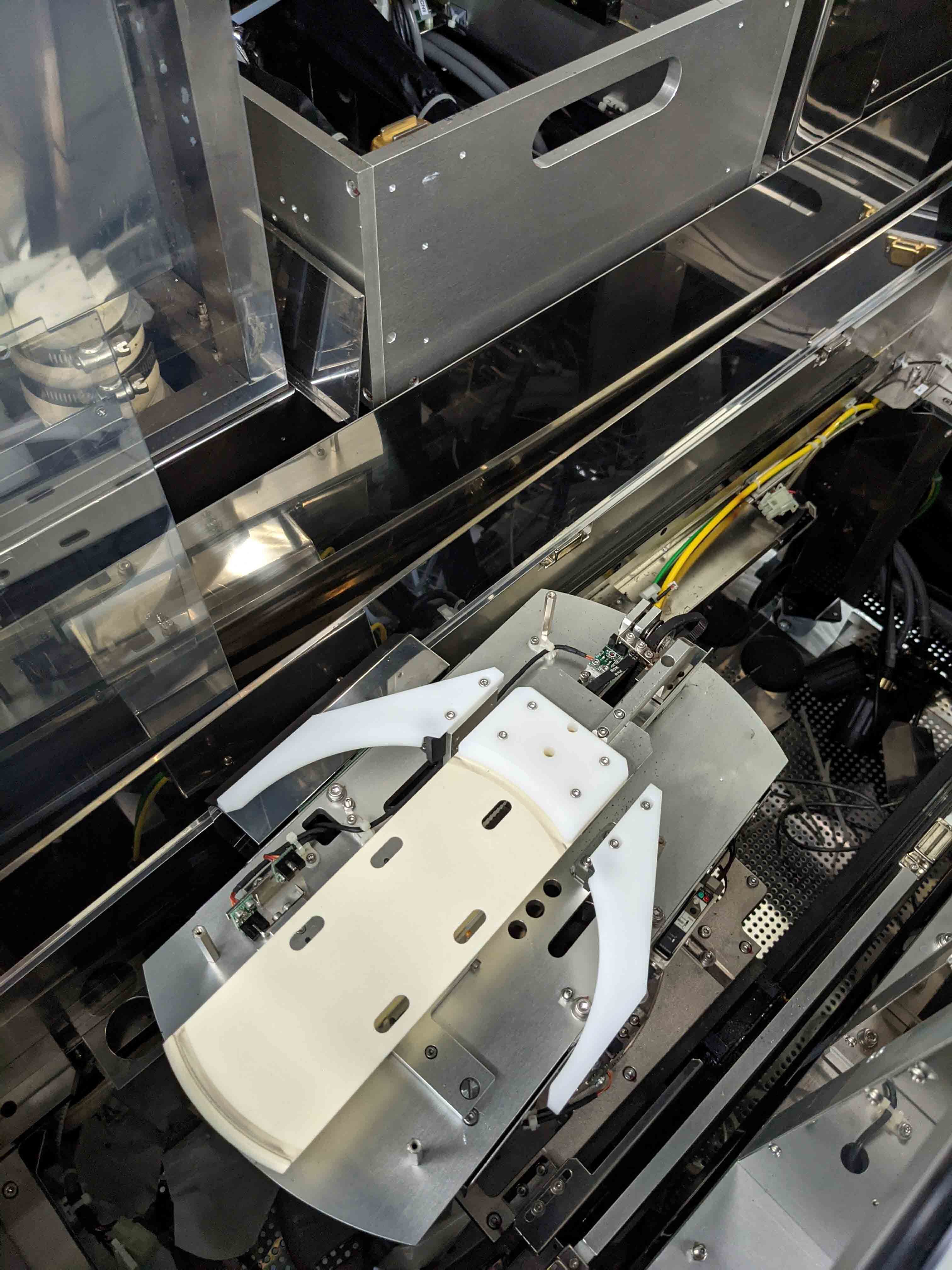

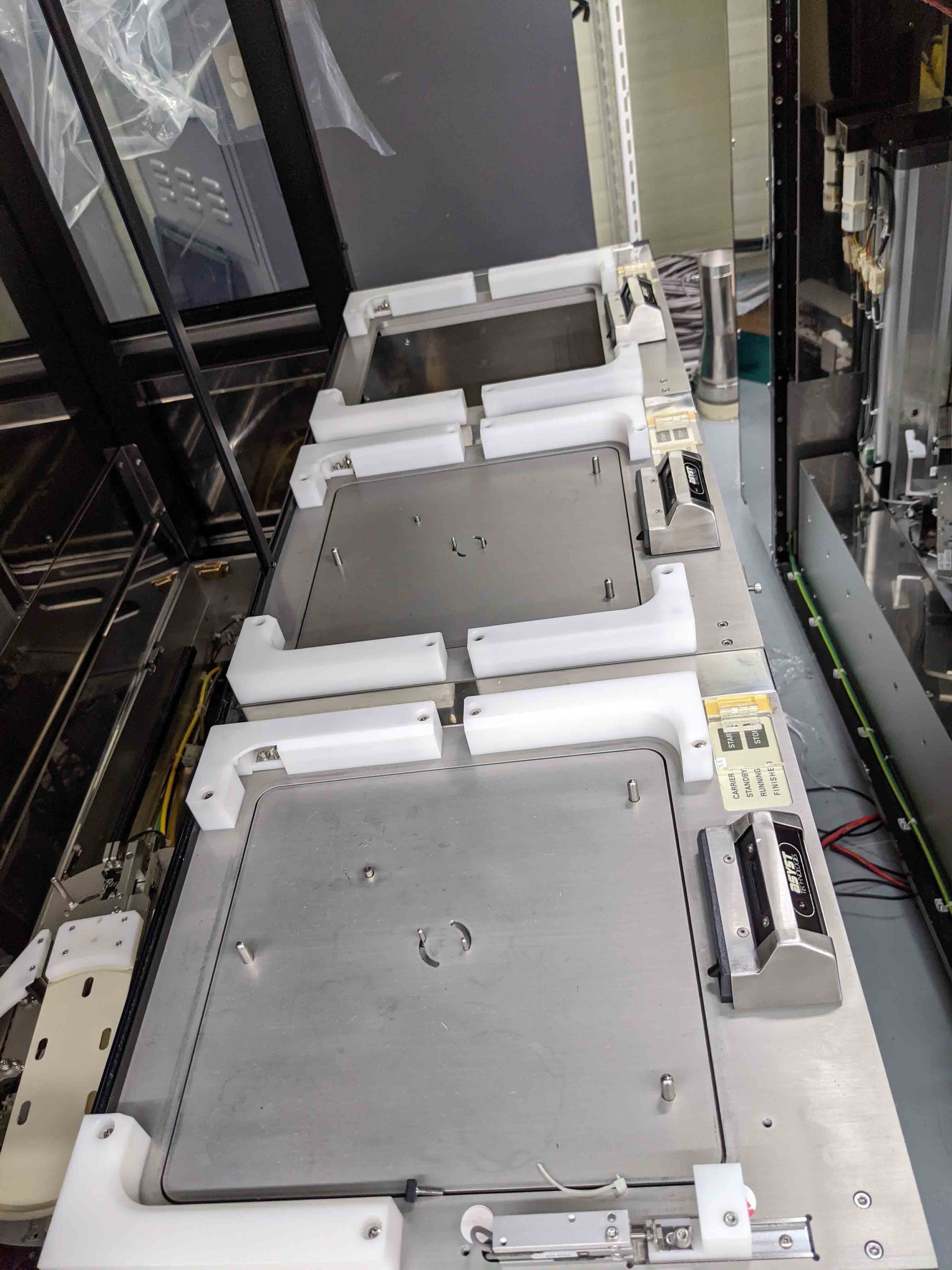

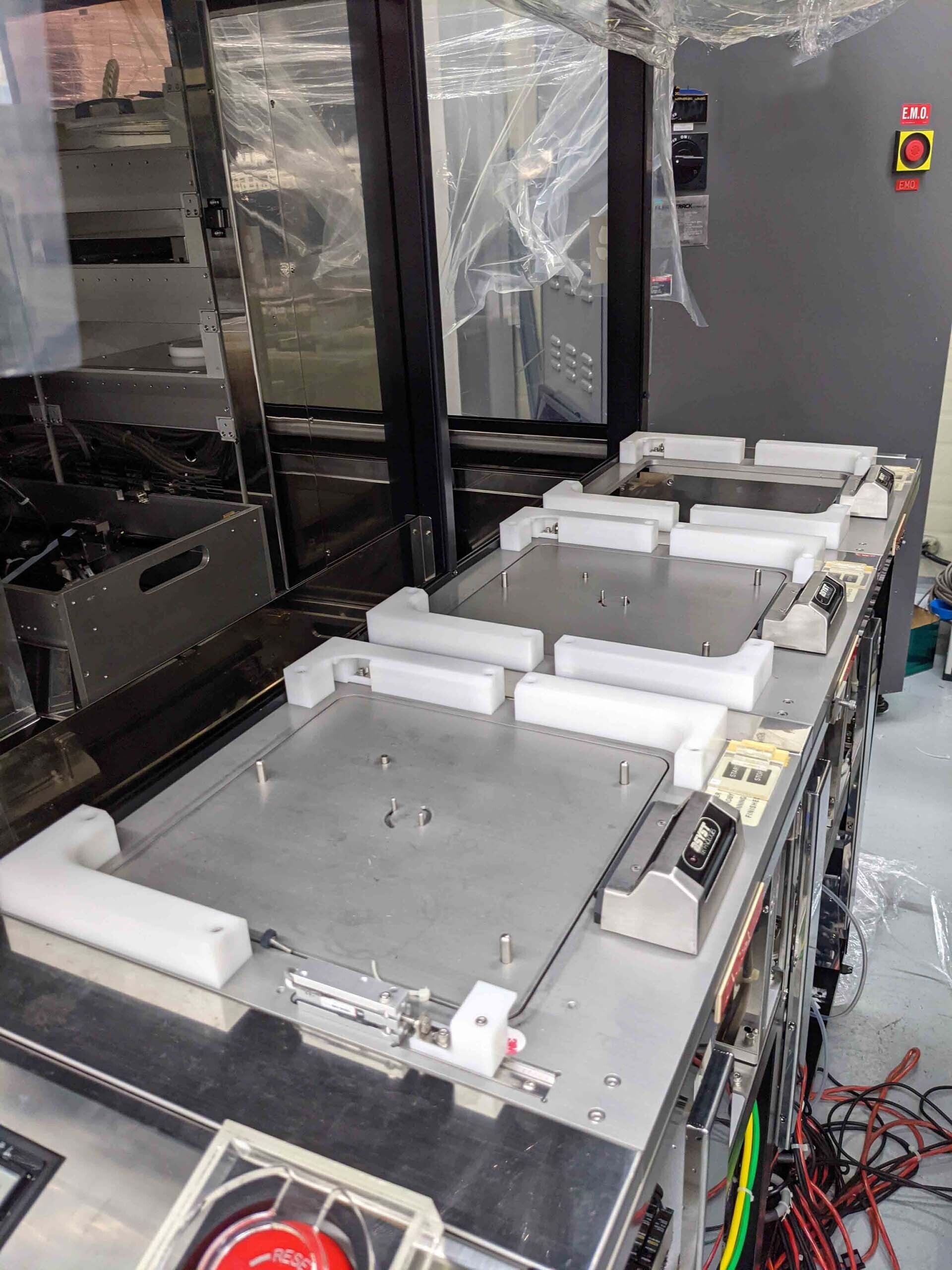

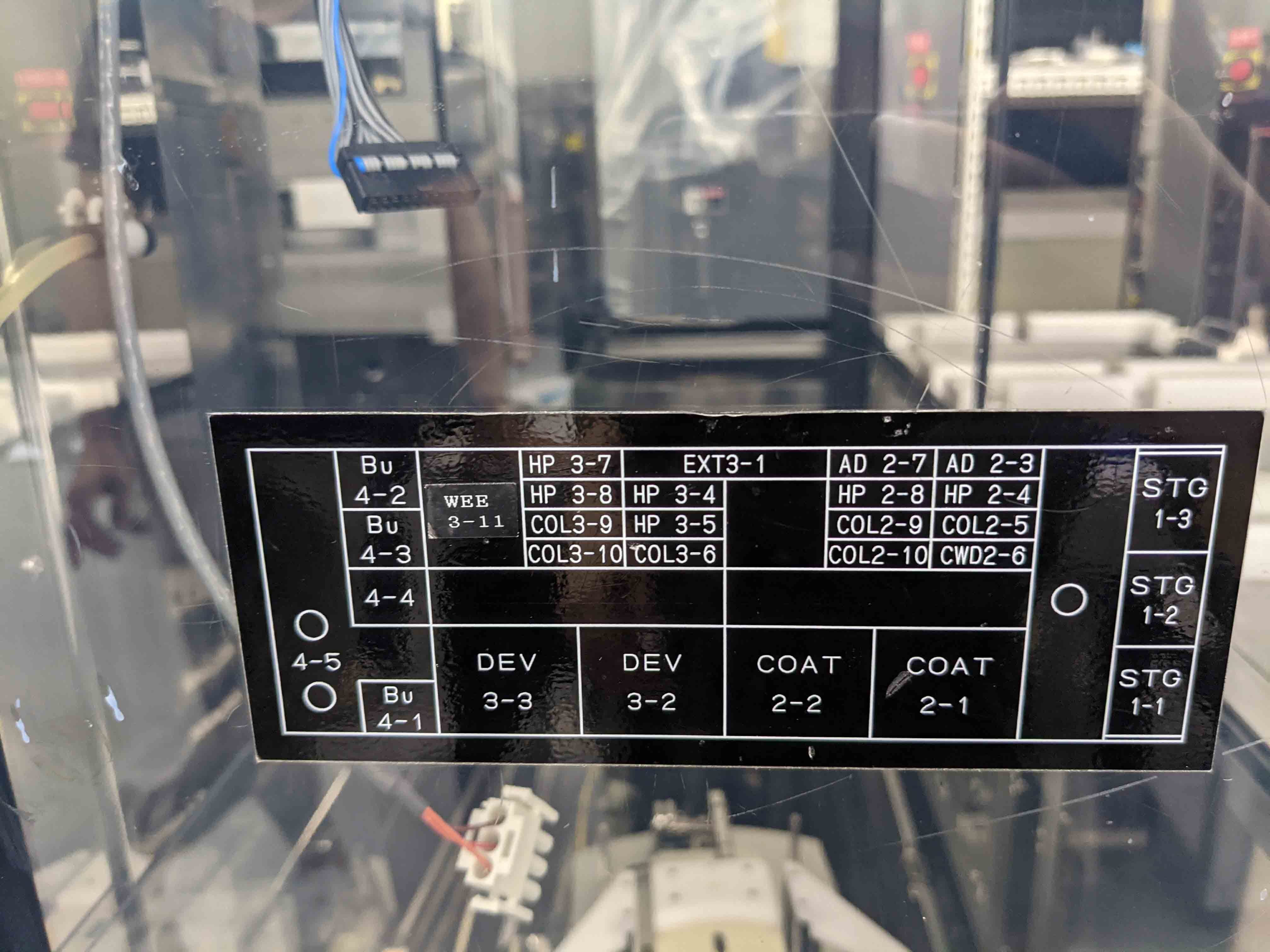

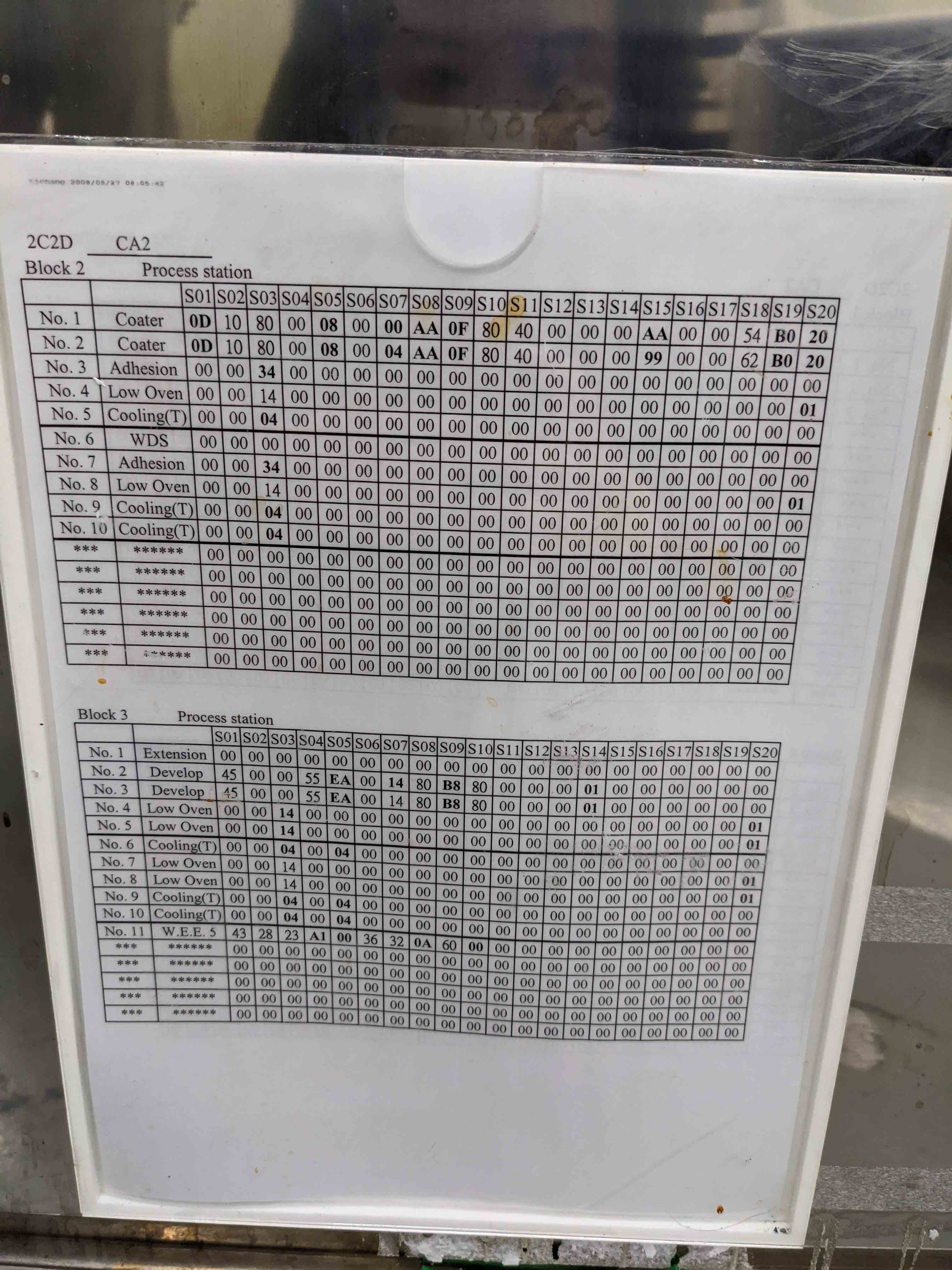

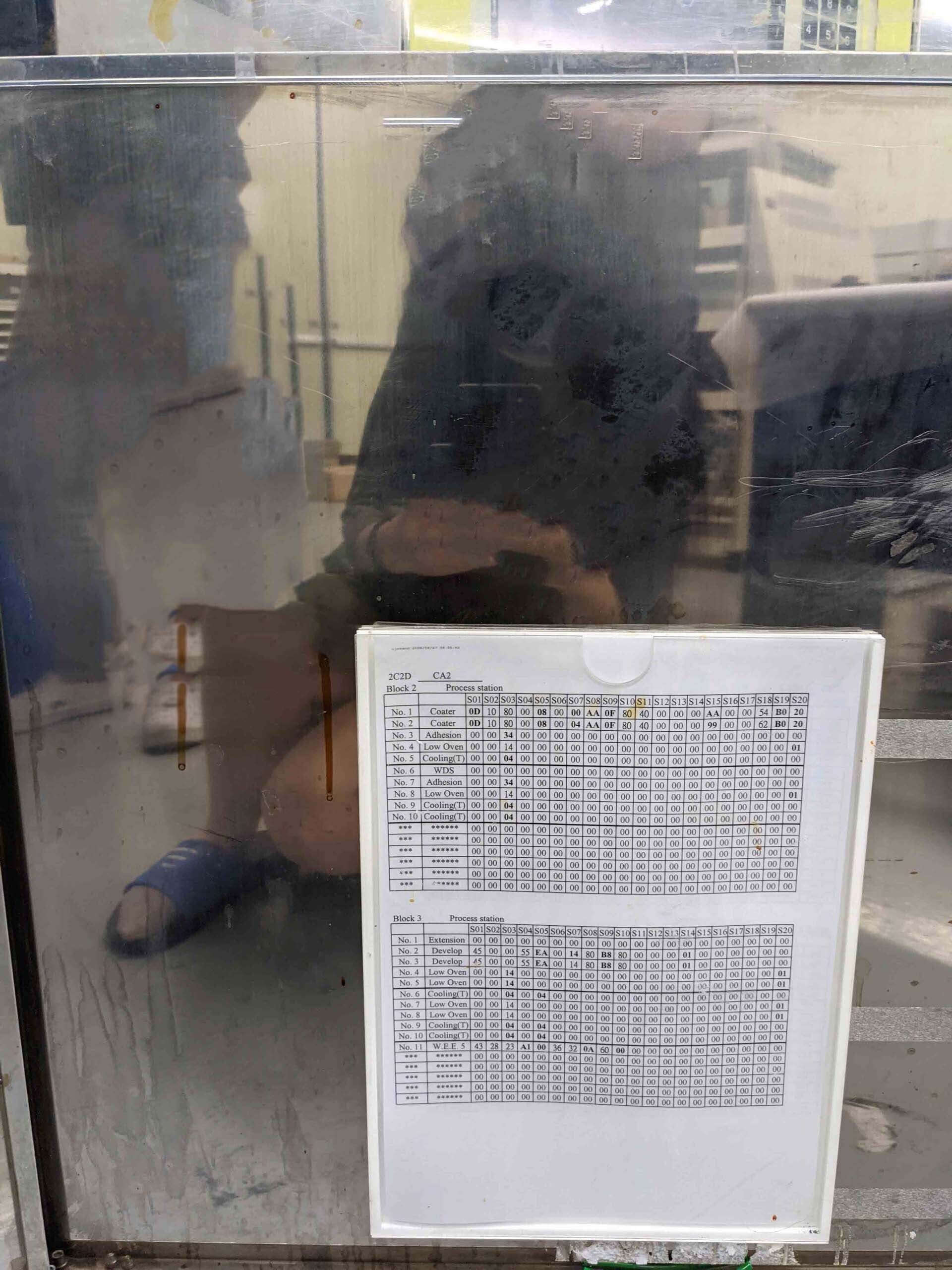

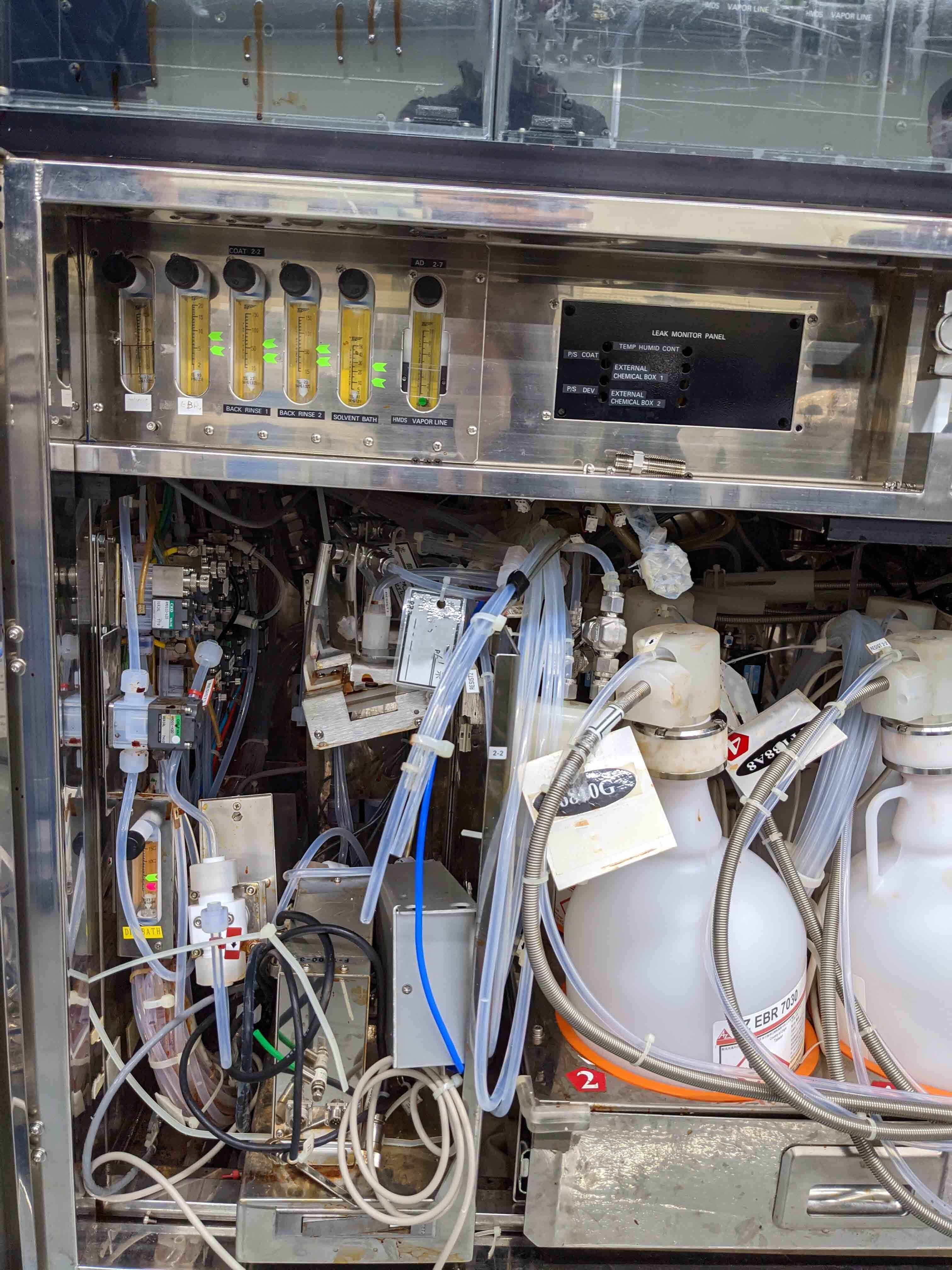

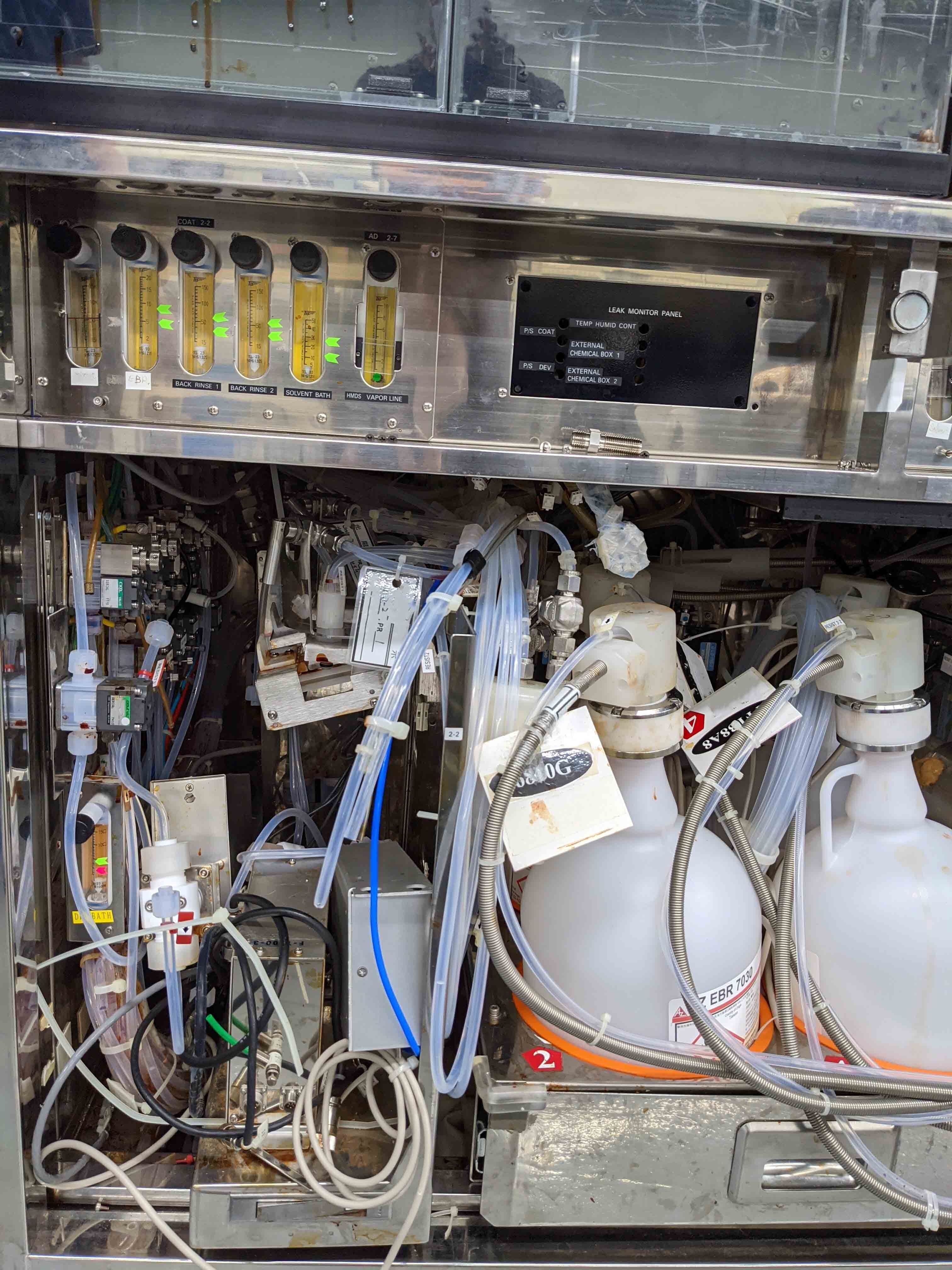

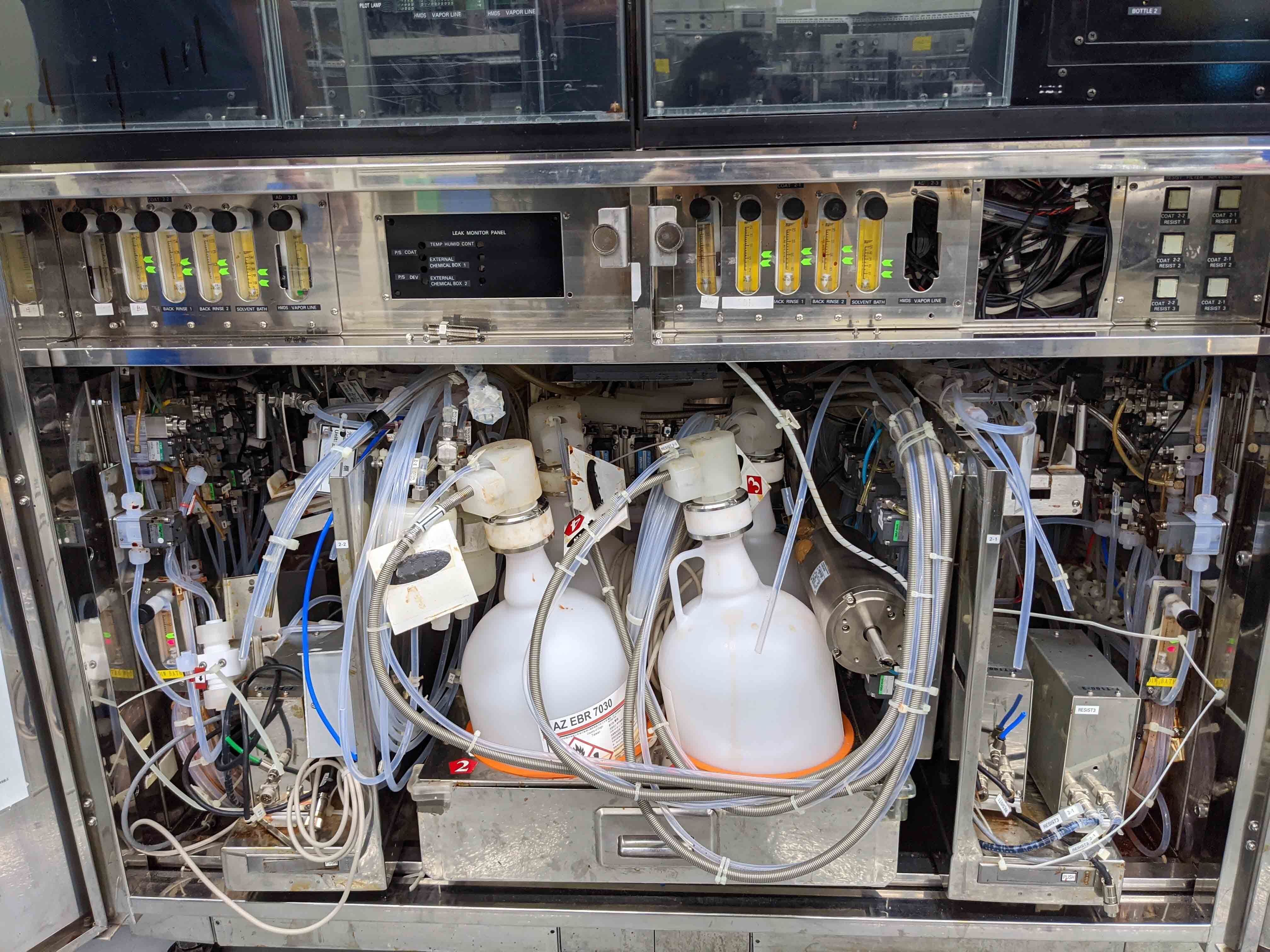

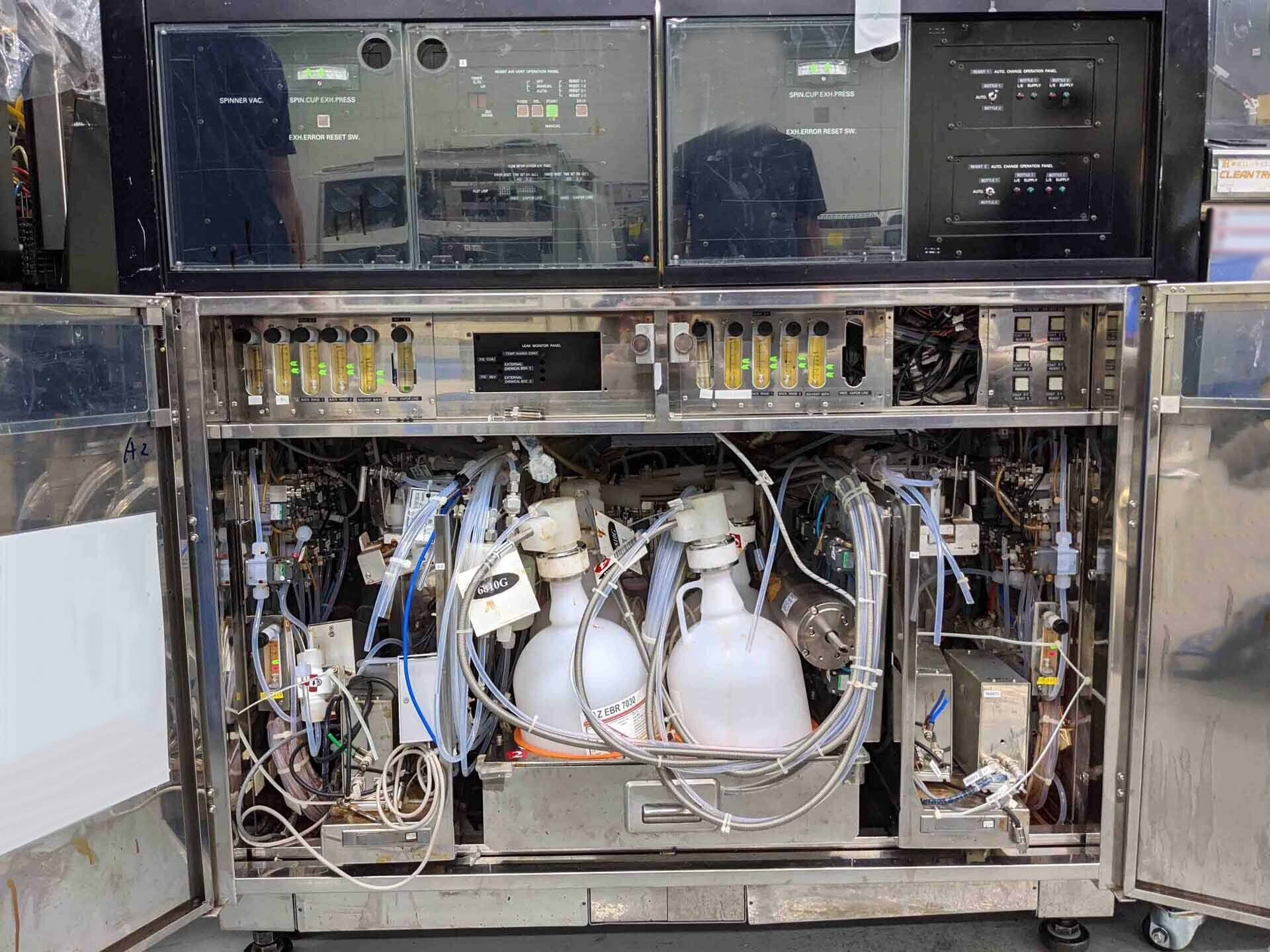

(2) Coater / (2) Developer system, 8"

Dual blocks

Coater: (3) Nozzles

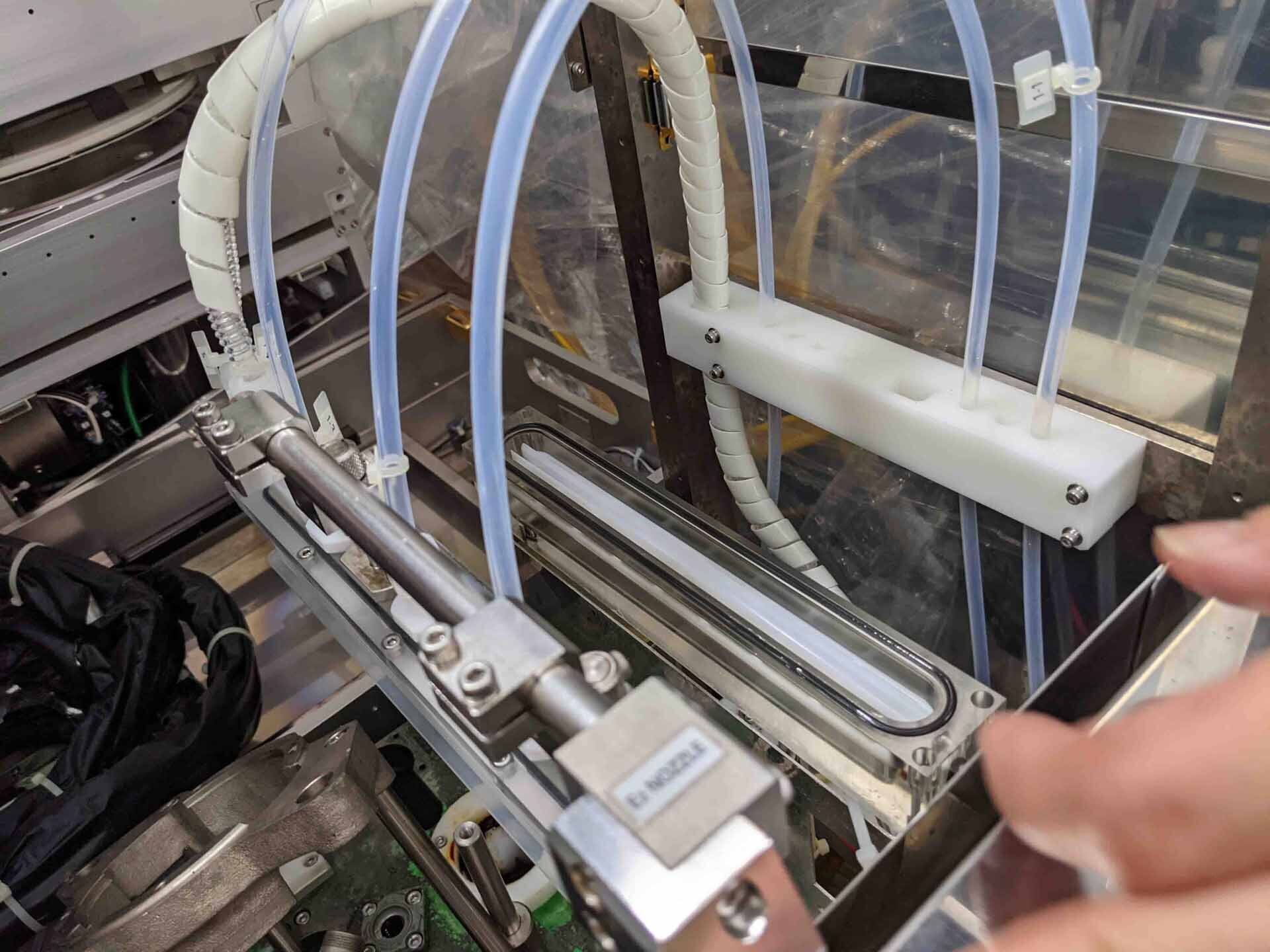

Developer: E2 Nozzle

Wafer flow: Right to left (CSB Unit right side and interface station left side)

Tank auto switch off / Exchange missing

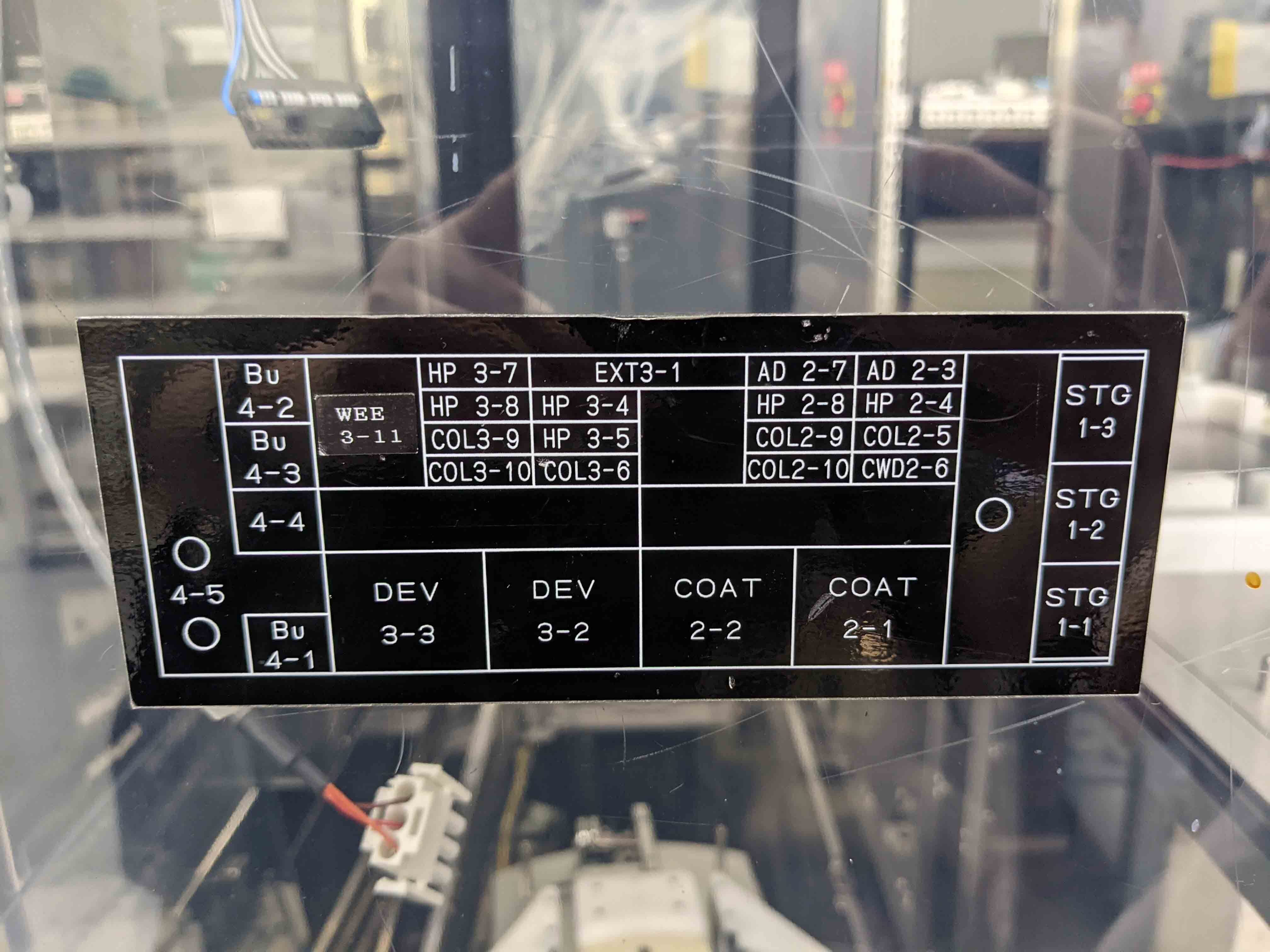

Block 1:

FC-9821Ke Controller

Stage / Indexer: SMIF / Cassette station

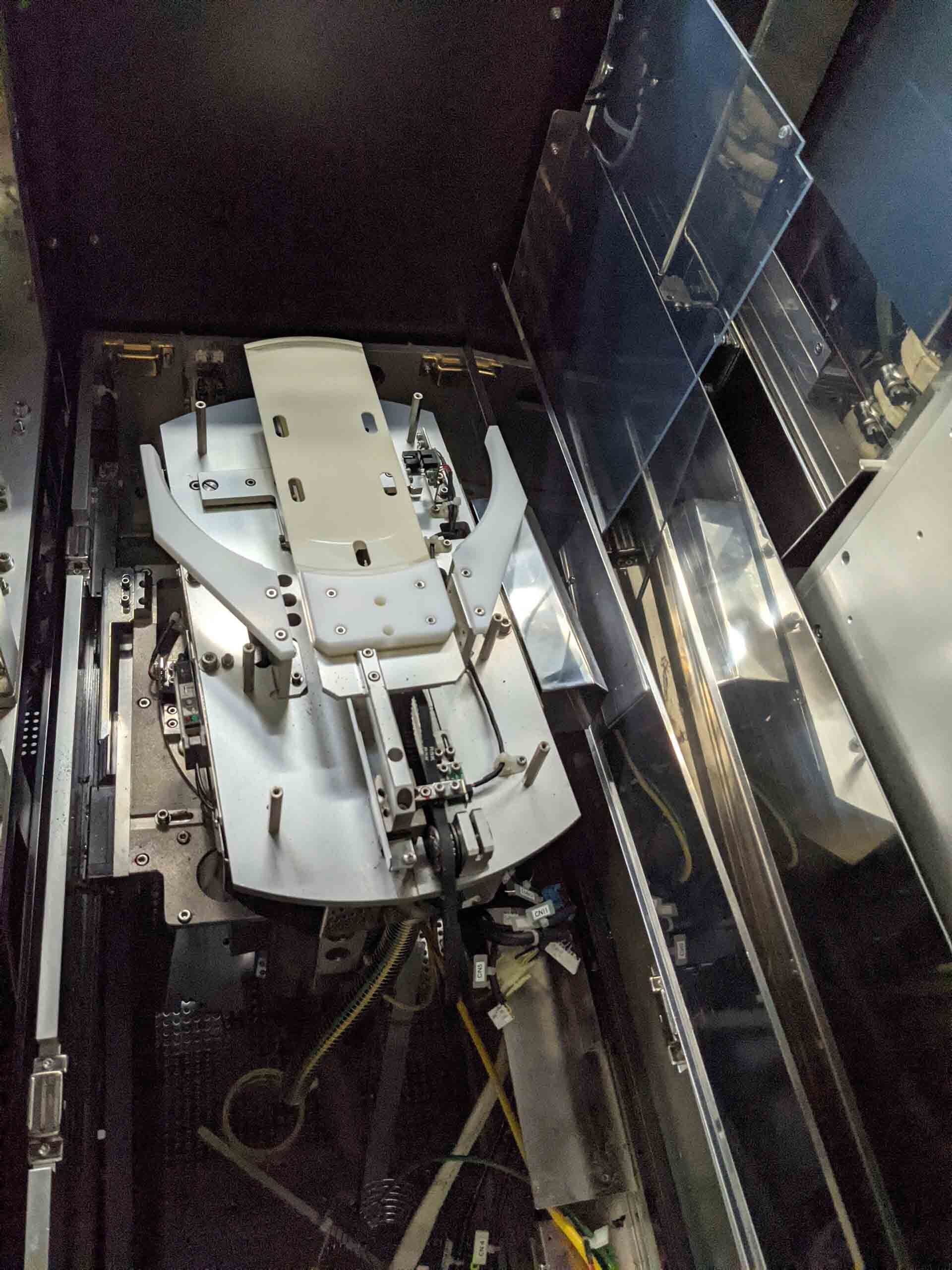

Cassette Station Arm (CSA)

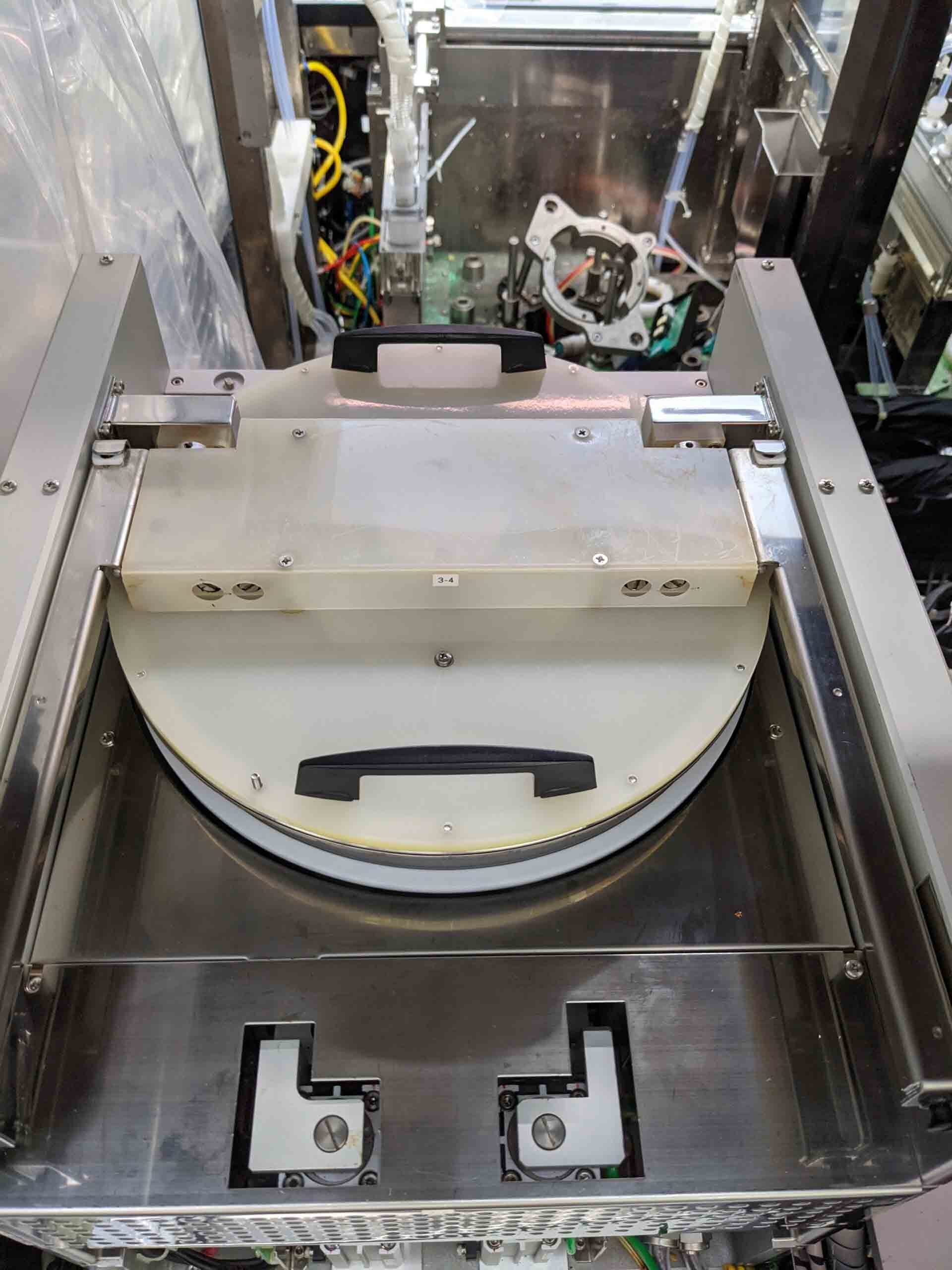

Block 2:

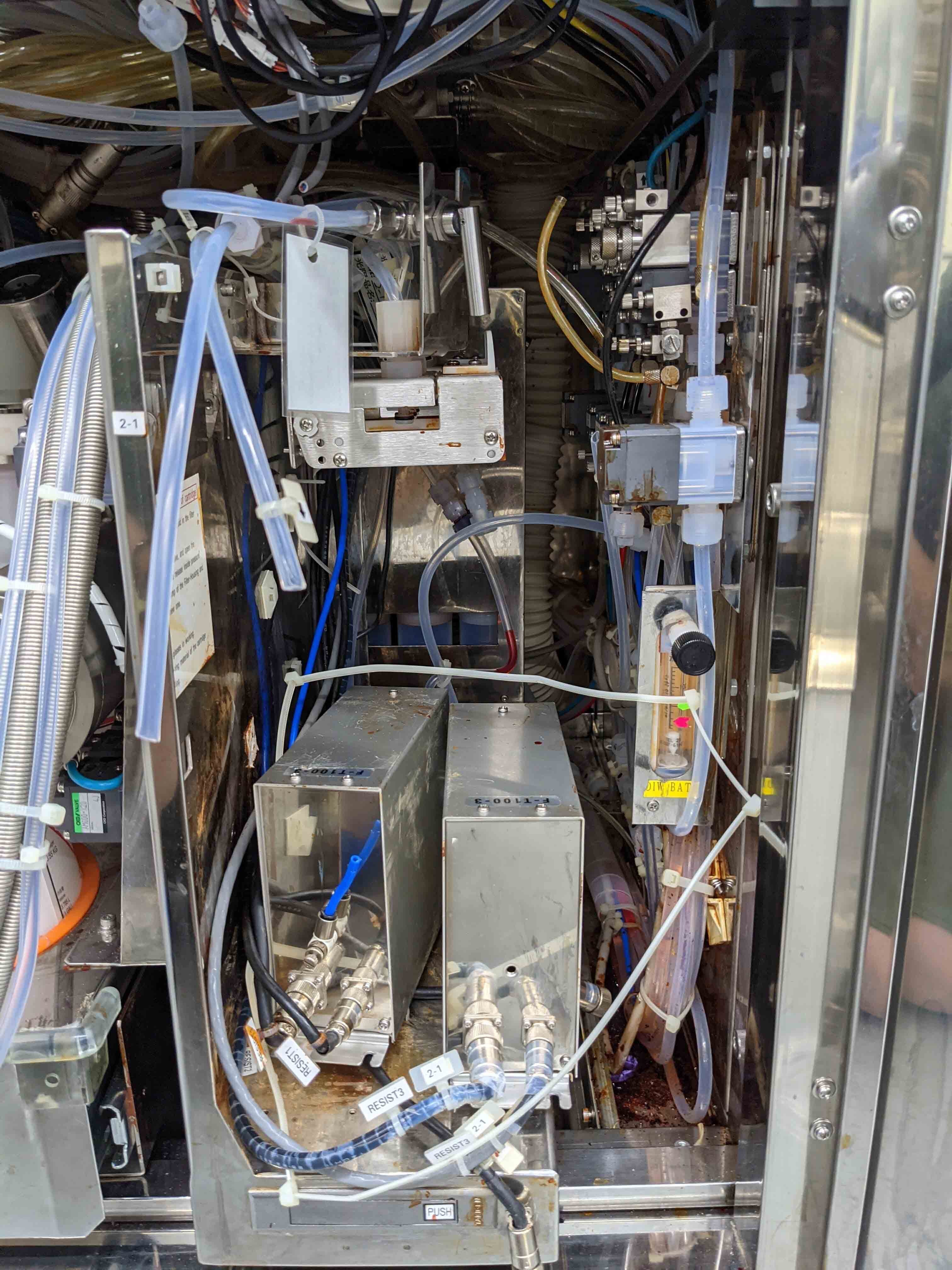

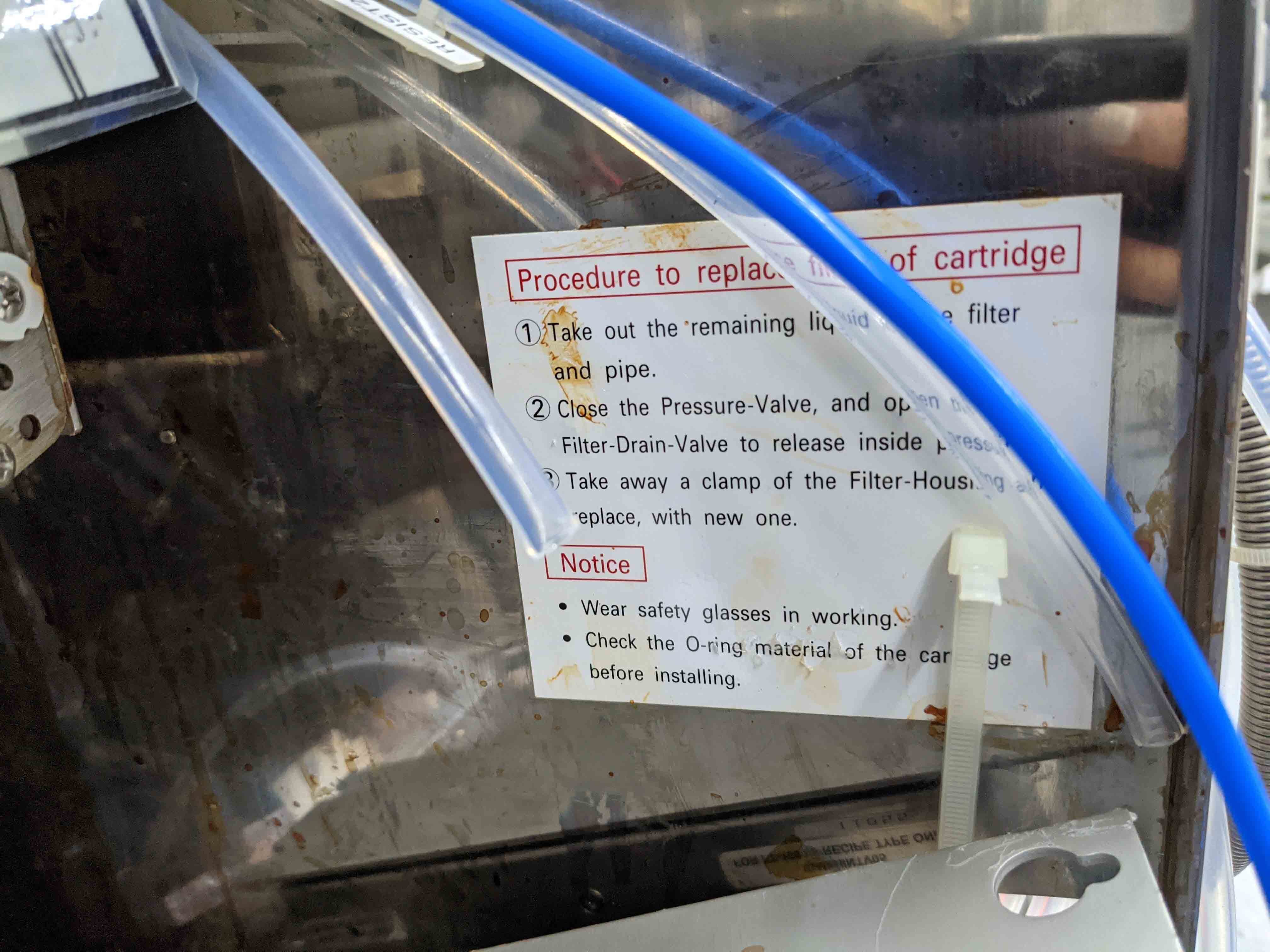

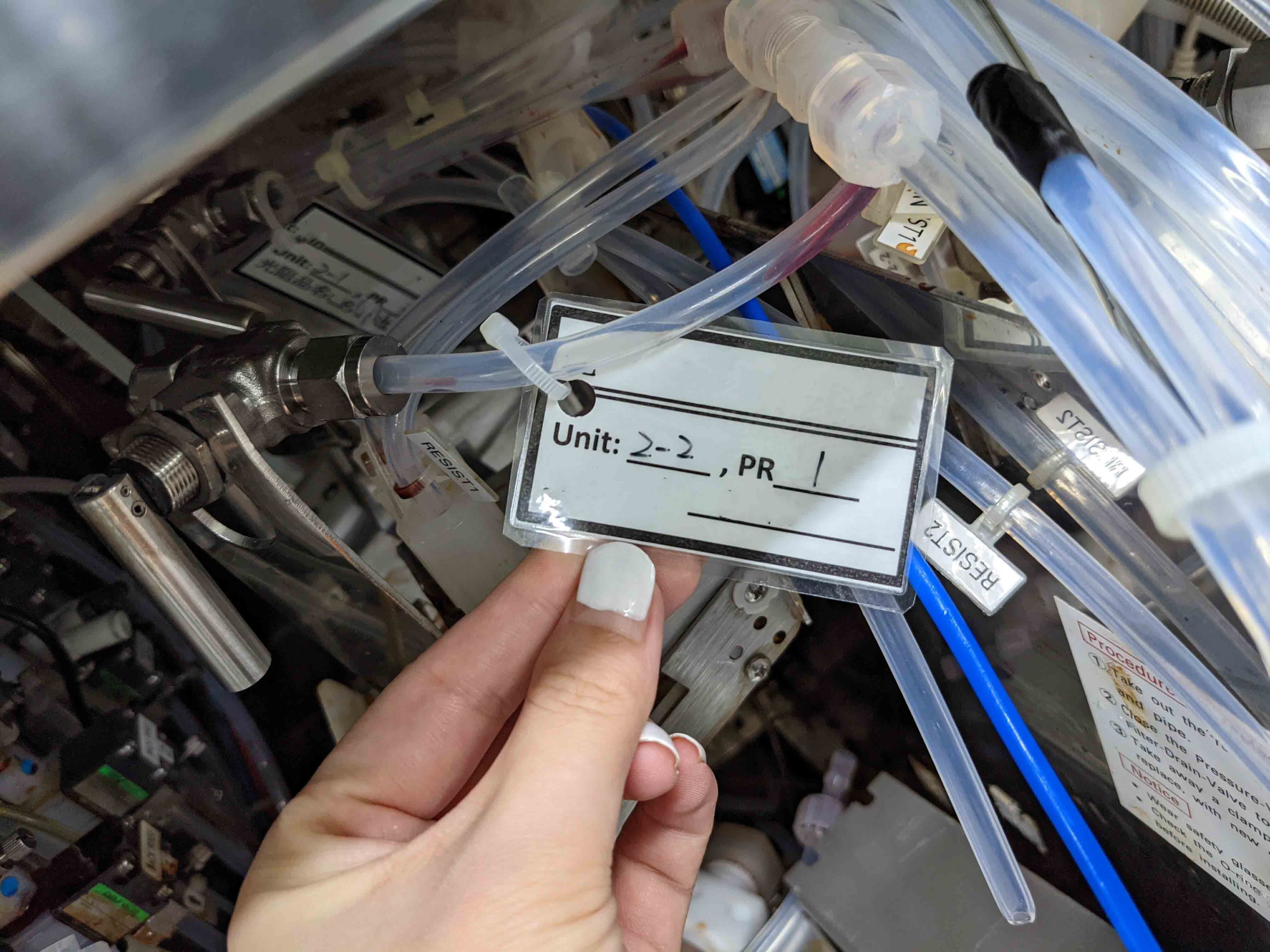

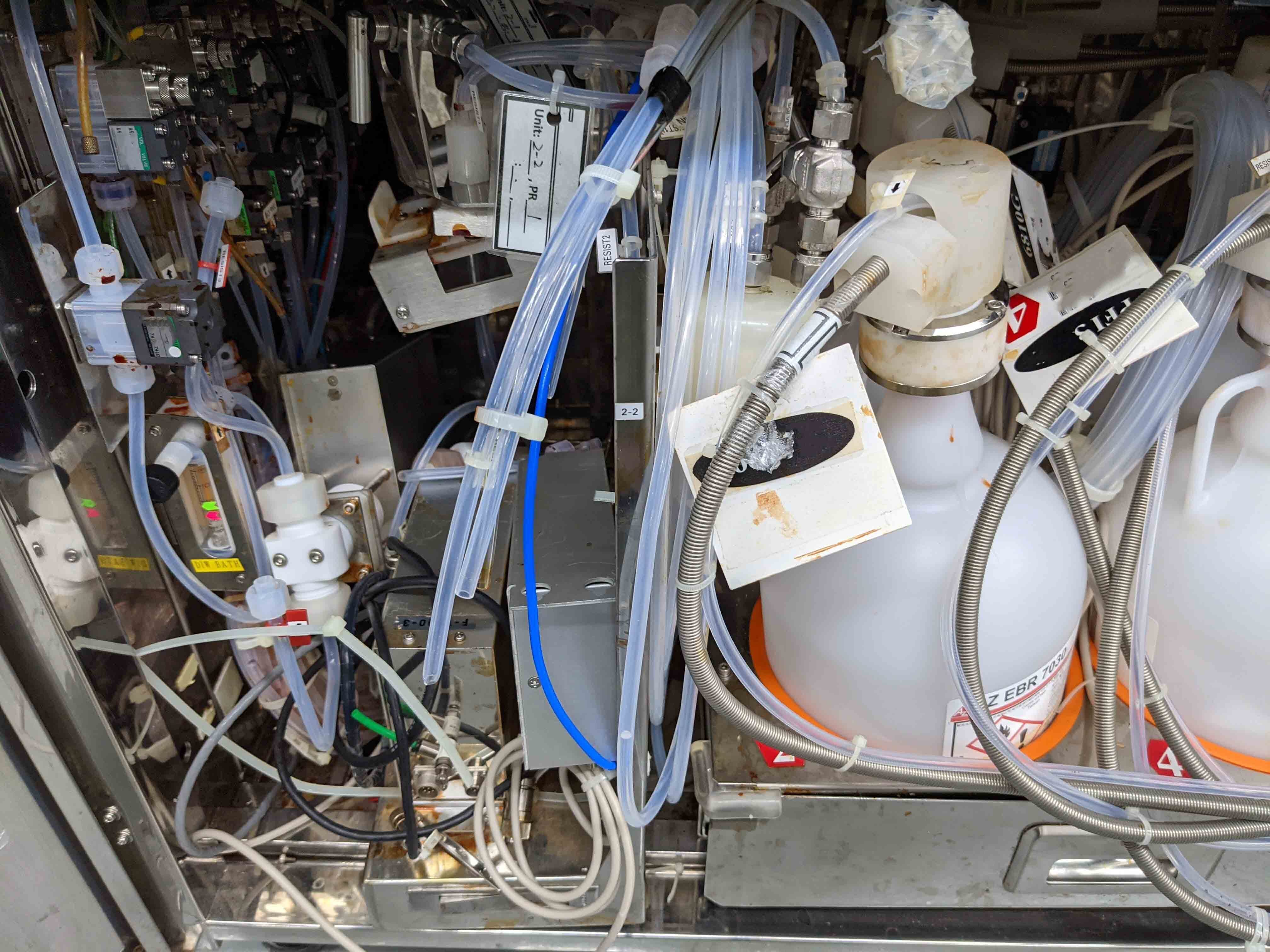

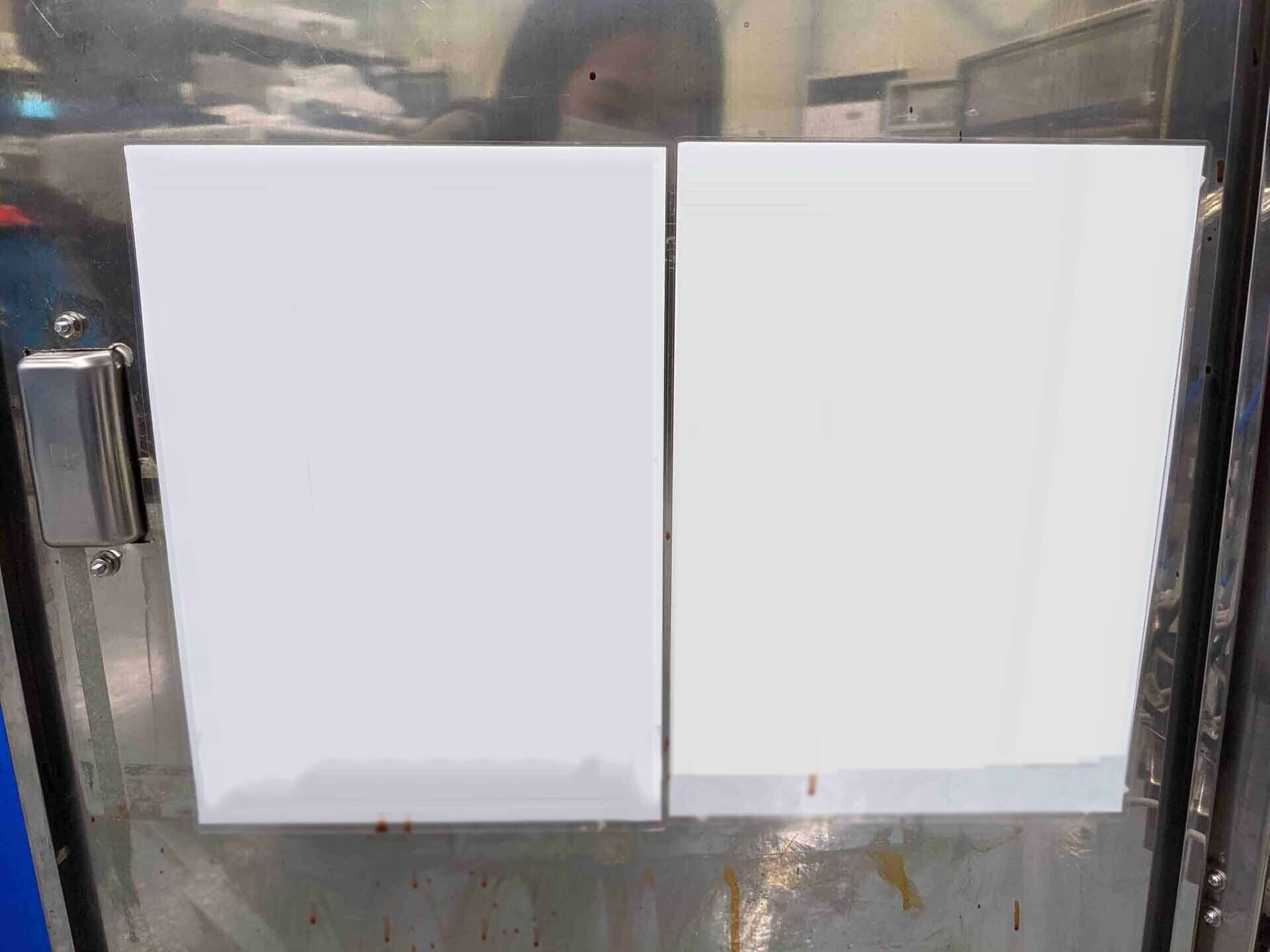

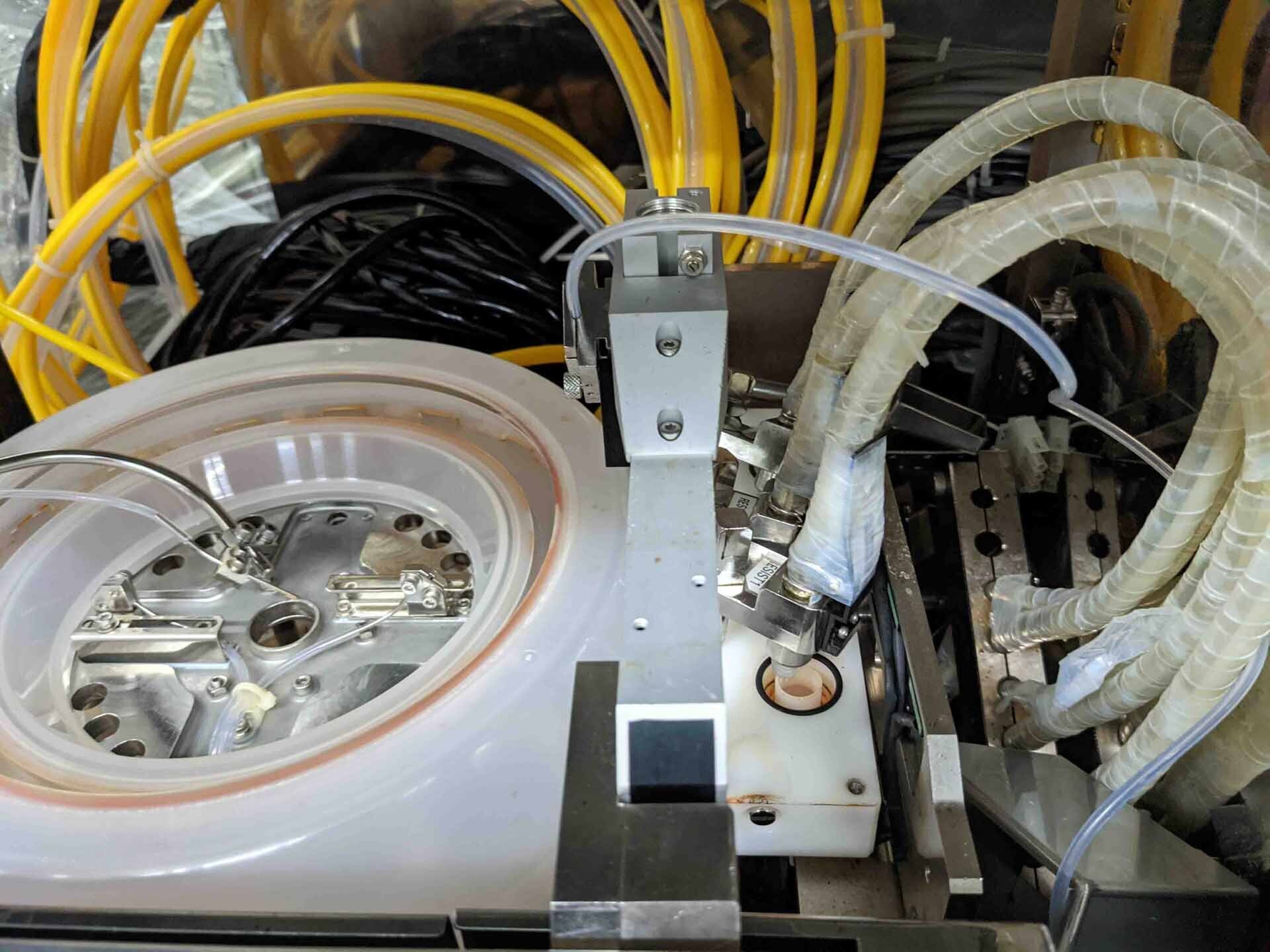

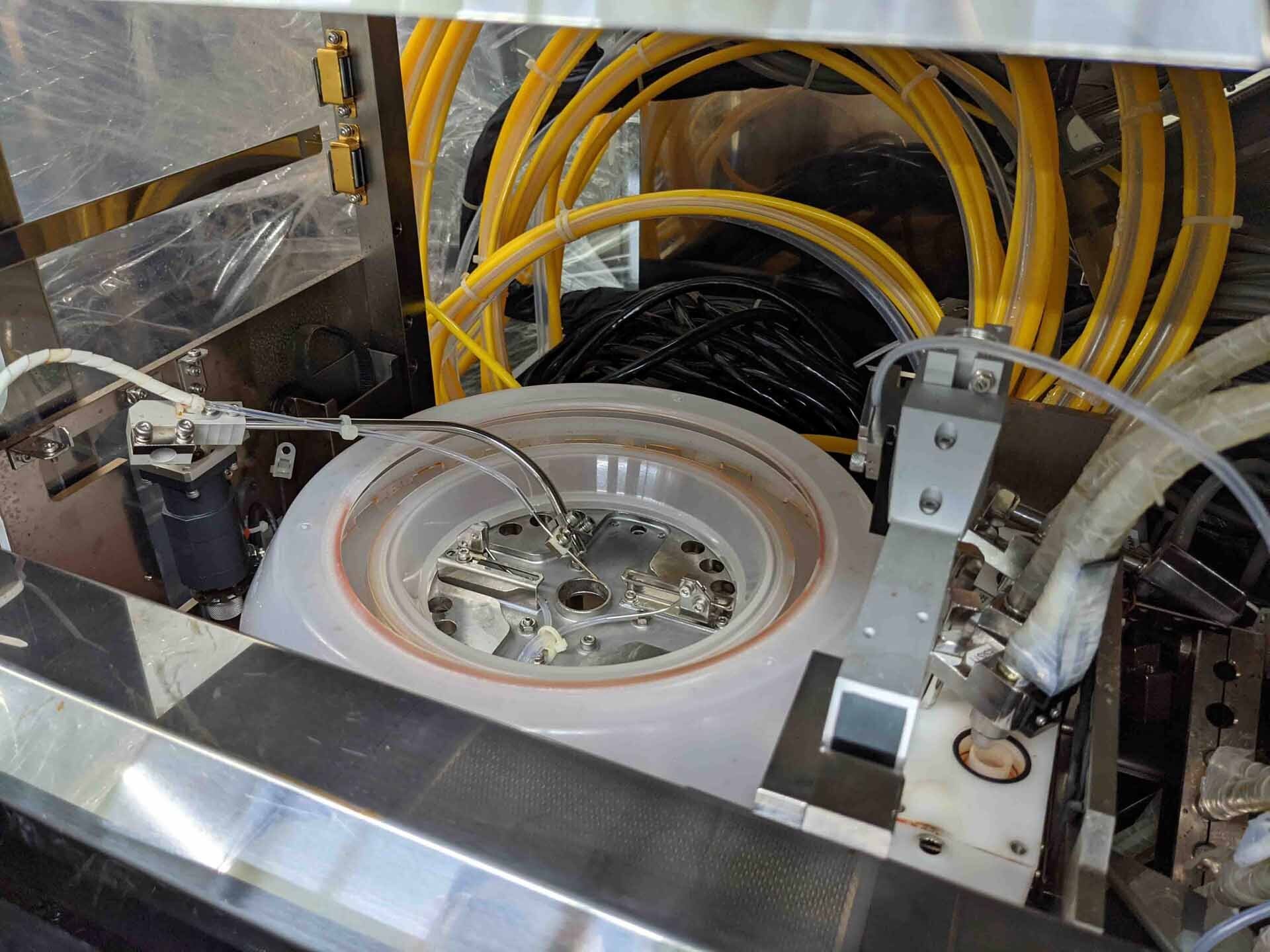

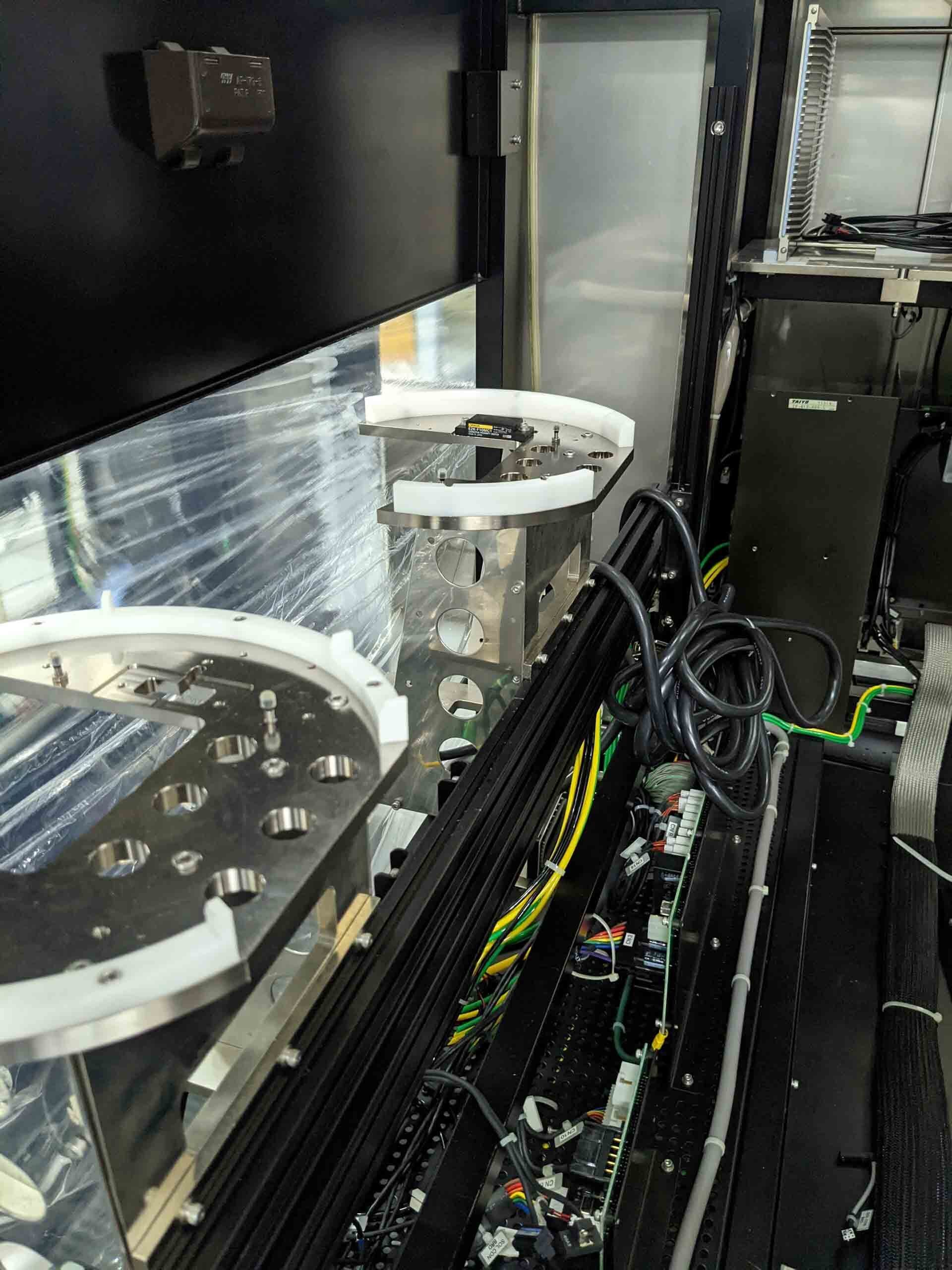

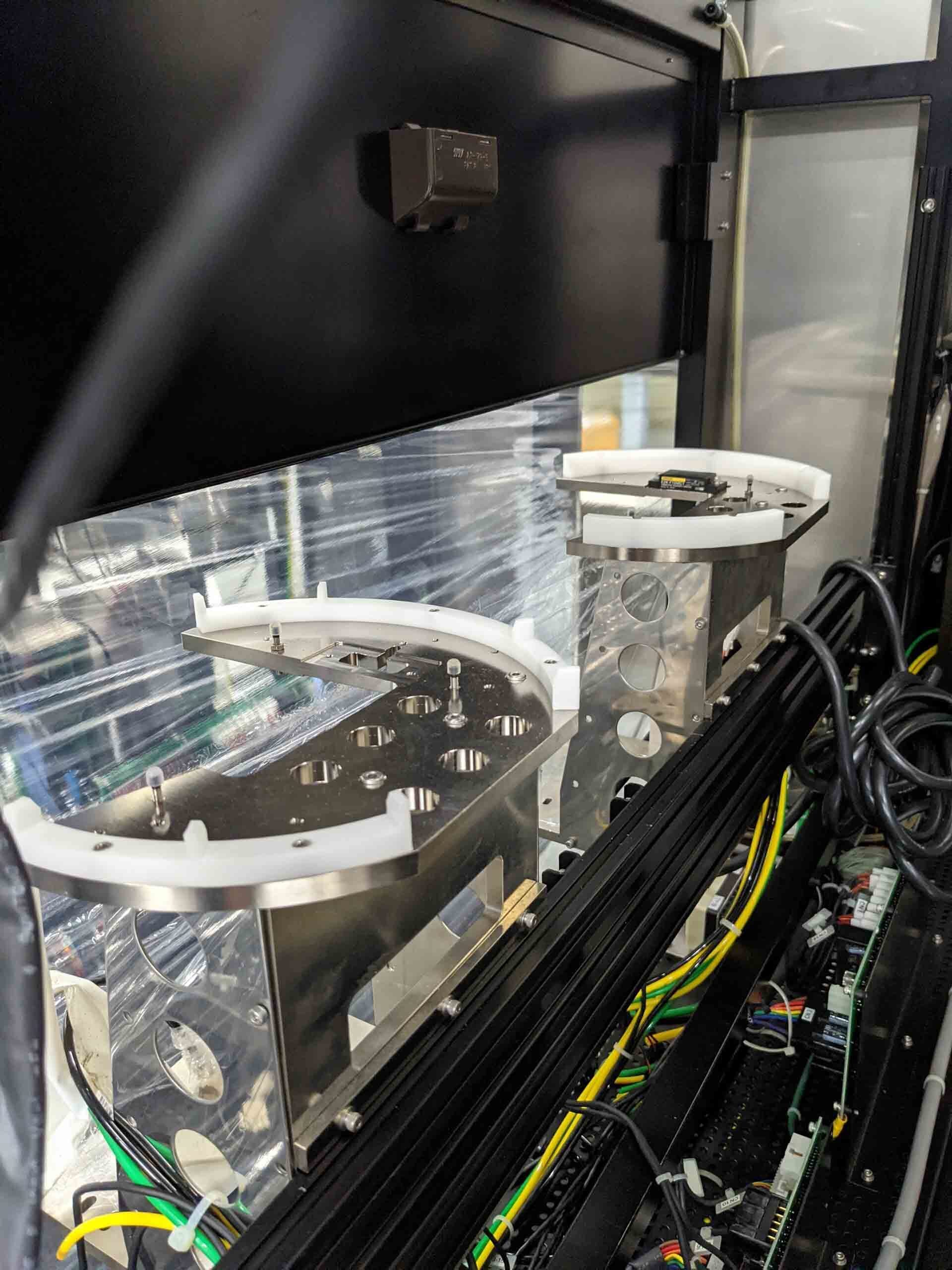

Normal photo resist coater 2-1, 2-2:

(2) Photoresist dispense nozzles per coat unit

(2) Photoresist dispense nozzles and 2-RRC Resist pump per coater

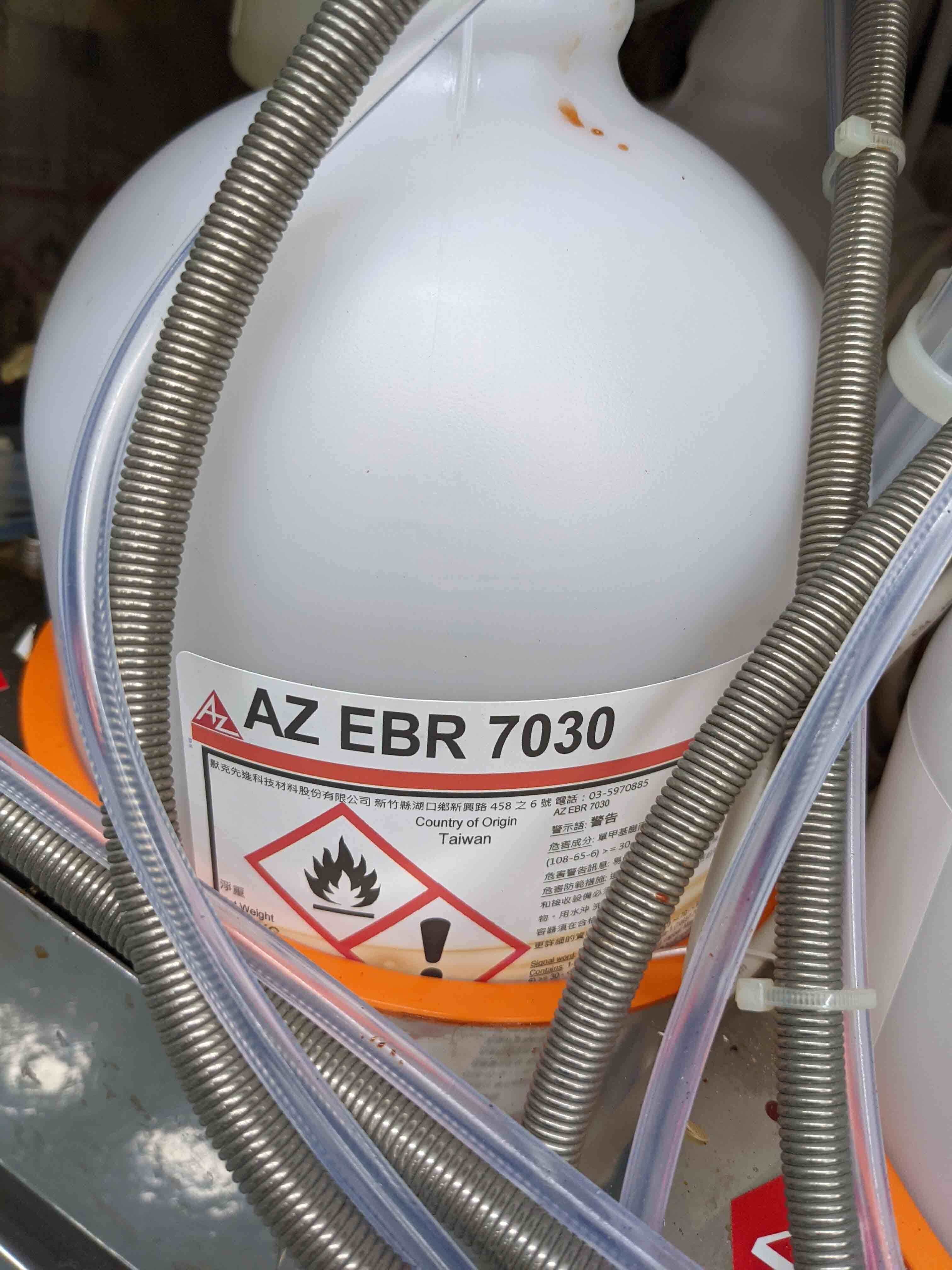

Side rinse nozzle (Programmable side rinse EBR) for normal coater

Dual back rinse nozzle

Photoresist temperature control

Motor flange temperature control

Photoresist drain type: Direct gravity

Photoresist bottle: 2-Space

Photoresist auto exchange

Auto dummy dispense system

Cup type: PP Upper cup and inner cup

Auto damper: Cylinder

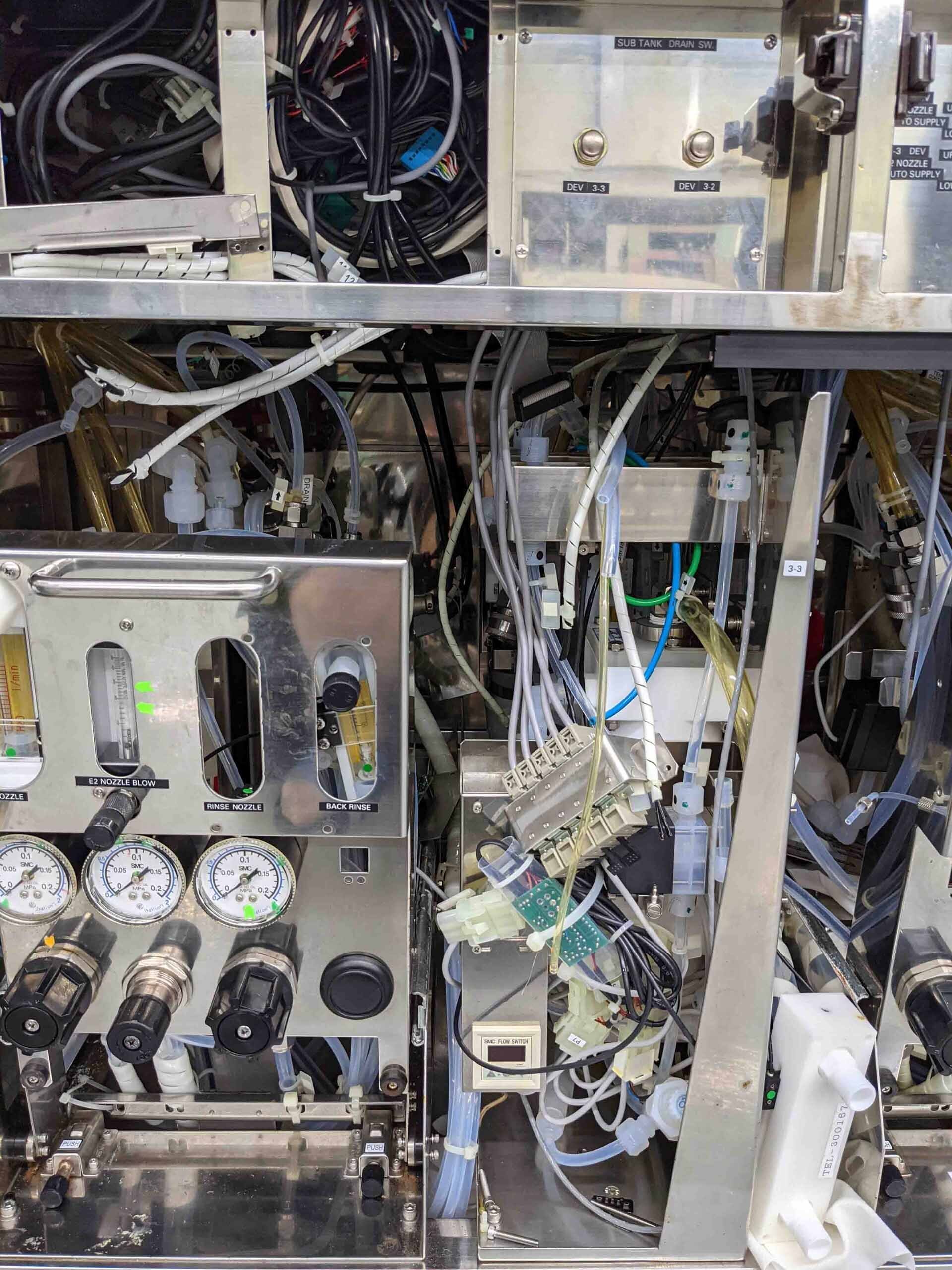

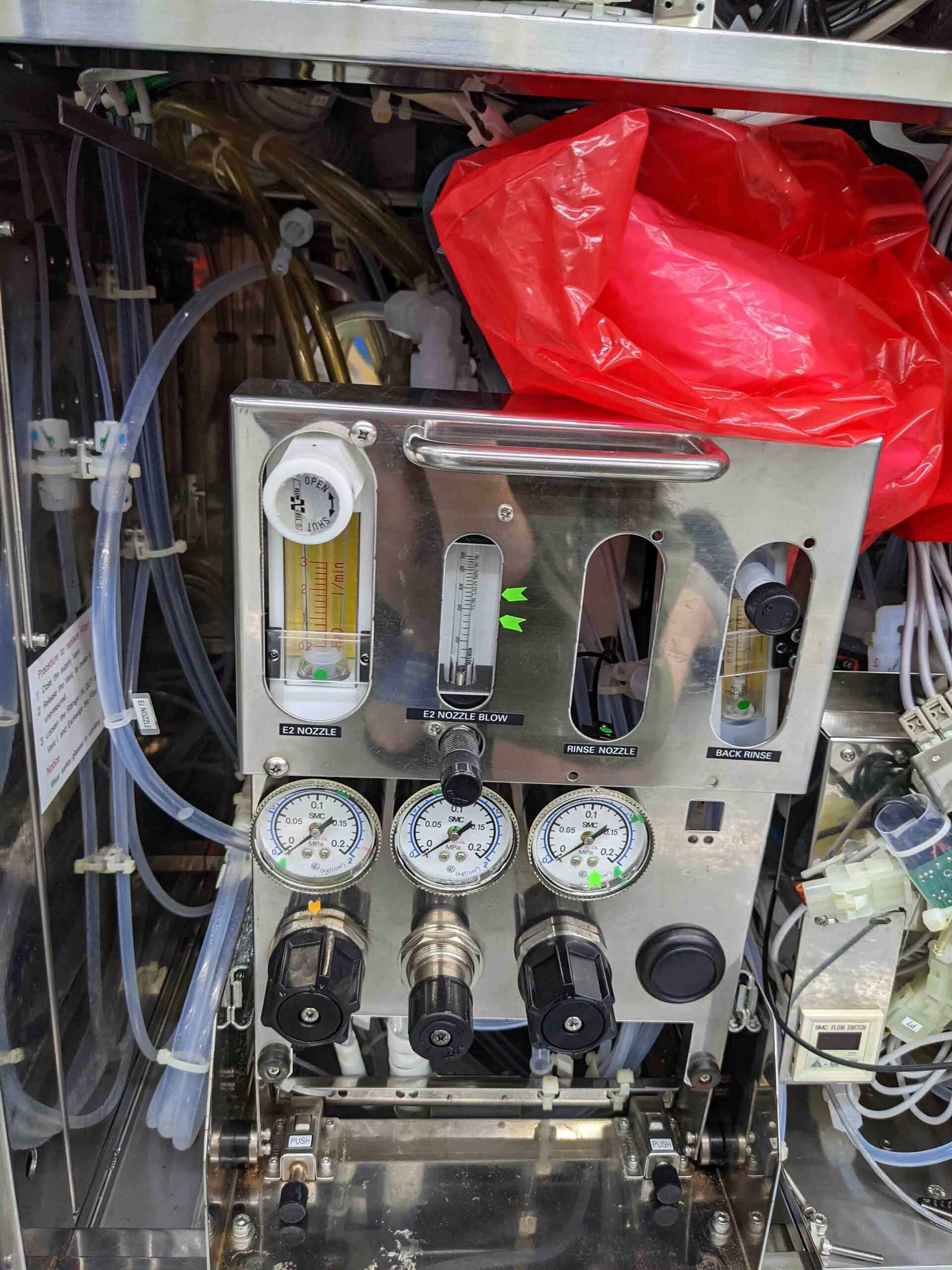

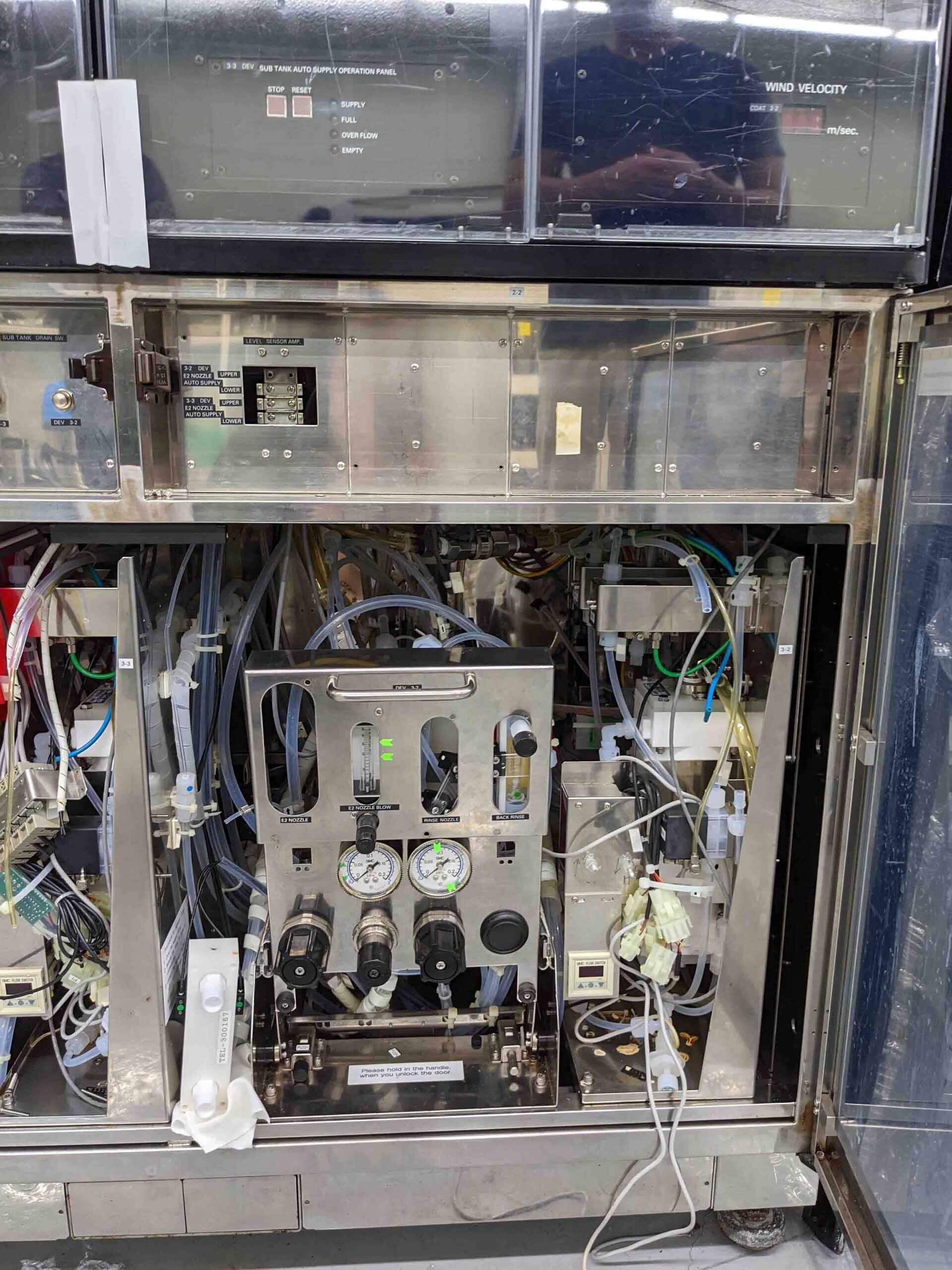

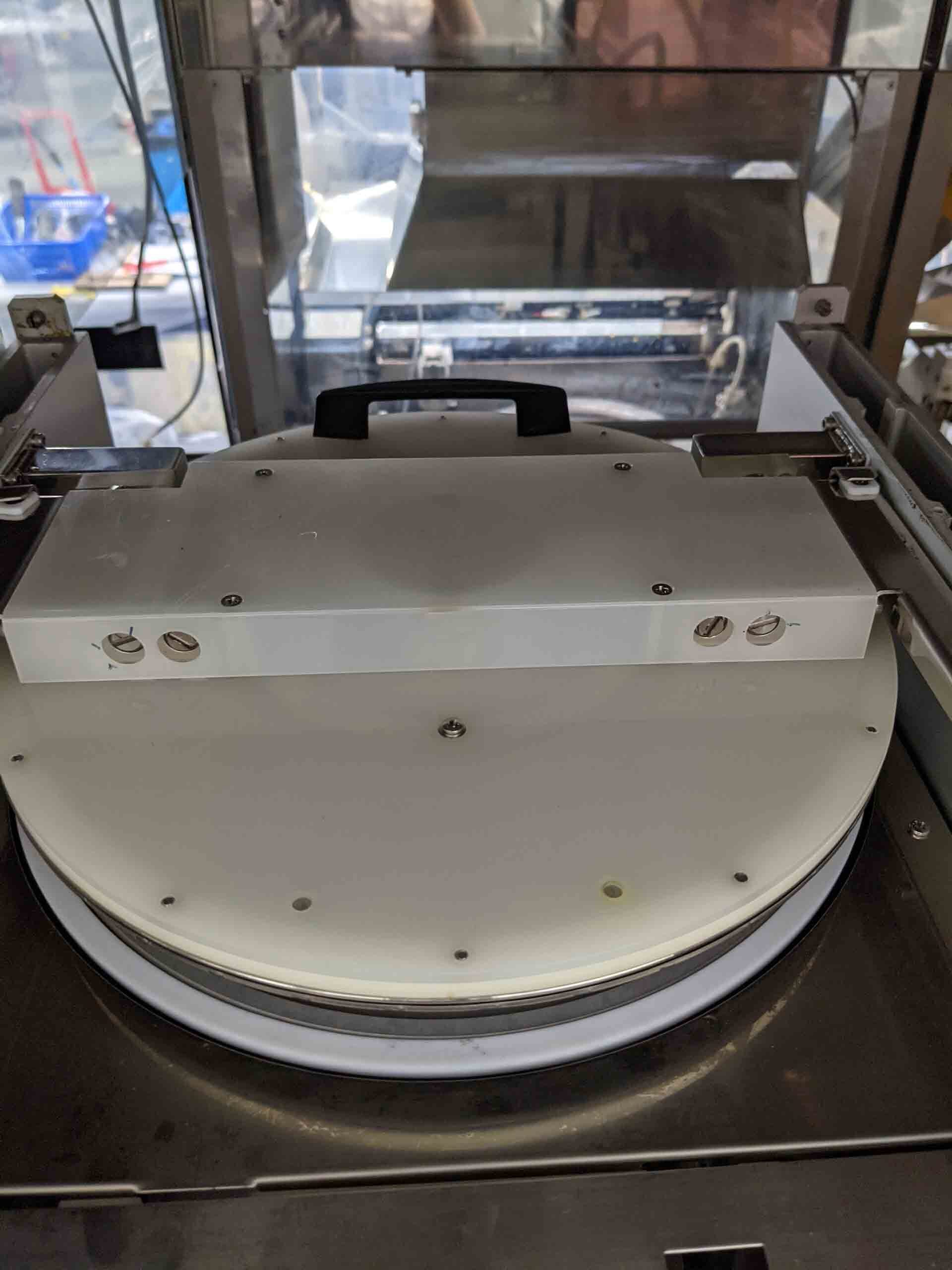

Block 3:

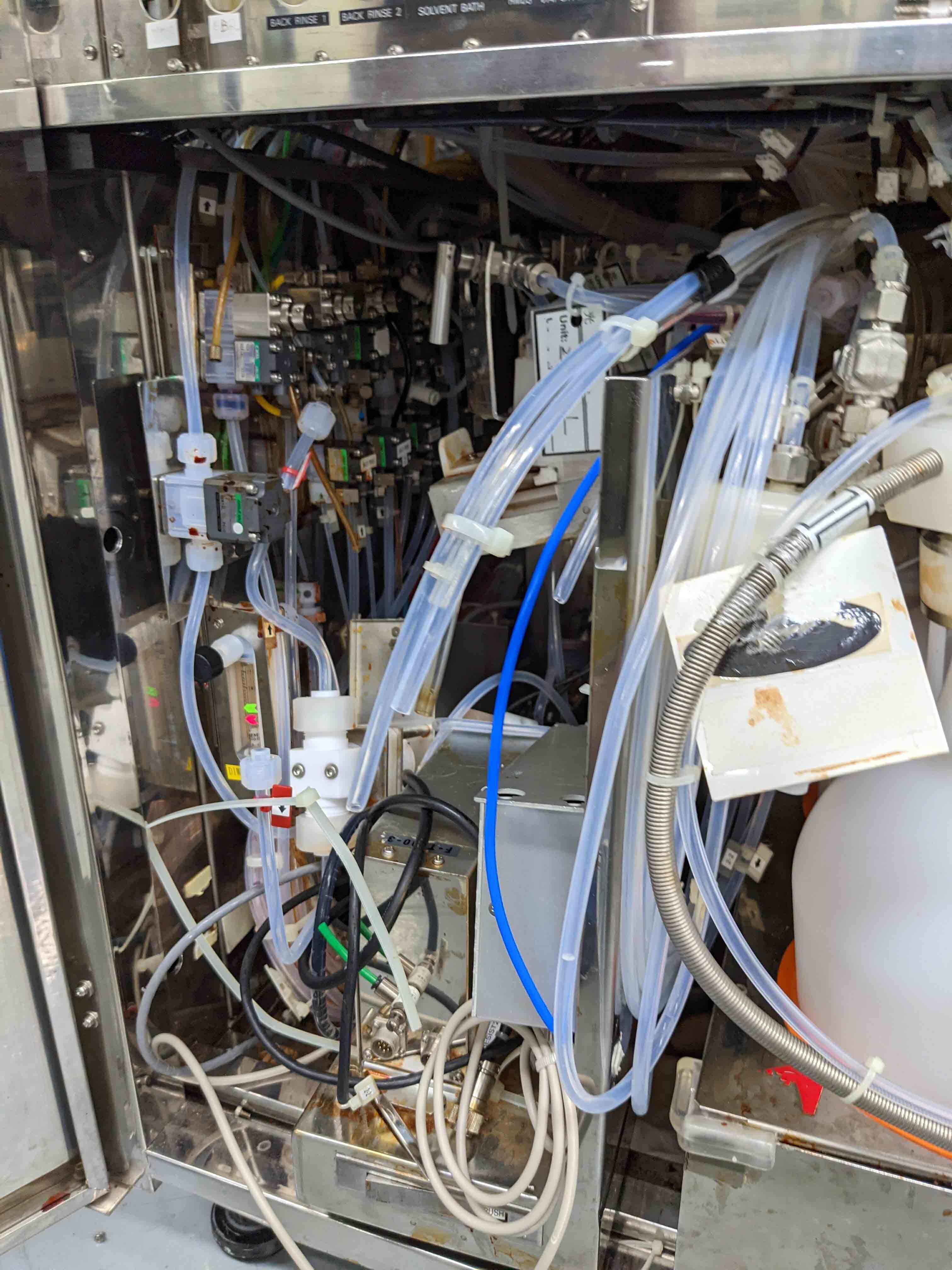

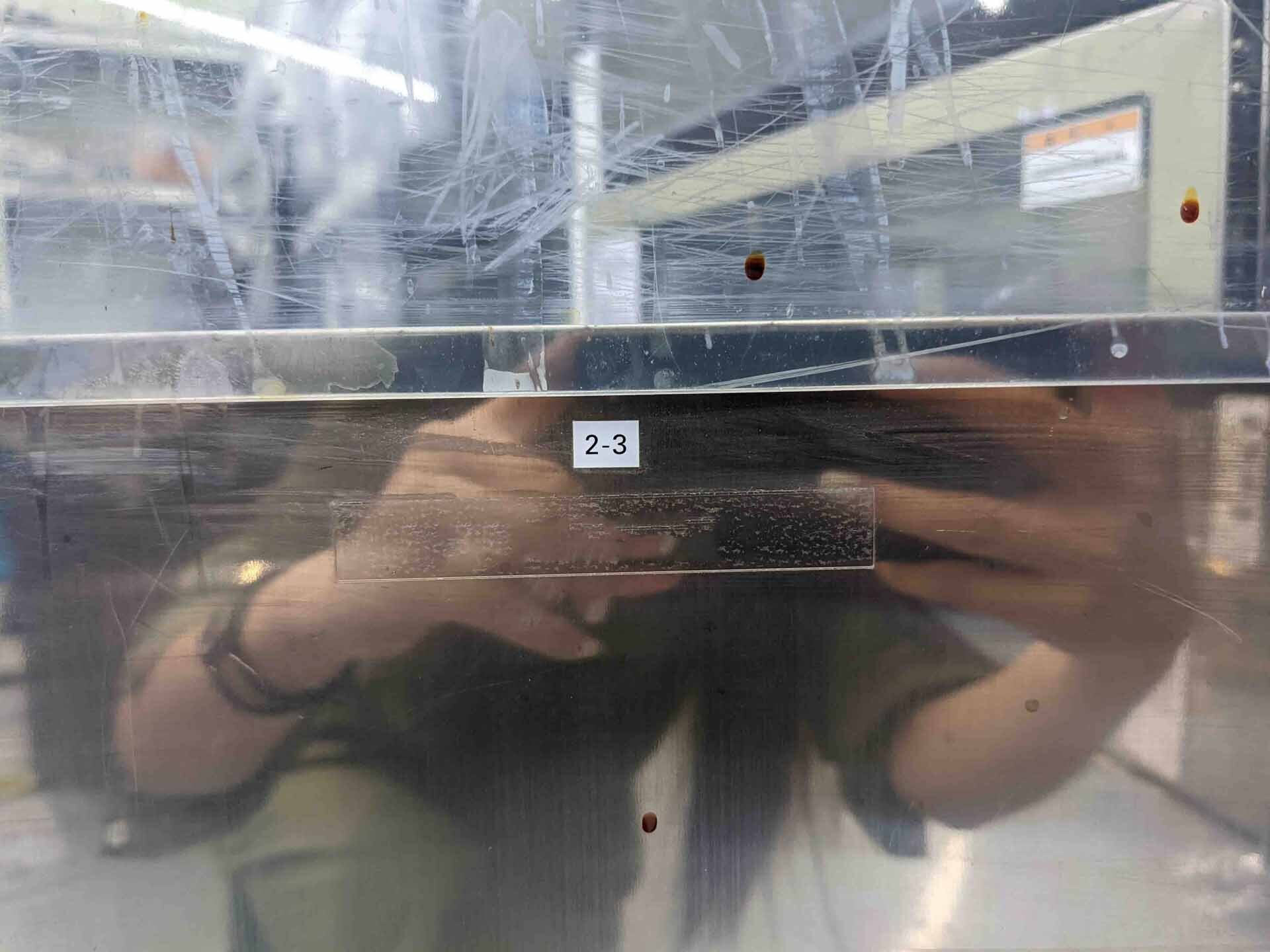

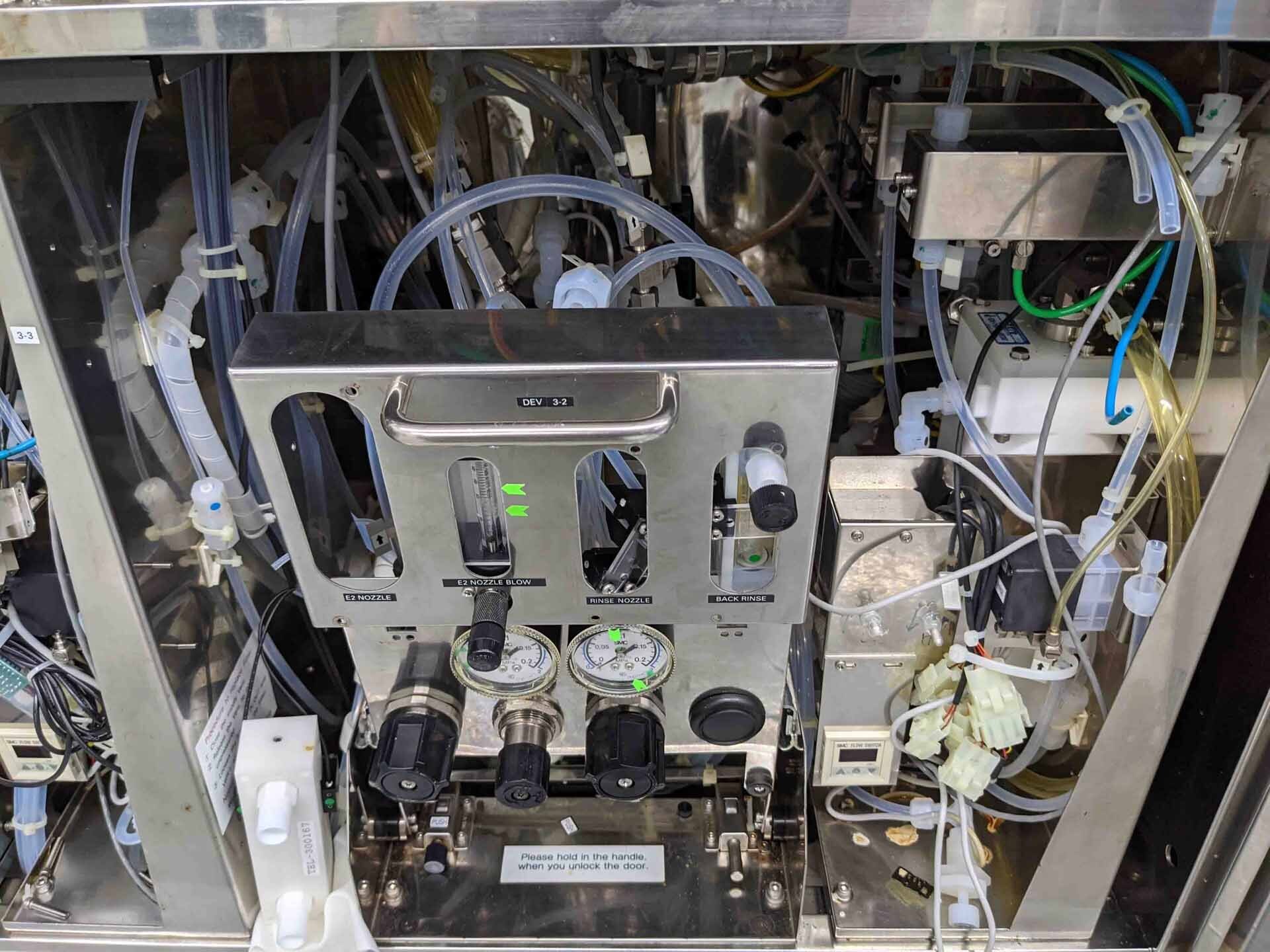

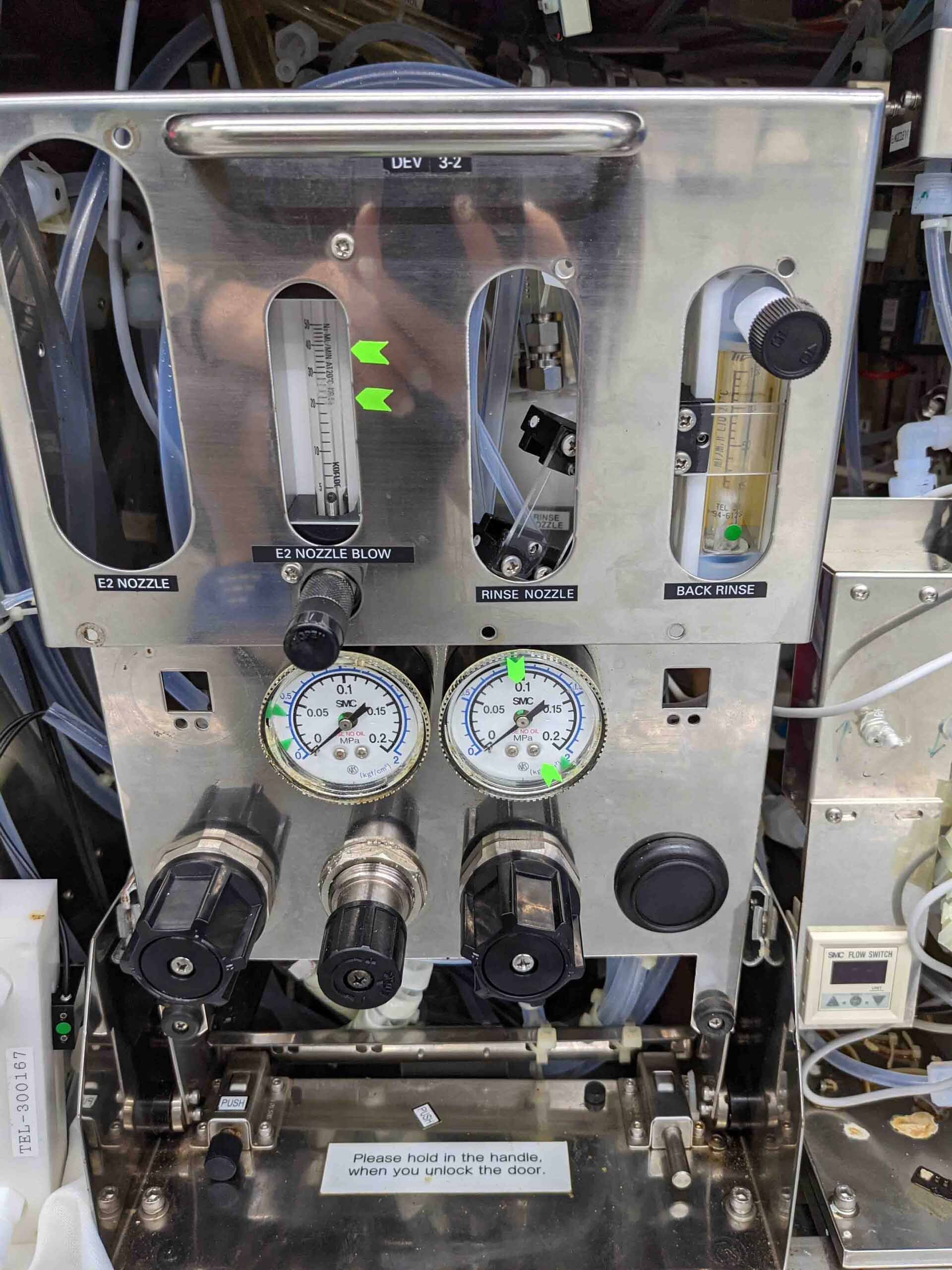

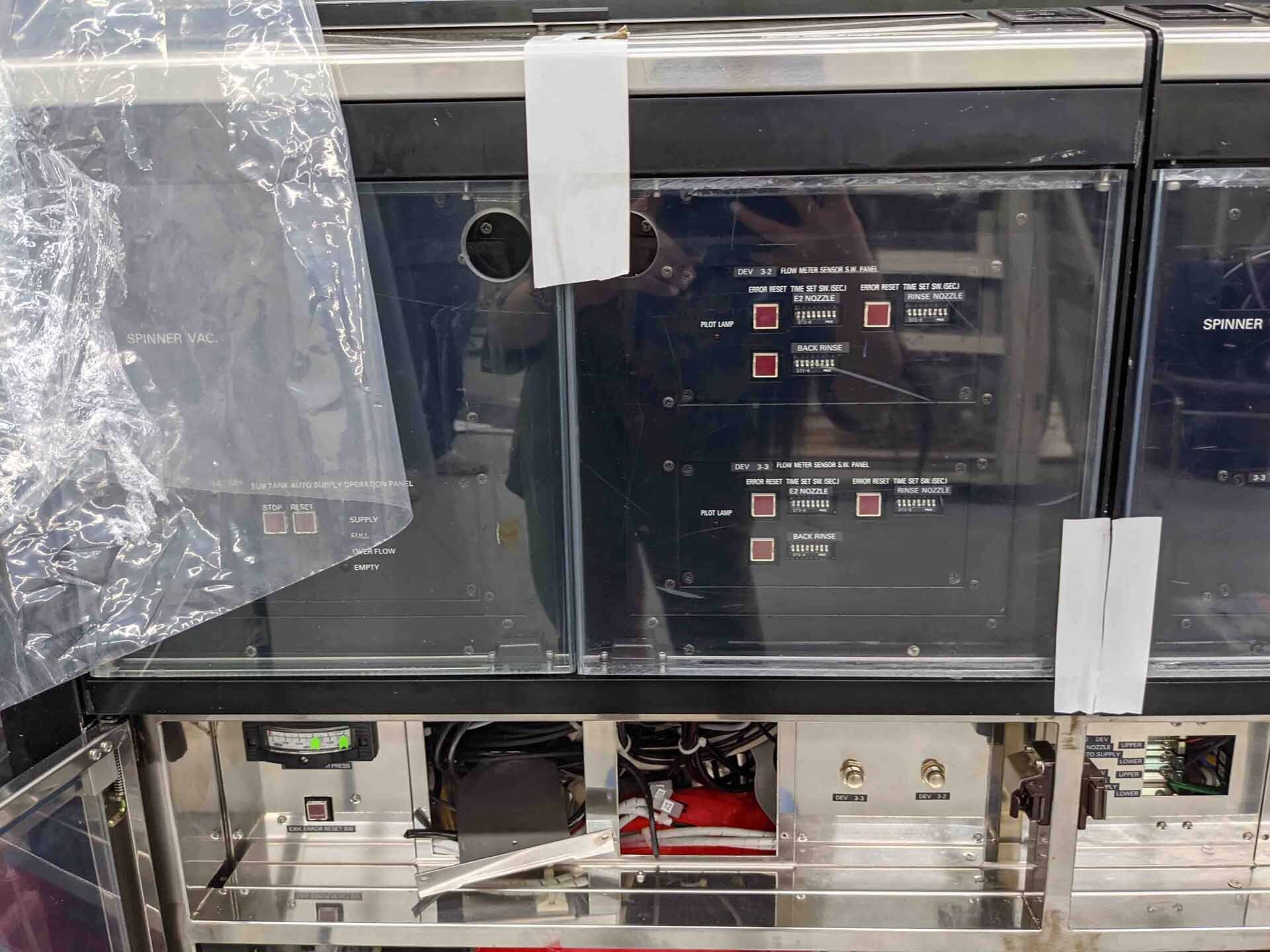

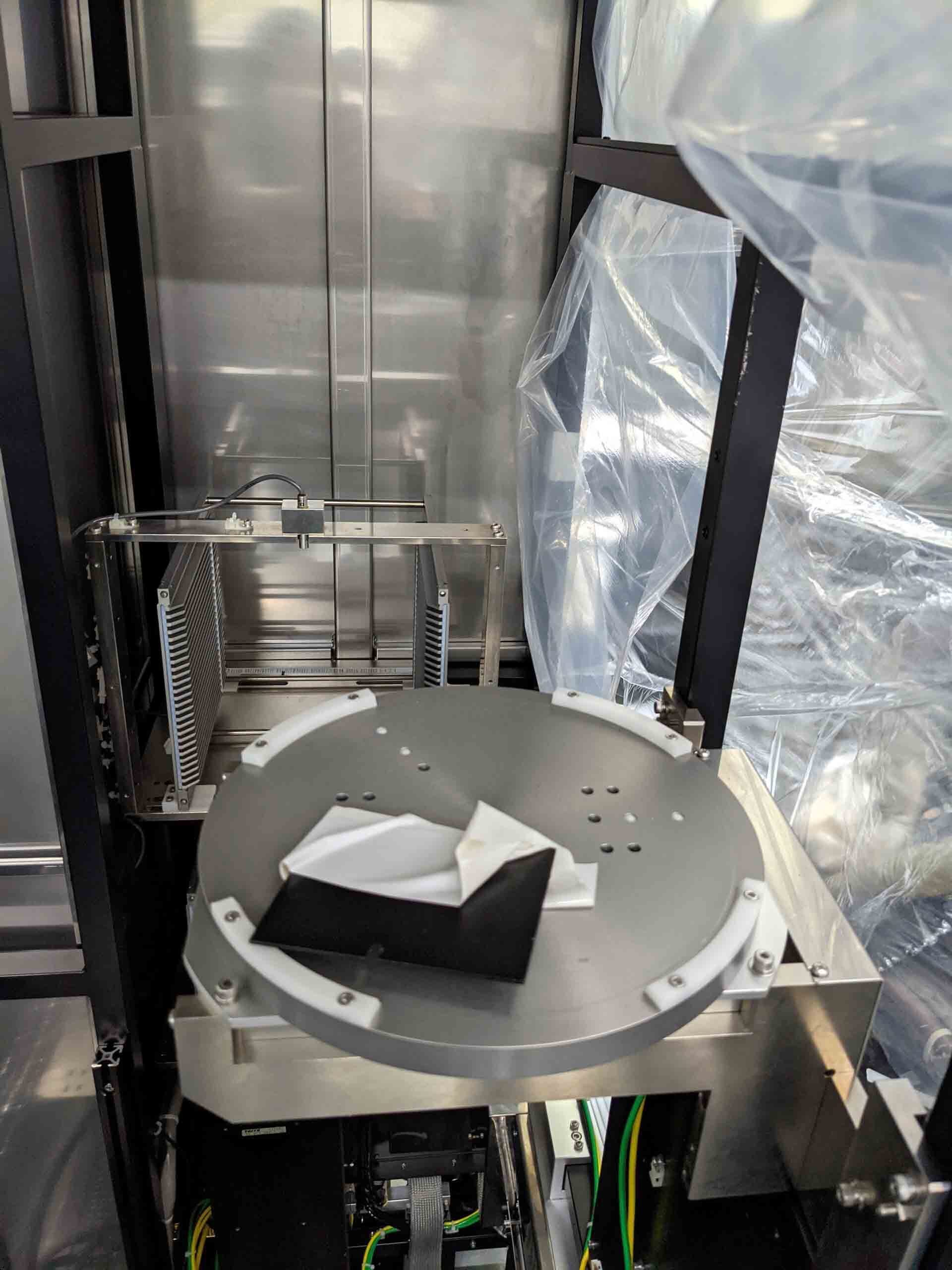

Developer 3-1, 3-2 Unit:

Single E2 nozzle

Dual top rinse nozzles

Back rinse nozzles

Developer temperature control

Motor flange temperature control

Drain type: Direct gravity

Auto damper

Auto dummy dispense system

Cup type: Stainless steel for upper and PP for inner

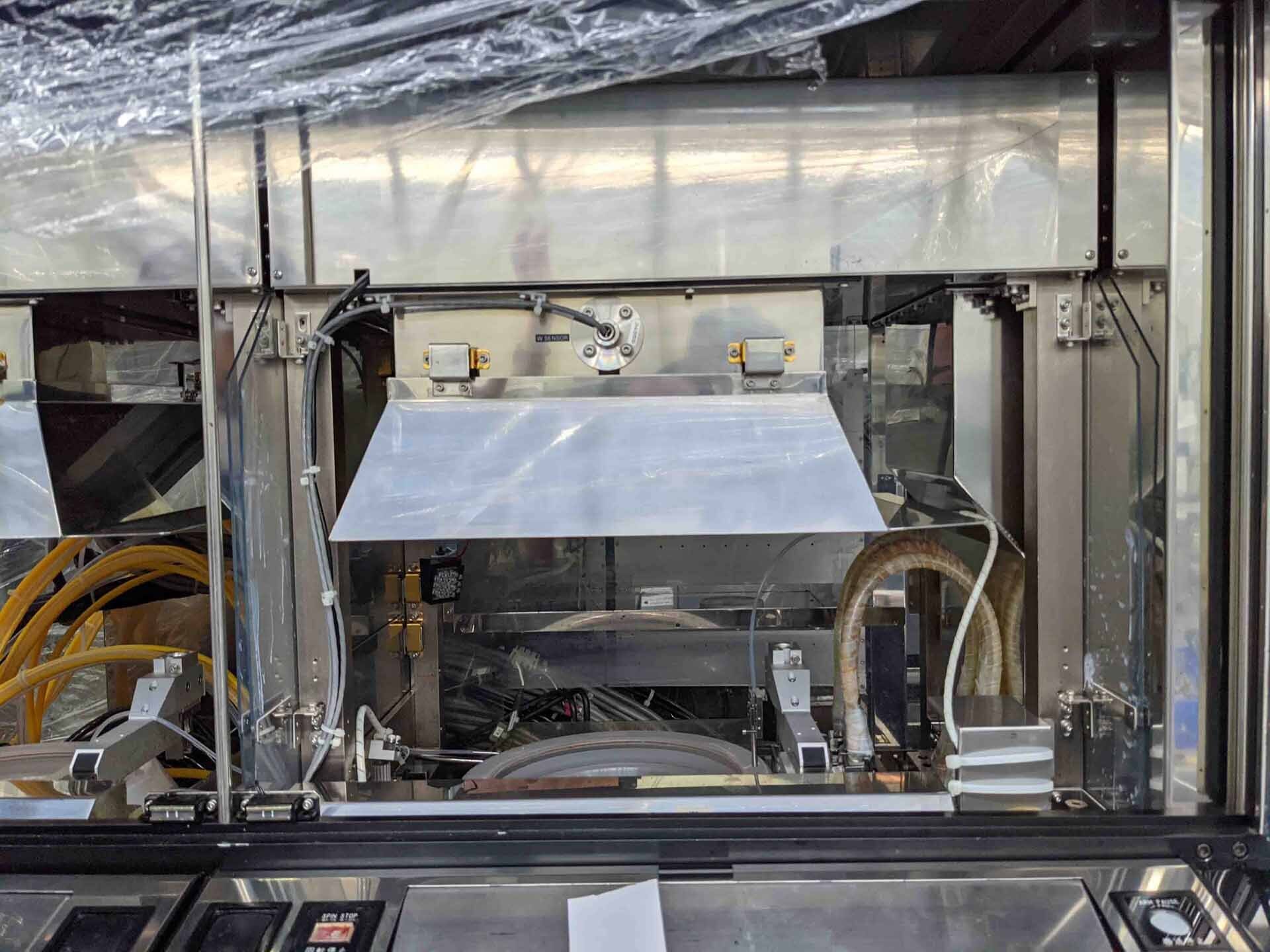

(2) Low temperature ovens (LHP)

(4) Cool plate units

SHINWA Temperature and Humidity Controller (THC): 2-CUP

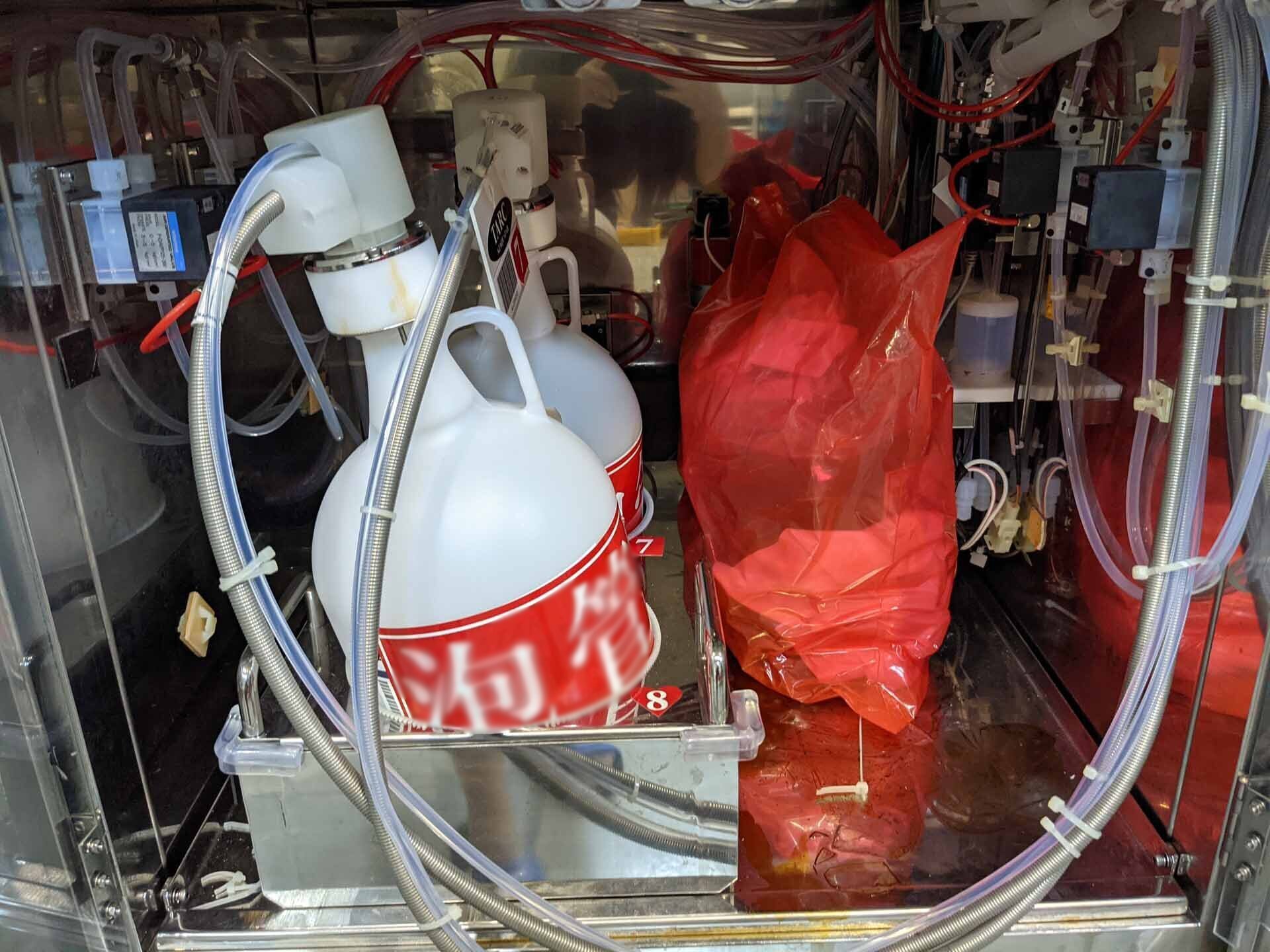

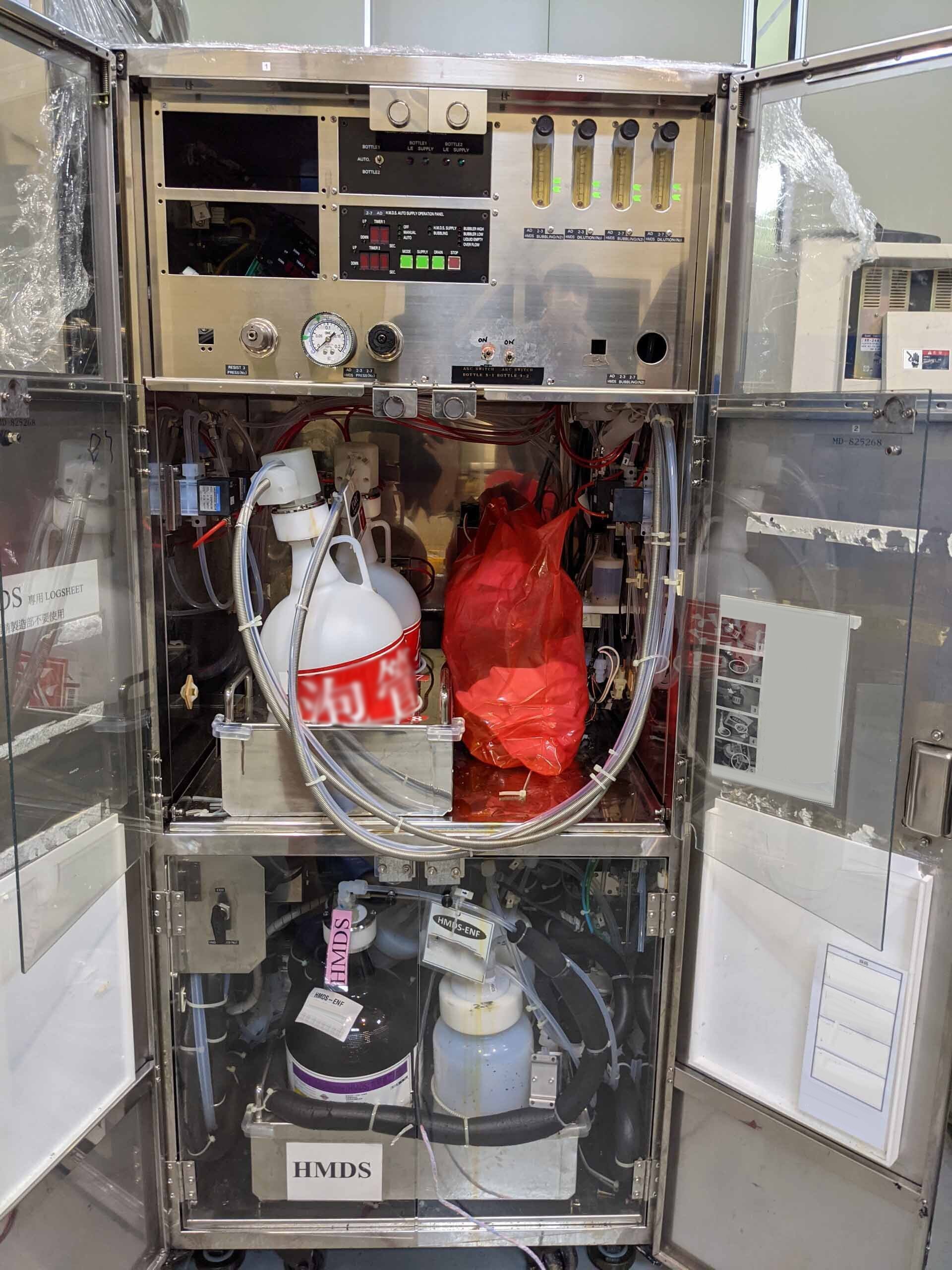

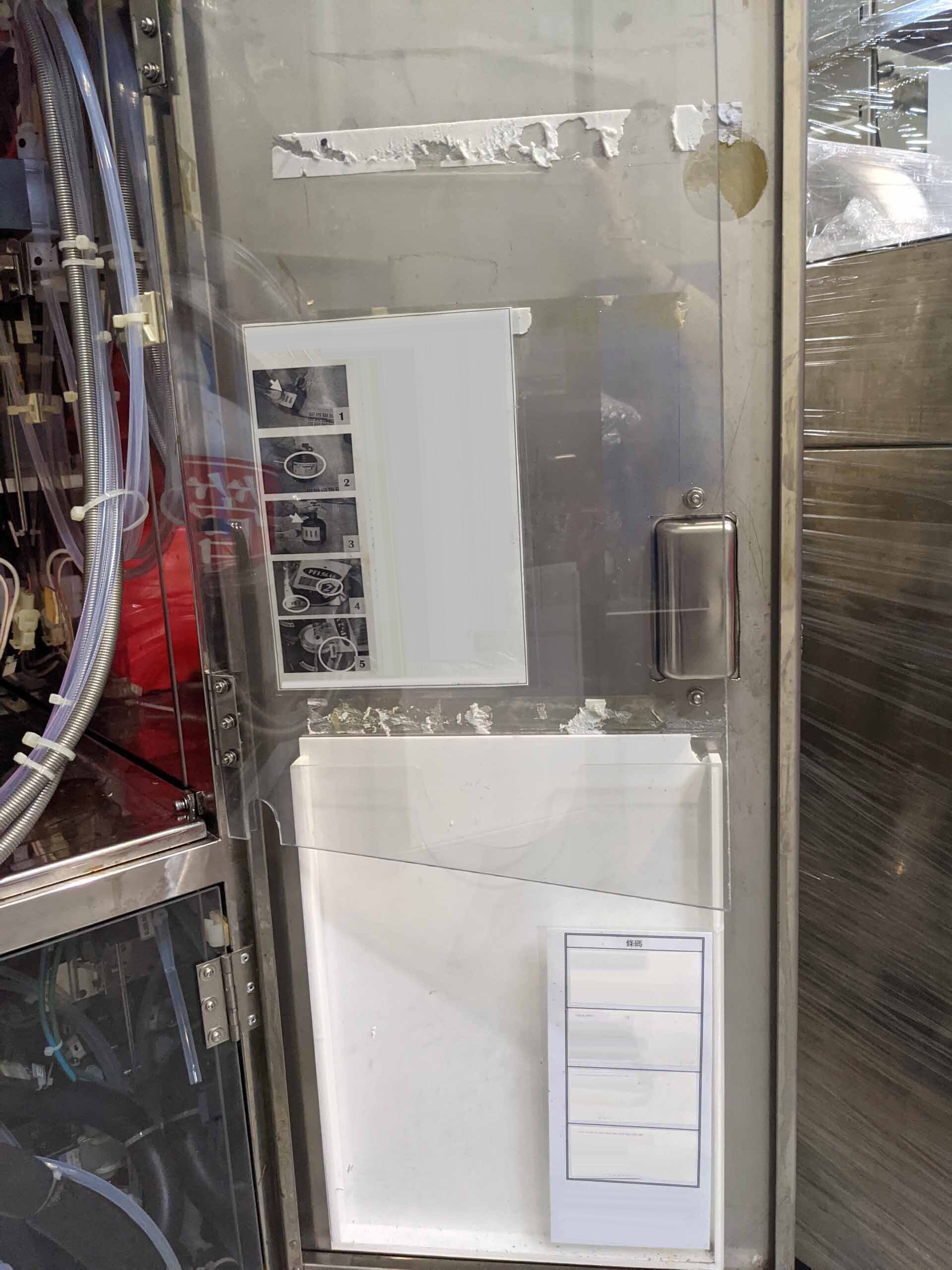

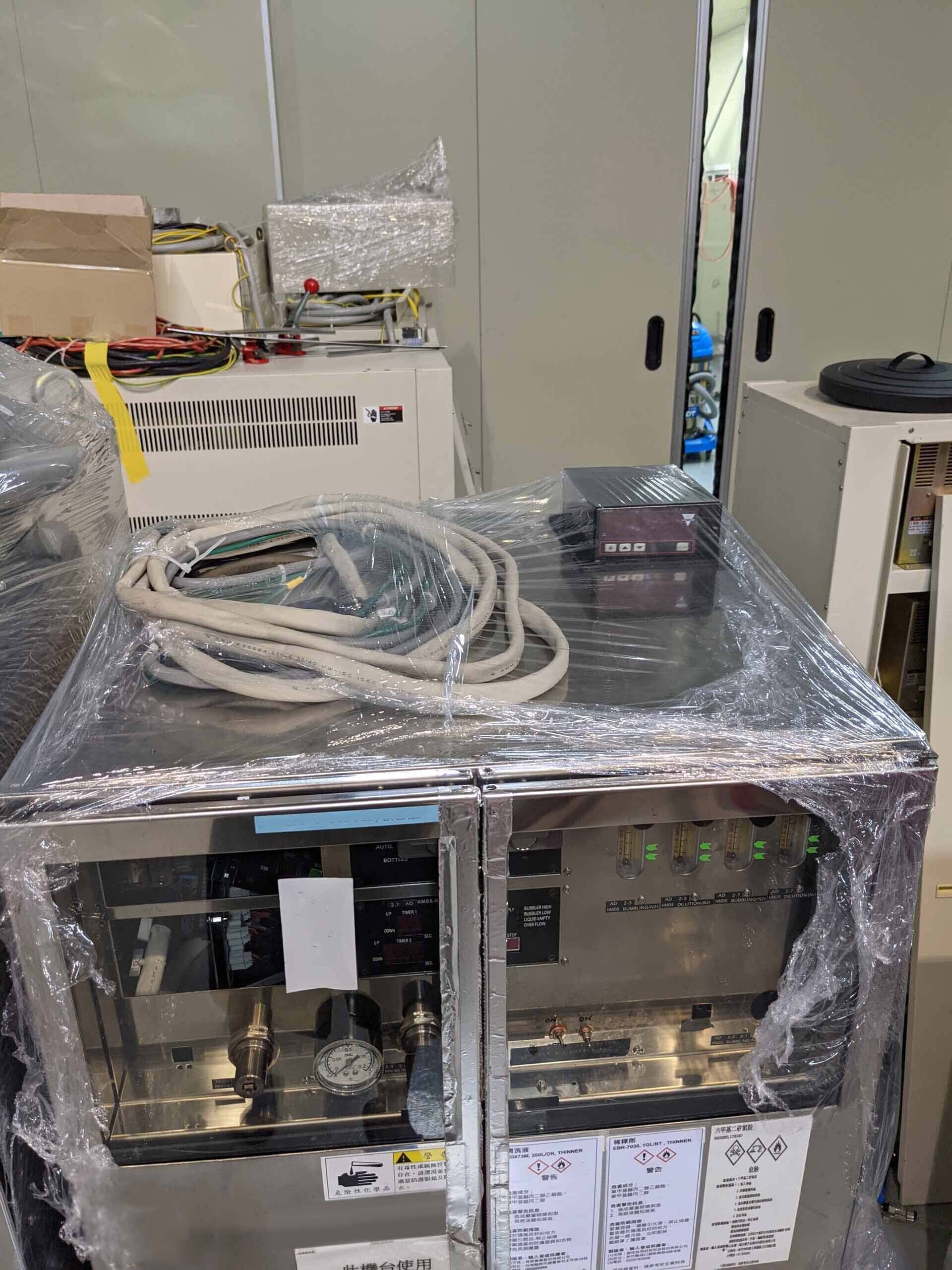

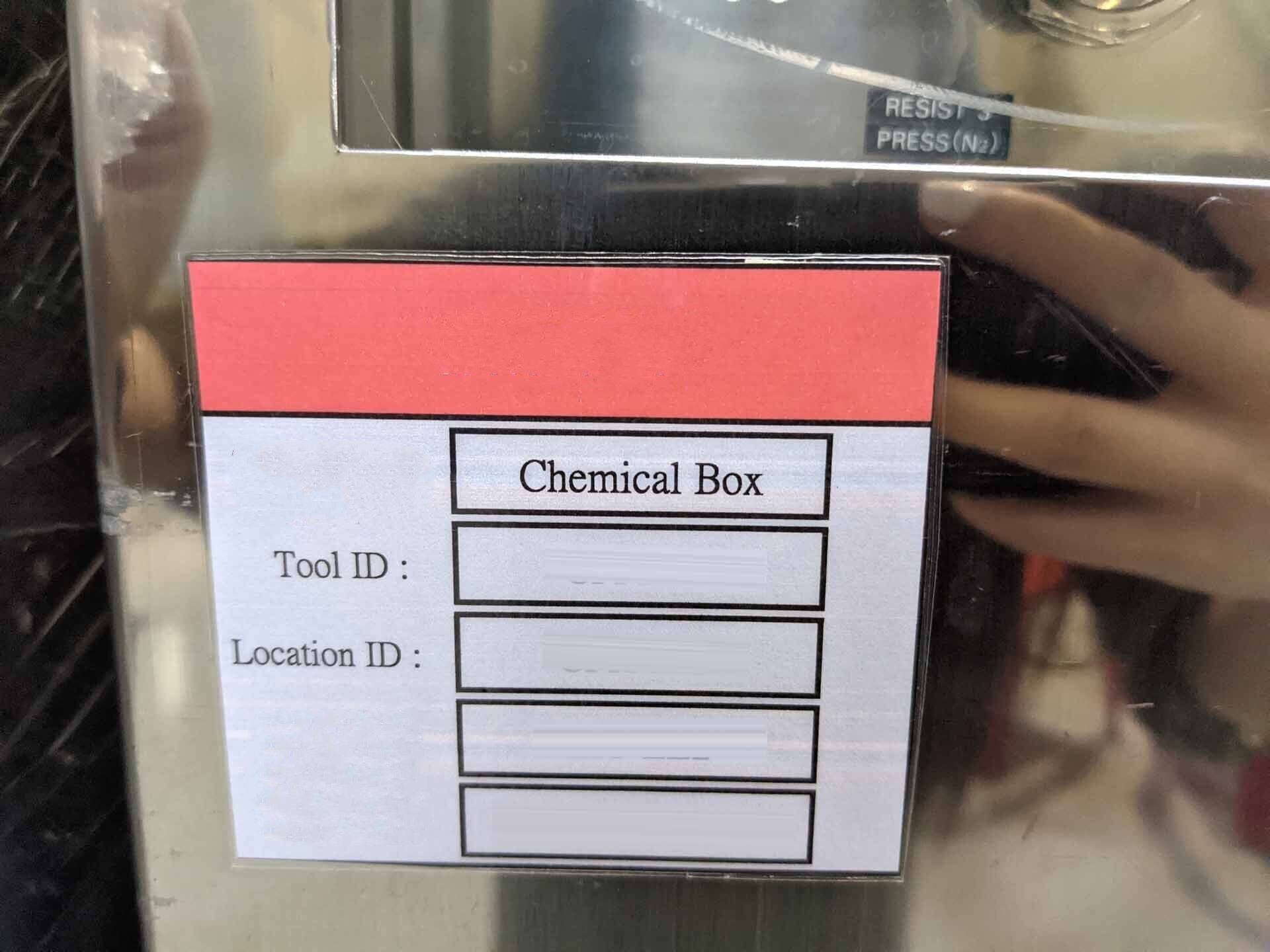

External chemical supply system:

Section-1: Solvent supply system

Solvent chemical type:

Chemical Center Supply System (CCSS)

With (2) of 3-litres teflon buffer tank

Type: (2) Buffer tanks (3litre/Tank, teflon) (2) Coaters

Tank auto switch off / Exchange

Section 2: Develop:

Develop chemical type

Chemical Center Supply System (CCSS)

With (2) of 3-litres teflon buffer tank to cover (2) DEV Units

Tank auto switch-off / Exchange

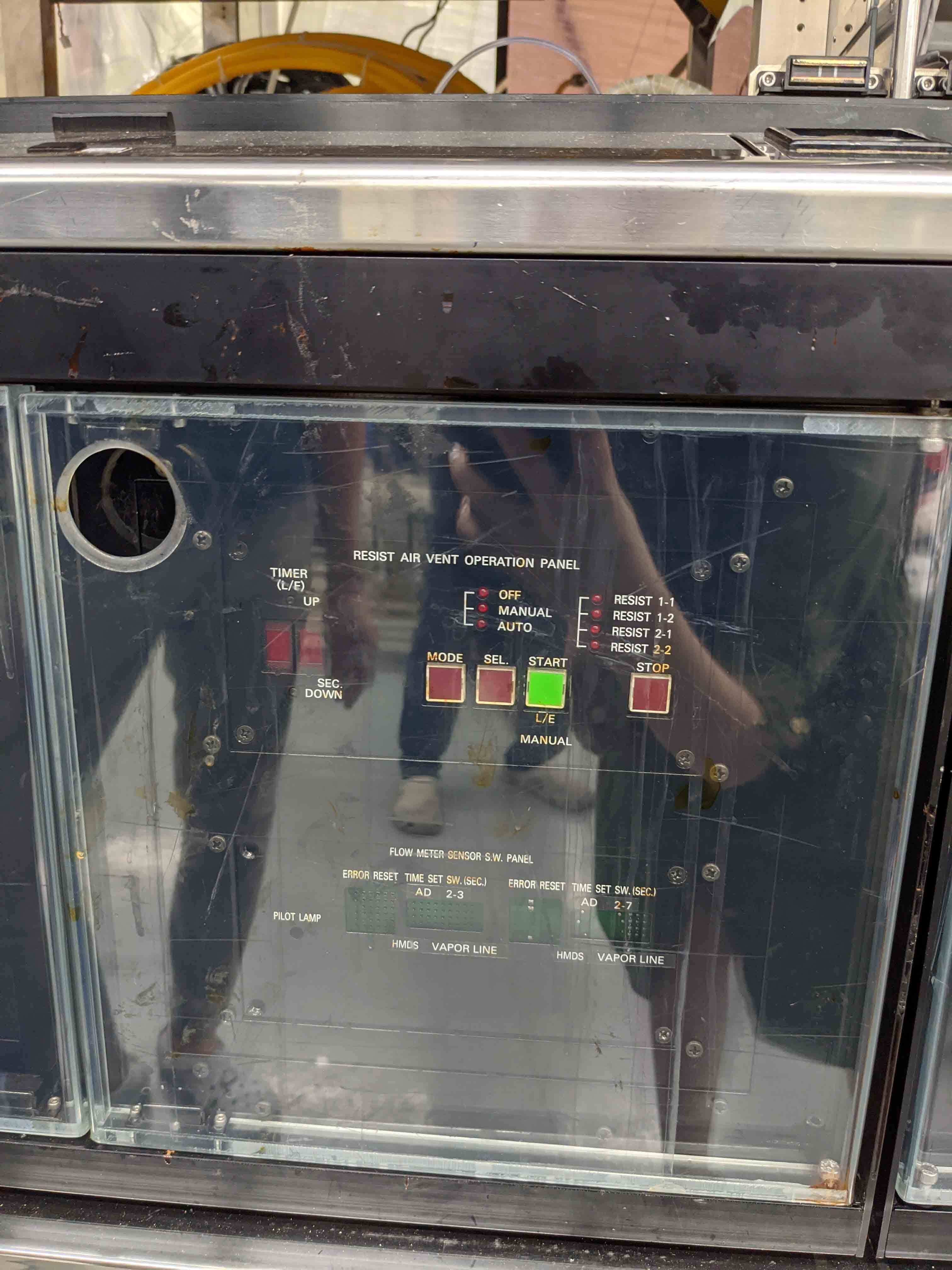

HMDS Supply system for 2 AD Unit:

Chemical type

1/4-Gal bottle

With 1L Buffer tank per ADH

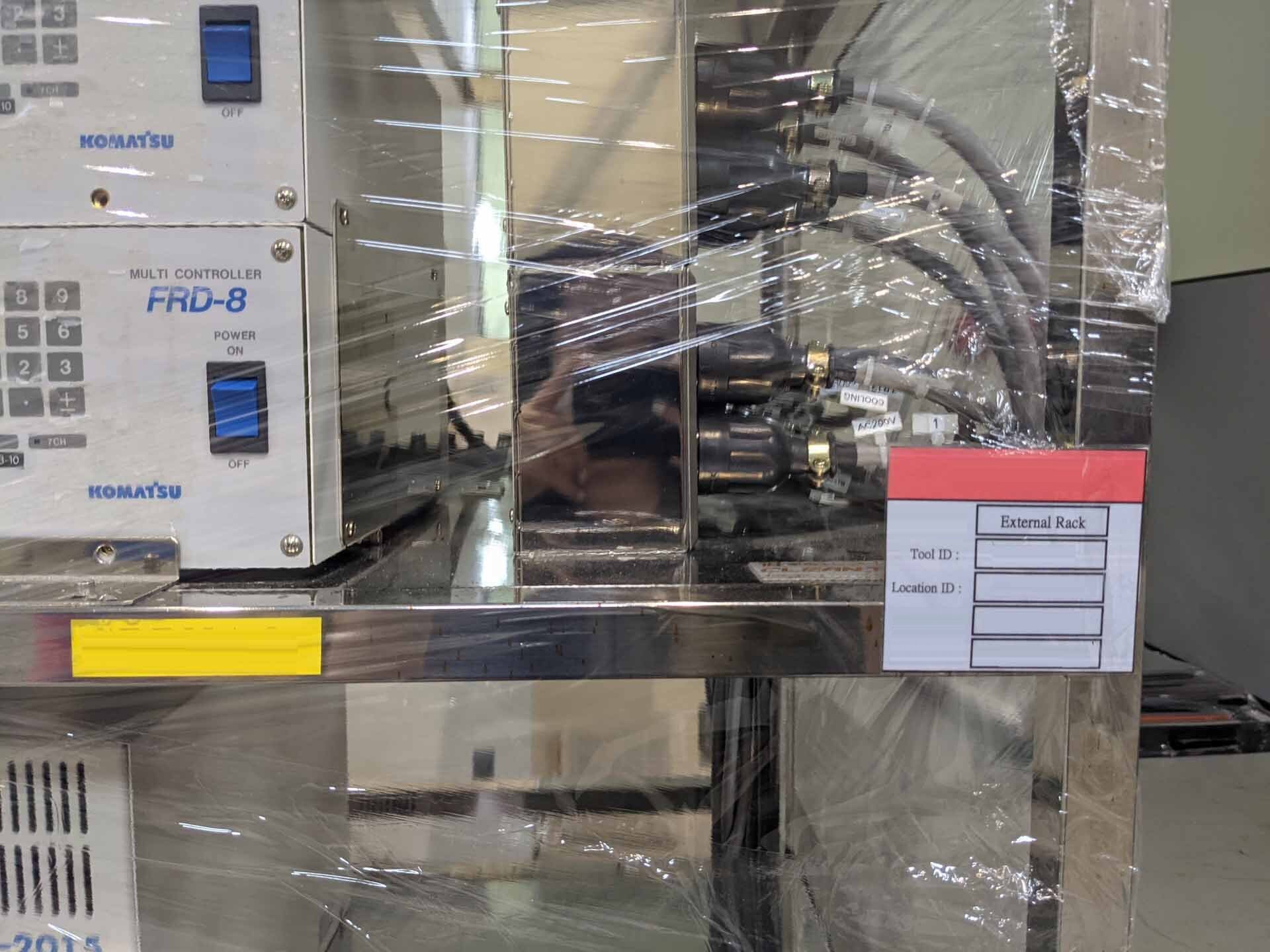

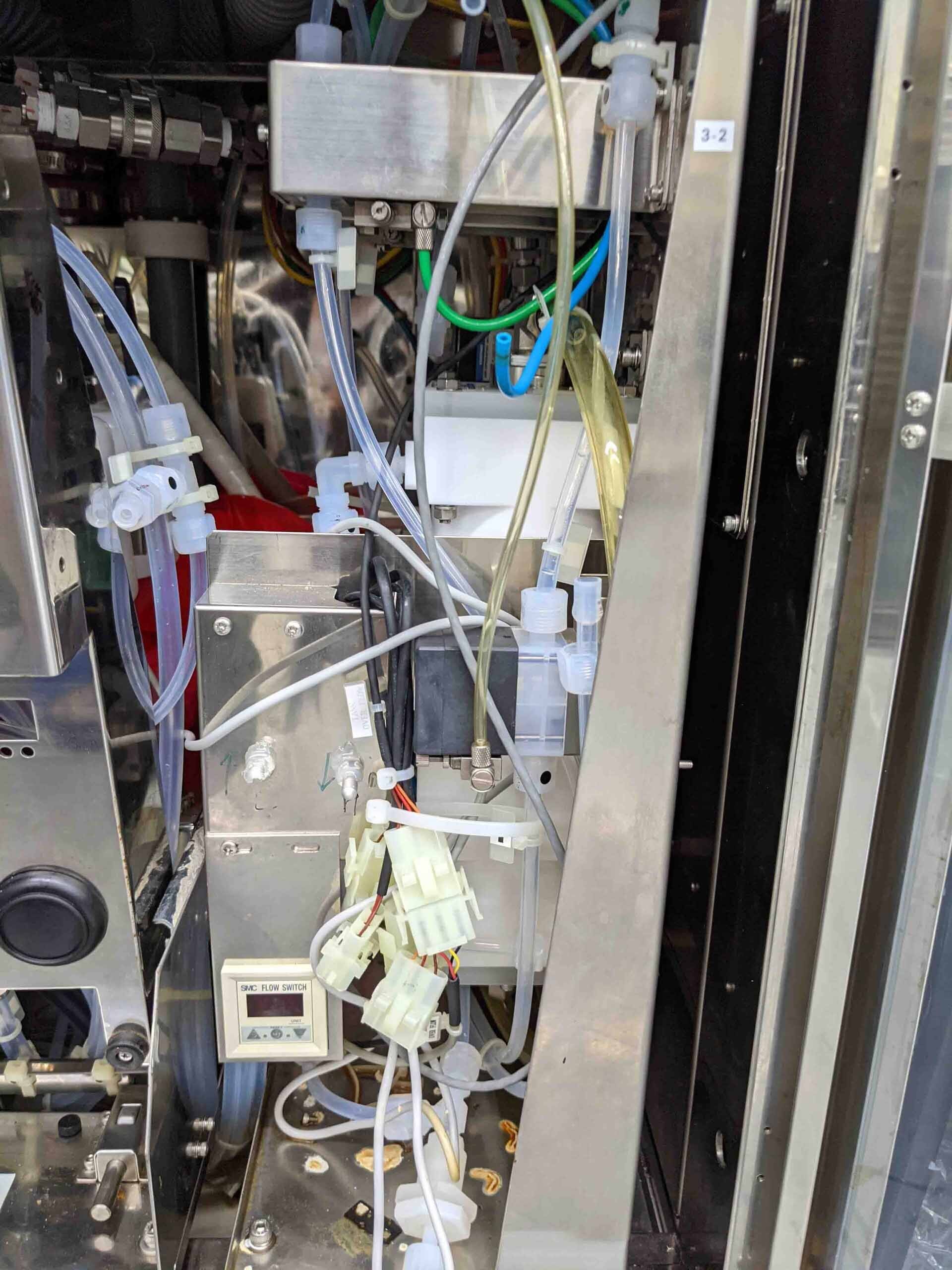

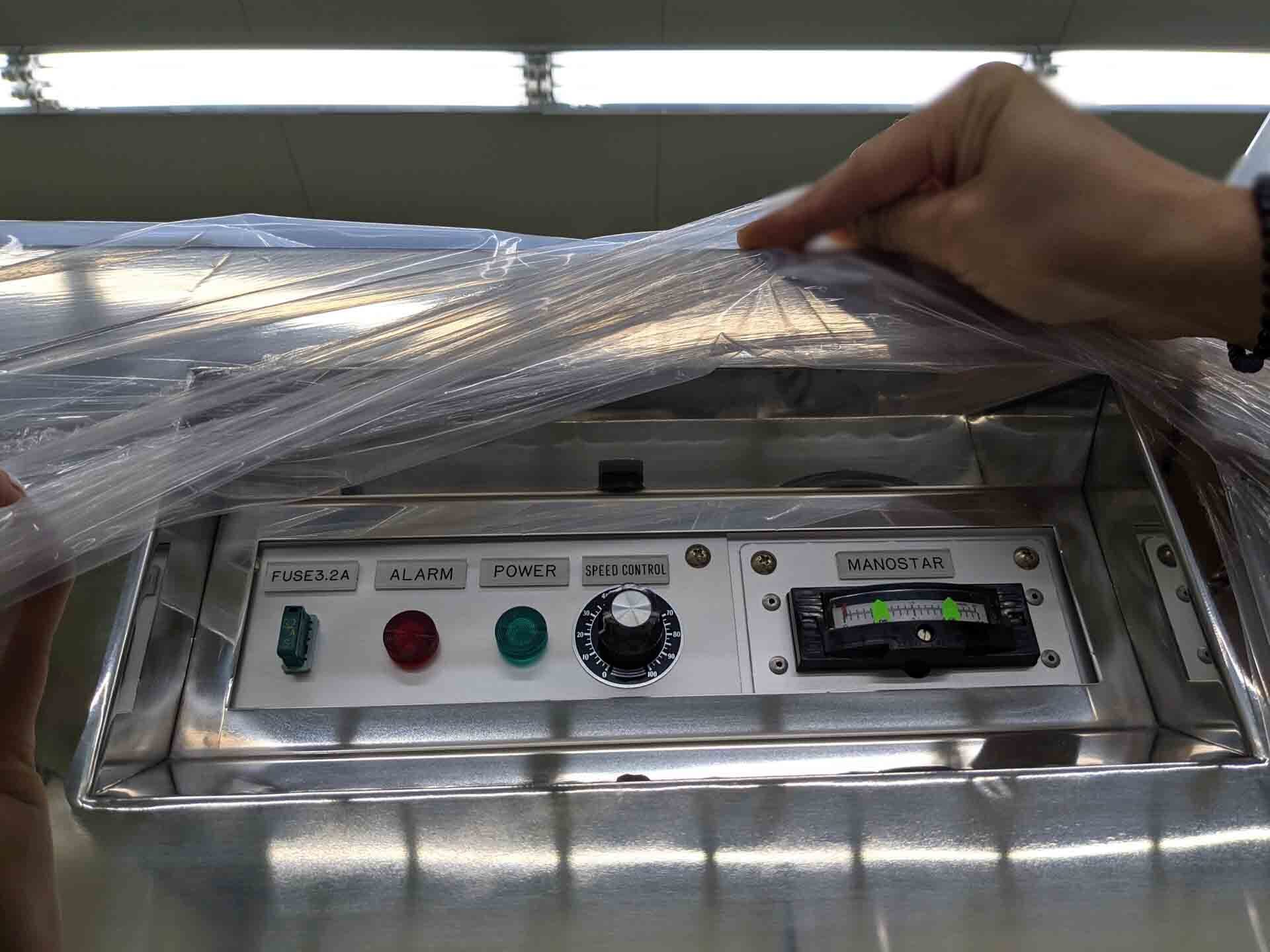

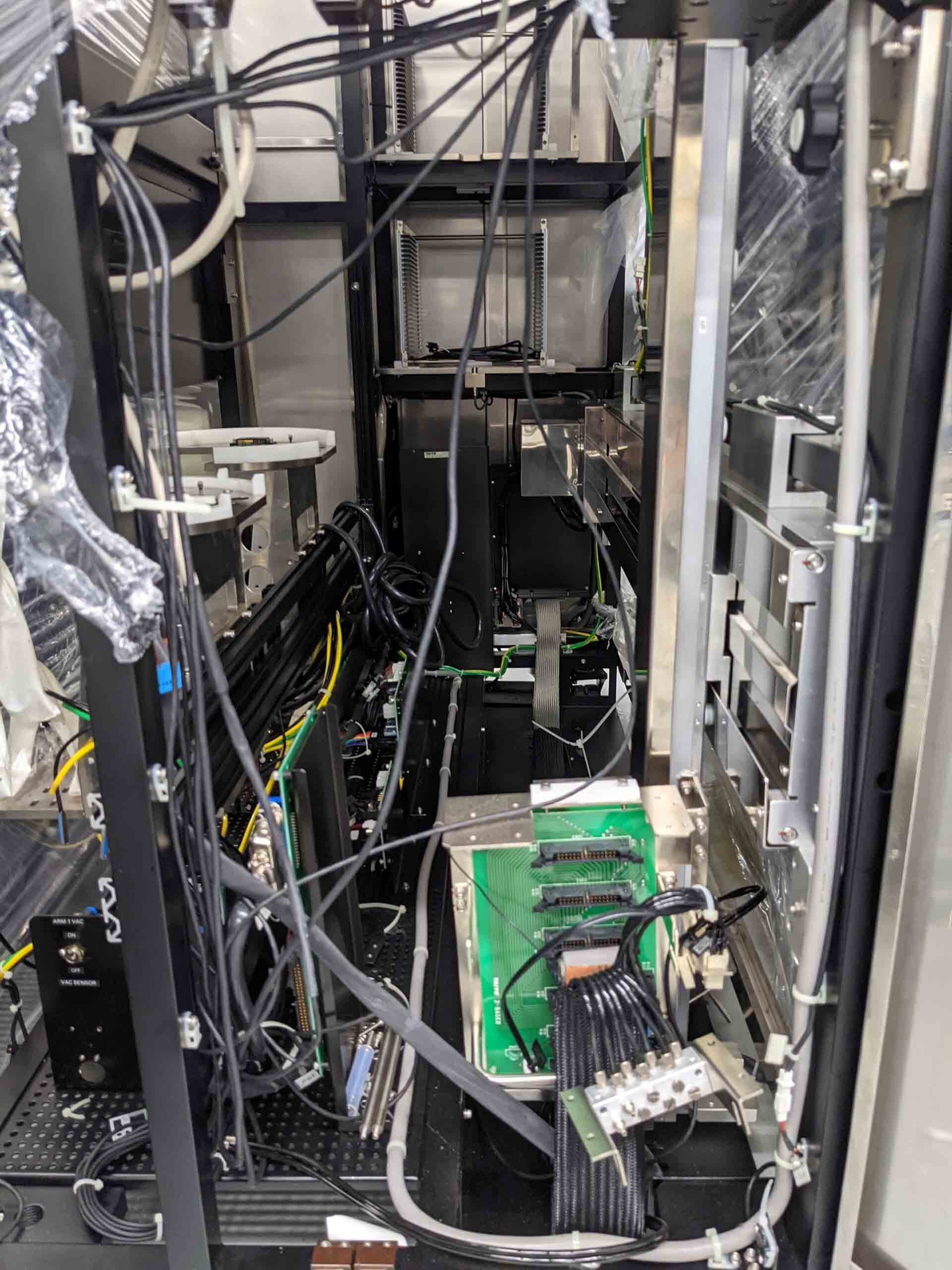

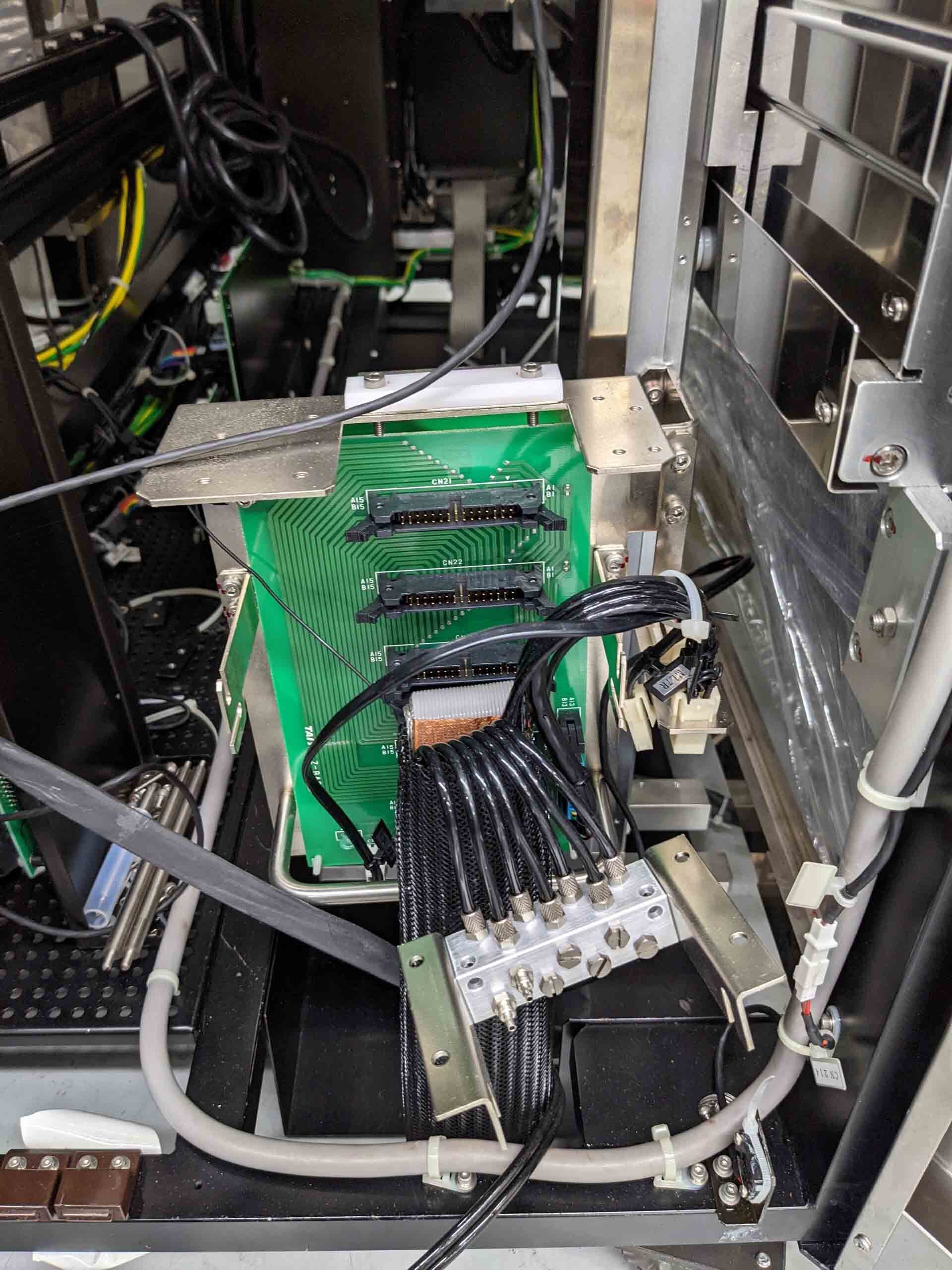

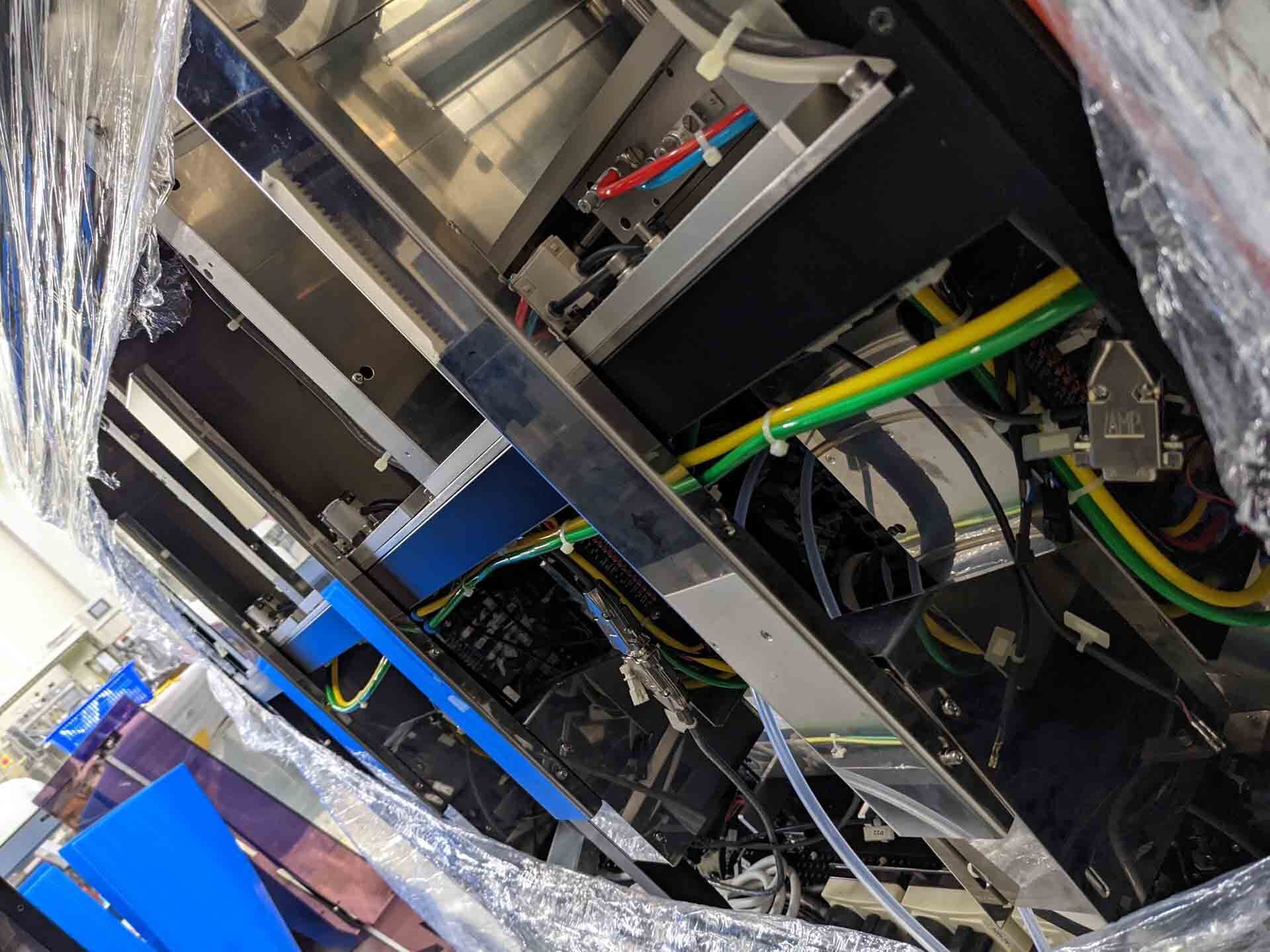

SMC Multi controller: Rear mail body

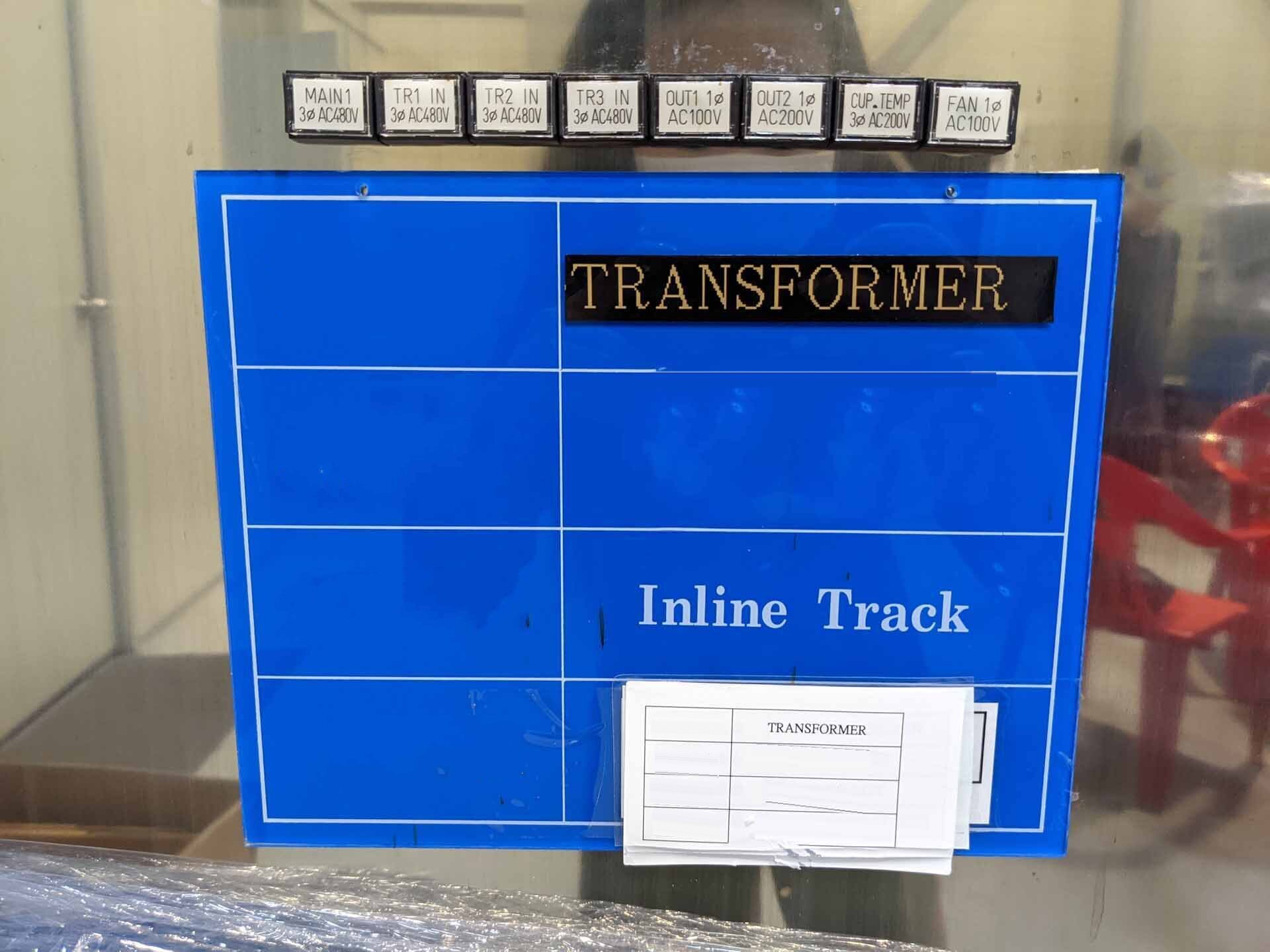

Power transformer AC cabinet : 208 VAC, 3 Phase, 50/60 Hz

ASML

(6) Hot transfer plates: HP3-4 / HP3-5 / HP 3-7 / HP 3-8 / HP2-4 / HP 2-8

(5) Cold transfer plates: COL2-9 / COL2-10 / COL3-6 / COL3-9 / COL3-10

Does not include Hard Disk Drive (HDD)

Missing parts:

CSB Unit:

X, Y, Z Theta motor

Y, Z Motor driver

FFU

COAT 2-1:

EBR Cylinder

Spin chuck

RRC Pump

Spin motor driver

Spin connection board

VAC Sensor

(4) Solenoid valves

COAT 2-2:

EBR Cylinder

Spin chuck

RRC Pump

Spin motor driver

VAC Sensor

(11) Solenoid valves

DEV 3-1:

DEV Spin motor and driver

DI Rinse arm cylinder

Spin unit base assembly

DEV Cup

Spin chuck

Spin connection board

Solenoid valve mainfold

VAC Sensor

D.I Rinse flow meter

(4) Flow meter sensors

DEV 3-2:

DEV Spin motor and driver

DI Rinse arm cylinder

Spin unit base assembly

DEV Cup

Spin chuck

Spin connection board

VAC Sensor

IFB:

Arm assembly

(2) Trabot arms for ASML

Y, Z Motor driver

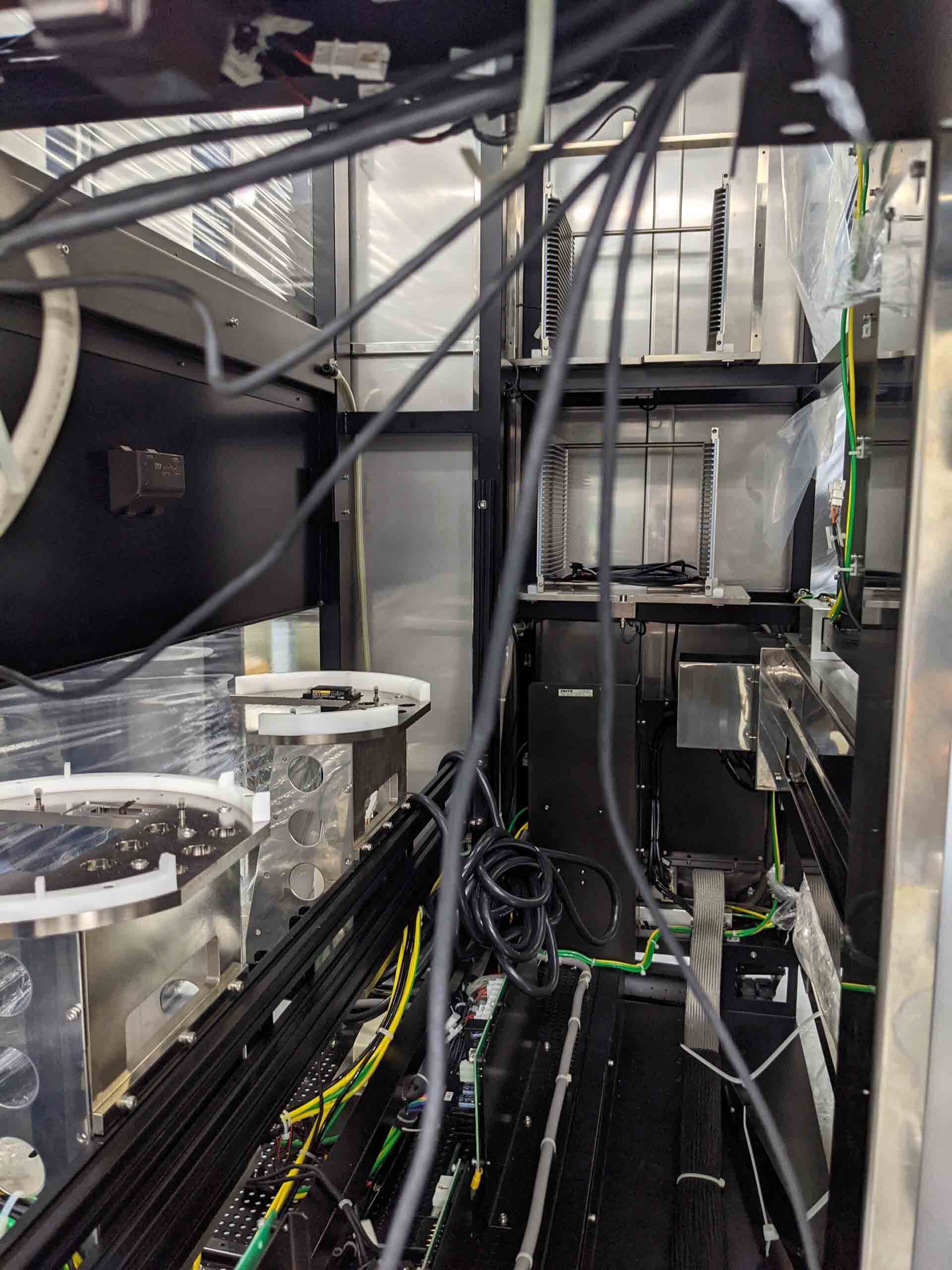

2-Block system:

FFU

Main arm assembly

Y, Z Motor driver

SIMF Card

TVME Card

(2) AD Units

HP Unit

Circulator pump

(10) DC Power fuses

3-Block system:

FFU

Main arm assembly

Y-Z Motor driver

TVME Card

(2) CP Units

(2) CPL Powers

(3) HP Units

Circulator pump

(10) DC Power fuses

WEE Lamp house

(2) Temperature and humidity controllers

1995 vintage.

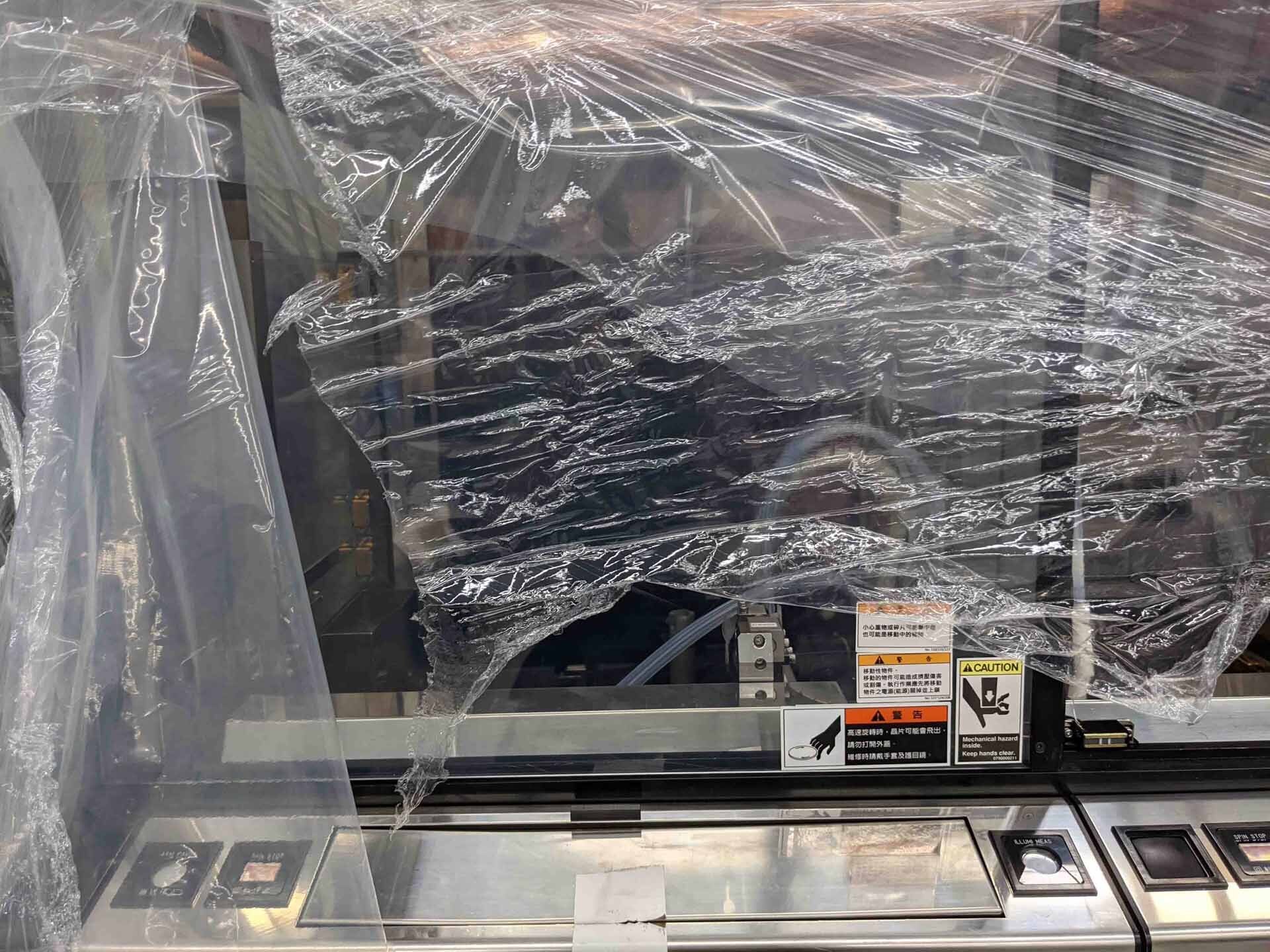

TEL / TOKYO ELECTRON Clean Track Mark 8 is an automated photoresist equipment for advanced semiconductor device fabrication, developed and manufactured by TEL. It is an integrated high throughput system providing a consistent, high quality production process with improvements in both speed and accuracy. The unit is equipped with robust, efficient cleaning and coating technologies, designed to minimize particle generation and minimize residues. The core of the machine is the Clean Track chamber, which is designed to hold wafers in place and ensure repeatability during the fabrication process. The chamber utilizes advanced chamber cleaning technology and a combination of plasma treatment, chemical cleaning and advanced coating technologies to reduce particles and other residues. The Mark 8 tool is further equipped with a variety of automated functions including, automatic substrate transfer and handling, an automated recipe asset, automated substrate verification, and automatic data logging of each substrate processed. The model is able to process different substrate sizes, substrate types and shapes with high precision. The equipment also features an advanced nozzle design to facilitate optimal coating and spraying of the photoresist material. Additionally, it is equipped with advanced particle detection systems to ensure that substrates with high levels of particles or other residues are not further processed. TEL Clean Track Mark 8 provides a low-cost, high-quality photoresist processing solution suitable for a range of different advanced device fabrication processes. Its modular design and components enable versatility and cost-effectiveness. Advanced gas flow and humidity control provide the ideal environment for photoresist coating, and automated substrate handling minimizes contamination. The system also enables process optimization by tracking variations in substrate processing and recording real-time data.

There are no reviews yet