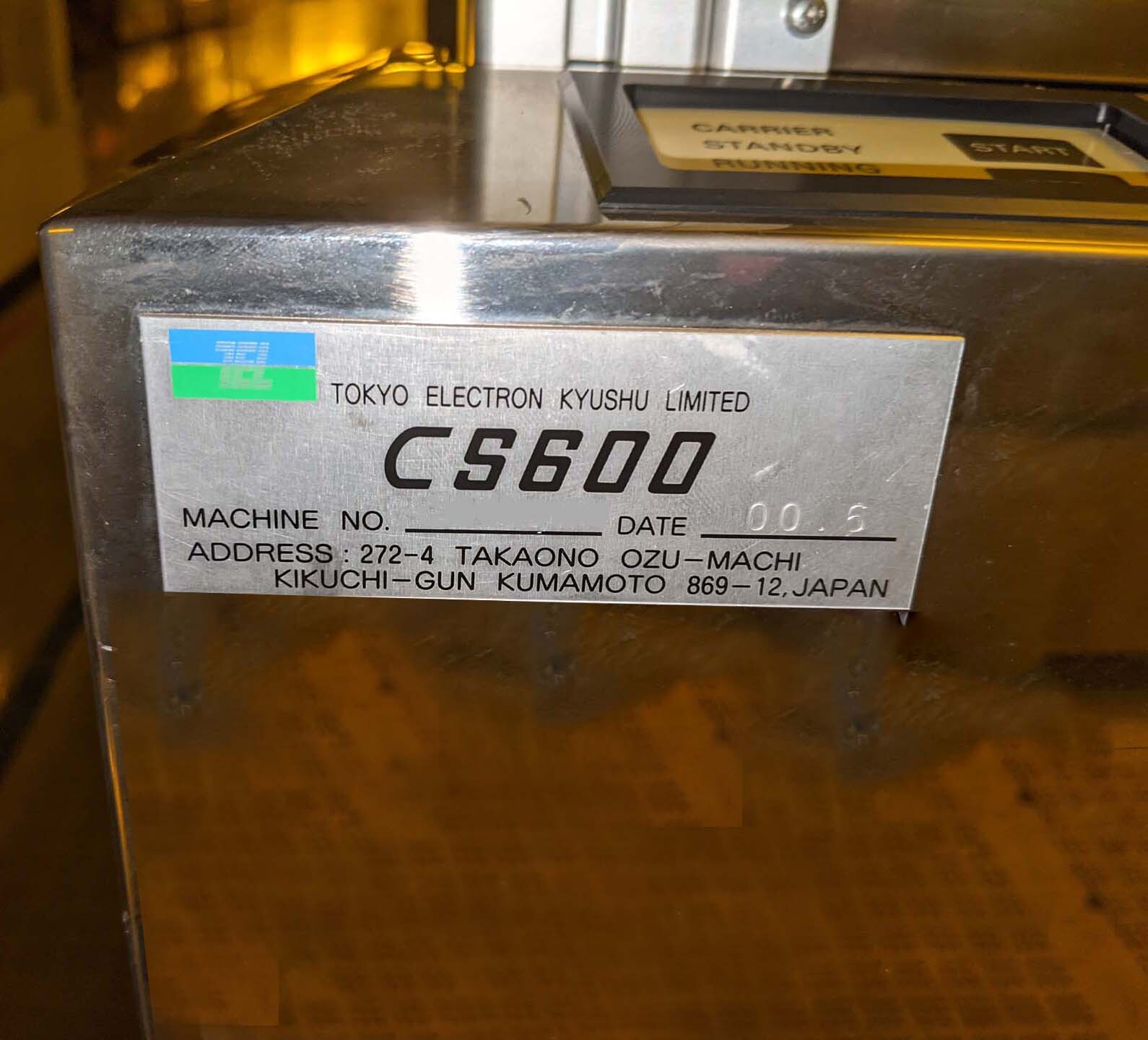

Used TEL / TOKYO ELECTRON CS-600 #9380656 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON CS-600 Photoresist Equipment is a high-tech device used in the semiconductor industry to create patterns on silicon wafers. It is used in the photolithography process, a key step in the fabrication process of semiconductor devices. TEL CS-600 is a sophisticated machine that uses chemical processes for creating intricate and uniform patterns on the wafer surface. The system features a multi-exposure capability, enabling it to deposit multiple layers of photoresist onto the wafer surface. This feature allows for the creation of exacting patterns and shapes. It also includes a resist coating and metrology inspection suite. The coating station dispenses photoresist onto the wafer surface and the metrology station inspects the resist layers 100 percent in-situ for high accuracy and repeatability. TOKYO ELECTRON CS-600 utilizes a state-of-the-art, high-speed precision mask-alignment unit. The machine's automated pattern recognition allows it to accurately read the mask patterns and accurately align itself, eliminating errors and inaccuracy. The highly precise alignment feature helps the tool produce patterns that eliminate misregistration errors and yield higher yields at production rates. CS-600 also features a fully automated setup and control asset. It enables operators to perform process recipes automatically and with repeatability. The model also makes it easer for operators to maintain and monitor the machine's health and performance. TEL / TOKYO ELECTRON CS-600 runs on a computer equipment, making it easy for users to interact with the hardware and access output data. It is also an extremely reliable system, designed to meet the most stringent wafer manufacturing requirements. It is also a very efficient unit, consuming a limited amount of space and providing fast and reliable patterning. Overall, TEL CS-600 Photoresist Machine is a highly sophisticated and reliable device used in semiconductor production. It enables users to accurately produce patterns in a short amount of time, while maintaining a high level of precision and repeatability.

There are no reviews yet