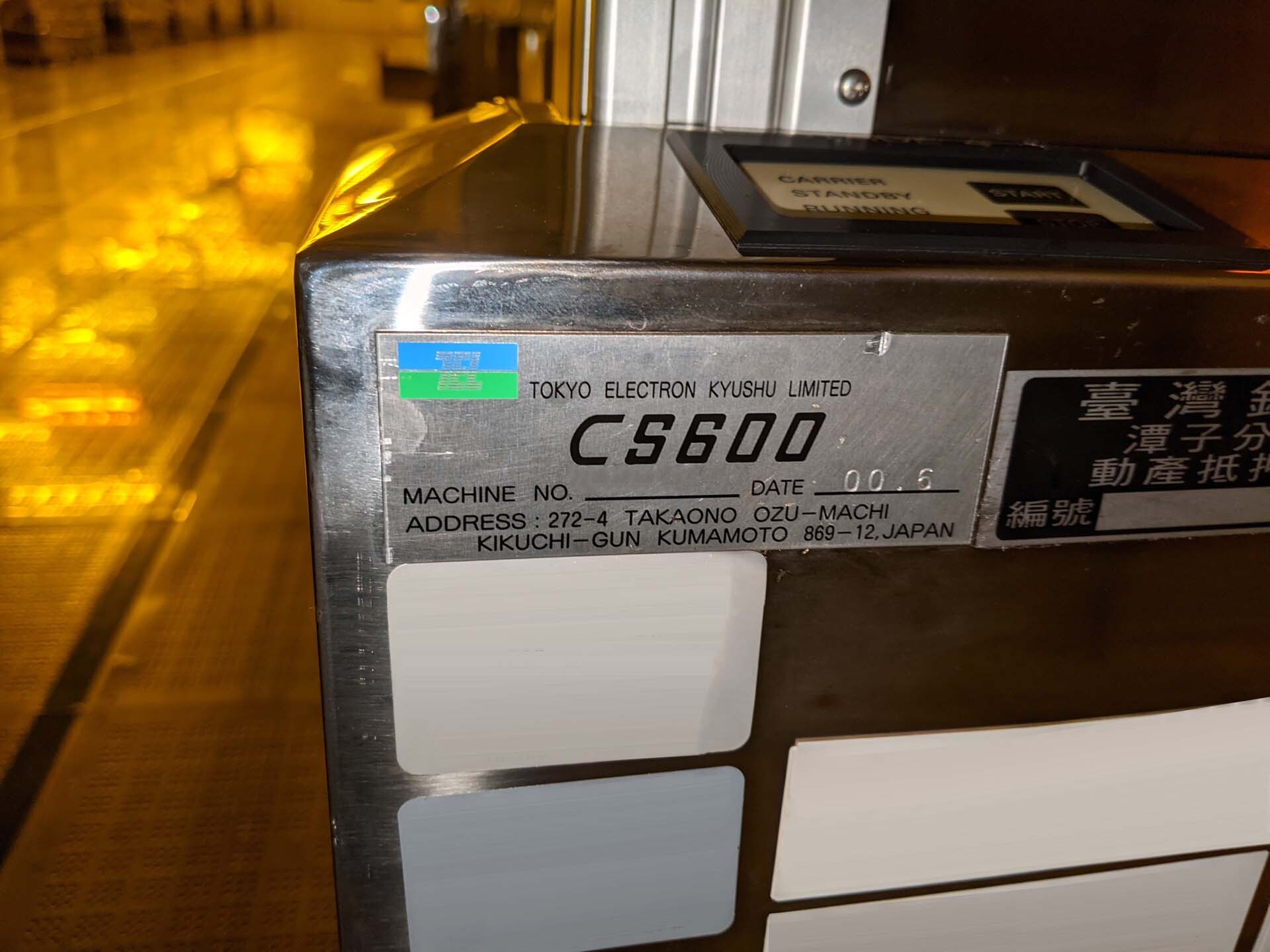

Used TEL / TOKYO ELECTRON CS-600 #9380670 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON CS-600 Photoresist Equipment is a complete lithographic suite that is based on the highly accurate and productive CS300 system. This unit uses a state-of-the-art excimer laser source for the lithography and a four-zone baking module for the resist uniformity and post-exposure baking. It is specifically designed for high-volume production of integrated circuits such as memory, logic, and CMOS devices. TEL CS-600 utilizes an advanced laser projection alignment detector to achieve accurate and precise alignment of the mask to the substrate. This advanced laser alignment technology allows for precise lithographic processing and high process yield. An autofocus detector is used to control the laser focus position and a reduced-defocus enable lens to maximize the machine's productivity. The laser exposure parameters are precisely optimized by using the laser's multi-stage emission structure and different defocus setting. The overlay accuracy of TOKYO ELECTRON CS-600 is improved by the optimizing of the laser beam spot size and the use of a double orientation mark. Furthermore, the laser source can be tailored to meet specific lithography applications. The laser is also equipped with high-power Preflash and Flood Flash features to ensure depth of field coverage. The resist processing on CS-600 is enabled with individually controlled temperature zones and uniform baking processes. The use of a high-resolution multi-zone baking module provides an improved lithographic performance and an increased process window. With the combined capabilities of laser projection alignment and the four-zone baking module, TEL / TOKYO ELECTRON CS-600 provides a robust resist process for high-volume integrated circuit manufacturing. The built-in advanced exposure control methods allows TEL CS-600 to be easily adapted to the requirements of various integrated circuit designs and fabrication processes. The wafer-to-wafer edge alignment is controlled by the tool's comprehensive wafer alignment design. The auxiliary sensing asset enhances the die-to-die alignment accuracy. TOKYO ELECTRON CS-600 also integrates a complete process control environment that enables quality control and process optimization. It is equipped with a comprehensive quality analysis model that is used to monitor the various lithographic parameters and process conditions. These data are then used to develop statistical process models that can be used for further optimization of the lithographic process. CS-600 is a highly integrated and optimized photoresist equipment for high-volume integrated circuit manufacturing applications. It is equipped with modern lithography and resist processing techniques and offers superior lithographic performance. The advanced control systems ensure that the photolithography process is optimized and quality can be maintained at the same time.

There are no reviews yet