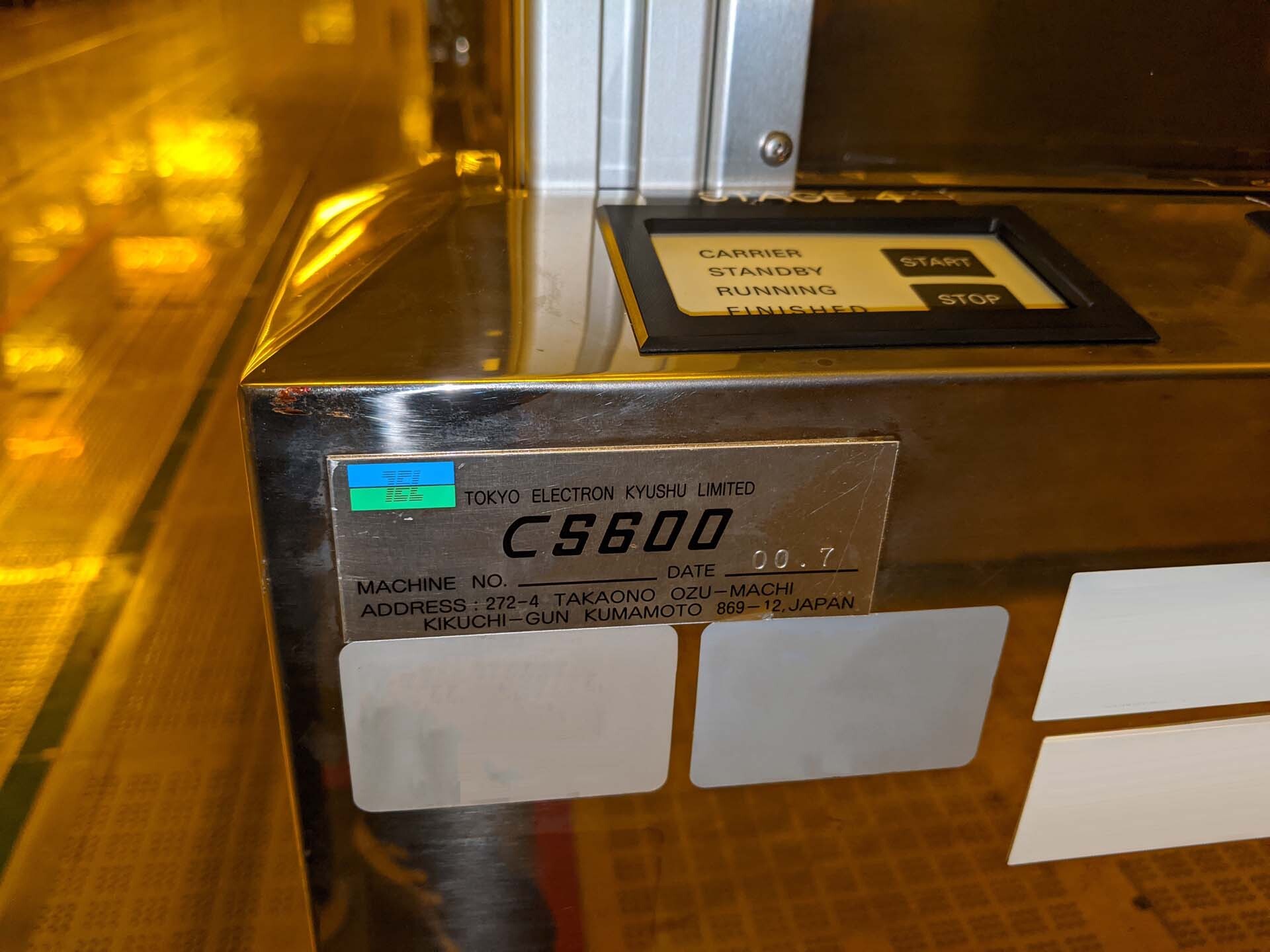

Used TEL / TOKYO ELECTRON CS-600 #9380673 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON CS-600 is a photoresist processing equipment designed for device fabrication in the semiconductor industry. The system utilizes proprietary vapor phase processes to maximize exposure uniformity, throughput, and yield for photoresist applications. TEL CS-600 is a fully integrated unit that provides a perfectly controlled process environment for complex device manufacturing. The machine is equipped with a top loader and vacuum arm which is designed to pick parts from their carrier then process them as programmed with an integrated CD/DVD burner. This CD/DVD burner provides the ability to read and store raw data before it is subjected to photomasks, which are then exposed to the resist. The CD/DVD burner also contains an enhanced data transfer mean that allows for detailed process control. The photomask is a key part of the process. Photomasks are used to limit and focus the exposure of the photoresist material. The photomasks used in TOKYO ELECTRON CS-600 feature a range of features of various sizes and shapes all designed to meet the customer's specifications. As part of this process, CS-600 utilizes a series of additional precision optical components such as lithography lenses, a glass top, mask exposure window, and an integrated mask aligner. For microlithography TEL / TOKYO ELECTRON CS-600 incorporates the AW-N120 software for image processing. This software is designed to fine-tune the image by setting laser exposure parameters, ensuring the highest degree of accuracy. After the imaging process, TEL CS-600 is equipped with an automatic laser scan calibration tool to guarantee exposure uniformity. TOKYO ELECTRON CS-600 is equipped with three baked-in processes designed to protect the photoresist from damage. By baking the photoresist surface at high temperatures during the spin-coating process, CS-600 ensures the highest quality uniformity and maximum adhesive characteristics for reliable surface adhesion. In addition, the asset is designed to incorporate a post-bake process that reflows the photoresist, further protecting the photoresist material from damage during subsequent processing. Finally, TEL / TOKYO ELECTRON CS-600 features a proprietary leveling process which employs advanced proprietary algorithms and utilizes multiple sensors to precisely apply resist to the entire substrate at a controlled uniform thickness. This is a critical feature for device manufacturing as it ensures that devices have reliable uniformity and yield. TEL CS-600 is the preferred choice for device manufacturers who require a perfectly controlled process environment and higher resolution imaging for complex device fabrication. With its precise performance, controlled environment, and automated processes, TOKYO ELECTRON CS-600 is perfectly designed for semiconductor professionals who work with high-resolution photomasks for device production.

There are no reviews yet