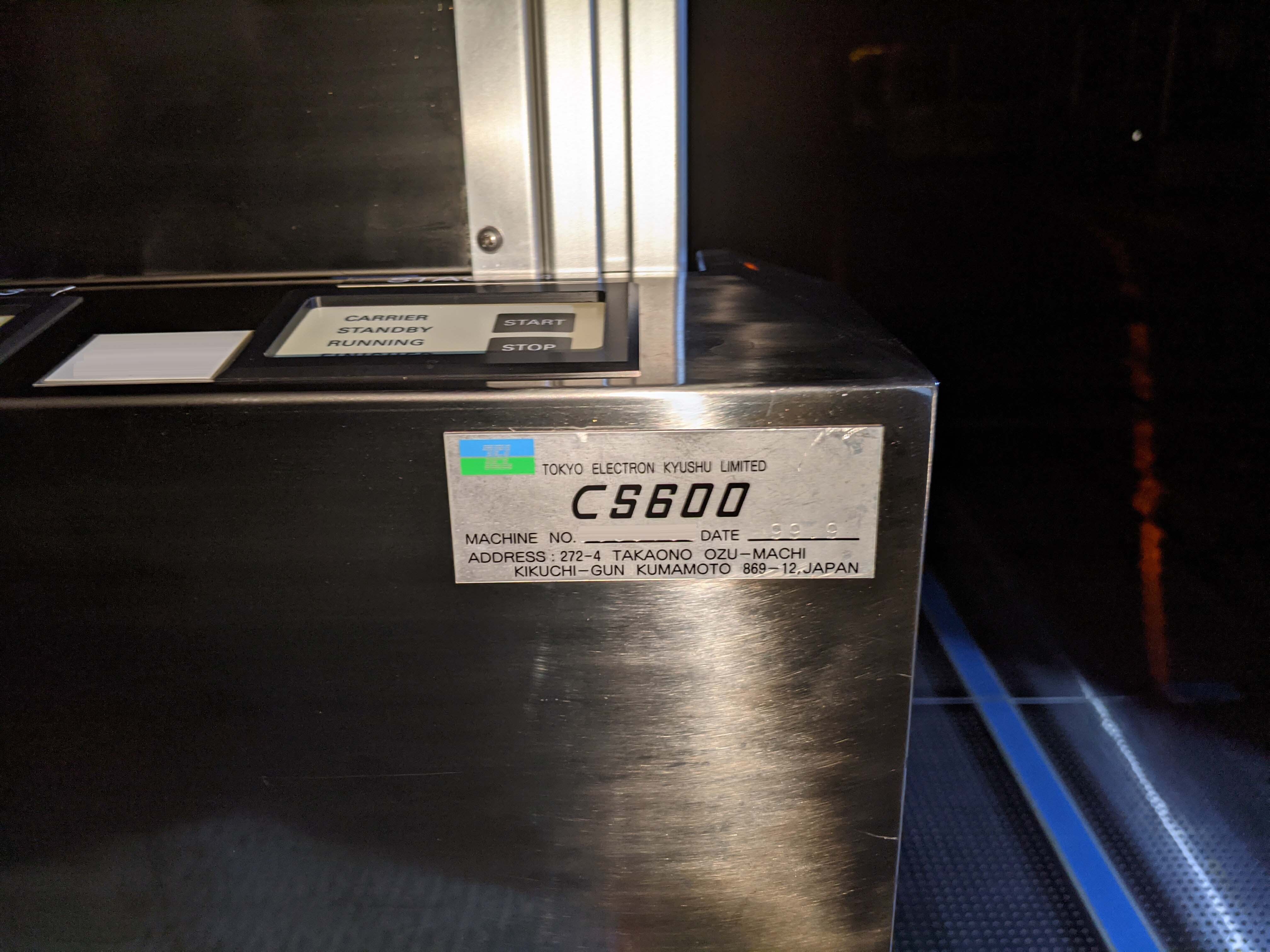

Used TEL / TOKYO ELECTRON CS-600 #9380687 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON CS-600 photoresist equipment is a high-precision, efficient system used in the photolithography process, which is often used in the production of integrated circuits. This unit provides superior performance for wafer processing and semiconductor manufacturing operations, achieving superior resolution, speed, and accuracy. The machine consists of 3 main components. TEL CS-600 projector utilizes a stepper motor tool, linear feedback devices, an enclosed environment, and an image rotation asset for precise projective image placement. This ensures optimal alignment and placement of light exposures during the resist processing step. The knife-edge aligner of the model is used to measure the blade edge characteristics such as sharpness, wave length, width, height, and light blocking characteristics. This allows for precise blade edge alignment, ensuring that light exposure is completed accurately and evenly across a wafer. Finally, TOKYO ELECTRON CS-600 features a spin-processor, which spins the wafer to enhance uniform distribution of the photoresist and enhance the photolithographic fidelity. Using CS-600 equipment is simple. First, operators load a wafer into the system and input the desired image-processing algorithm. The unit then performs the photolithography process, accurately propelling light exposure on desired areas of the wafer. The result is a high-precision lithographic image with consistent feature resolution, repeatability, and depth. Finally, the machine accurately spins the wafer, ensuring uniform distribution of the photoresists for optimal image fidelity. TEL / TOKYO ELECTRON CS-600 tool is a reliable and efficient photoresist asset that is designed to enhance the accuracy and durability of the integrated circuit manufacturing process. Its superior performance and reliability make it an ideal choice for wafer processing and semiconductor manufacturing operations.

There are no reviews yet