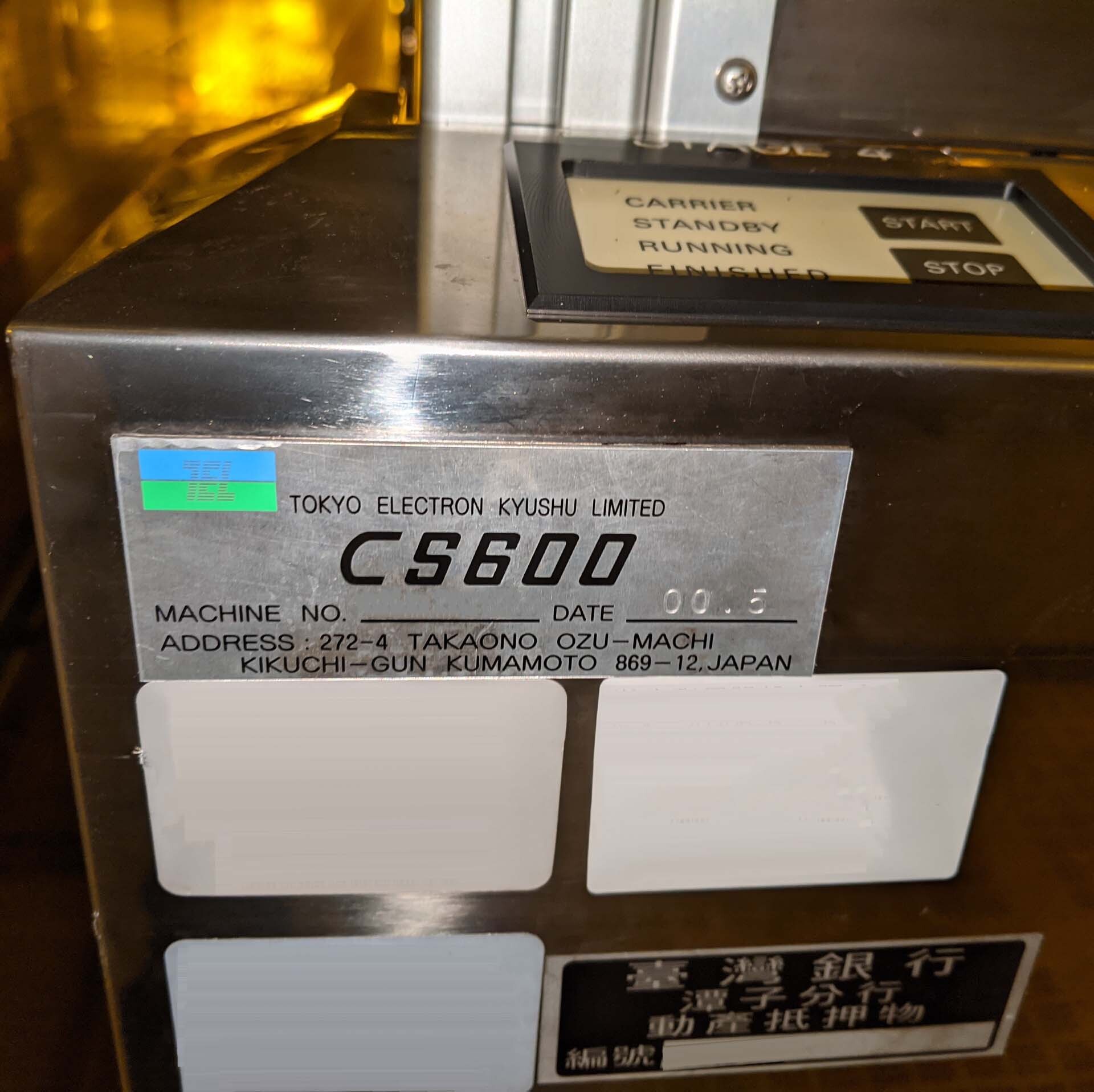

Used TEL / TOKYO ELECTRON CS-600 #9399456 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON CS-600 is a photoresist (PR) equipment designed for high-performance dielectric patterning. It utilizes all-in-one platform to give users the most cost-effective and efficient photoresist development and dry etching processes. TEL CS-600 photoresist system can be applied for a wide range of applications that require precise patterning of materials, such as in the manufacture of integrated circuits, LED lighting and display products. TOKYO ELECTRON CS-600 features a high speed and precise single wheel design, allowing for particle-free processing and handling of sensitive components. It features a dual scanner unit and each unit is capable of processing up to 100 wafers with a dual wavelength KRYDFE output of 90kHz and 200kHz, respectively. CS-600 also offers an optional four wheel option for higher speed, accuracy as well as for greater processing capacity. The four wheel option also offers enhanced wafer preconditioning, allowing for better pre-exposure and coating of the wafer. TEL / TOKYO ELECTRON CS-600 photoresist unit can be used with various coatings and thicknesses of PRs and provides excellent control of the thickness of the walls of the developed patterns. TEL CS-600 also features a semi-automatic PR scrub process, allowing for uniform and repeatable results during pattern development. In terms of data entry, TOKYO ELECTRON CS-600 is integrated with the company's SPS-nanoManager database software for control of wafer substrate properties and parameters. The machine also offers a real-time substrate data-loading processes and can use any database interface. On the safety side, the tool is compliant with ISO 14644-13 particle- and solvent-free environment requirements. Overall, CS-600 photoresist asset is designed to be cost-effective and provides users with precision, speed and reliability while processing materials, and reducing the risk of damage to sensitive parts in the process. By offering good wafer preconditioning, excellent PR scrub process control and real-time substrate data-loading, users will benefit from the maximum processing capacity of the model and the best possible results.

There are no reviews yet