Used TEL / TOKYO ELECTRON CS500 #9269714 for sale

URL successfully copied!

Tap to zoom

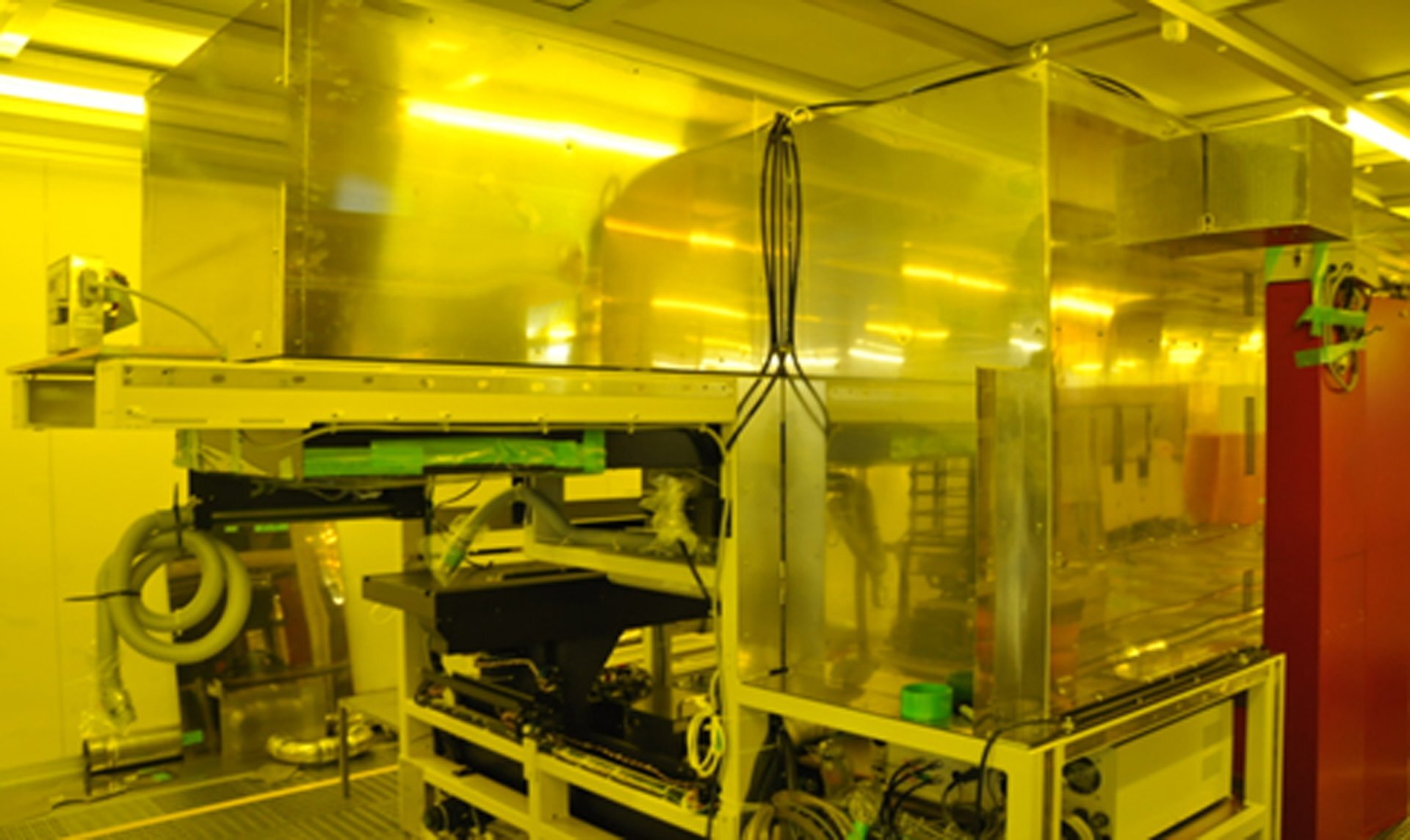

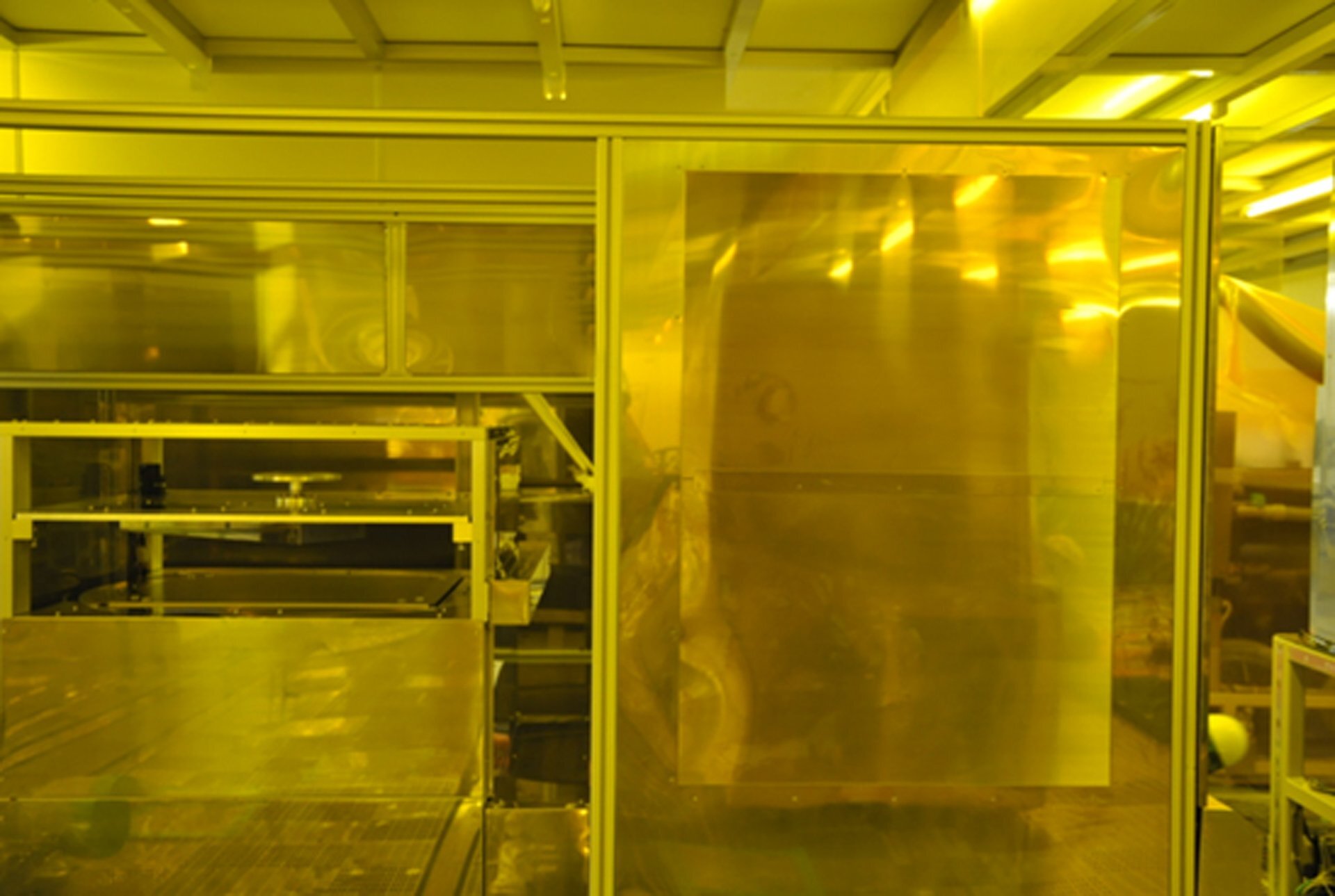

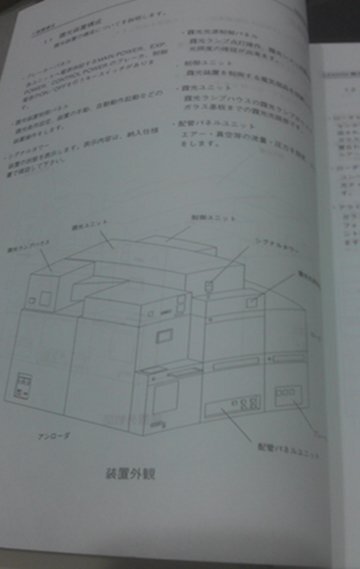

TEL / TOKYO ELECTRON CS500 is an automated photoresist coating equipment designed for the processing of resist substrates for use in semiconductor fabrication. TEL CS500 is based upon a single axis stage which allows for 360 degree coverage of the substrate. This allows for a highly efficient application process as the system can be powered on and off for rapid and precise resist loading. TOKYO ELECTRON CS 500 resin is fed into a syringe pump, allowing for precise and accurate control of the coating solution. The pump is then used to apply and spread the resist solution across the entire wafer in a 'track-follow' mode. This ensures uniform and consistent coverage of the resist across the substrate. TEL / TOKYO ELECTRON CS 500 has several different modes of operation. These include a self-calibration mode, which allows users to check the uniformity and coverage of the resist prior to coating, making it easier to identify any parameter setup or calibration errors. The unit also features an automatic temperature control machine. This ensures a consistent temperature throughout the entire process, to ensure an accurate and consistent application of the resist. TOKYO ELECTRON CS500 also features a built-in fault detection tool. This helps alert users to any issues before the resist is dispensed, allowing for faster corrective action if required. CS500 is compatible with a wide variety of resists, ranging from negative to positive, and from low to high viscosity. This allows for rapid changeover of resists for small-scale or large-scale production. Finally, CS 500 also allows for easy connection to a network of computers, allowing for remote control and operation of the asset. This is useful for large-scale production, allowing for remote supervision and adjustments of any parameters. Overall, TEL CS 500 is an automated photoresist coating model designed to provide uniform and consistent distribution of a resist layer across a substrate with minimal manual intervention. Its automated features and its compatibility with a wide variety of resists make it an ideal choice for use in semiconductor fabrication.

There are no reviews yet