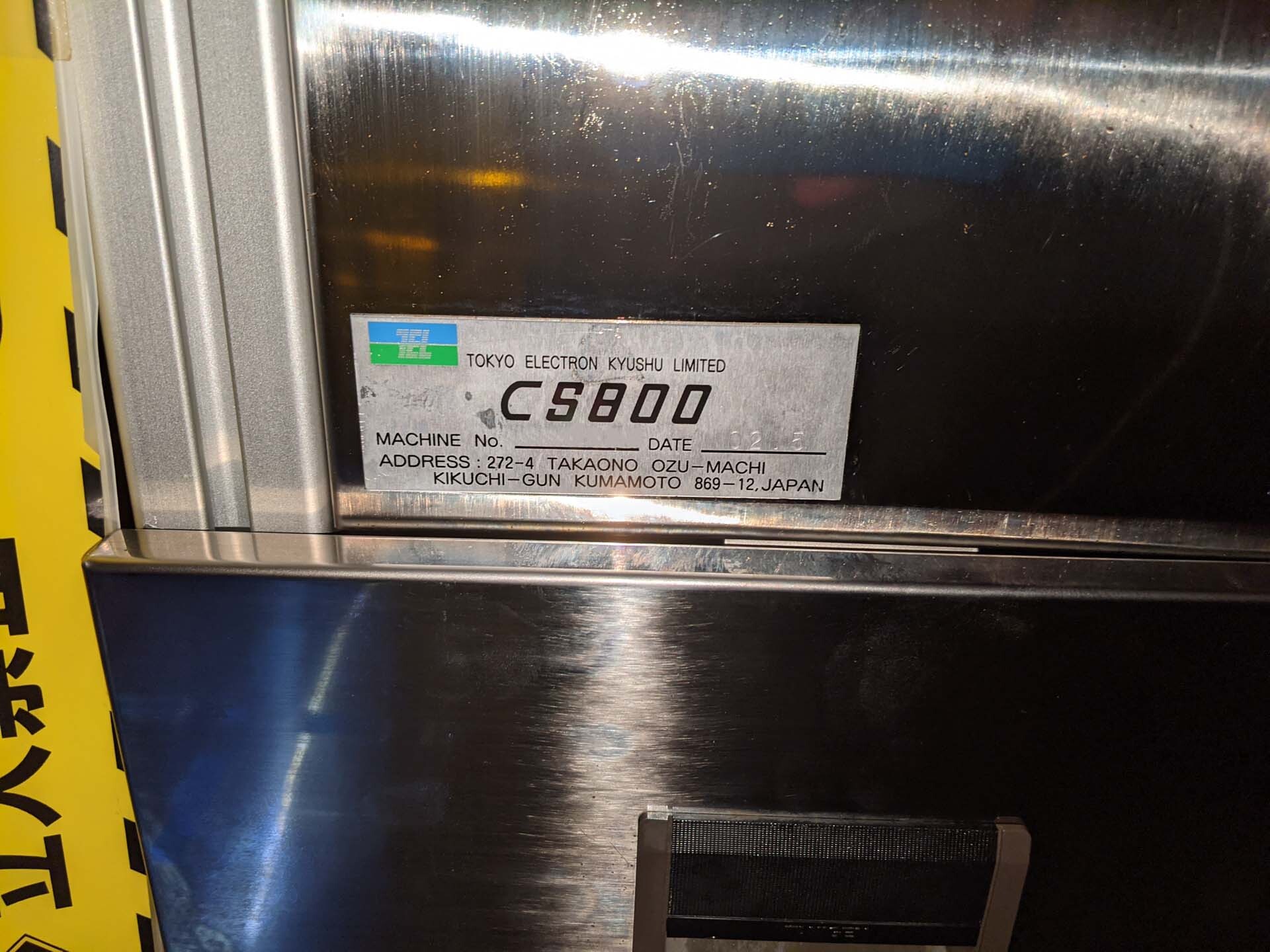

Used TEL / TOKYO ELECTRON CS800 #9399459 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON CS800 is a photoresist equipment designed for semiconductor chip patterning. This system is capable of providing a high resolution patterning of photoresist on the wafer level. The unit consists of a mainframe, a batch processing unit, a spin processor, and a CDS monitor. The mainframe is used to control the machine and includes a graphical user interface that makes it easy to operate. It also includes a variety of communication ports, allowing for integration with other systems used in the semiconductor manufacturing process. The mainframe can be configured with programmable controls and can be automated to handle repetitive tasks. The batch processing unit is used to process multiple wafers in one cycle at high speed. This allows for increased throughput, reducing the overall time required for wafer processing. The process unit is designed to be used with a spinner and can hold up to five cassettes of wafers at one time. The spin processor is used to spin the wafers during the patterning processes. It is designed for high-speed, sensitive operation to ensure accurate processing. The spinner is fitted with a variety of motion and control mechanisms such as an automatic spindle speed adjustment, a slotted guide ring, and a brake. The CDS monitor is used to monitor the progress of the patterning process in real time. This monitor has a range of features such as data acquisition, signal and drift detection, and image comparison. The CDS monitor can be used to detect any potential defects or issues before they impact the final wafer quality. TEL CS 800 photoresist tool is designed to provide a high resolution patterning at the wafer level. Its features, such as the mainframe, batch processing unit, spin processor, and CDS monitor, allow for easy and accurate operation, making this asset a must-have for semiconductor chip manufacturers.

There are no reviews yet