Used TEL / TOKYO ELECTRON Lithius i+ #9407206 for sale

URL successfully copied!

Tap to zoom

ID: 9407206

Wafer Size: 12"

Vintage: 2007

Coater / Developer system, 12"

CIM: SECS, GEM

Process: 193 nm Immersion

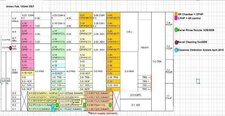

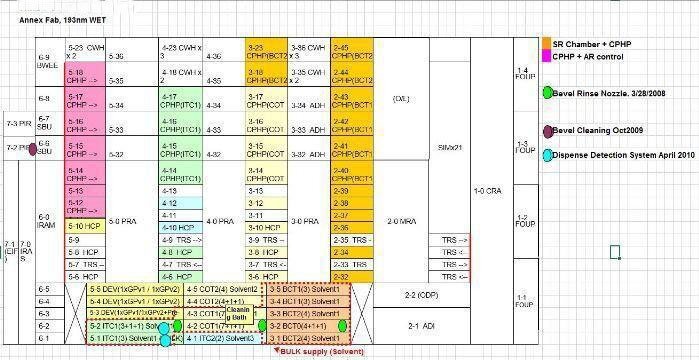

BWEE

(11) HCP

(25) CPHP

(3) DEV

(3) ITC

(3) ADH

(5) BCT

(4) COT

(4) FOUPs

(2) Solvent cabinets

(2) SHINWA Temperature and Humidities

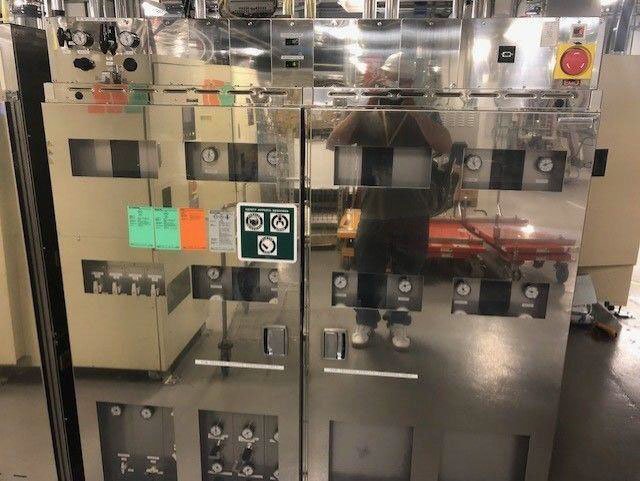

Power box

DEV Cabinet

Handler system:

SIM

ITR

CRA

IRAM

MRA

(3) PRA

Missing parts:

(2) ADI

ITC

(2) CPHP Bad plates

COT

2007 vintage.

TEL / TOKYO ELECTRON Lithius i+ is a next-generation photoresist equipment used for the lithography process of advanced semiconductor devices. It is capable of advanced imaging performance, as well as higher productivity and improved yield rates. TEL Lithius i+ provides an advanced imaging system for both front-end and back-end processes, which allows for high-resolution patterning of wafers with a 0.3um minimum line-width. It comes with a fully automated alignment unit that works quickly and precisely, and can process up to 4 wafers at the same time. The machine also features advanced motion and temperature control systems, which enable a smooth, continuous flow during the lithography process. The photoresists used in TOKYO ELECTRON Lithius i+ are designed to give improved performance during lithography, and allow for the creation of smaller features. The tool can also detect and correct any potential errors during the lithography process, leading to greater yields and improved production rates. The asset is equipped with advanced thermal control, allowing for the stable processing of wafers regardless of their size and complexity. Its advanced optics model allows for accurate resolution and contrast manipulation at the molecular level. The advanced automation level of the equipment ensures fast, accurate operations from alignment to exposure. The system includes both optical and laser alignment tools to ensure accurate wafer positions for maximum resolution. Its internal monitoring systems can detect any aberrations caused by impurities, providing a high degree of confidence in the accuracy of the results. The data produced by the unit can also be used for generating automated process control reports, which provide valuable data for improving the accuracy and yield of the lithography process. Finally, the machine is compatible with a wide variety of other systems, providing seamless integrations and making it easy to use.

There are no reviews yet