Used TEL / TOKYO ELECTRON Lithius #9032288 for sale

URL successfully copied!

Tap to zoom

ID: 9032288

Wafer Size: 8"

Vintage: 2006

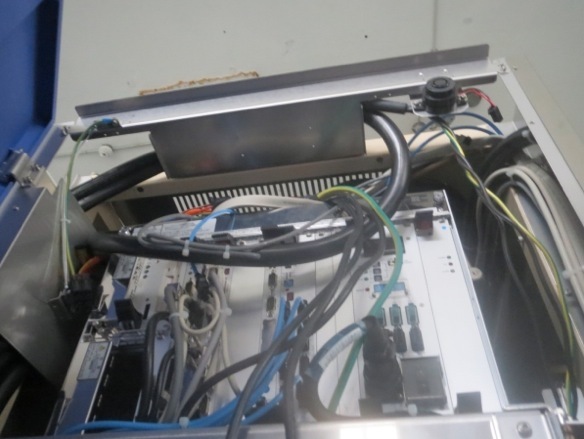

Track system, 8", parts machine

The tool was used for internal training which parts have been exchanged

Missing parts:

CSV arm

(2) ADH

CPHP bake

Hard disk

2006 vintage.

TEL / TOKYO ELECTRON Lithius is a photoresist equipment used for photolithography processes in the semiconductor industry. Photolithography is a printing technique used to transfer a design pattern onto a substrate using light-sensitive chemicals. The photoresist system consists of a light source, a photomask containing the design pattern, and a photoresist material. The light source is typically a UV laser or a mercury arc lamp. The photomask is a piece of glass, metal, or plastic with a design pattern, holes, or grooves etched into it. The photoresist is a light-sensitive material that is applied on top of the substrate. When exposed to light, the photoresist becomes activated, causing it to form a chemical reaction with the substrate, etching the pattern into the surface. TEL Lithius unit is designed to improve the accuracy of photolithography processes. It utilizes electrode measuring systems and laser detection systems to improve the accuracy of the photomask and photoresist systems. The use of multiple electrodes allows the machine to detect any deformations in the photoresist material, as well as any particles, ensuring the accuracy of the photoresist pattern. Additionally, the precision laser detection tool utilizes simultaneous observation accuracy and automatically adjusts for misalignment and motion errors during the process. TOKYO ELECTRON Lithius asset is also designed to allow for circuit feature sizes to be smaller than those achievable with conventional photolithography processes. This is accomplished utilizing the precision laser detection model and the microprocessing circuits available in the equipment. The precision laser detection system is used to detect the size, shape, and orientation of the photomask and the photoresist, making it possible to create exceedingly small features on the substrate. The microprocessing circuits also allow for the photolithography processes to be automated, giving the user the ability to control and adjust the output parameters such as line width. Overall, Lithius unit is highly accurate, automated, and capable of creating circuit features of small size. This makes it ideal for use in the semiconductor industry, providing efficient and reliable photolithography processes.

There are no reviews yet