Used TEL / TOKYO ELECTRON Lithius #9102159 for sale

URL successfully copied!

Tap to zoom

ID: 9102159

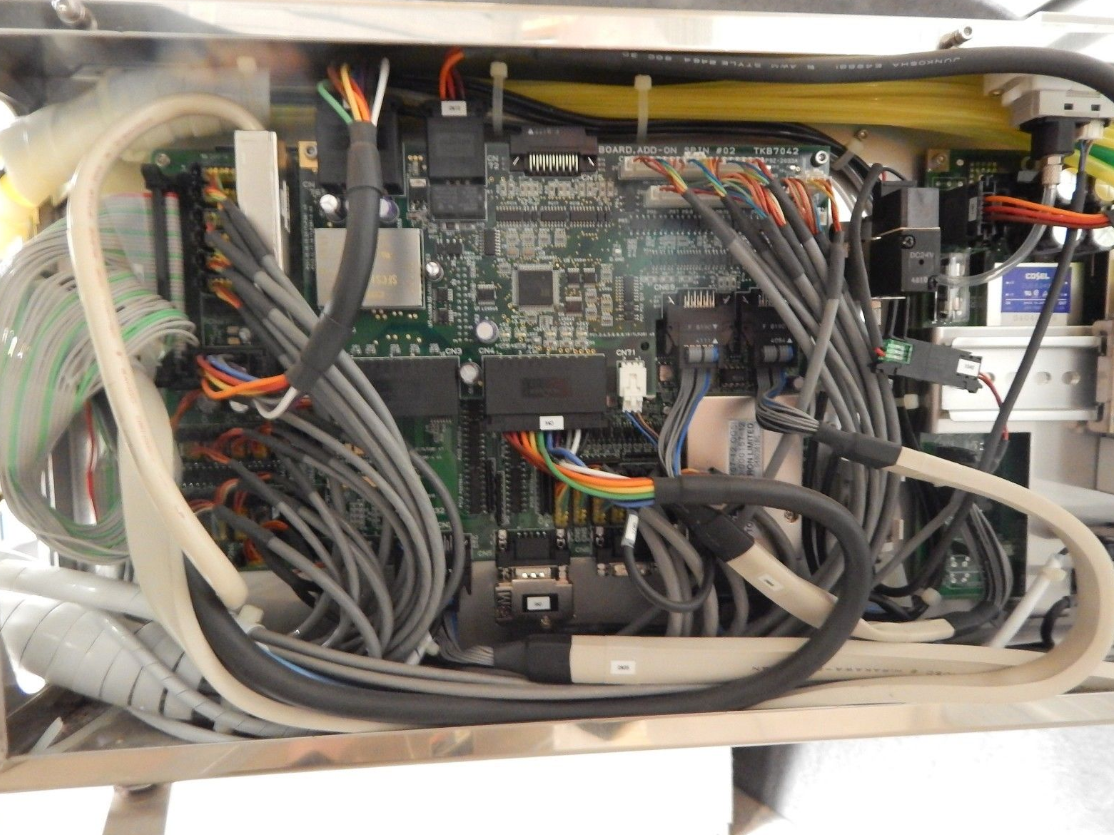

Coater / developer plate station

Clean track

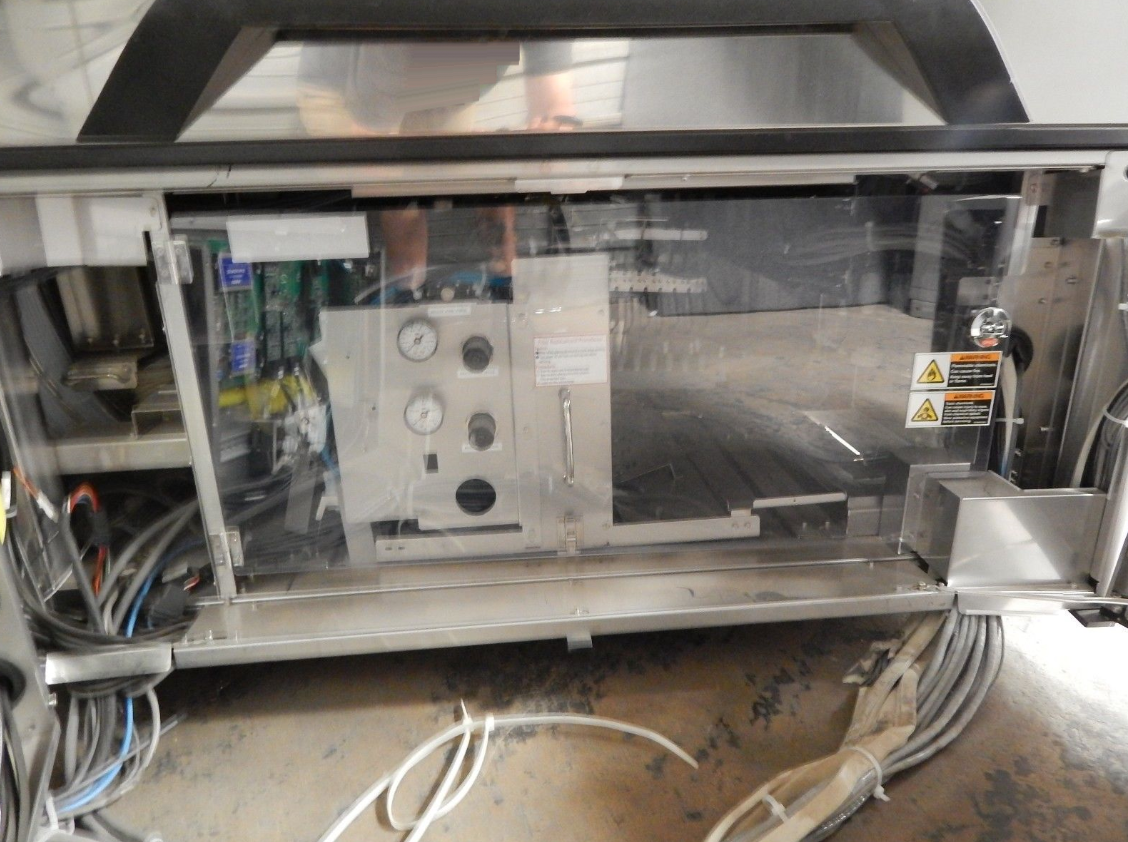

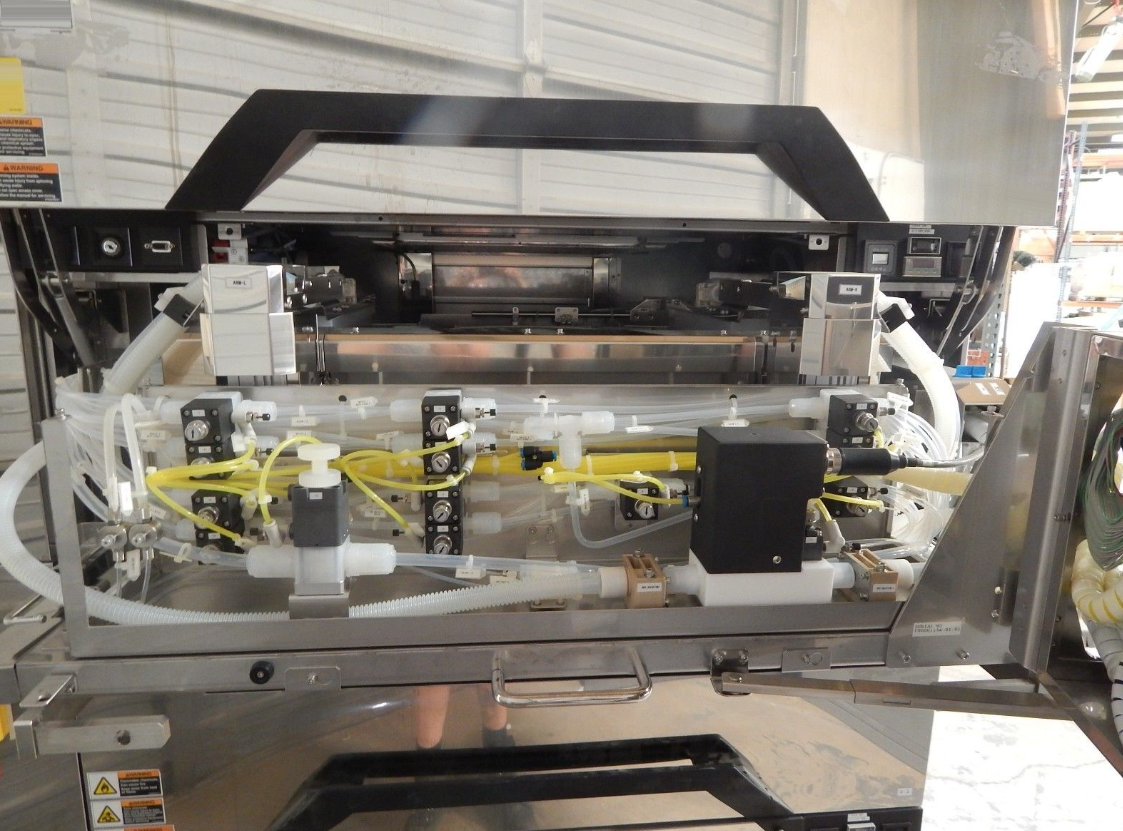

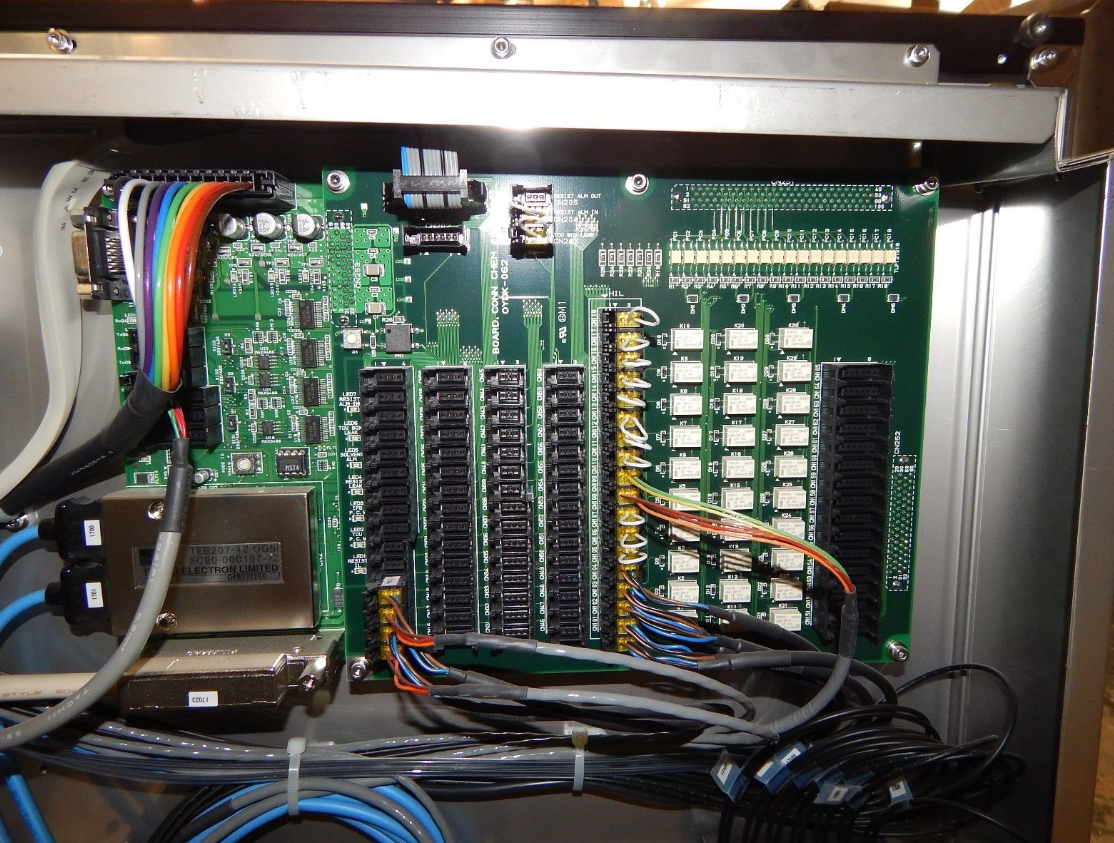

Process Block

Process Block Robotics Arm

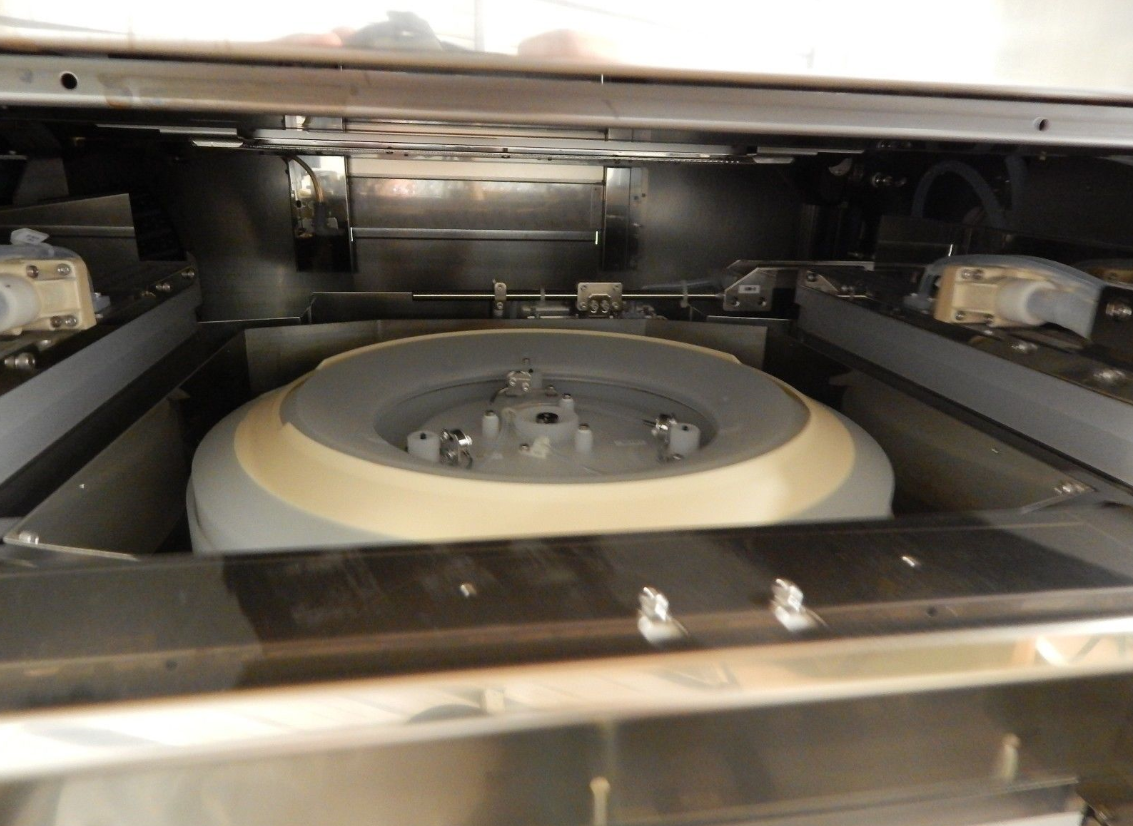

Coat Process Station

Develop Process Station

Plate Process Station.

TEL / TOKYO ELECTRON Lithius is a photoresist equipment used in the manufacture of semiconductor devices, such as computer chips, and other electronic components. The system applies a light-sensitive material, or photoresist, to a silicon wafer. When exposed to light, certain portions of the silicon wafer will be etched away, depending on the photoresist's exposure. The physical shape of the components can then be etched into the remaining areas, leaving the resulting product with its desired micro-dimensional pattern. TEL Lithius photoresist unit is a vacuum-based capability that is developed to script a critical layer of even coverage of photoresist materials across a full silicon wafer or other substrate. The machine controls the movement of multiple processes simultaneously to offer best uniformity and productivity. It follows the lithography process step by step ensuring the comprehensive programming of the special properties required for end process performance. The tool has the capability of handling 200mm silicon wafers, and also functions with larger diameter 300mm wafers, as well as with other substrates, like glass. A wide spectrum of resists, from positive to negative, is available for use in the asset. Different resists have to be used for each technician's specific purposes and a number of substrates such as quartz, quartz-on-quartz, glass, or silicon, depending on the application. This enables a multitude of uses from semiconductor applications to display and solar cell applications. TOKYO ELECTRON Lithius photoresist model works by functioning in a series of steps, which include spin rinse, pre-coat, post-coat, pre-bake, gentle bake, and soft bake. Each of these steps are monitored to ensure that the desired results are met, and adhesion and process latitude are within specification. The equipment is also capable of using a multi-layer resist strategy with both positive and negative type resists, allowing for extremely high quality patterns to be engineered. The entire system is software driven, allowing for ease of use and programming. It supports multiple-wafer capability, enabling a fully automated solution that can replace manual wafer handling. Additionally, the unit is equipped with a number of process characteristics that are both safe and reliable, such as temperature, exposure time, spin speed, and pressure, all of which must be precisely timed in order to obtain the desired results. Overall, Lithius photoresist machine provides a reliable and efficient way to manufacture highly complex and precise semiconductor components. It offer a great degree of control and accuracy, and its automated process ensures the consistent quality of the products.

There are no reviews yet