Used TEL / TOKYO ELECTRON Lithius #9105628 for sale

URL successfully copied!

Tap to zoom

ID: 9105628

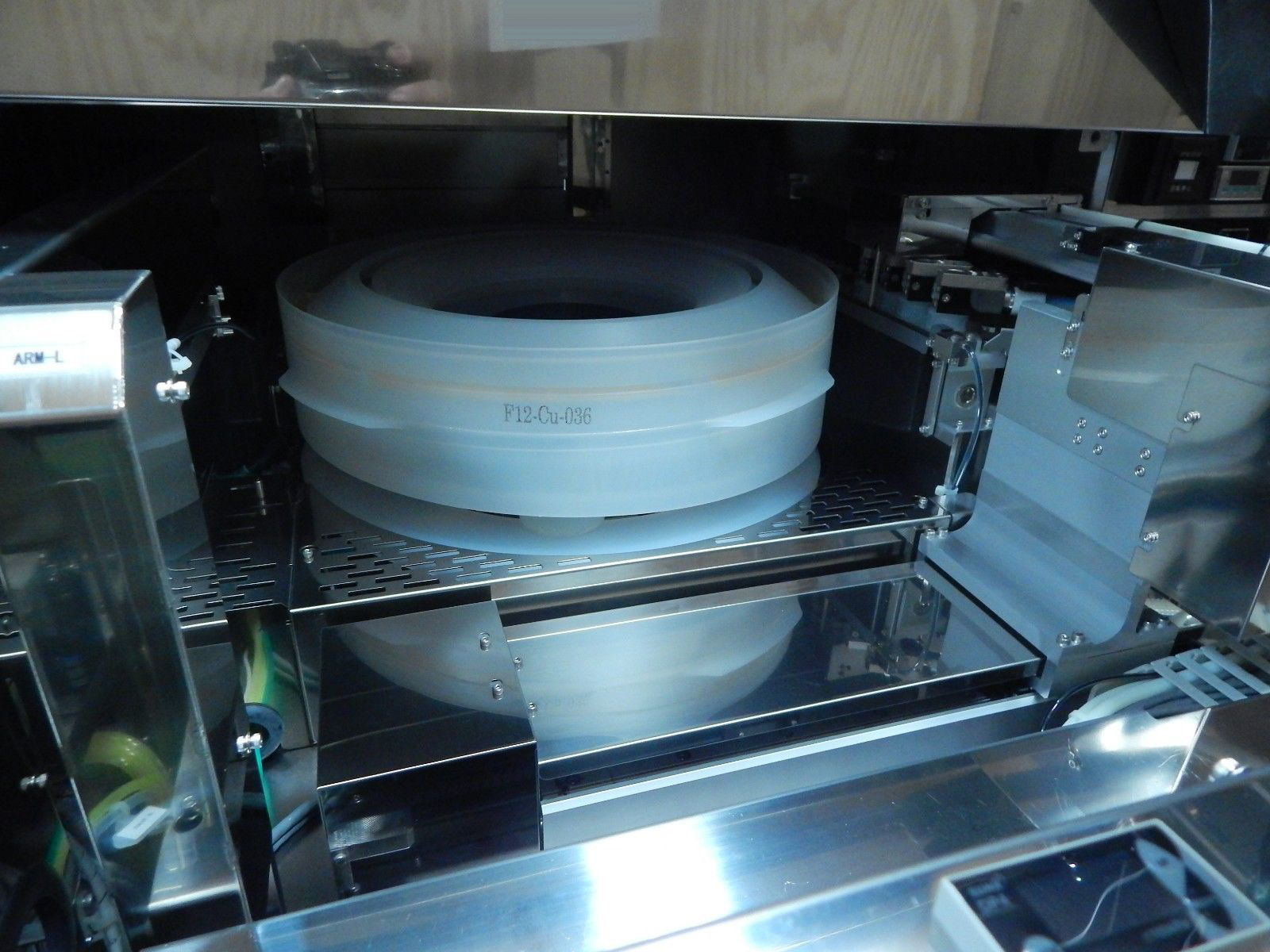

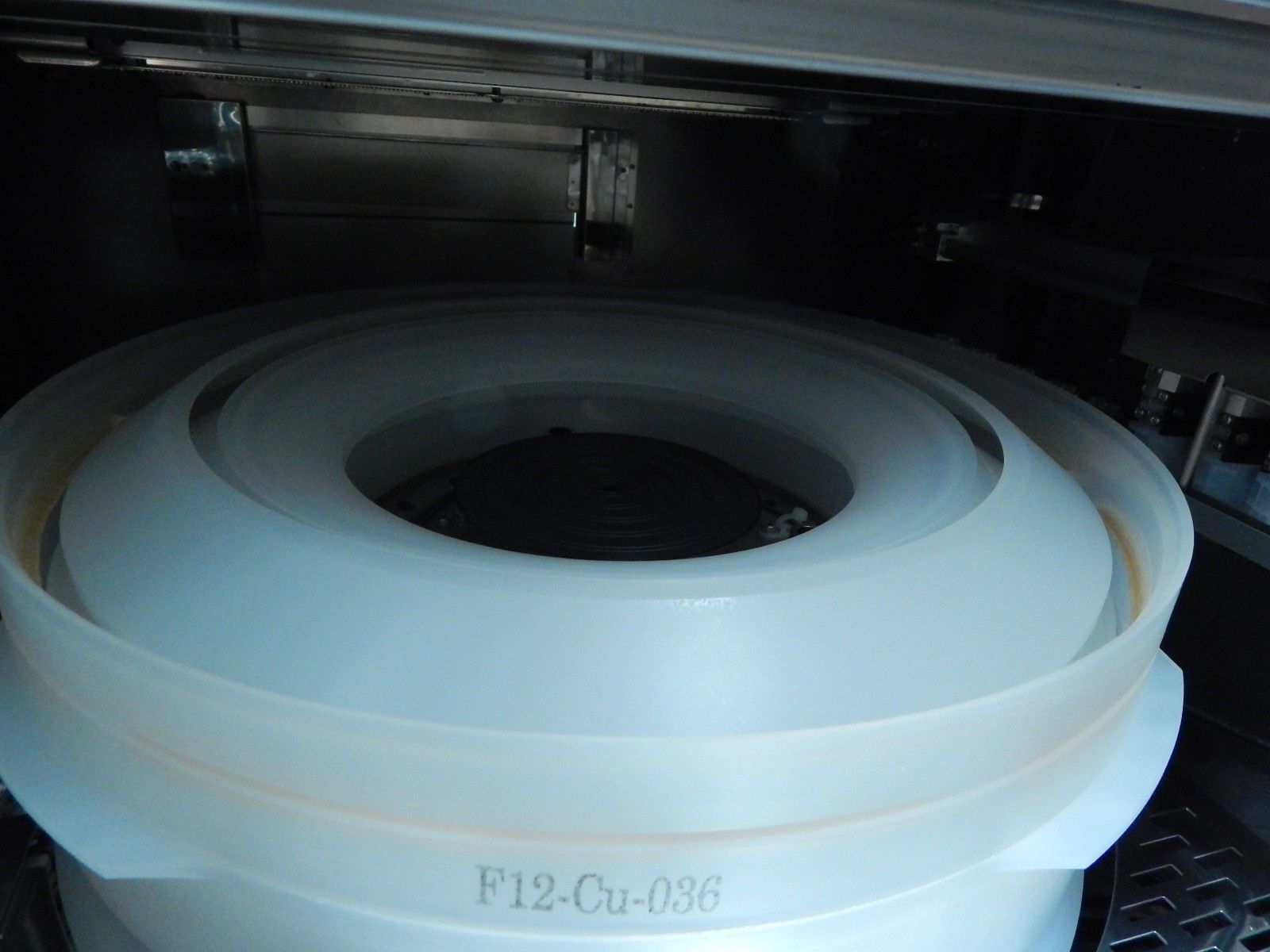

Coat Process Station

P/N: COT ASSY

Includes:

BASE ASSY - 5085-405081-1H

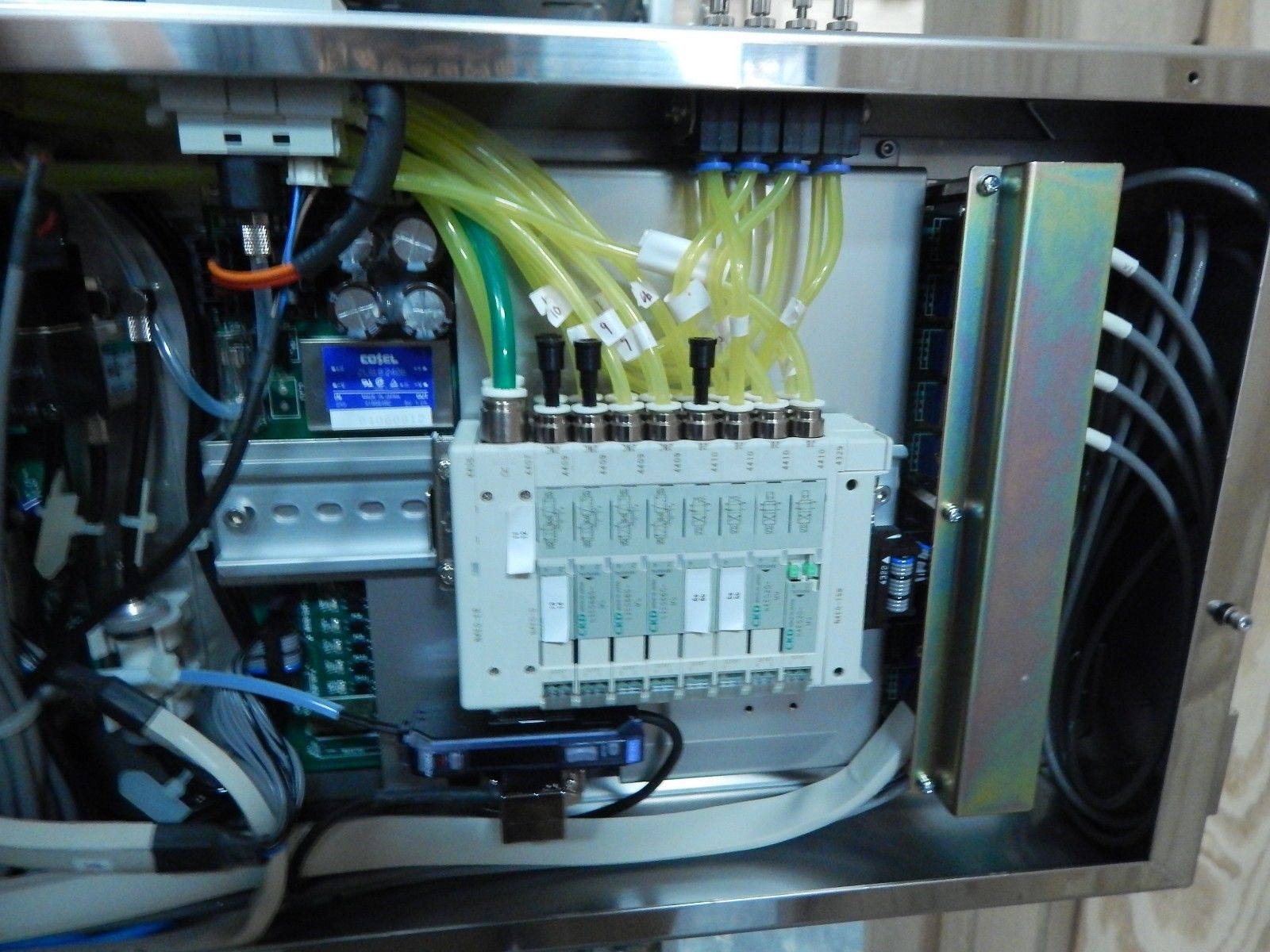

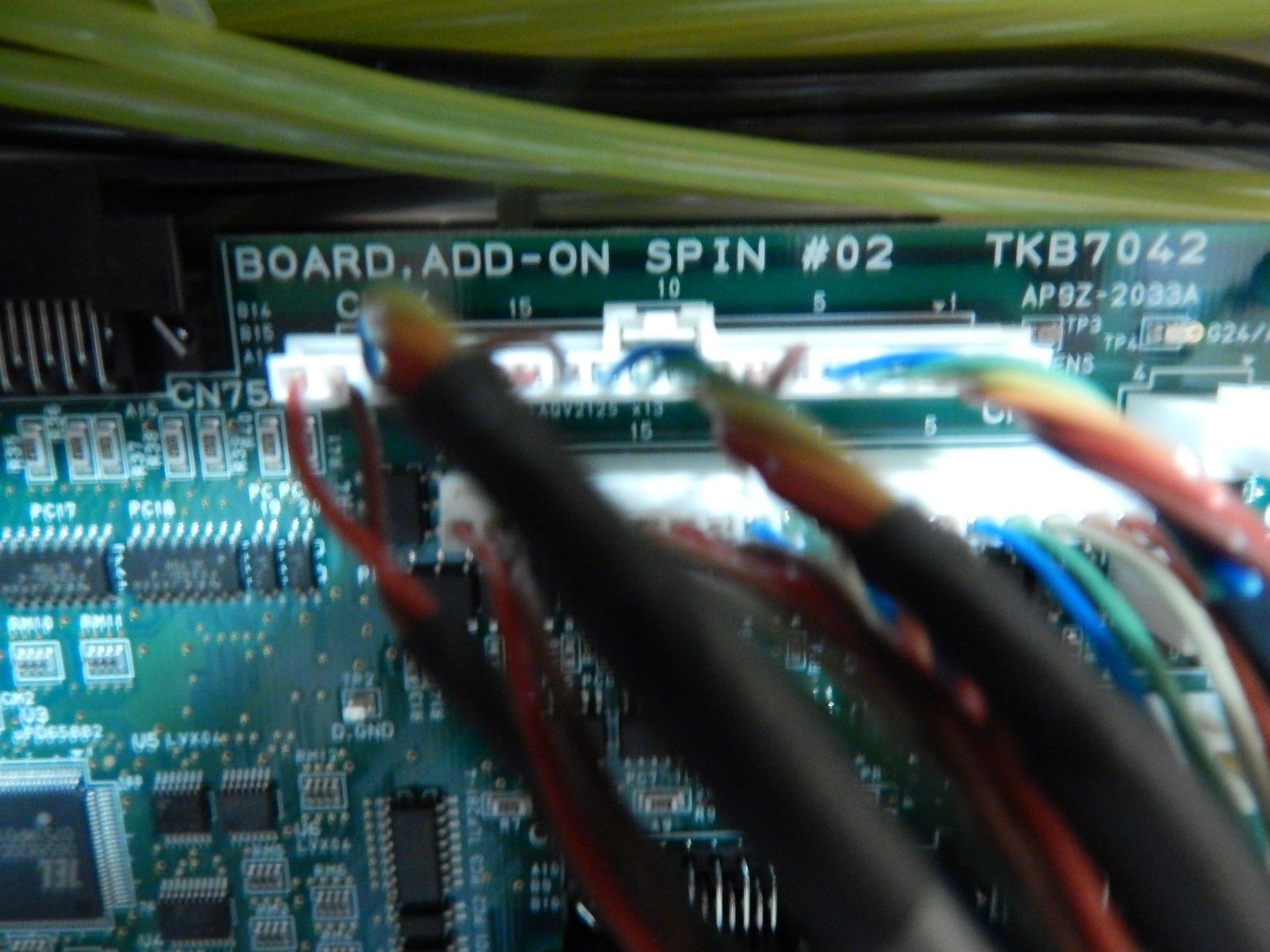

E-BOX ASSY - 5087-400387-1C

FRAME ASSY MOTOR - 5087-400383-14

3PIN ASSY - 5087-400384-18

DRAIN ASSY - 5085-404544-1B

BASE ASSY CUP - 5085-405400-16

WASHER NOZZLE ASSY BACK - 5085-401931-14

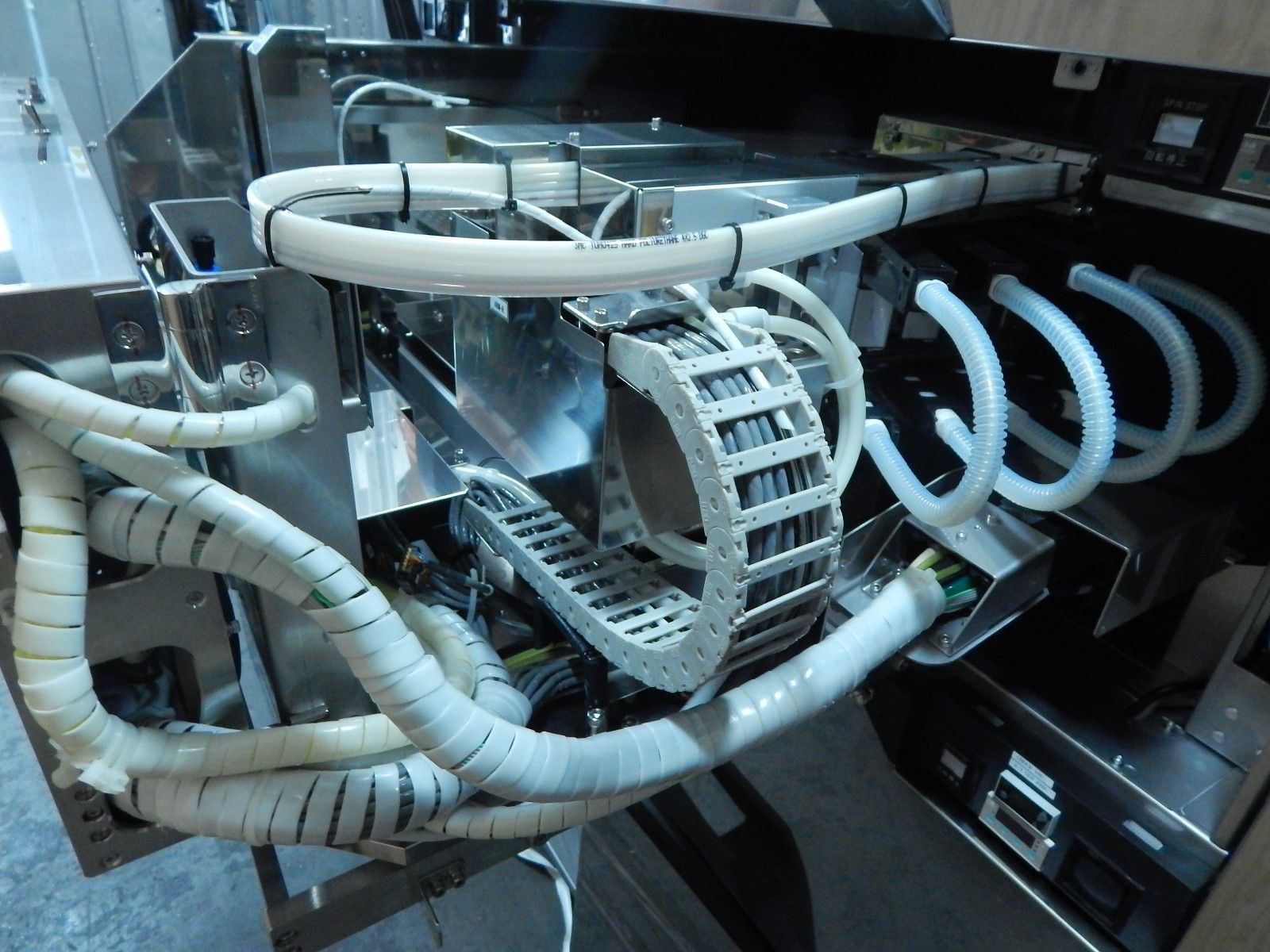

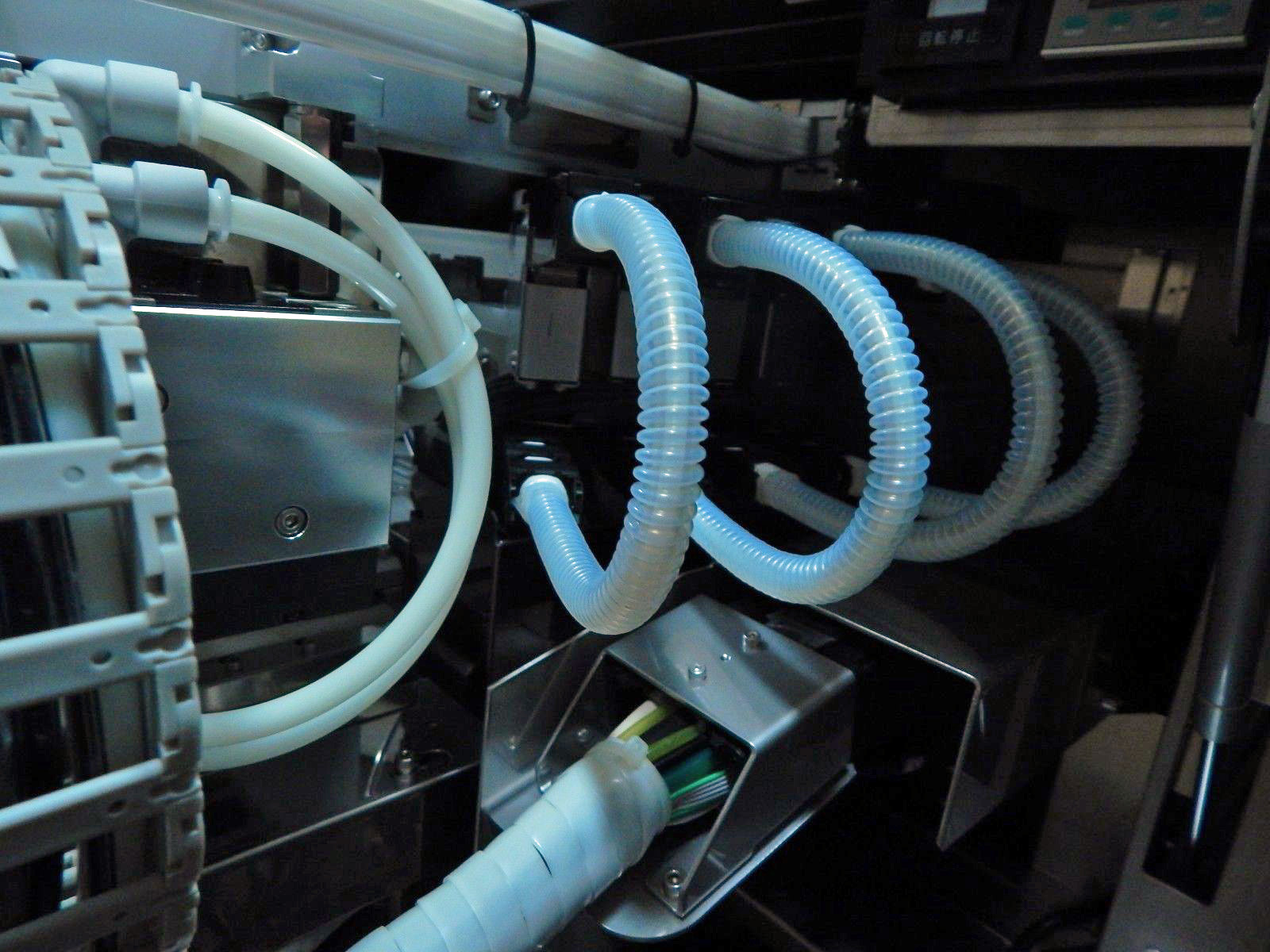

DUCT(COT)ASSY - 5087-403471-16

BATH ASSY EBR - 5085-401831-13

SCOPE ASSY - 5087-404467-12

AIROPE ASSY - 5085-405402-1E

SCAN ASSY - 5087-400391-12

SCAN (Z) ASSY EBR - 5087-404285-11

HOLDER ASSY TUBE - 5085-404660-11

COVER ASSY CUP - 5087-400390-19

SUPPORT ASSY - 5085-405144-18

EXH DUCT(COT) ASSY - 5085-412379-12

CHUCK(SS) ASSY - 5085-411385-11

PUMP ASSY(PF) DUCT - 5087-402634-14

CUP(COT300-306) ASSY - 5085-415131-11

SEAL ASSY, CUP - 5085-416408-11.

TEL / TOKYO ELECTRON Lithius Photoresist Equipment is an advanced lithographic processing technology specifically designed for precision lithography applications. This system uses an ultraviolet (UV) light source to create patterns on a silicon wafer that are then used as the basis for device manufacture. The main components of the unit include a specialized photoresist material, a mask or artwork, and an integrated precision optics and illumination machine. All components of the tool have been designed and optimized for high-precision lithographic processing. The photoresist material is a photosensitive polymer that enables the creation of intricate patterns on a silicon wafer. The photoresist used in TEL Lithius Photoresist Asset is a high-resolution, crosslinked photopolymer, which is highly sensitive to UV light. This photoresist is spin-coated onto a silicon wafer and subjected to a high precision alignment operation prior to exposure. An integrated precision optics model is used to project an artwork or mask pattern onto the photoresist. This artwork is precisely aligned to ensure that the patterns created by the UV light are within the tolerances specified by the device manufacturer. TOKYO ELECTRON Lithius Photoresist Equipment also utilizes a light-emitting diode (LED) array for illumination. LED lighting array is more reliable, efficient and generally has a broader spectrum range than other light sources used in microelectronics manufacturing. The LEDs produce a bright, uniform light beam that is directed precisely onto the photoresist-coated silicon wafer. Once exposed, the photoresist-coated wafer is then subjected to a series of chemical processes such as development and baking. During the development process, the photoresist is selectively removed from non-patterned areas of the wafer, leaving behind the patterned areas. The baking process further crosslinks the remaining photoresist, ensuring the ultimate hardness and electrical insulation of the patterned areas. Lithius Photoresist System provides a precision lithography solution for the production of high-quality integrated circuits. Its use of high-resolution photopolymer, precision optics and LED lighting array enables consistent feature-scale processing and device manufacture. Additionally, its capability to produce intricate patterns with minimal tolerances provides an ideal tool for the manufacture of today's highly complex electronic devices.

There are no reviews yet