Used TEL / TOKYO ELECTRON Lithius #9111798 for sale

URL successfully copied!

Tap to zoom

ID: 9111798

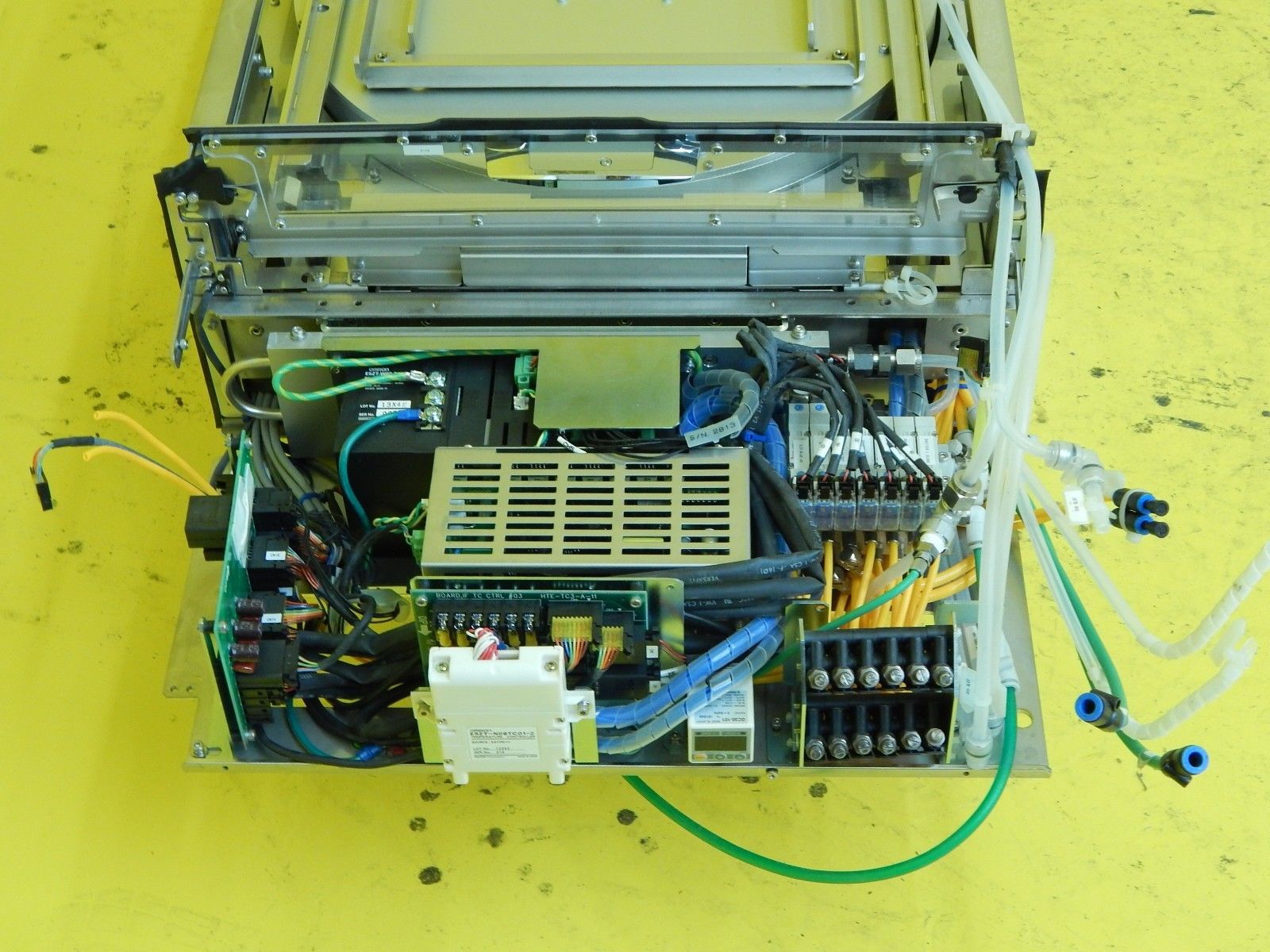

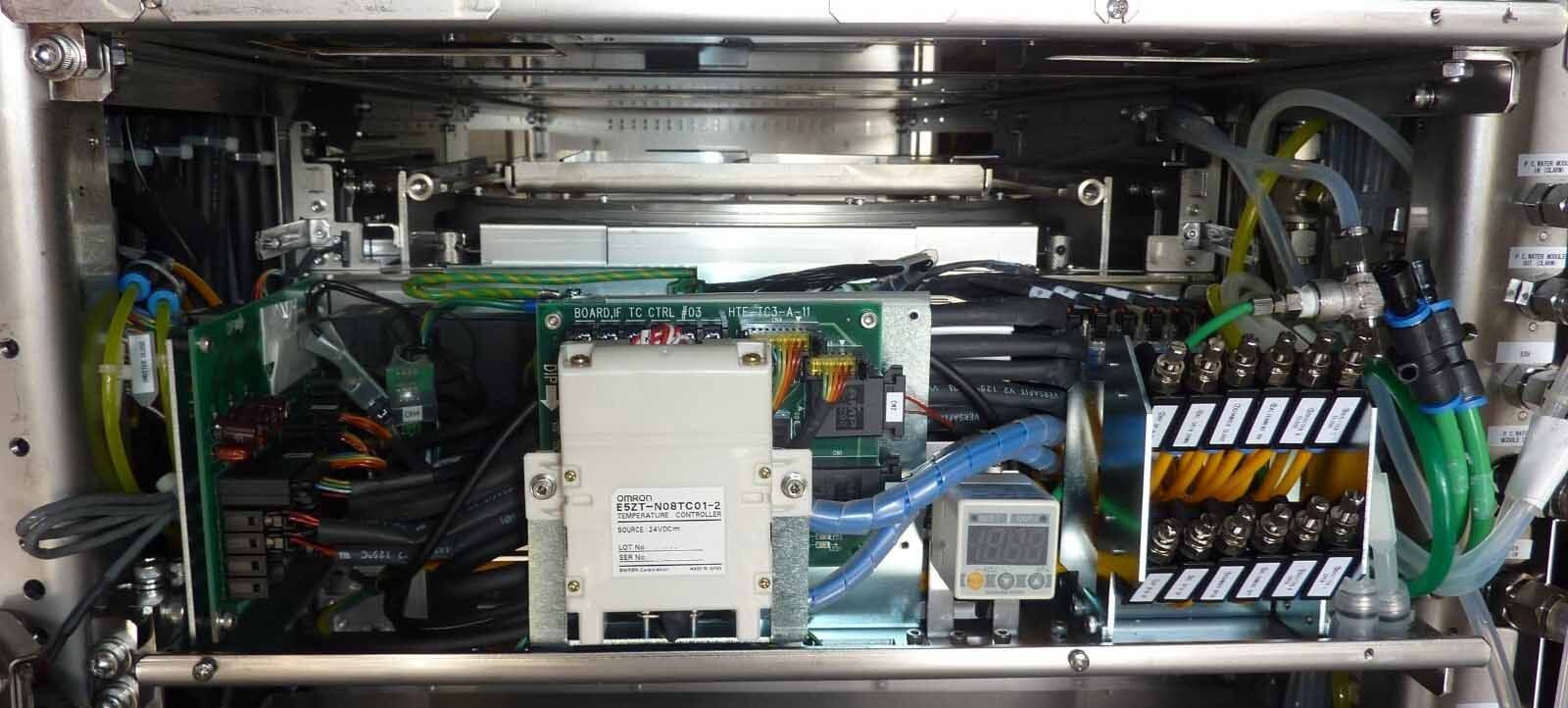

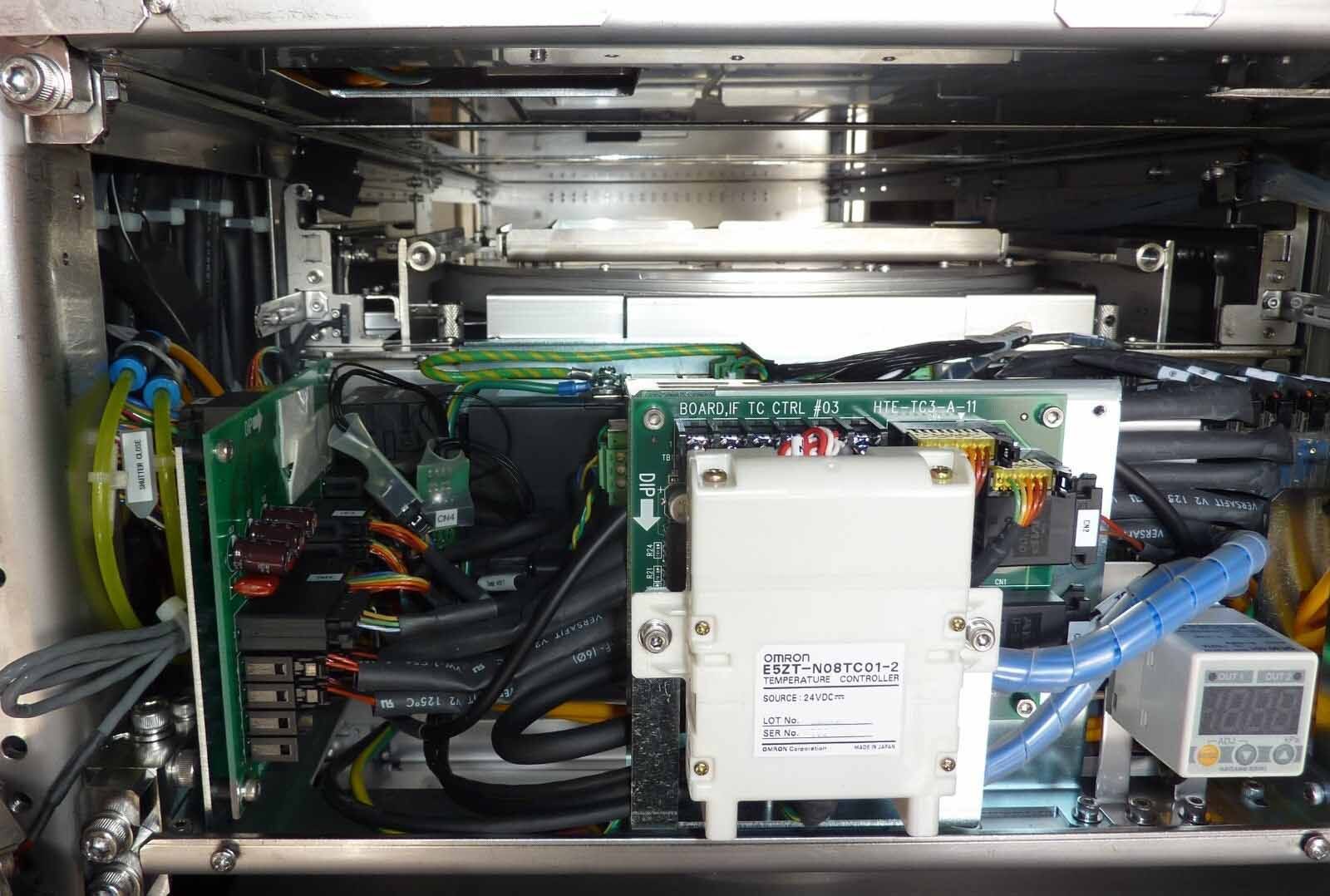

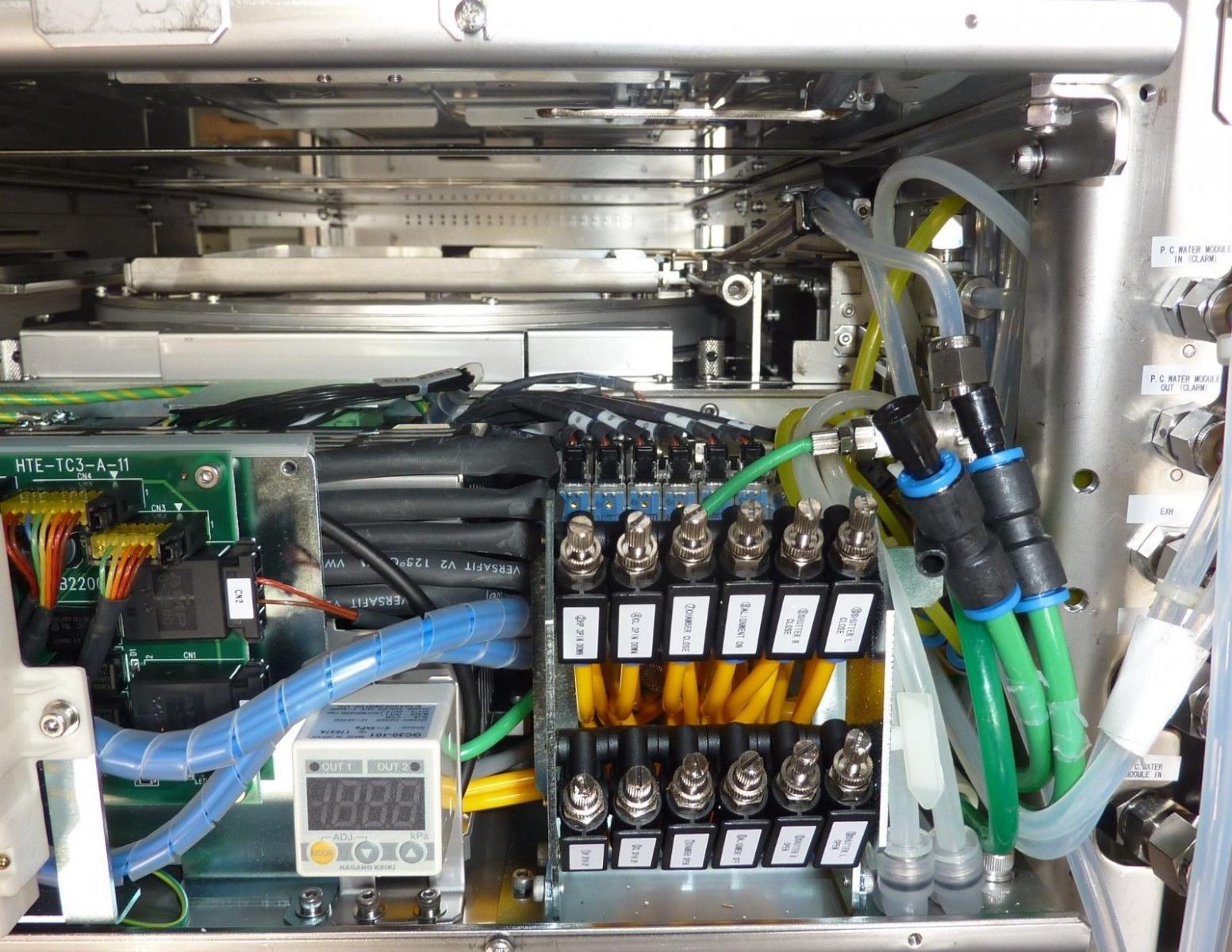

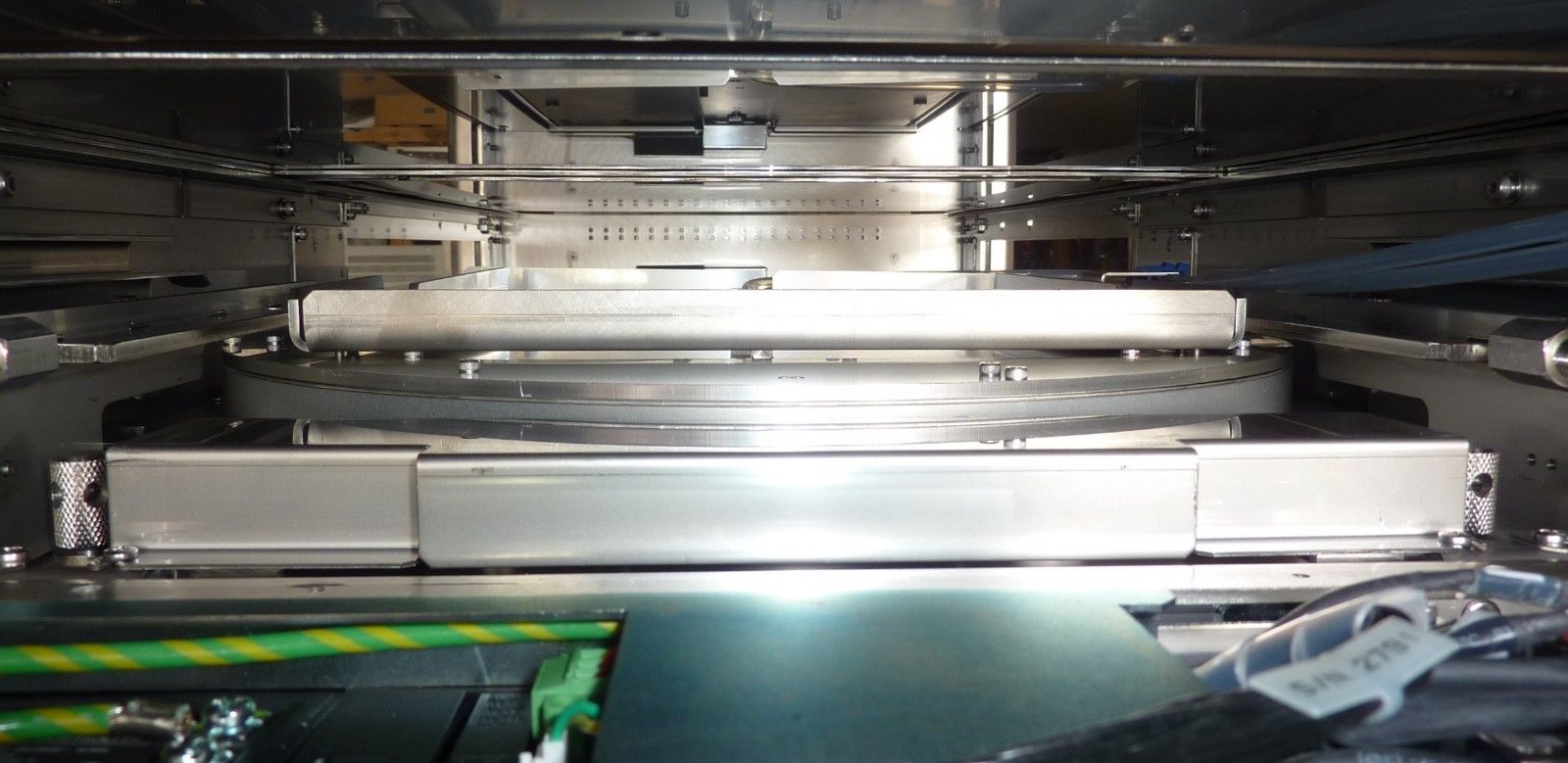

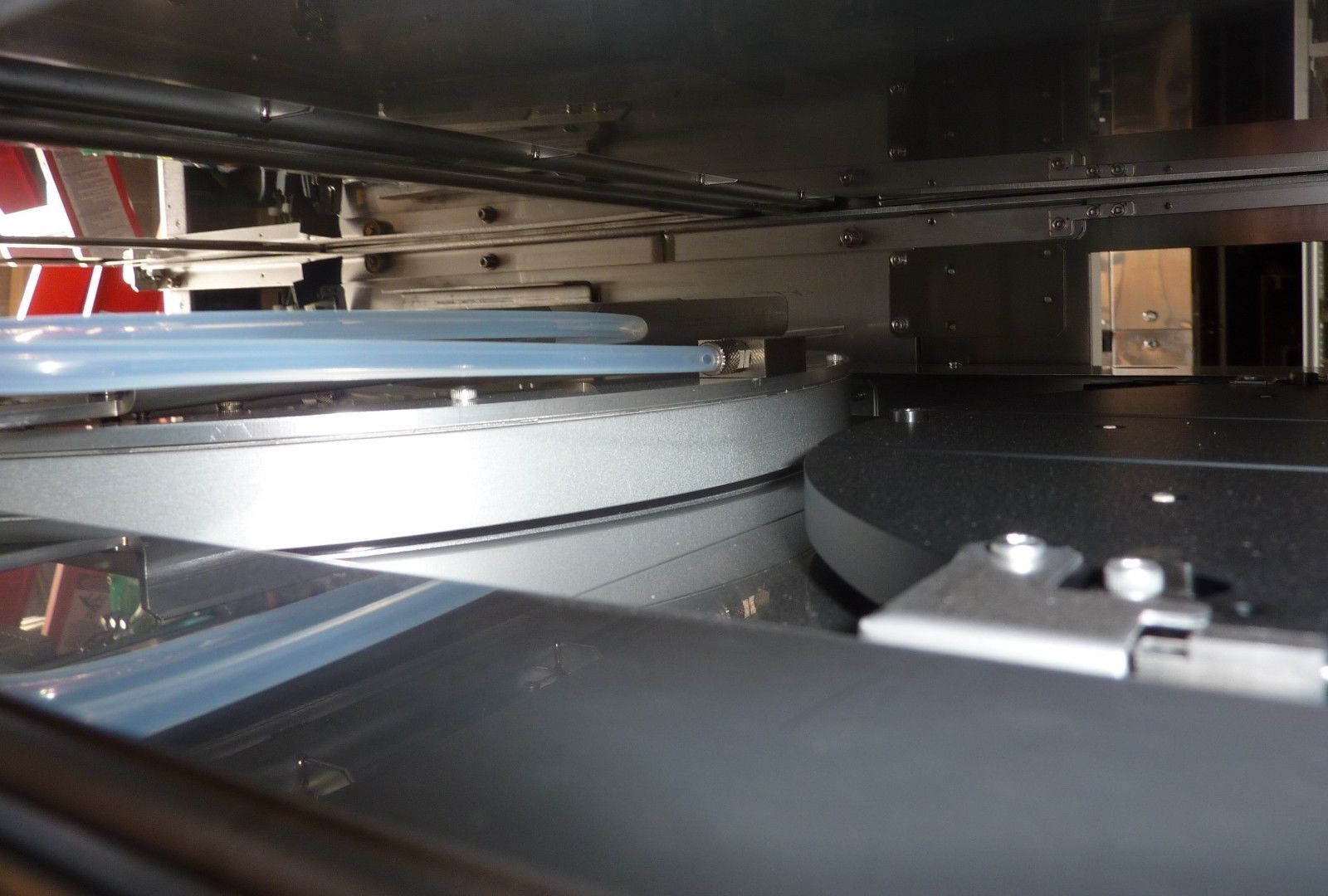

CPHP General Chambers

RAME(HP)ASSY, P/N: 5087-402251-17

FRAME(COOL)ASSY, P/N: 5087-402252-17

CHAMBER SLIDE BASE ASSY, P/N: 5087-401726-14

BASE(COOL)ASSY,ARM SLIDE, P/N: 5087-402253-13

PIN(HP)ASSY, P/N: 5087-401371-12

PIN(COOL)ASSY, P/N: 5087-401367-13

SUPPORT ASSY(CPHP), P/N: 5085-412744-12

PLATE ASSY(CPHP-KCR), P/N: 5085-404671-11

CHAMBER ASSY, P/N: 5085-409714-15

COOL ARM ASSY, P/N: 5087-402970-18

BASE(E-CPHP) ASSY, P/N: 5087-401373-18

COVER(CHHP)ASSY, P/N: 5085-407305-14

COVER(CLHP)ASSY BACK, P/N: 5085-409715-12.

TEL / TOKYO ELECTRON Lithius is a next-generation photoresist equipment designed to deliver extremely accurate and reliable exposures of photoresist patterns. This system utilizes digital imaging and the latest in advanced lithography techniques to produce extremely sharp, high-resolution imaging features for advanced semiconductor processes. TEL Lithius unit is designed to meet the exacting requirements of the most modern semiconductor processing. The machine features a highly reliable, full-auto exposure tool that can both accept user-defined patterns and native machine-generated patterns. The user is provided with a range of exposure parameters (including wavelength, wavelength accuracy, and exposure time) and the results can be fine-tuned based on the requirements of the job. The asset can also process large images quickly, with exposure time of only 0.3 seconds, and with a resolution of up to 0.15 µm. The model can also be easily integrated with other optical systems, making it very useful in large-scale production applications. TOKYO ELECTRON Lithius' state-of-the-art illumination process utilizes advanced optics, and programmable illumination parameters such as spot size, numerical aperture, and polarization. This combination of features allows for optimal photoresist images, as well as tight, precise lines and high-quality, uniform density in the resulting pattern. Another key feature of the equipment is the proprietary PhotoStencil Software, which offers a wide range of pattern assignment and manipulation capabilities. The software is also highly customizable and can be easily tailored to various applications. The PhotoStencil Software also ensures precise registration and alignment of image patterns, and a wide range of additional features including auto notch correction, multiple exposure simulation, and real-time data monitoring. The system also incorporates several software solutions that allow users to simulate their exposure process in various conditions, allowing them to better predict and optimize the process according to the customer's needs. Overall, Lithius Photoresist unit involves a combination of precision optics, optical integration, ergonomic design, advanced lithography techniques, and software technologies to produce extremely accurate and reliable images for semiconductor devices. The user-friendly features, ease of setup, and the ability to operate in several different environments make the machine an ideal solution for modern semiconductor processing.

There are no reviews yet