Used TEL / TOKYO ELECTRON Lithius #9397192 for sale

URL successfully copied!

Tap to zoom

ID: 9397192

Wafer Size: 12"

Vintage: 2005

System, 12"

Material / Chemical:

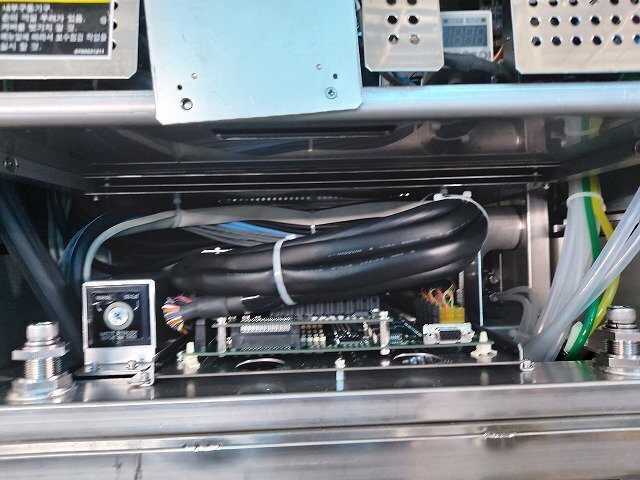

Operating system: LINUX / Windows

SMIF

Hard Disk Drive (HDD) missing

Process: HT-PYRO (1250C)

Safety: TEL Standard

Layout type: U/Box

Tool direction: LL

Front furnace body: Coating (FDP Standard)

Heater [Range of temperature]: High VMU-40-007EXT(41) [850-1250°C]

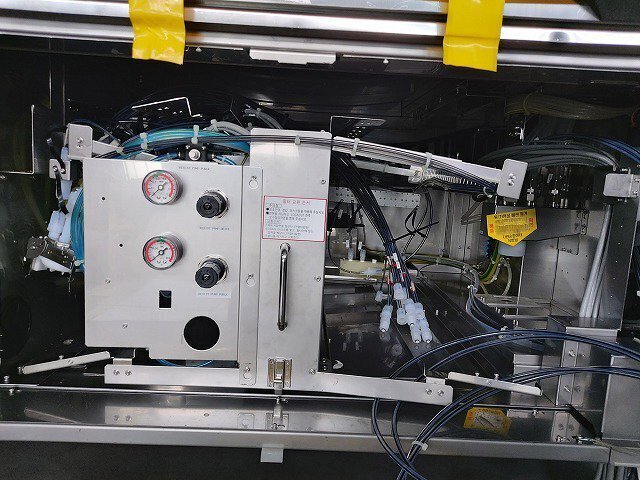

Process:

Pressure: ATM

Temperature: 1250°C

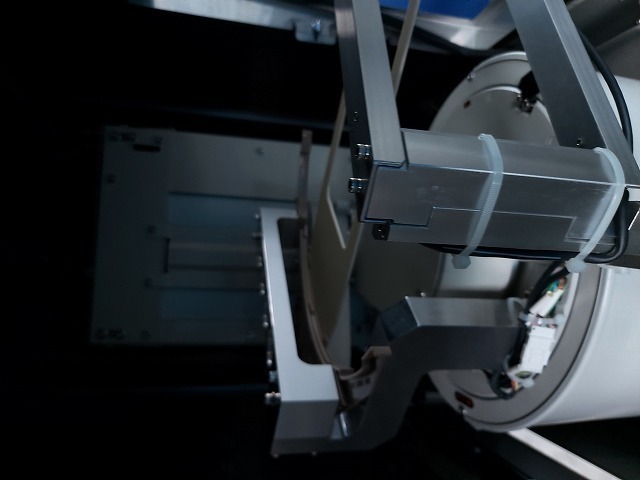

Wafer / Cassette transport:

SEMI Standard - Notch, 12"

T/S Wafer jump out detection

Fork type / Material: 1+4 / Al203

Wafer In / Out order: ED -> P -> M / M -> P -> ED

Cassette:

Miraial (MK-823S-H)

Slot: 26

Stocker: 21

Monitor cassette:

In P1, P2, M / Out P1, P2, M

Fork :

Wafer detection

Wafer displacement detection

Pitch conversion

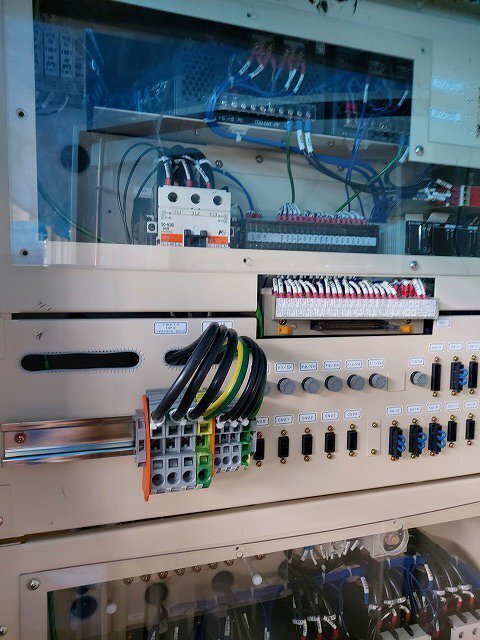

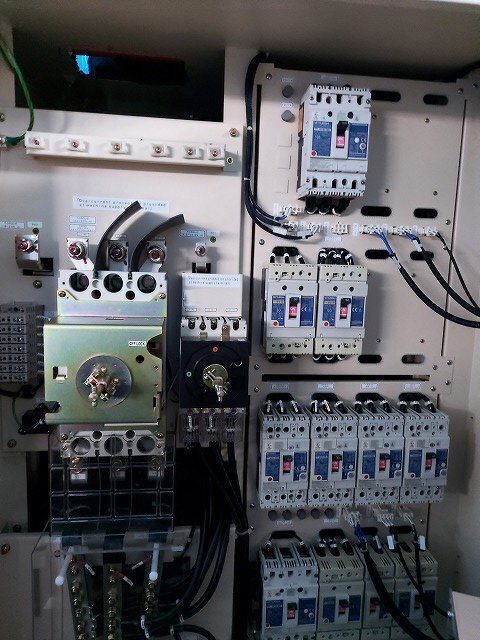

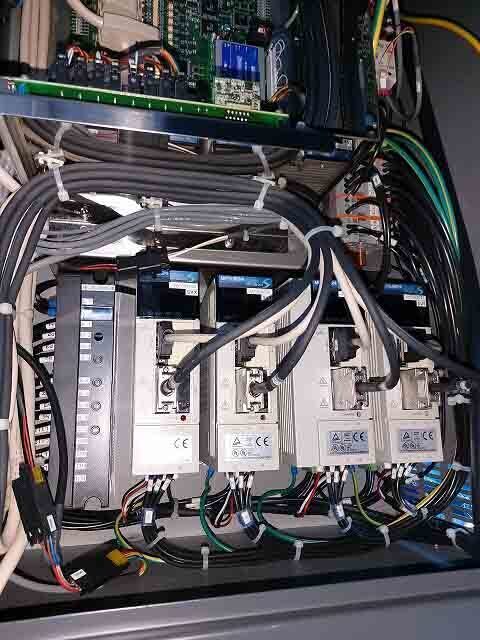

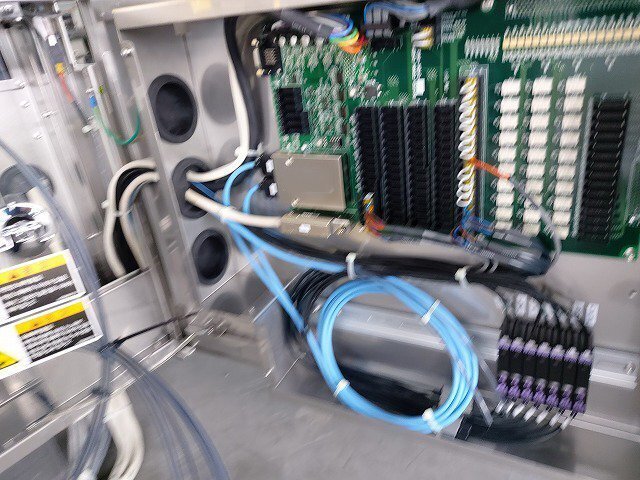

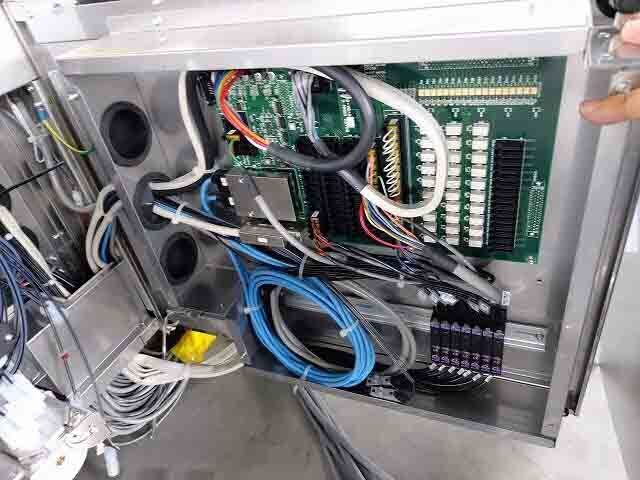

Hardware composition:

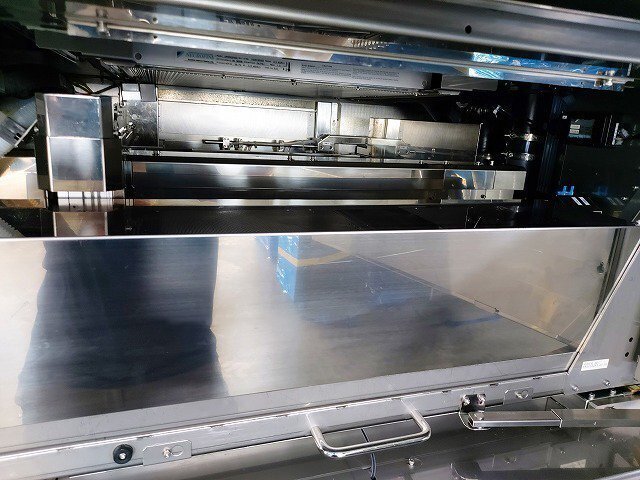

Load module:

(4) TEL / SEMES Standard load ports

(1) TEL / SEMES Standard loader arms

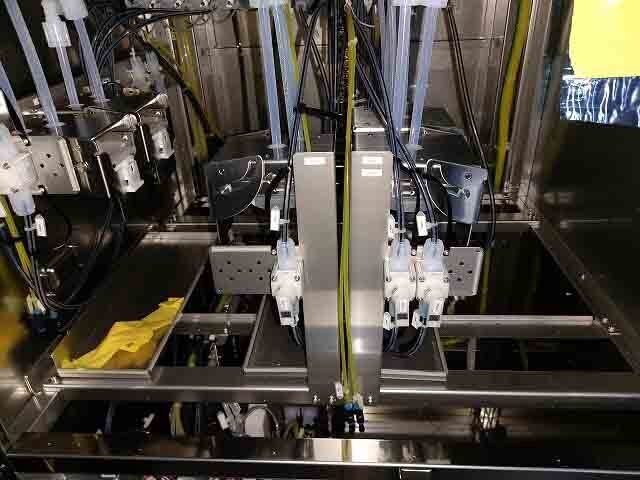

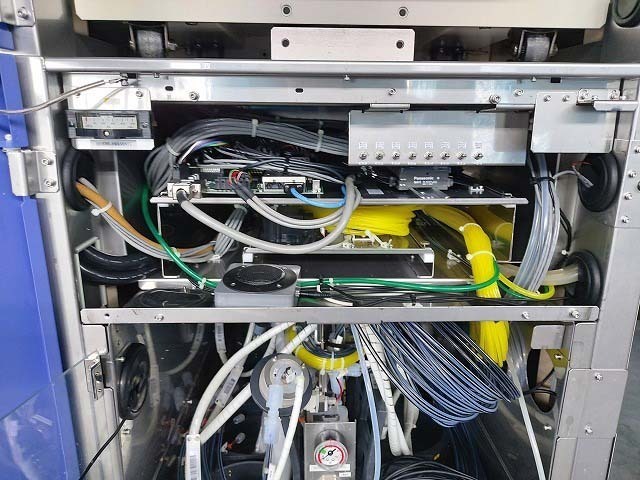

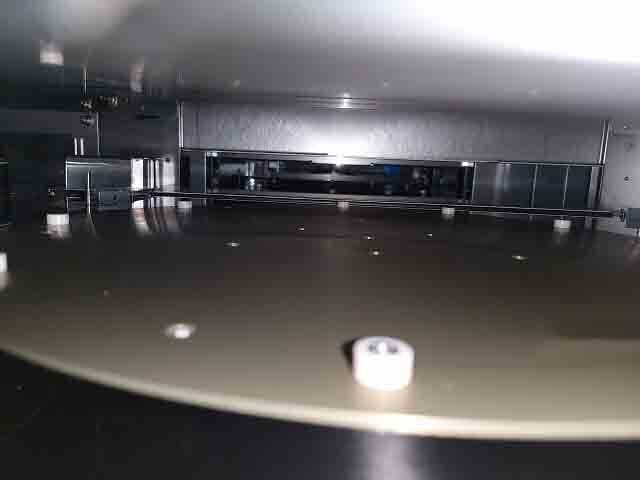

Transfer module (platform):

(5) TEL / SEMES Standard transfer robot arms

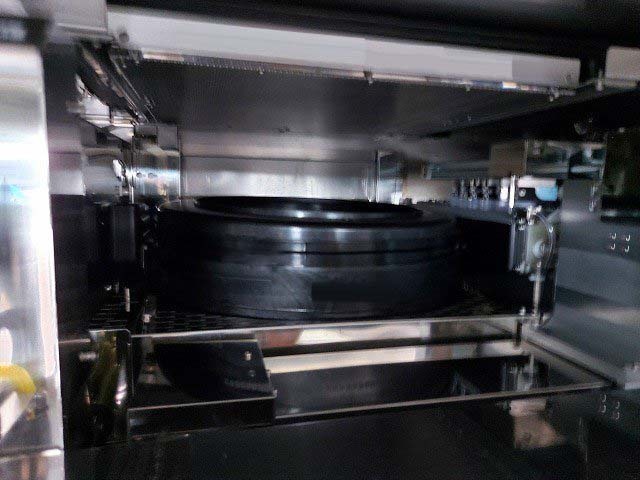

Process module:

TEL / SEMES Chamber process module specification

(17) Pumps

RF Generator

Gas box

PC

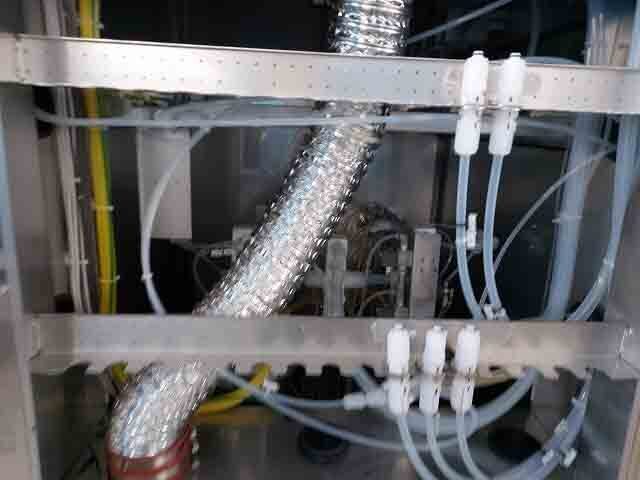

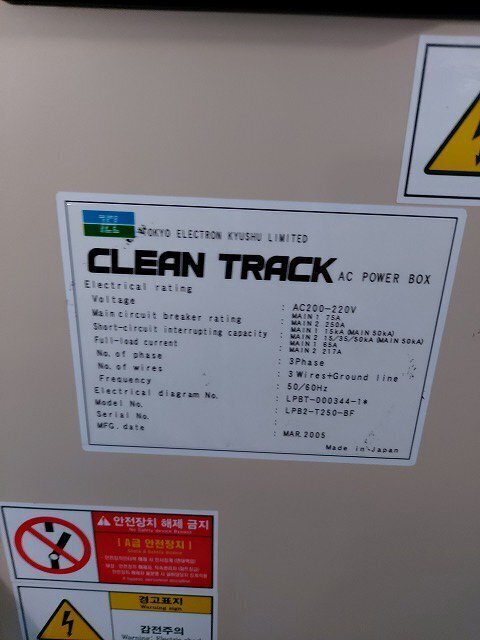

Utility:

Distribution panel

THC

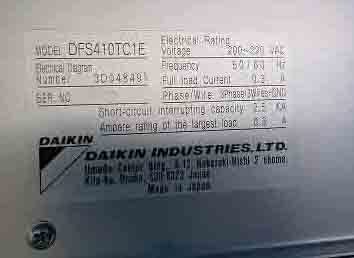

Chiller

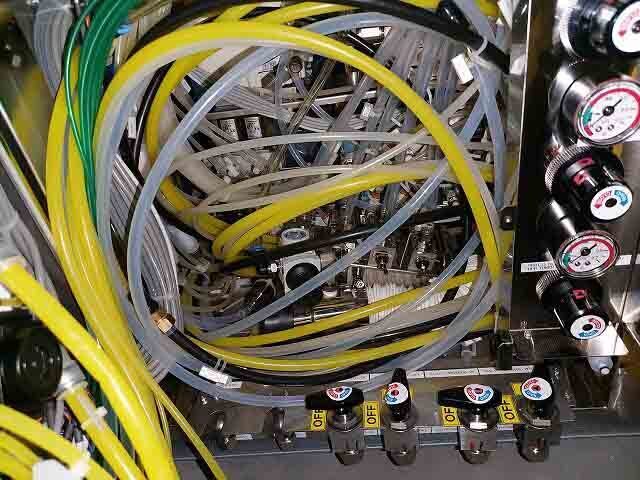

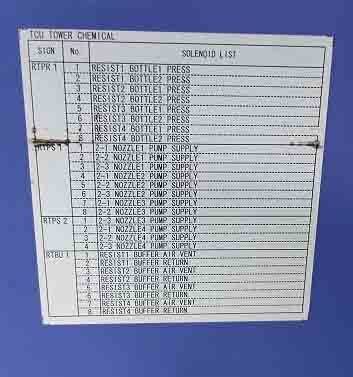

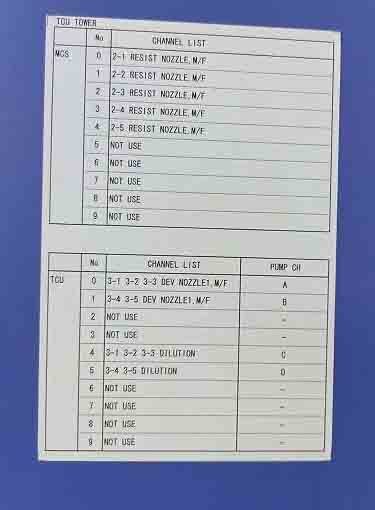

(2) Chemical boxes

ETC

Parts and tool

Module:

(4) PM1 Soft bakes

(5) PM2 PEB

(5) PM3 Hard bakes

(3) PM4 ADH

(5) PM5 COT

(5) PM6 DEV

(1) PM7 WEE

(1) PM8

(1) PM9

Litho tool:

Lens

Laser

Light source

Alignment

Power

2005 vintage.

TEL / TOKYO ELECTRON Lithius is a leading-edge photoresist equipment used in the fabrication and production of semiconductor and other electronics-related components. Photoresist is a light sensitive polymer used in a variety of microfabrication and photolithography processes. TEL Lithius system is comprised of four main components: liquid Crystal Display (LCD) imagesetter, an aligner, stepper tool, and track unit. The LCD imagesetter uses advanced optics to generate a high-precision image mask. The image data generated, known as a layout, is programmed into the LCD display. The layout is then projected onto the photoresist-coated wafer and the lithographic process begins. To ensure pinpoint accuracy, the LCD imagesetter has been tested out to 8x magnification and has an alignment accuracy rate better than 1 micron, which is important in the production of precise components. The aligner is used to precisely position the photoresist-coated wafer onto the stepper tool. This is performed with a vision machine and a wafer handler, both of which are capable of moving the wafer quickly and accurately in a sequence of predetermined steps. The aligner also utilizes a local electrode atomizer (LEA) tool to minimize the disruption of patterns while photoresist-coated wafers are being aligned. The stepper tool is the heart of the asset. It consists of an advanced stepper head with a motorized base, precision stage and a high-resolution microscope. The stepper head is responsible for controlling the illumination and powering the stepper tool, while the base enables safe and precise movement of the wafer. The microscope allows for positioning and alignment of the photoresist-coated wafer and is capable of imaging features as small as one-tenth of a micron in size. The last component of TOKYO ELECTRON Lithius model is the track equipment. This is responsible for the distribution of chemicals used during the photolithographic process. The track is a platform system which distributes chemicals, such as andeveloper and photoresist, to appropriate workstations in a precise, ordered sequence. This helps to ensure the uniformity and accuracy of the production process. In summary, Lithius unit is a state-of-the-art photoresist machine used in the production of semiconductor and other electronics-related components. Its LCD imagesetter provides precise image positioning and alignment, while the aligner facilitates accurate positioning of the photoresist-coated wafer. The stepper tool ensures precise imaging and control, and the track tool distributes chemicals in an orderly and uniform fashion. Together, these components ensure that photoresist-coated components are produced correctly and efficiently.

There are no reviews yet