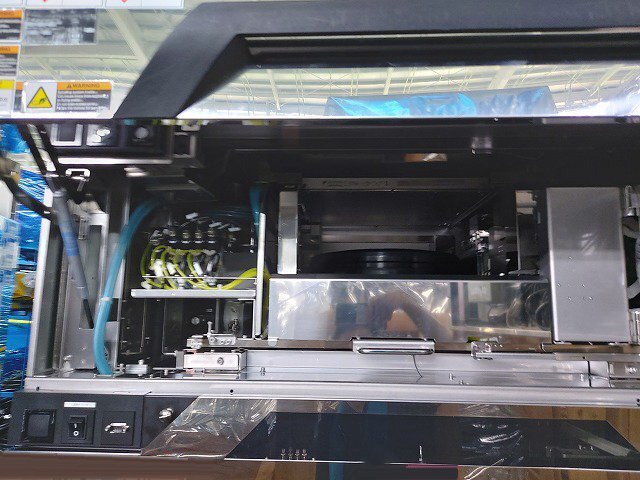

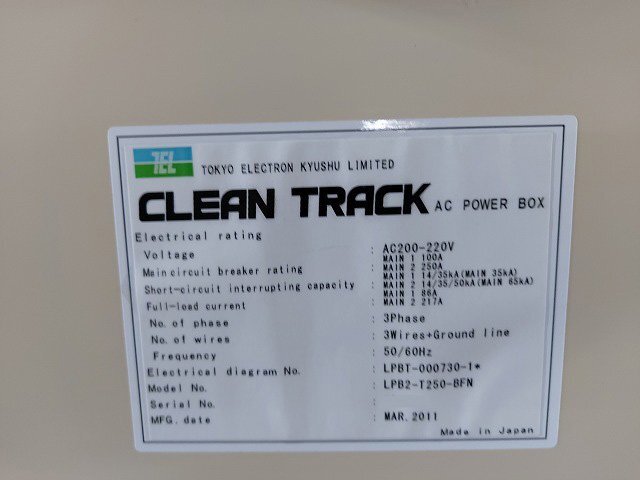

Used TEL / TOKYO ELECTRON Lithius #9397193 for sale

URL successfully copied!

Tap to zoom

ID: 9397193

Wafer Size: 12"

Vintage: 2012

System, 12"

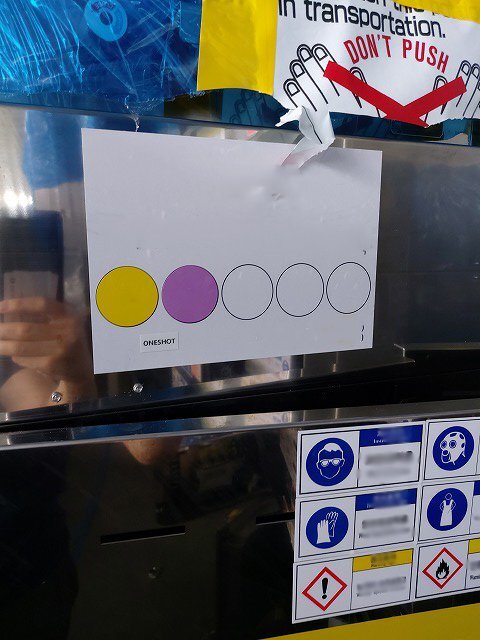

Material / Chemical:

PR, HMDS, Thinner, DEV

ArF Sub-process

Operating system: LINUX / Windows

SMIF

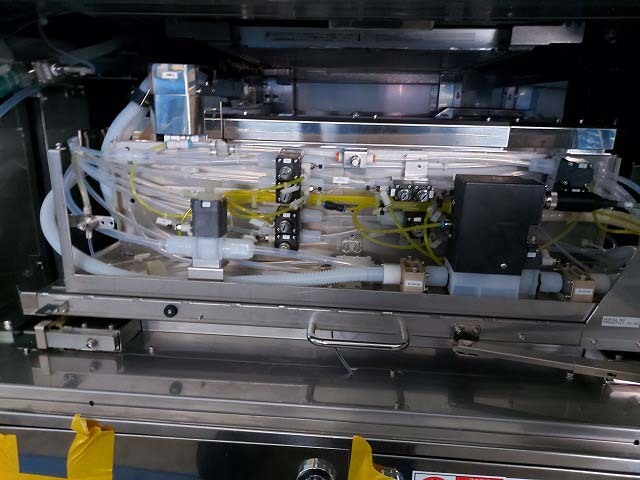

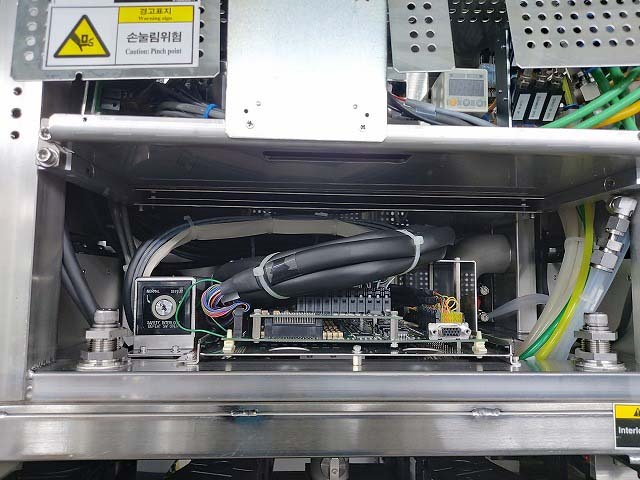

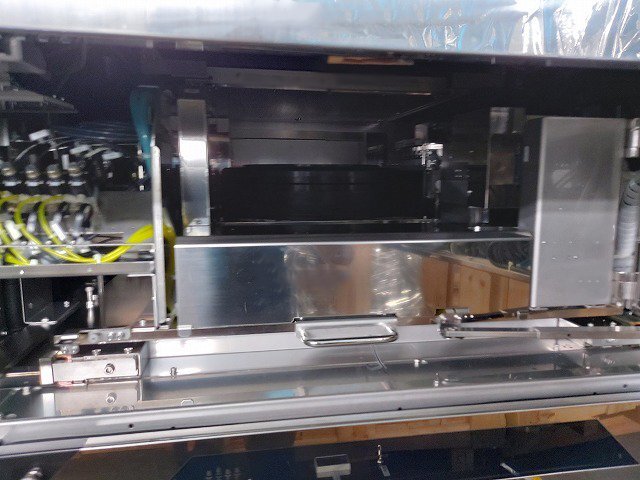

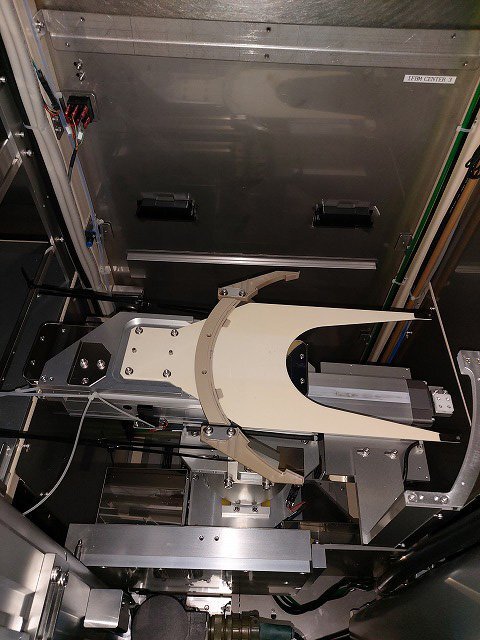

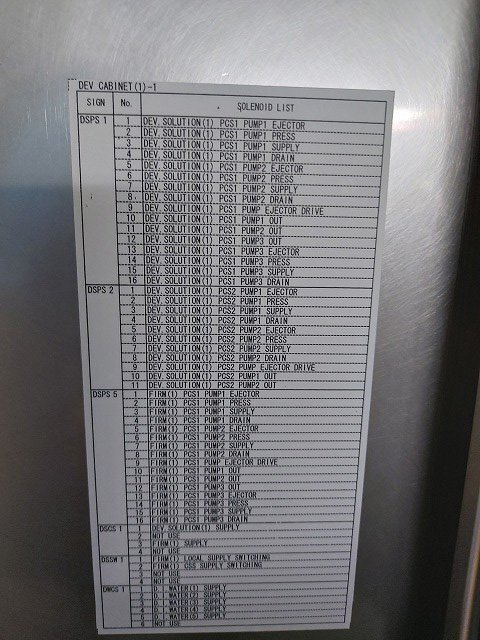

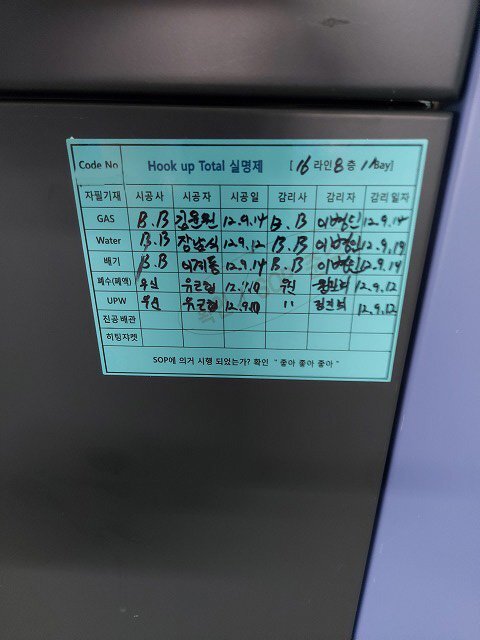

Hardware composition:

Load module:

(4) TEL Lithius load ports

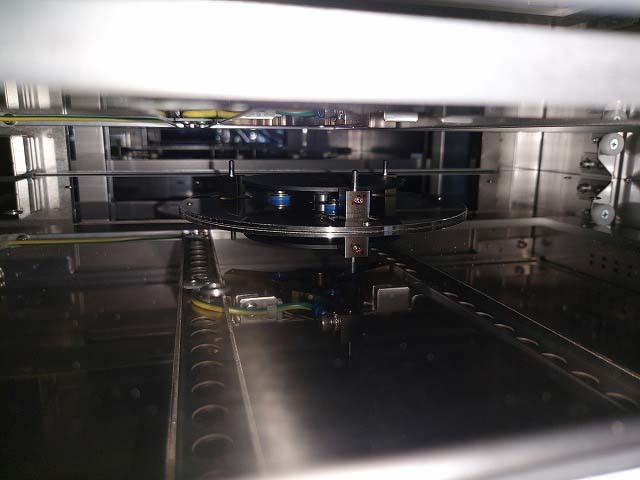

(1) TEL Lithius loader arm

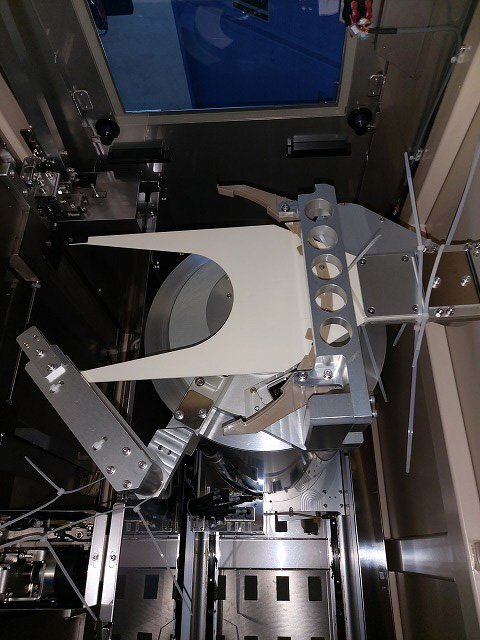

(5) TEL Lithius transfer robot arms

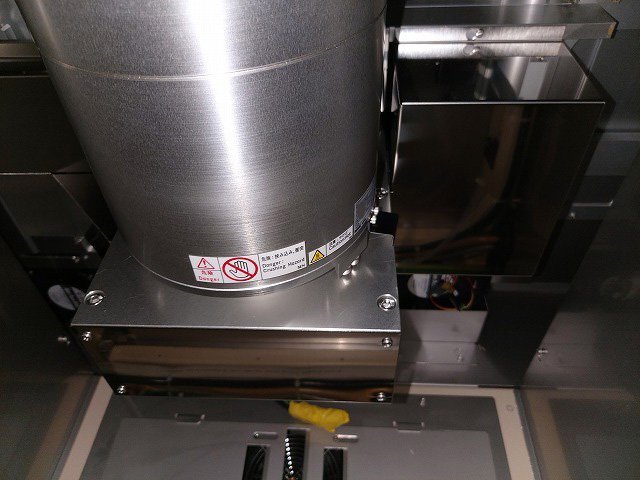

Process module:

Chamber

Pump

RF Generator

Gas box

PC

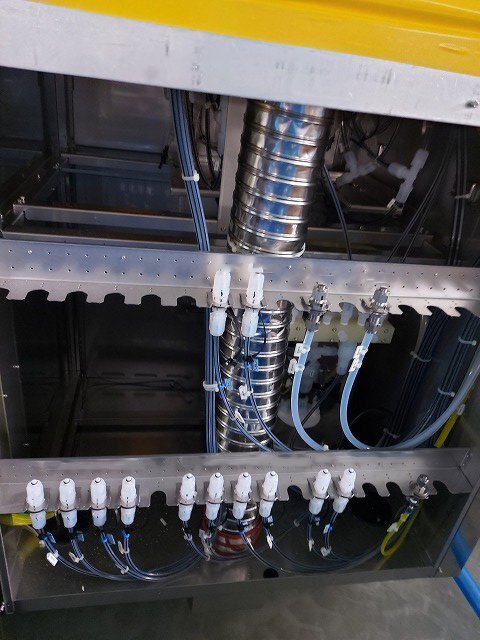

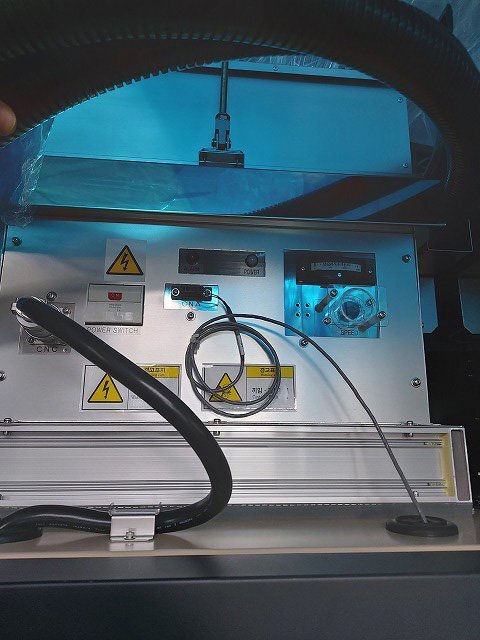

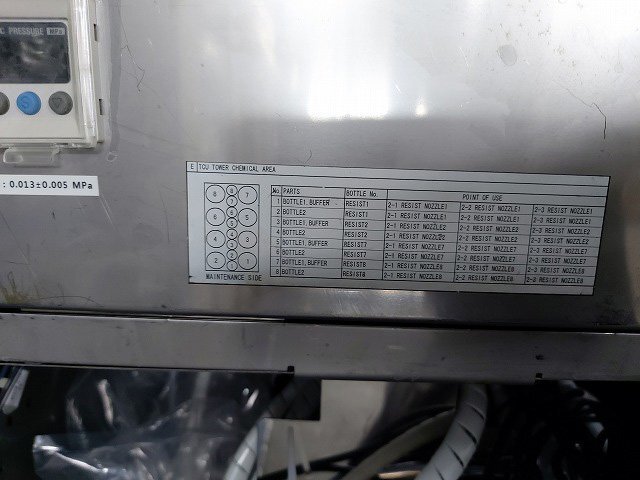

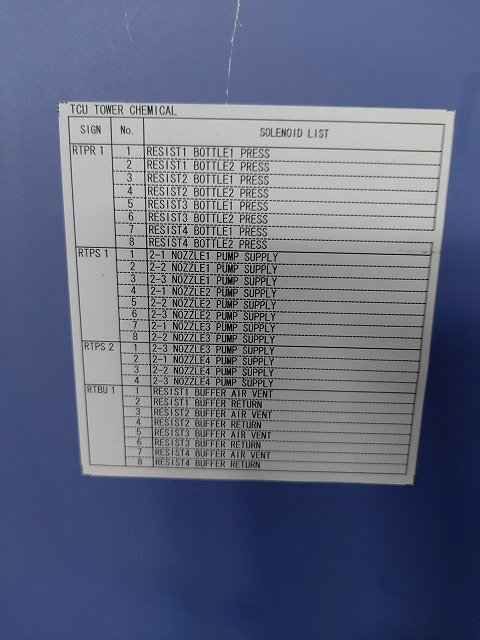

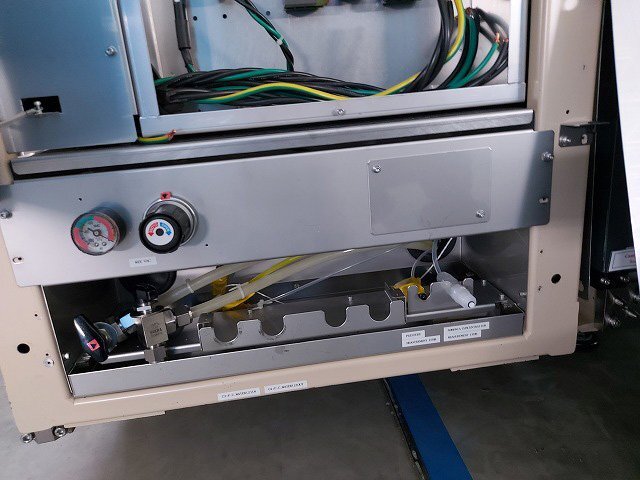

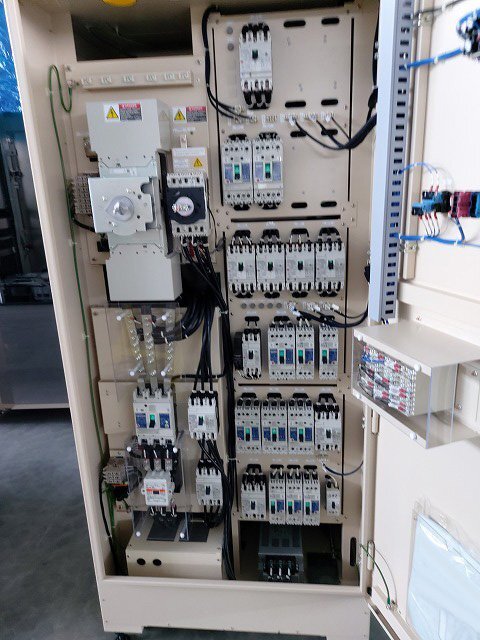

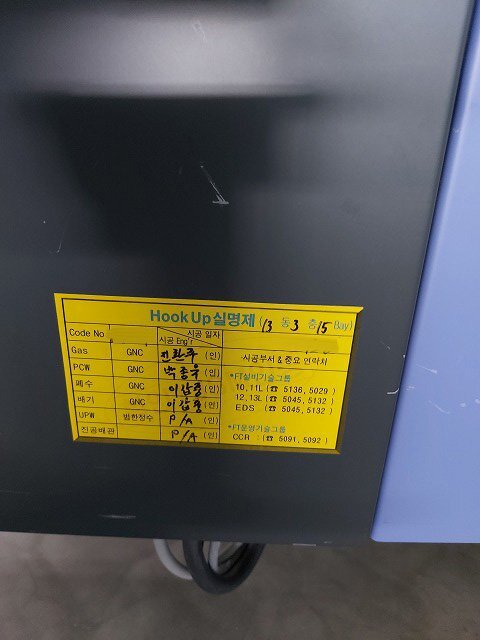

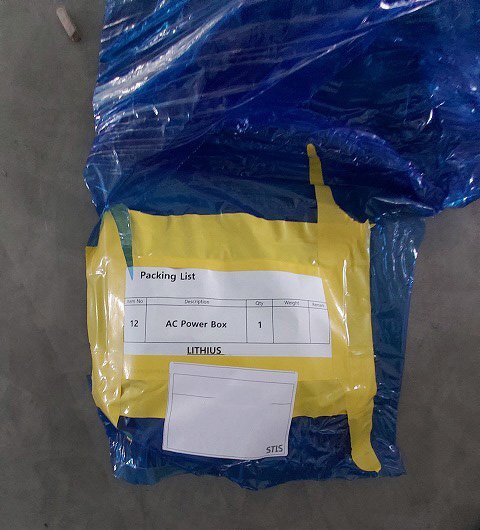

Utility:

Distribution panel

THC

Chiller

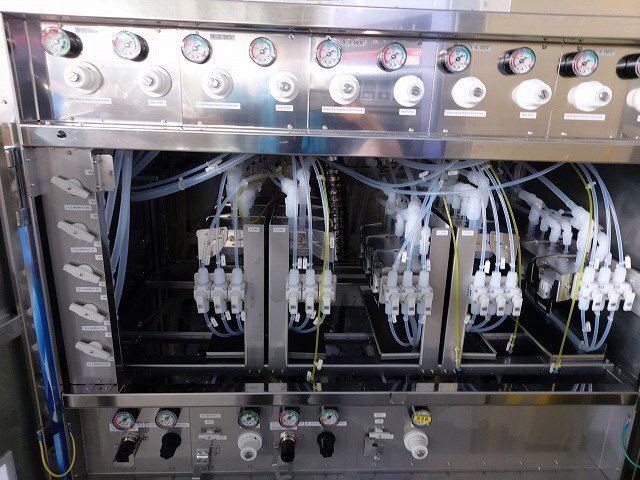

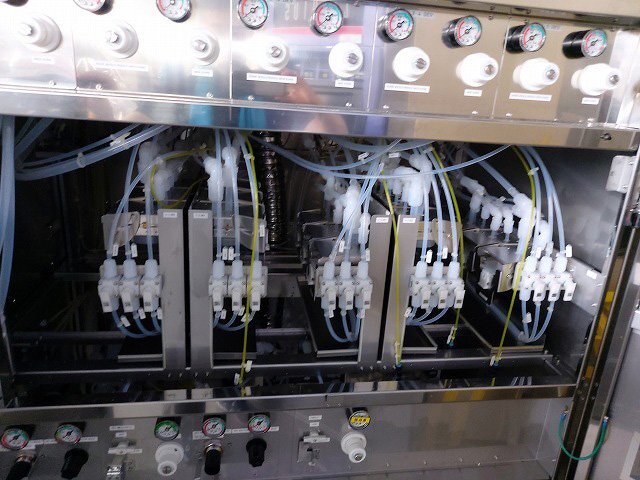

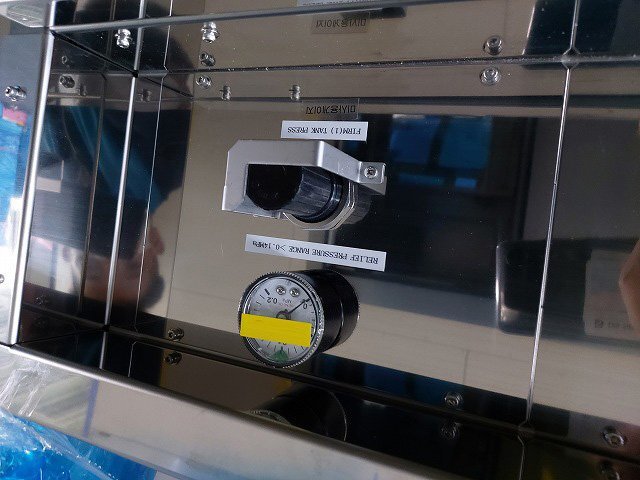

Chemical box

ETC

Parts and tool

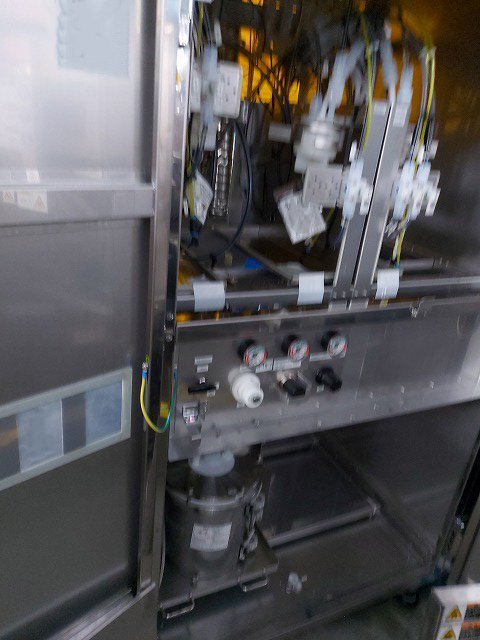

Module:

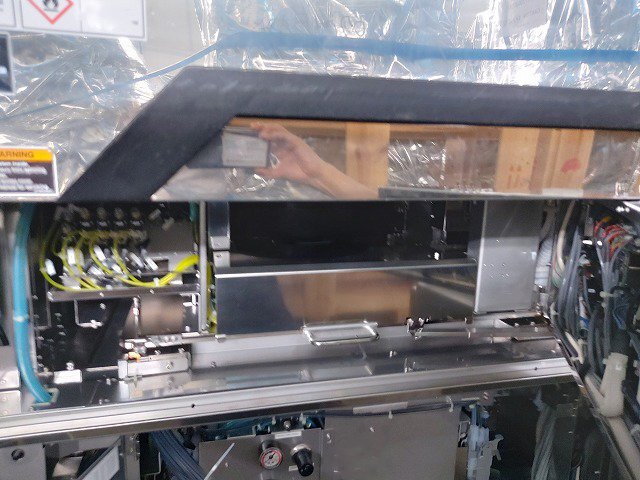

(8) PM1 Soft bakes

(4) PM2 ARC bakes

(8) PM3 PEB

(3) PM4 Hard bakes

(3) PM5 ADH

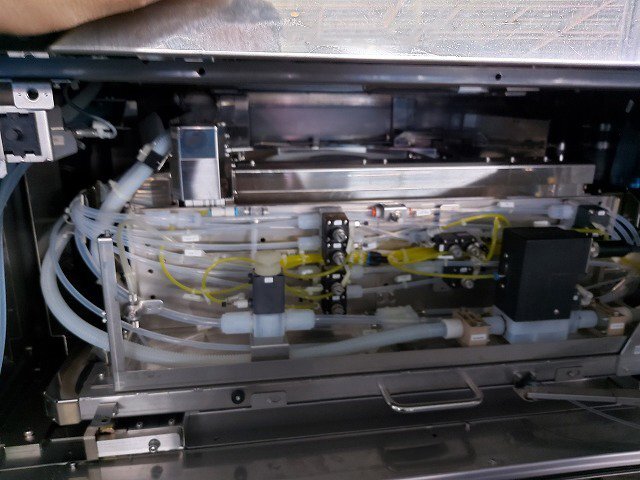

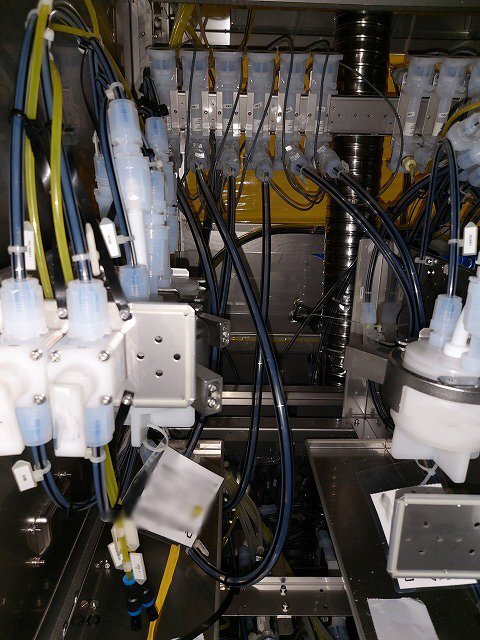

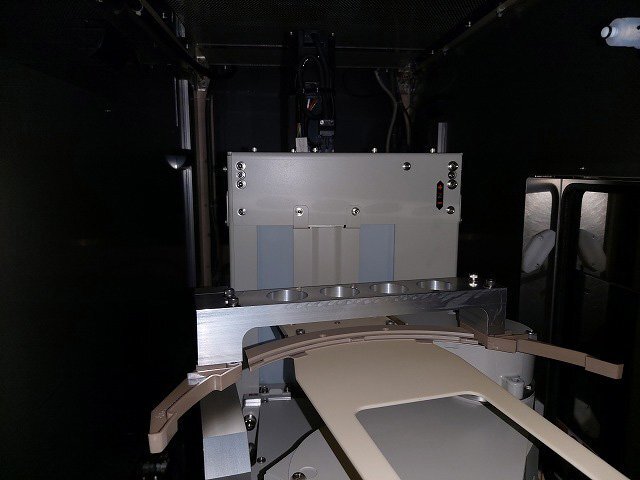

(5) PM6 COT

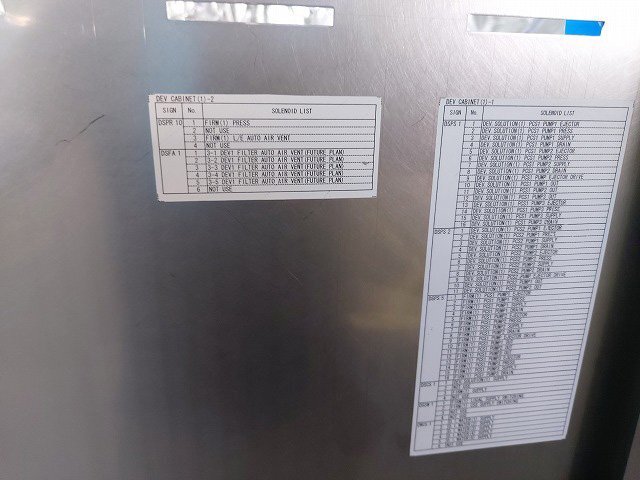

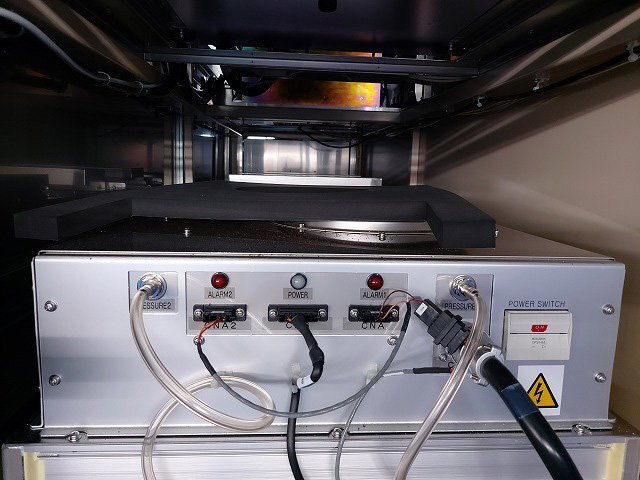

(5) PM7 DEV

(1) PM8 WEE

PM9

Litho tool:

Lens

Laser

Light source

Alignment

Power

Process: HT-PYRO (1250C)

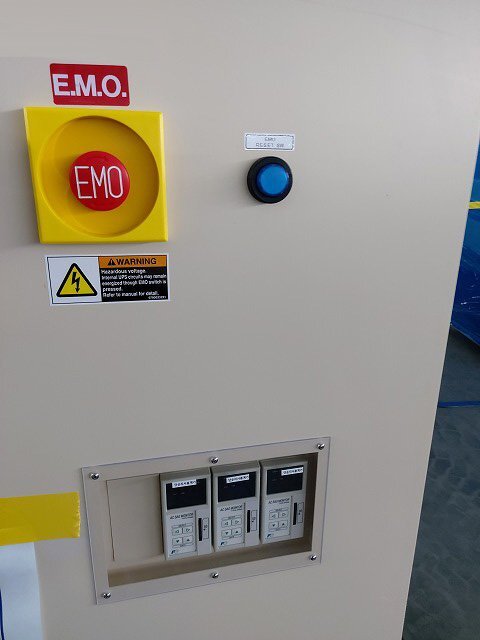

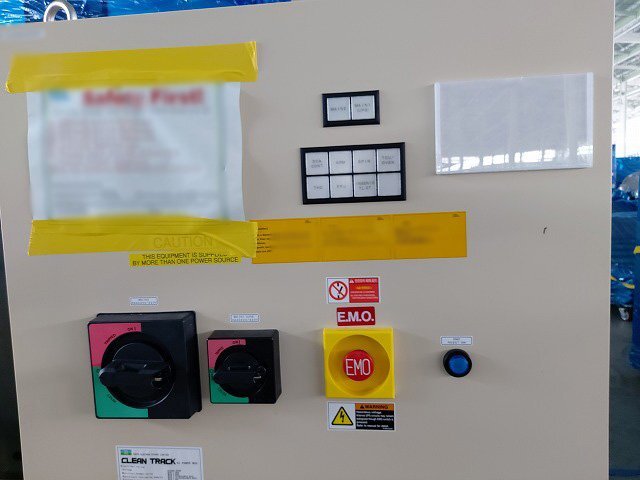

Safety: TEL Standard

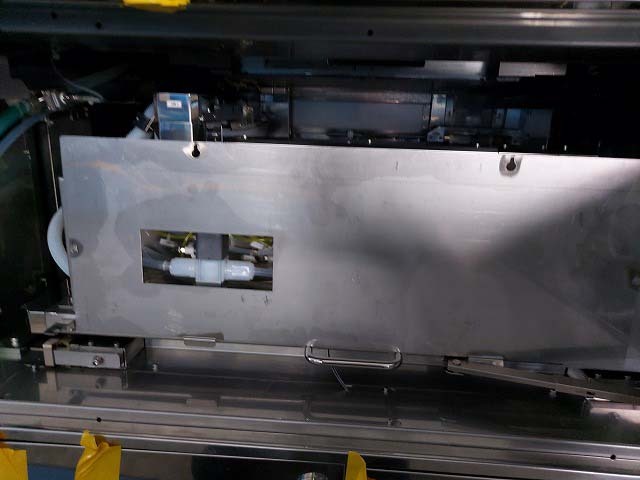

Layout type: U/Box

Tool direction: LL

Front furnace body: Coating (FDP Standard)

Heater (Range of temperature): High VMU-40-007EXT(41) [850-1250°C]

Process:

Pressure: ATM

Temperature: 1250°C

Wafer / Cassette transport:

SEMI Standard - Notch, 12"

T/S Wafer jump out detection

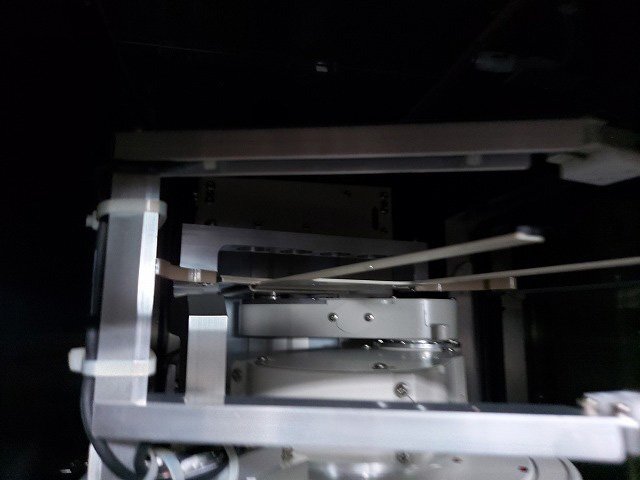

Fork type / Material: 1+4 / Al203

Wafer In / Out order: ED -> P -> M / M -> P -> ED

Cassette:

Miraial (MK-823S-H)

Slot: 26

Stocker: 21

Monitor cassette:

In P1, P2, M / Out P1, P2, M

Fork :

Wafer detection

Wafer displacement detection

Pitch conversion

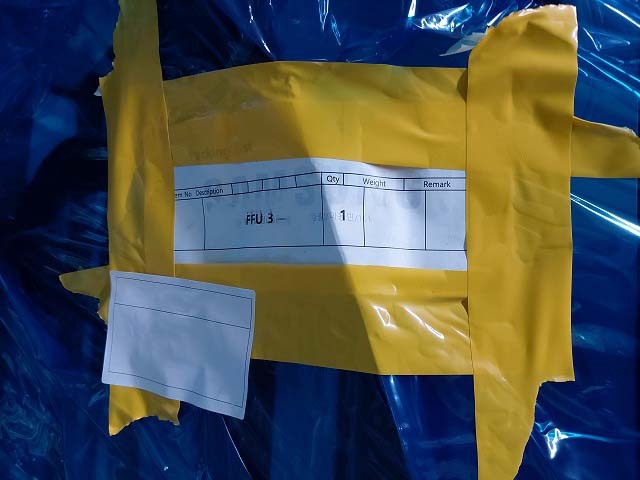

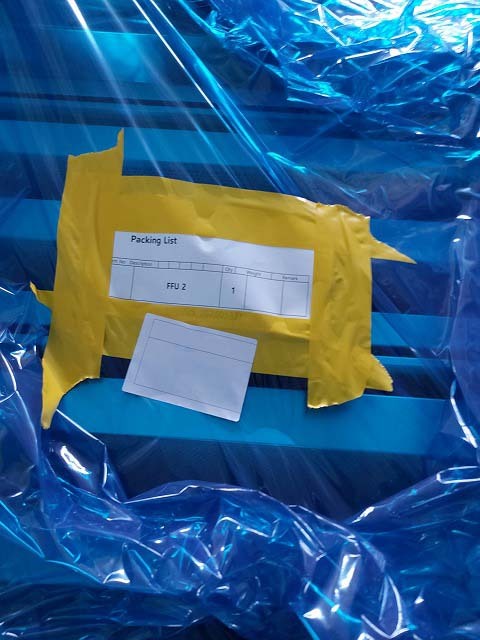

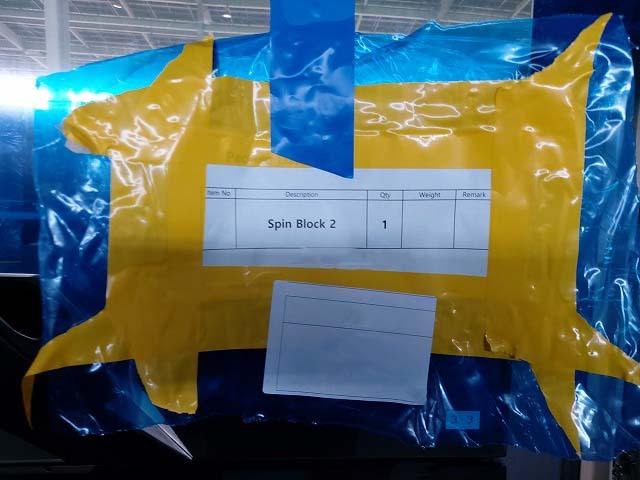

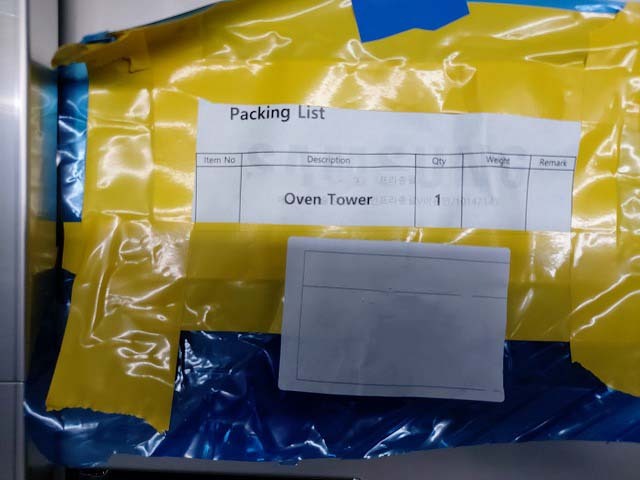

Missing parts:

S/V ADH256 Chamber coat error

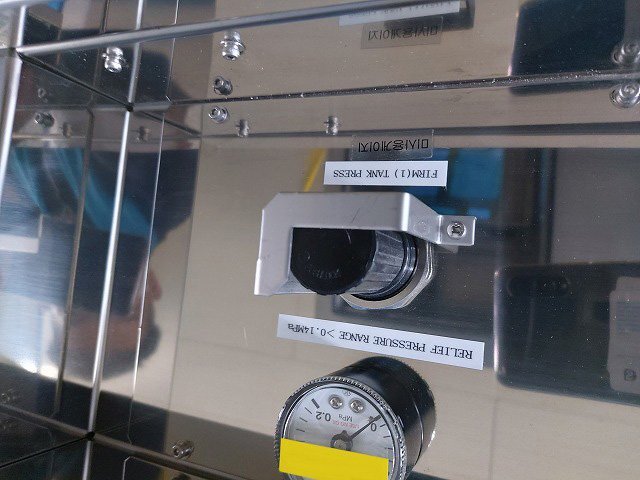

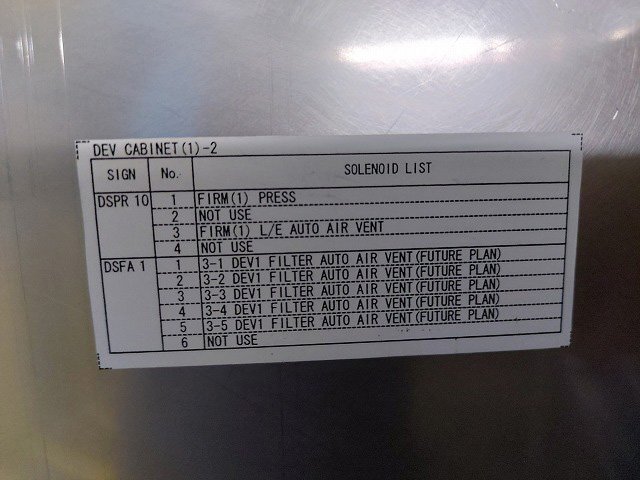

DEV303 AOV Bath rinse

DEV303 AOV Firm rinse

IRAS R-Axis driver

Port clamp cylinder

COT201, COT203 Spin chuck

LHP Temperature board

Mapping arm assembly

WEE Fan

L-Arm Z-motor

IRAS Z-Driver

IRAS Y-Driver

IRAS X-Driver

IRAS X-motor

UPS Battery swap

Control power supply swap

EC Controller swap

CRA Cover, ITL Switch

Ejector

Y-Driver

X5 Cable

DEV 301 Spain I/O Board

(2) Borads, COT MTR

4-Ports assembly

Hard Disk Drive (HDD)

2012 vintage.

TEL / TOKYO ELECTRON Lithius is a photoresist equipment that is used in a variety of manufacturing processes. Photoresist systems are used to prepare and process a substrate for further processing or manufacturing steps. TEL Lithius is a next-generation photoresist system made by TEL, a technology solutions provider. The unit allows customers to develop a resist process in a few steps. It can provide accurate patterning control, while improving resolution and depth of focus in high-resolution microlithography. The machine can increase process throughput and improve yields in various photolithography processes. TOKYO ELECTRON Lithius is capable of performing advanced lithography techniques, such as thin-film imaging, deep-ultraviolet lithography and atom-beam lithography. It also supports photopatterning, a technique where a single mask is used to pattern high-resolution patterns on a single wafer. The tool utilizes several advanced technologies, including an electron beam source, solid immersion lenses, variable numerical apertures, and an integrated objective projection lens. This combination of technologies allows the asset to produce higher resolution and finer patterns compared to other photoresist techniques. The model is designed to be easy to use and operate, allowing customers to select parameters or recipes that can be quickly changed to adjust the process. The equipment offers customers with a degree of flexibility that can be tailored to their specific needs. The system offers enhanced film thickness control, a larger beam current envelope, and improved substrate material performance. These features provide customers with improved throughput and accurate patterning results. Lithius is ideal for chipmakers and other manufacturing applications, such as organic photovoltaic modules, high-density interconnects, microfluidics, and advanced substrates. The unit can be utilized for a variety of processes, including implantation, patterning, and dry etch and wet etch. Overall, TEL / TOKYO ELECTRON Lithius is a powerful and versatile photoresist machine that is designed to streamline and improve photolithography processes. It is an ideal solution for customers looking for an advanced tool with improved throughput and better yields.

There are no reviews yet