Used TEL / TOKYO ELECTRON Mark 7 #9119206 for sale

URL successfully copied!

Tap to zoom

ID: 9119206

Wafer Size: 6"

Vintage: 1995

Track system, 6"

Left to right for 8"

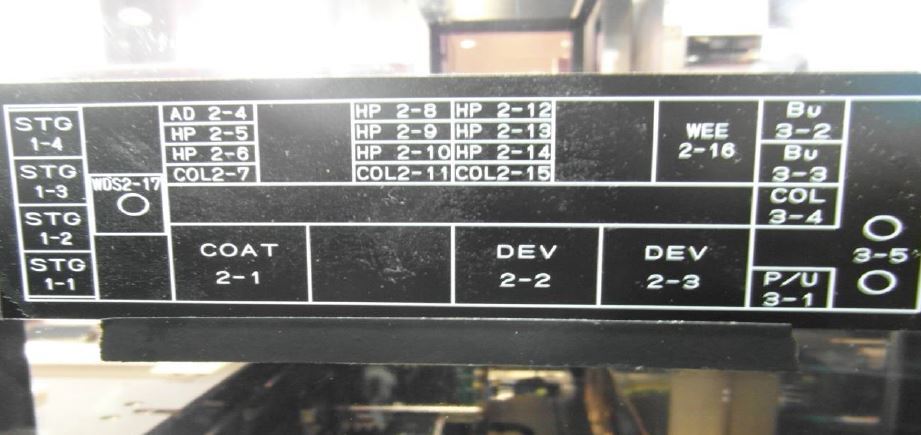

Indexer: (4) cassette stage (uni-cassette)

Configuration:

Main body

IF

Chemical cabinet 1

Chemical cabinet 2

THC

PC rack

Main controller: NEC FC-9801F

C/S Robot type: vacuum arm, ceramic pincette

Main robot type: 3 pincette arm

Indexer: laser diode mapping sensor

COAT:

(4) Resist nozzles / bellows pumps

(1) Gallon resist bottle / thinner local supply (canister)

EBR nozzle / back rinse nozzle

Local drain (1st SUS 10L tank/drain pump)

DEV:

Nozzle type: E2

Rinse nozzle / back rinse nozzle

Local supply / facility drain

WEE:

TEL Standard

UL-200T-L1 UV Light source

AD:

TEL Standard

Local supply

Currently warehoused

1995 vintage.

TEL / TOKYO ELECTRON Mark 7 is a photoresist equipment used in the photolithography process for semiconductor device production. It removes waste light generated during the process through laser light technology, while controlling the optical conditions of a substrate surface. TEL MARK7 uses a 633nm or 635nm laser wavelength for the laser light source, in combination with an adjustable slit and oscillation optics. The system contains a reflector and optical filter assembly, which can be adjusted for the intensity and tilt of the laser beam. It also contains a high-precision shutter which is capable of precisely controlling the exposure period of the substrate. TOKYO ELECTRON MARK-7 also has a built-in photoresist dispensing unit that can dispense photoresist material at consistent rates without misting or dripping. The machine is designed to minimize environmental contamination and minimize background interference. It is capable of achieving high-precision surface results by setting multiple parameters such as the slit-angle and laser power. The tool has an extremely accurate spatial resolution of 1μm, making it capable of producing high-quality results on a variety of substrate surfaces. TEL / TOKYO ELECTRON MARK7 is an extremely efficient asset with high precision control, making it an ideal choice for the manufacture of semiconductor devices. It is highly reliable and boasts a long life-span due to its robust construction. The model can also be easily set up and is extremely user friendly. Overall, MARK-7 is an advanced photoresist equipment used in the manufacturing of semiconductor devices. It is capable of providing highly precise results due to its laser-light technology and adjustable slit and oscillation optics. It is highly reliable and user friendly, making it an ideal choice for the production of extreme quality substrates.

There are no reviews yet