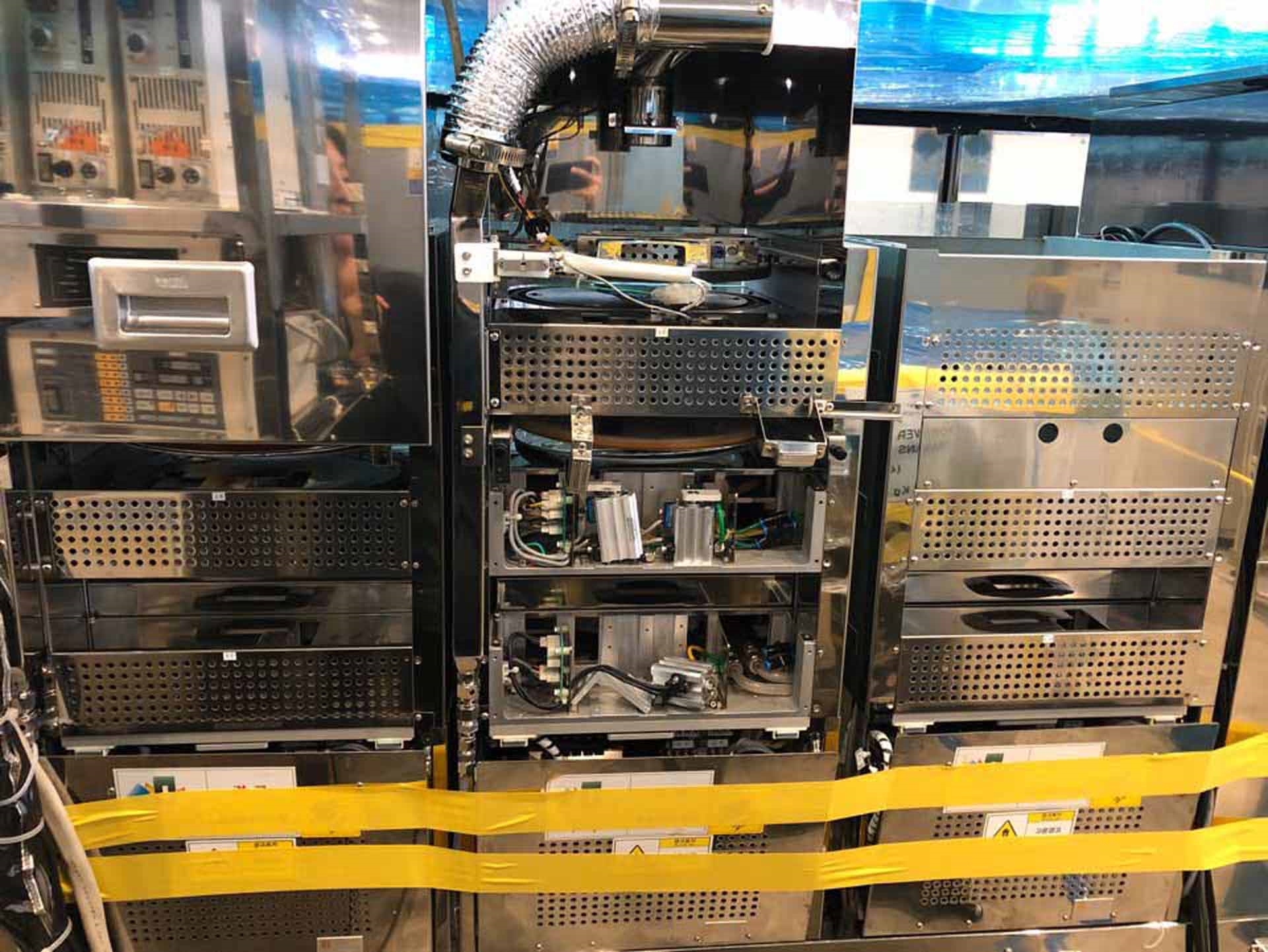

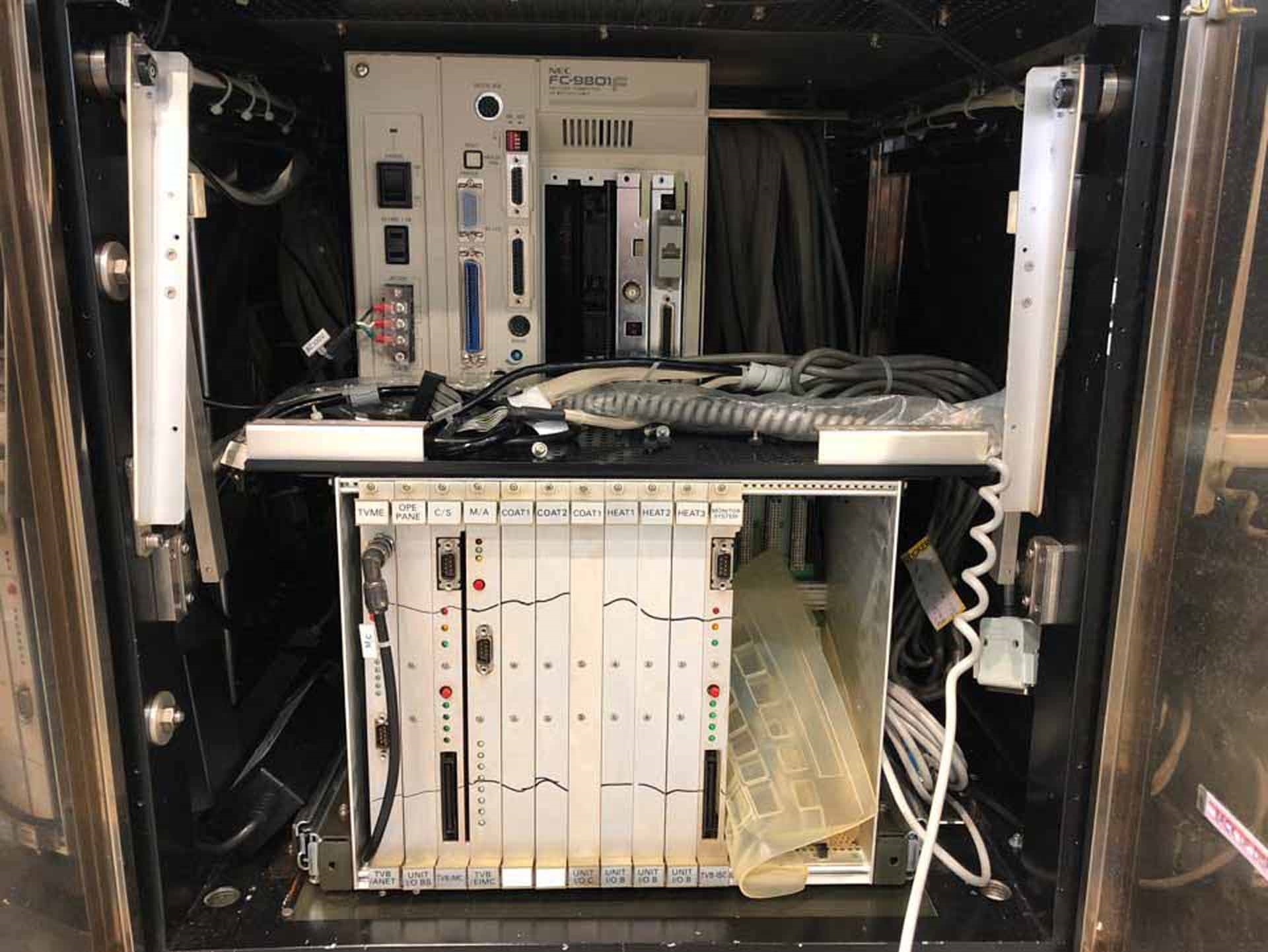

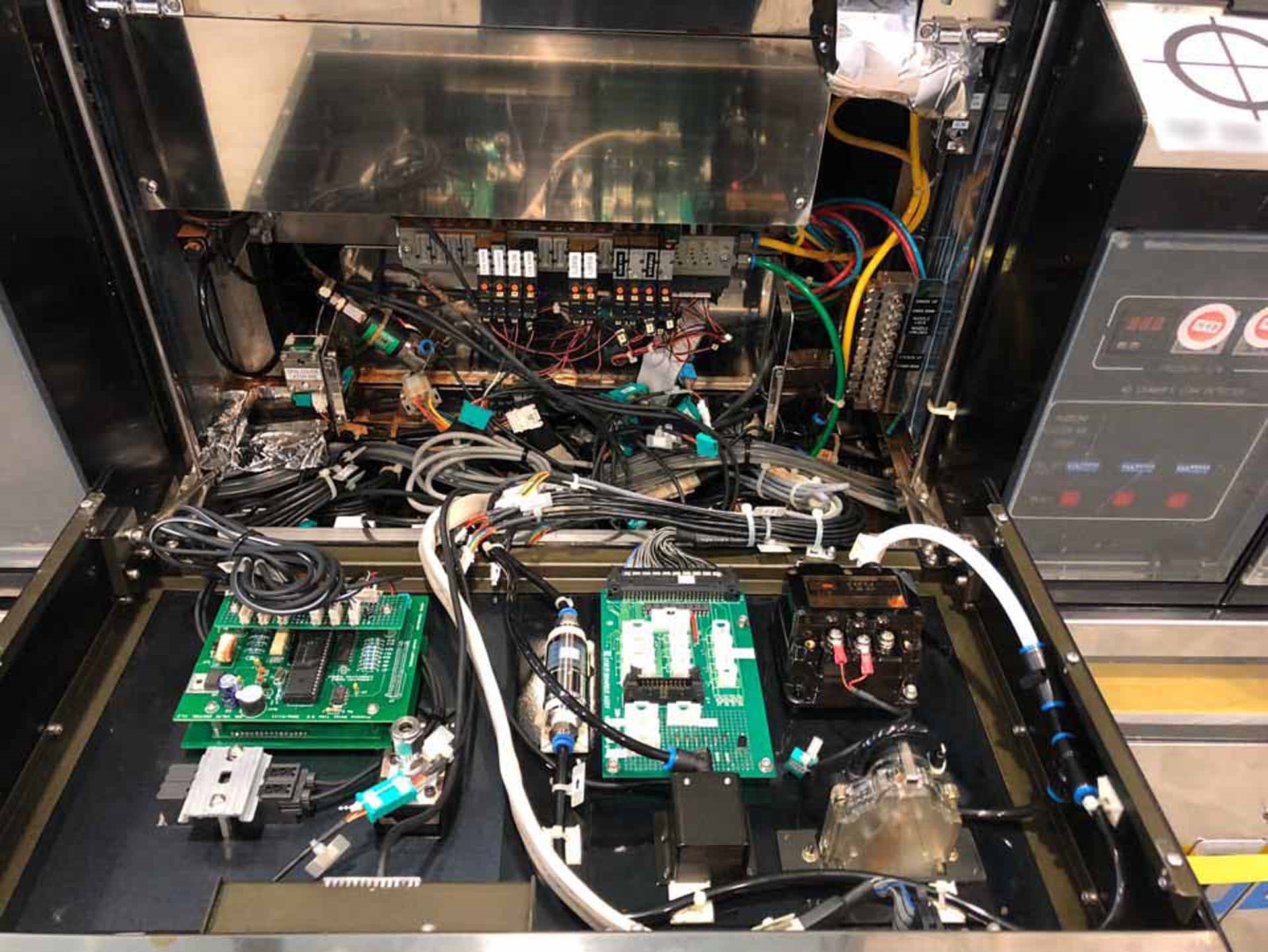

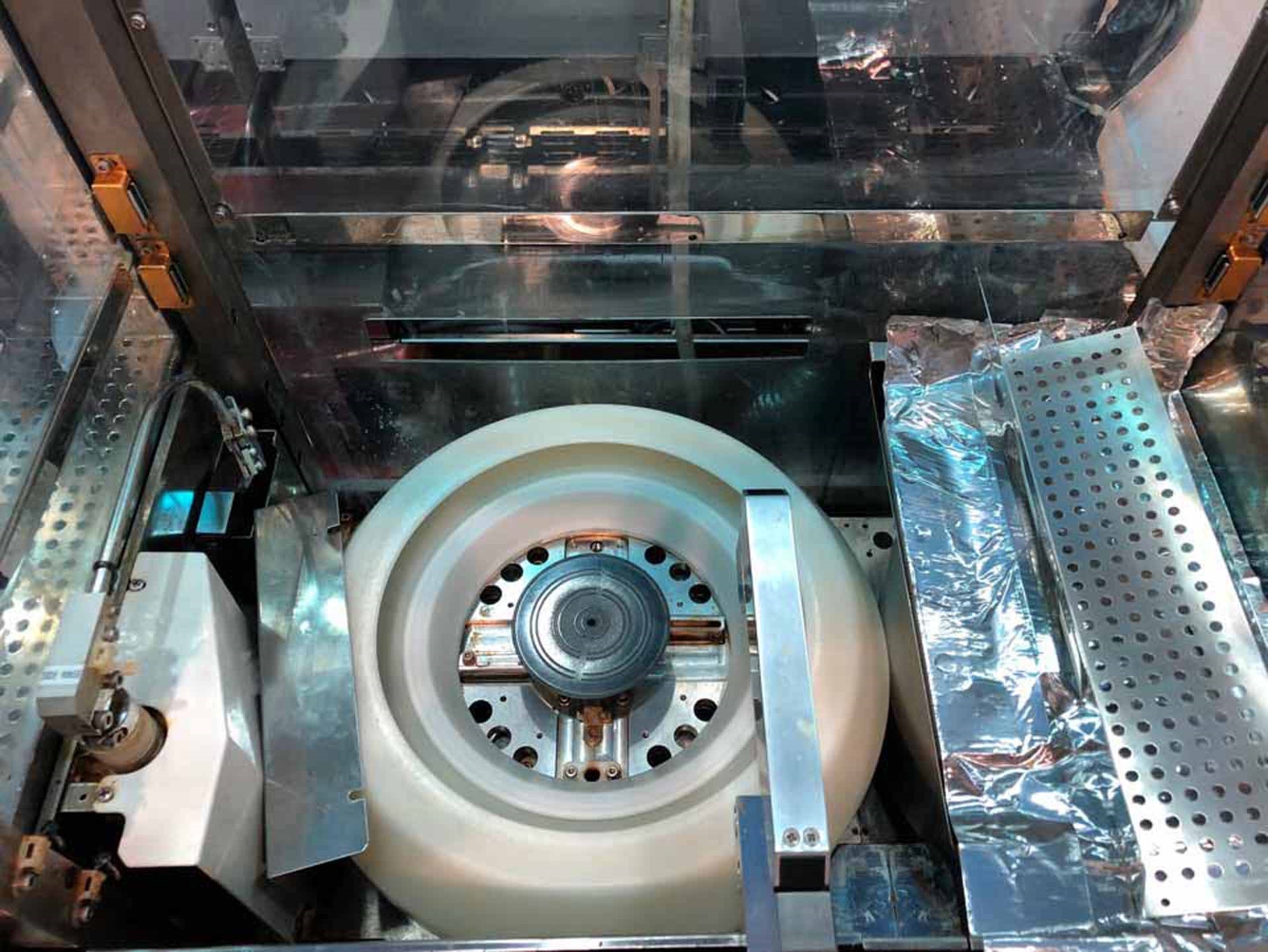

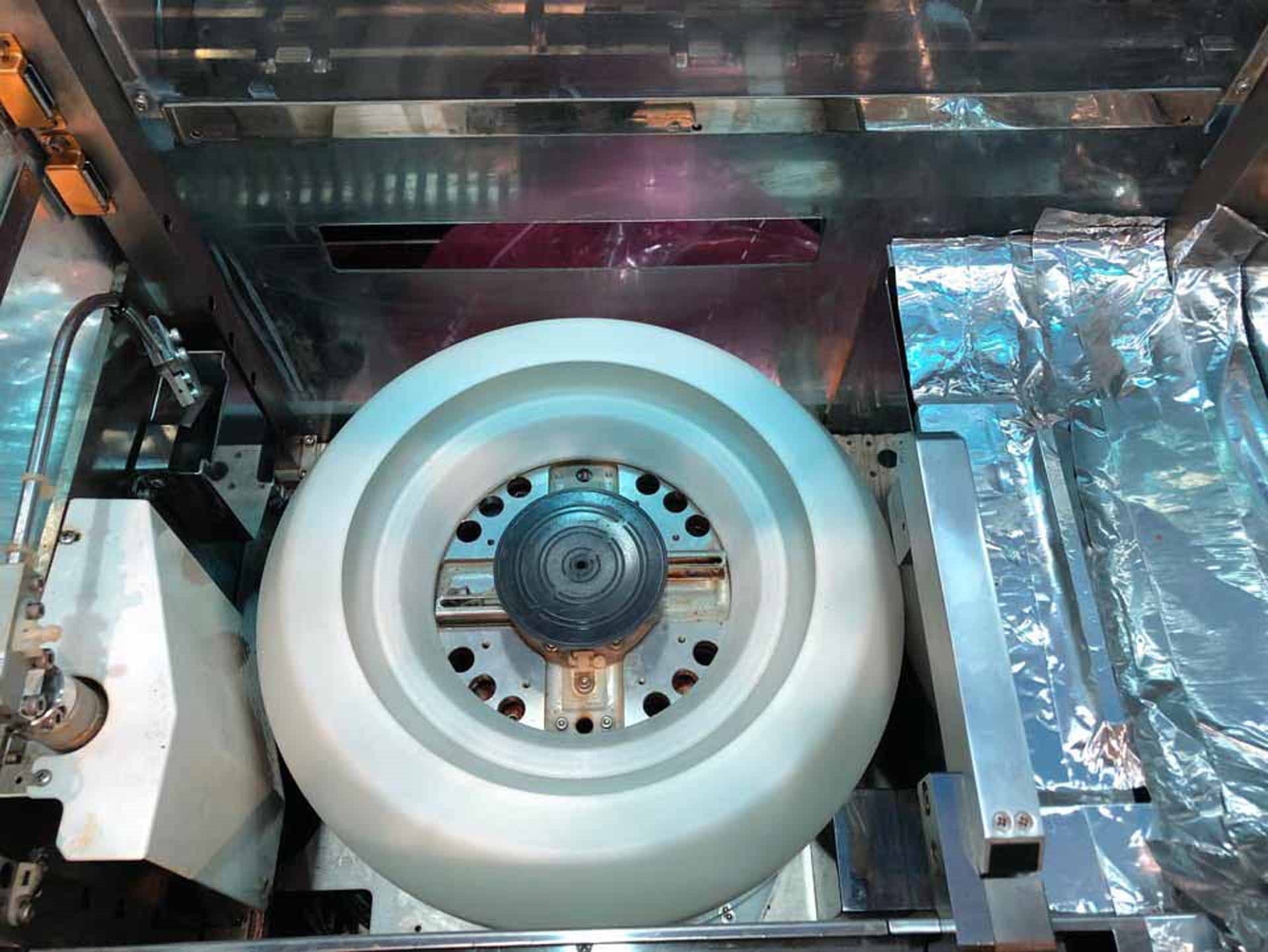

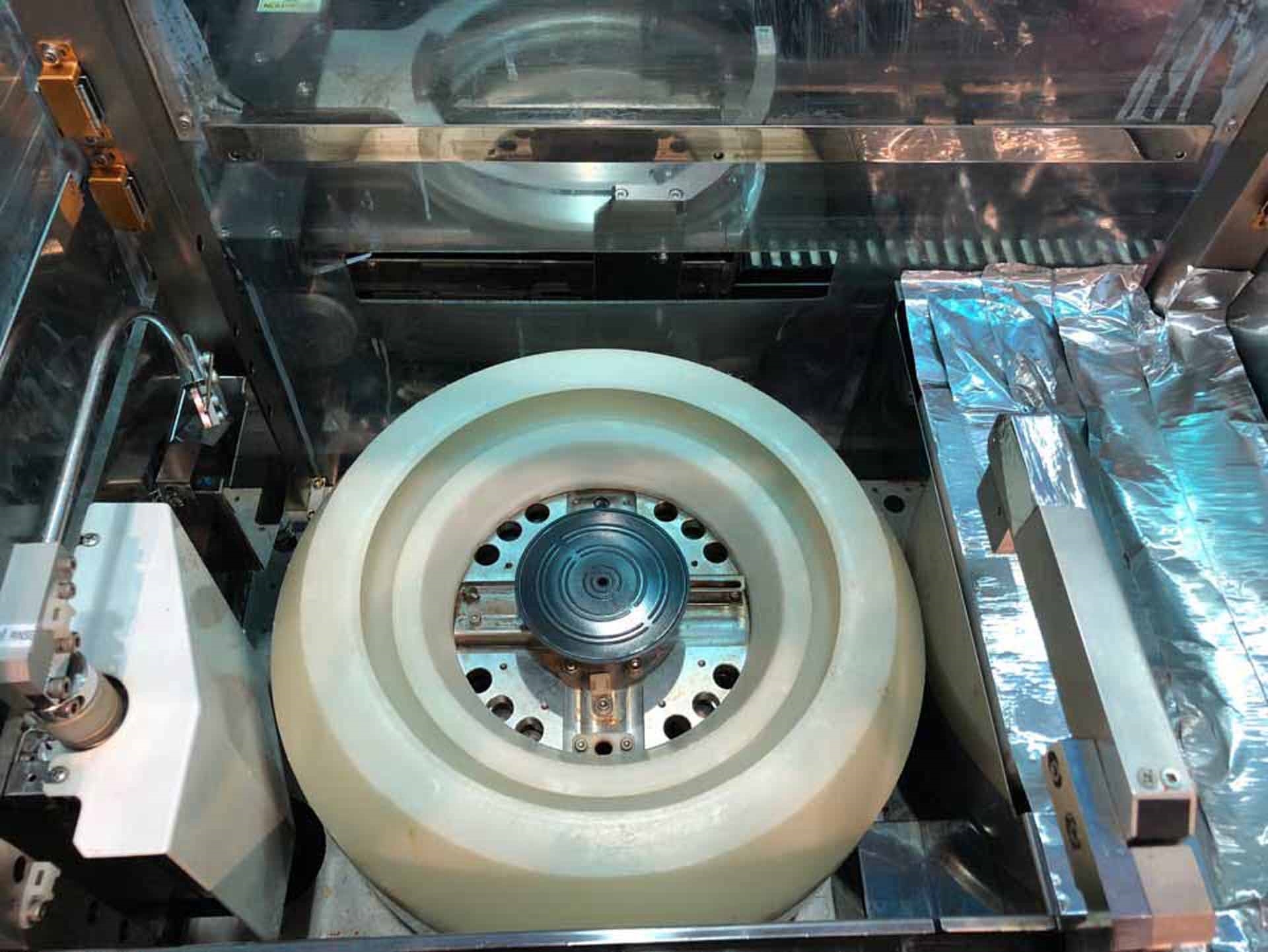

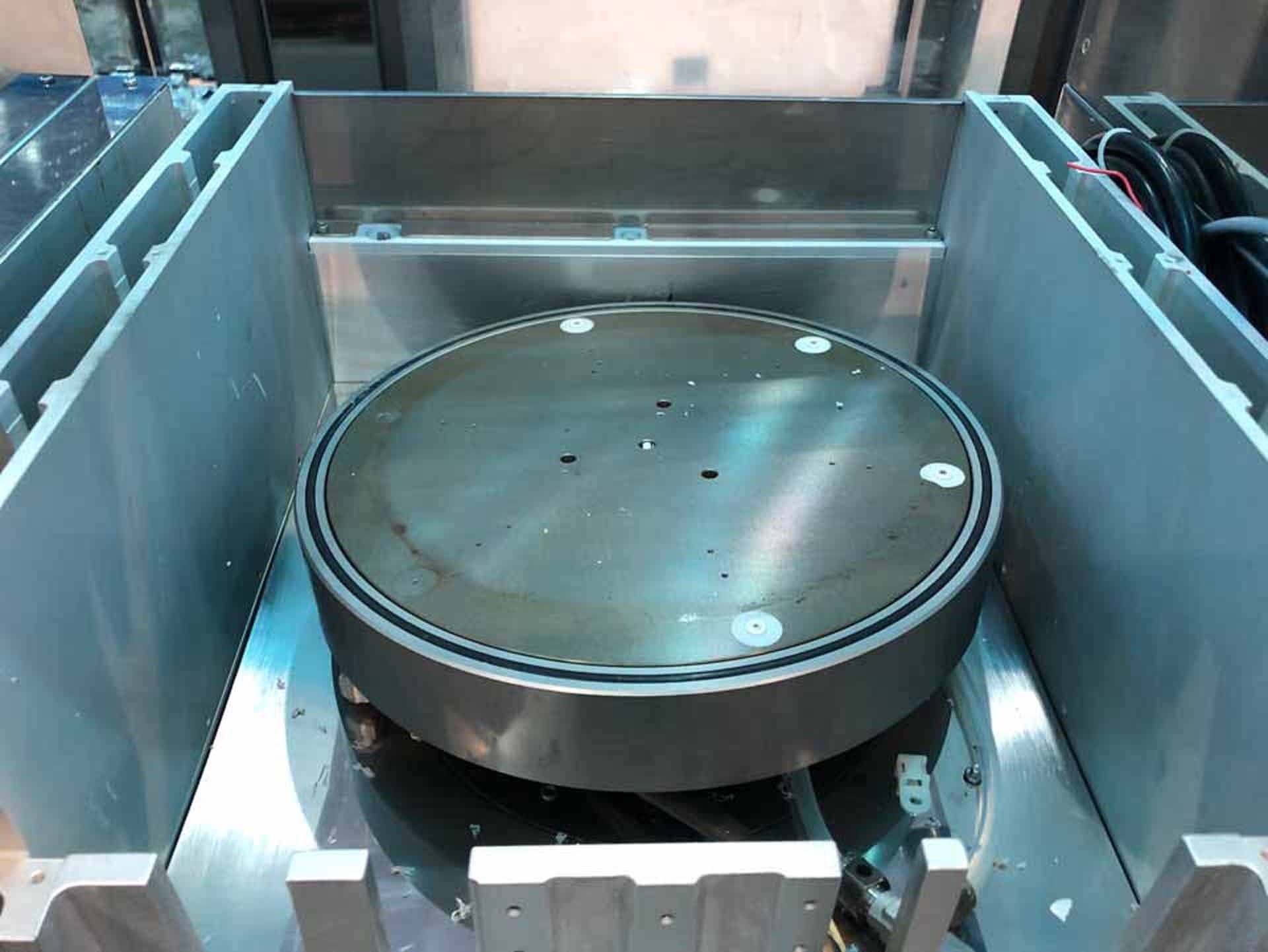

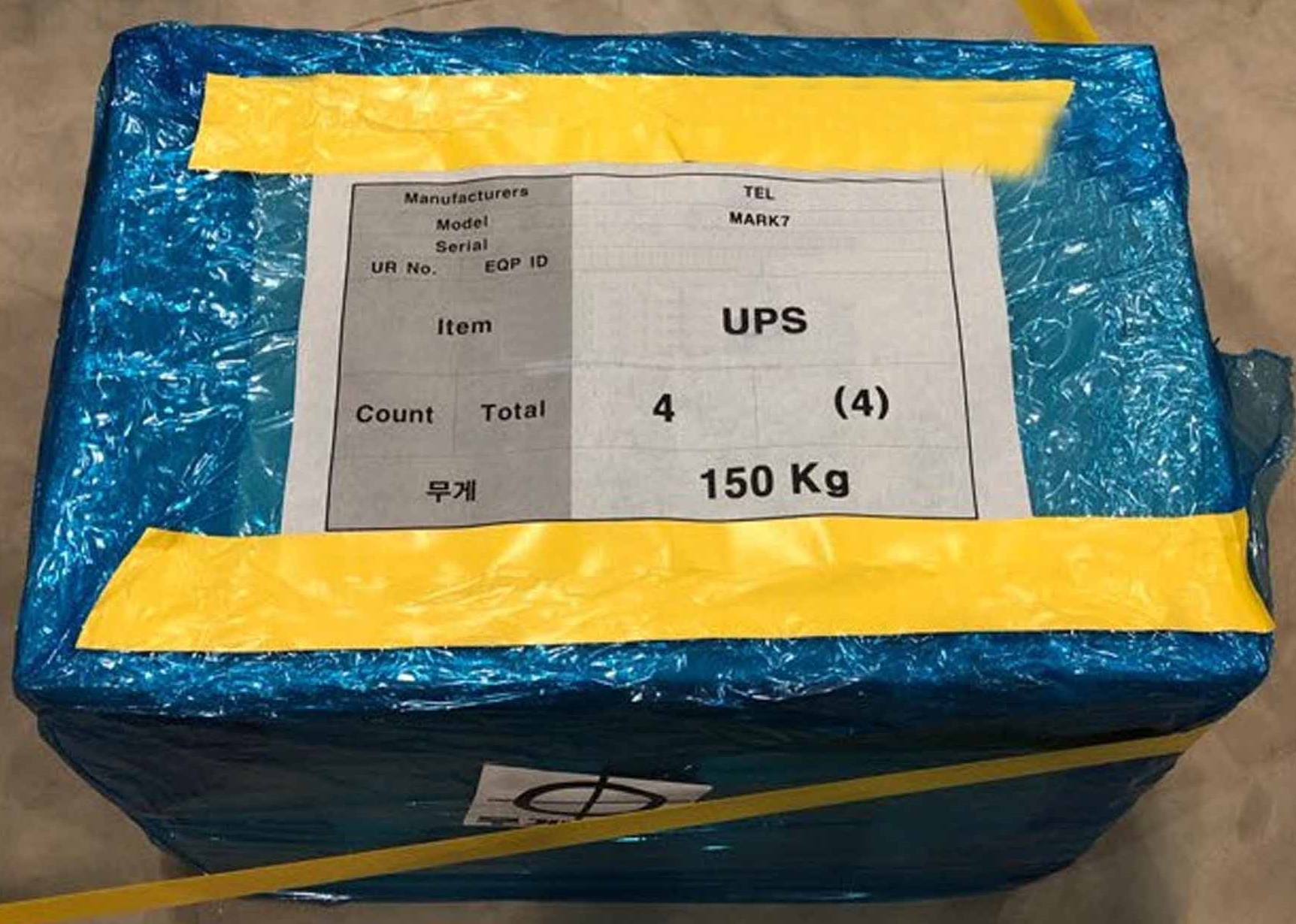

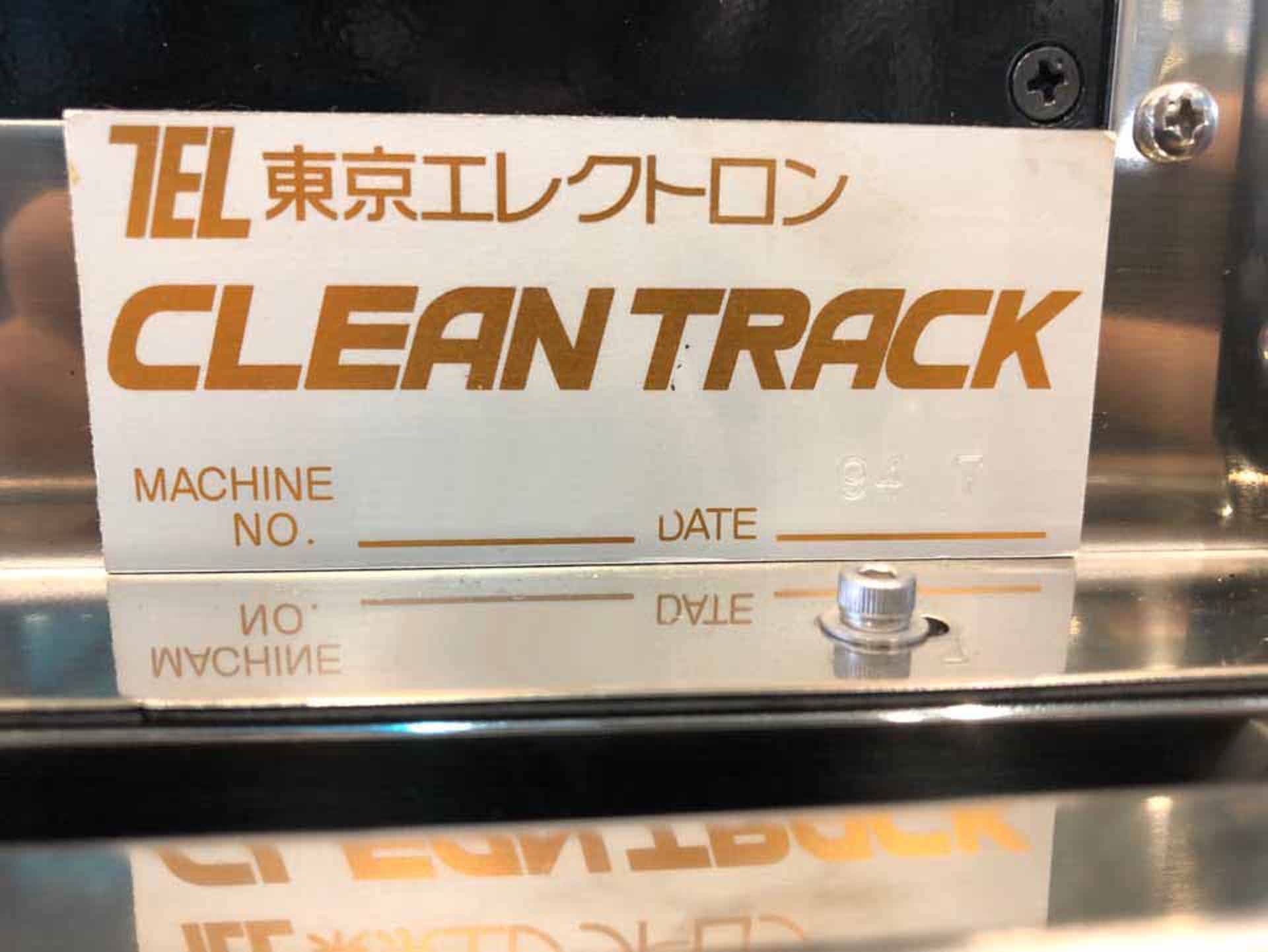

Used TEL / TOKYO ELECTRON Mark 7 #9244882 for sale

URL successfully copied!

Tap to zoom

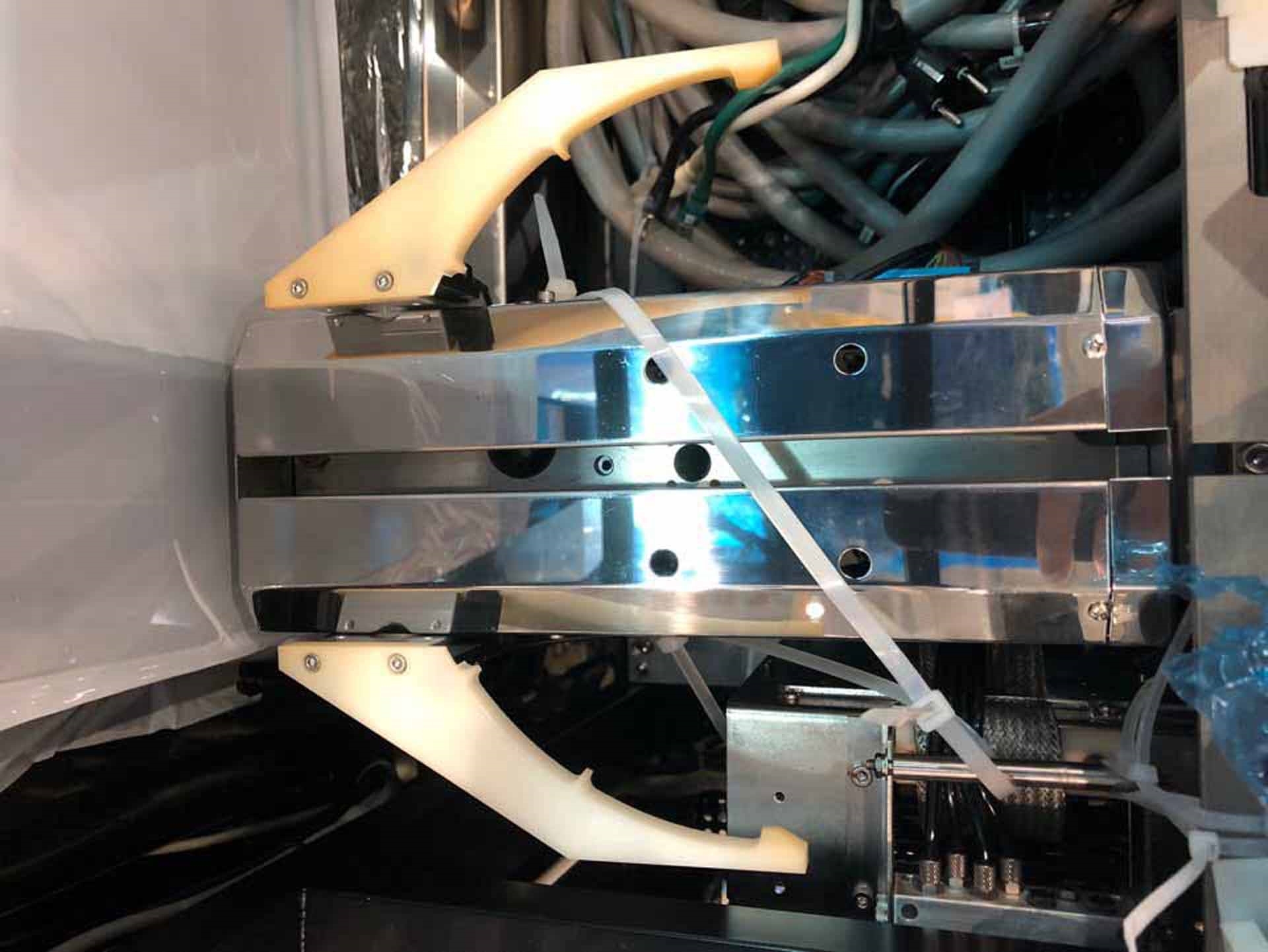

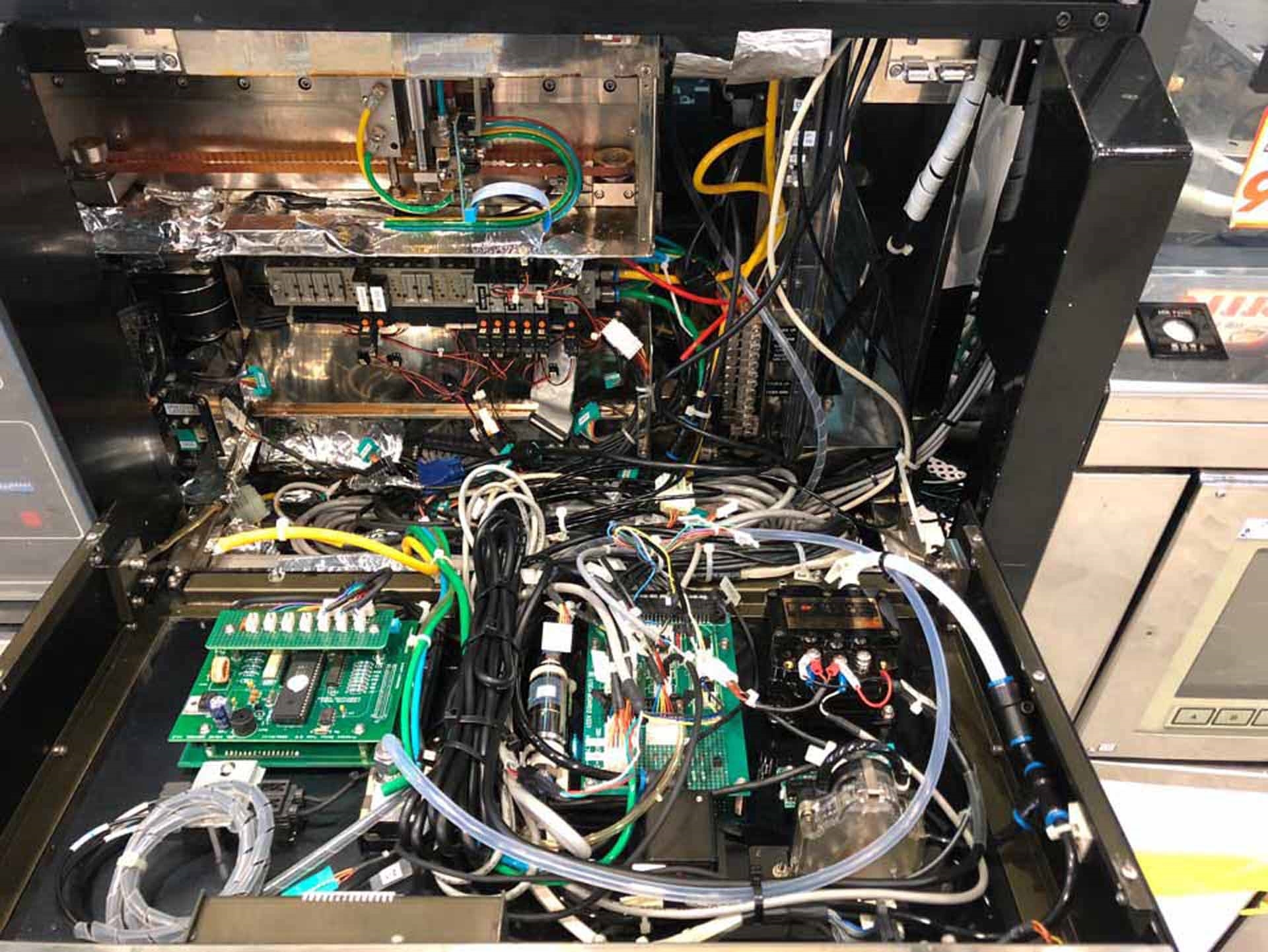

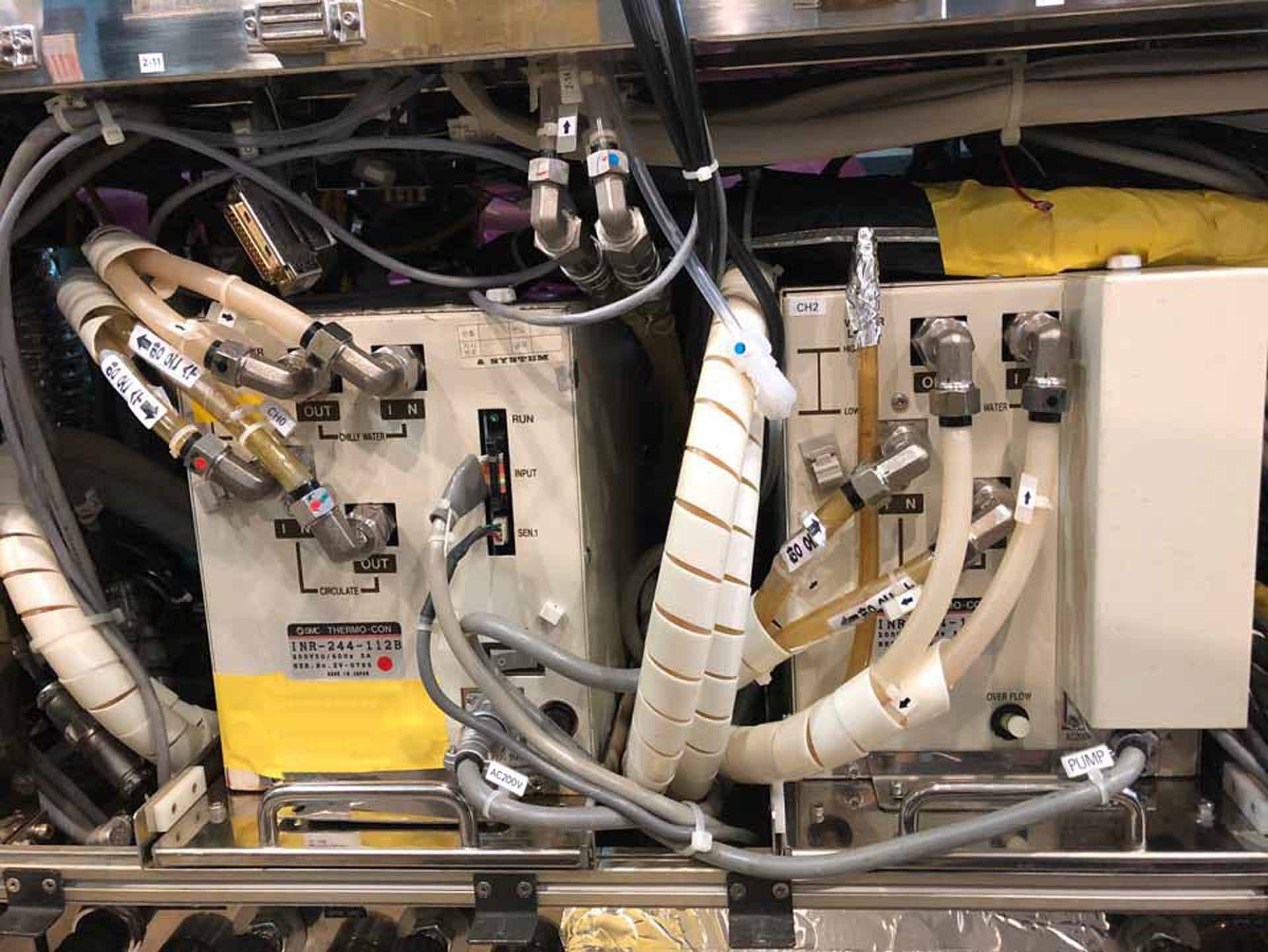

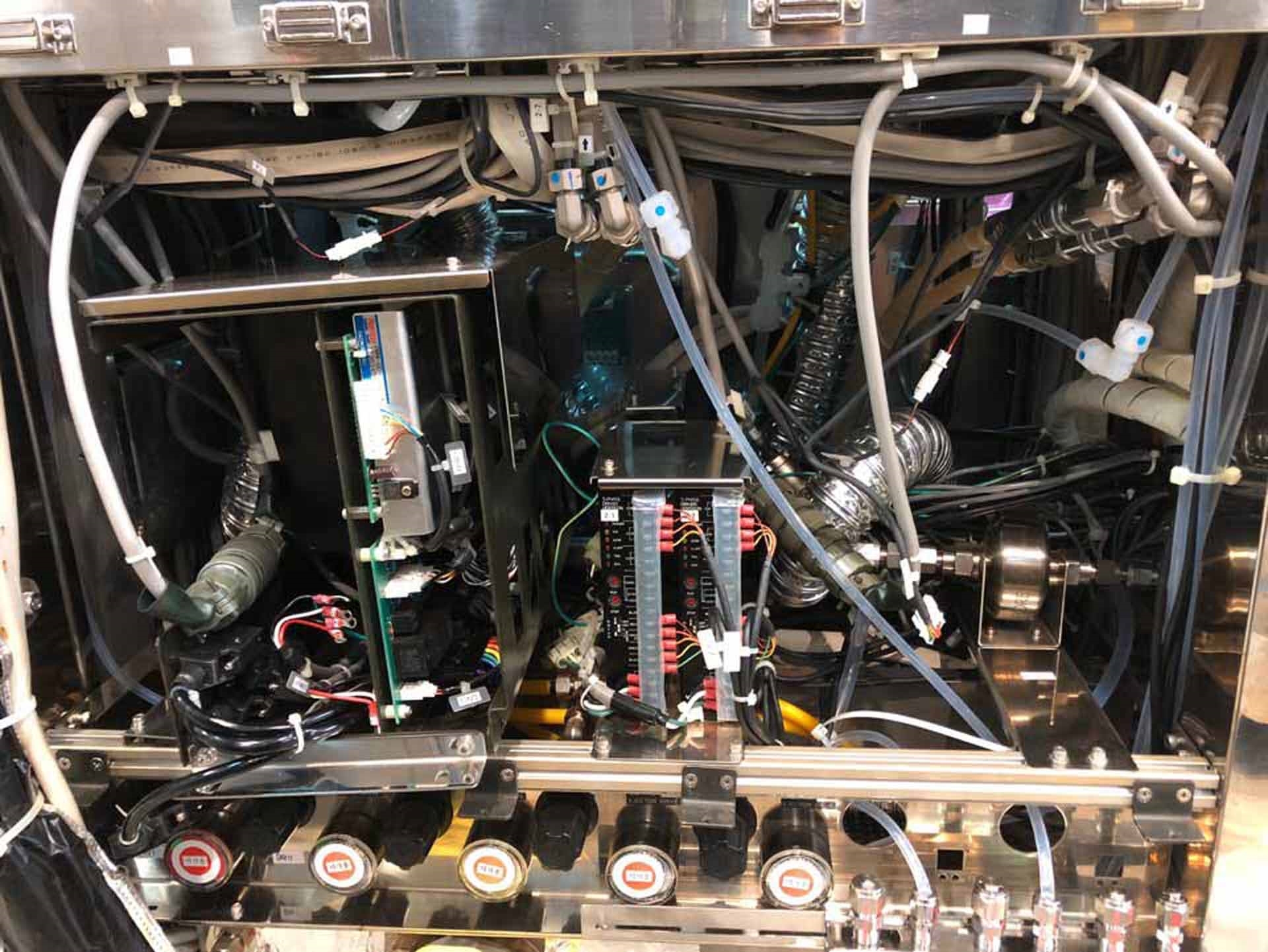

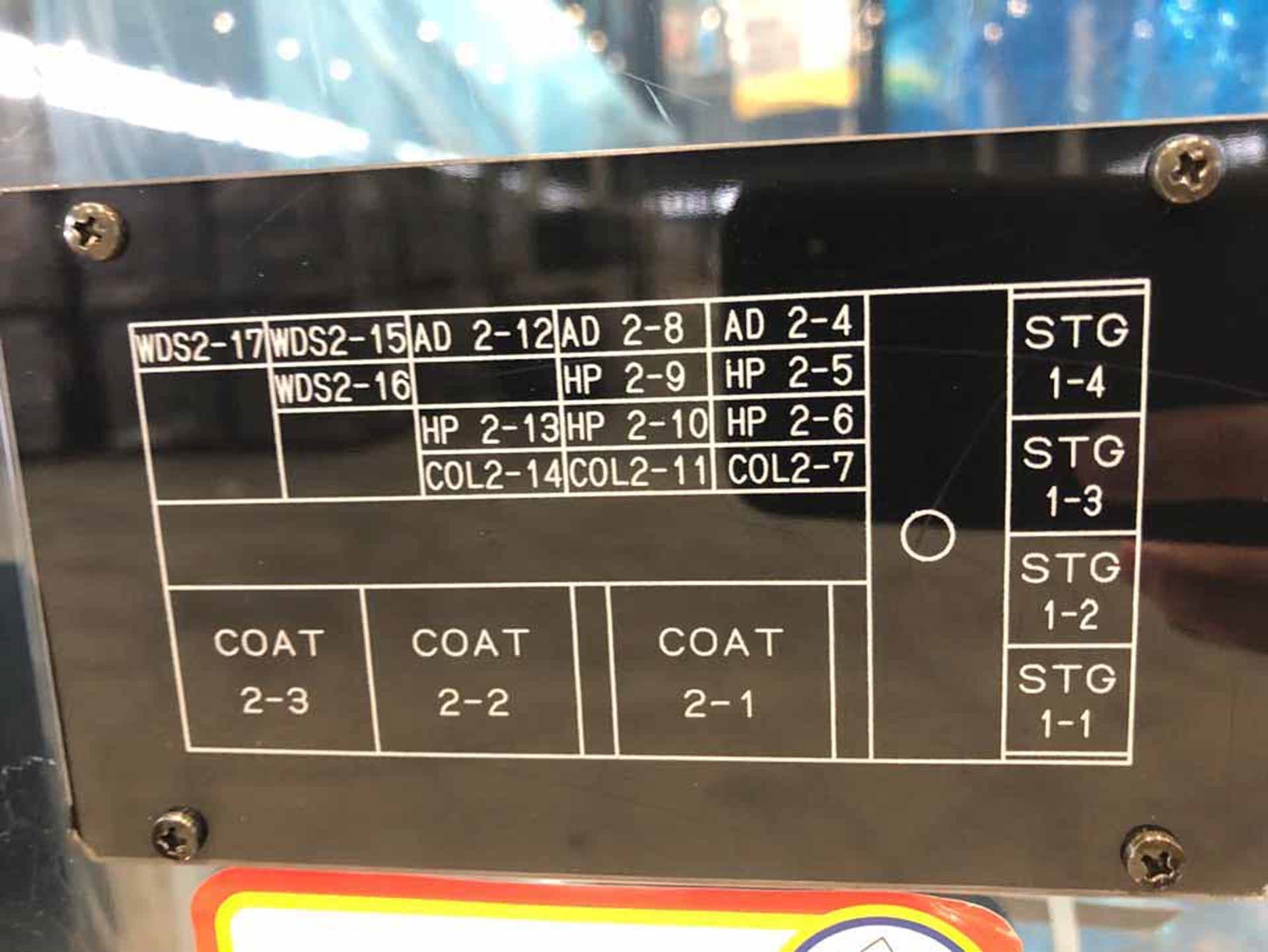

TEL / TOKYO ELECTRON Mark 7 is a high-precision photolithographic equipment designed for use in the semiconductor and microelectronics manufacturing industry. The system is a highly advanced version of the traditional photolithography process used to fabricate integrated circuits and other electronic devices. It combines photoresist technology and a variety of integrated processes for accurate, precise, and highly repeatable image printing and layer formation on a variety of materials. TEL MARK7 photoresist unit comes with a specialized imaging light source to ensure accurate and repeatable exposures, which consistently produces the same resolution and fidelity with each shot. The imaging light source incorporates a variety of optical elements including a mercuric iodide lamp, a monochrome quartz film, and a long optical path that allows for varied angles of exposure while maintaining consistent imaging over the entire field. The machine also includes a stepper that accurately moves the imaging lens over the surface of the substrate. Additionally, the tool is equipped with a specialized image-cutting laser that allows for exposure of fine lines, dots, and intricate patterns. The laser is constructed from a Nd:YAG material and incorporates a rotating drive that allows for accurately controlling the exposure sequence. The laser also includes an auto focus asset that enables high-precision resolution cutting work. TOKYO ELECTRON MARK-7 photoresist model performs with an impressively low exposure error rate, providing consistent, accurate results with each exposure. In addition, the equipment is designed to follow a set of procedure rules through an integrated feed-and-pass mechanism, which reduces the risk of operator errors substantially. The machine can also perform automated exposure sequences, enabling faster and more standardized production times. Overall, MARK7 photoresist system is a reliable, high-precision imaging unit that is capable of producing consistent, accurate results. The machine offers many features that allow for improved accuracy, resolution, and repeatability, making it ideal for use in the semiconductor and microelectronics industry.

There are no reviews yet