Used TEL / TOKYO ELECTRON Mark 8 #9155226 for sale

URL successfully copied!

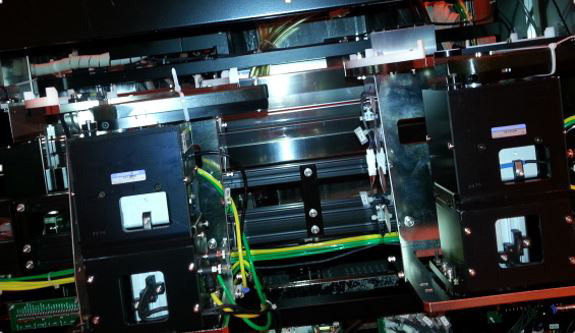

Tap to zoom

ID: 9155226

Wafer Size: 8"

Vintage: 1995

Wafer coater, 8"

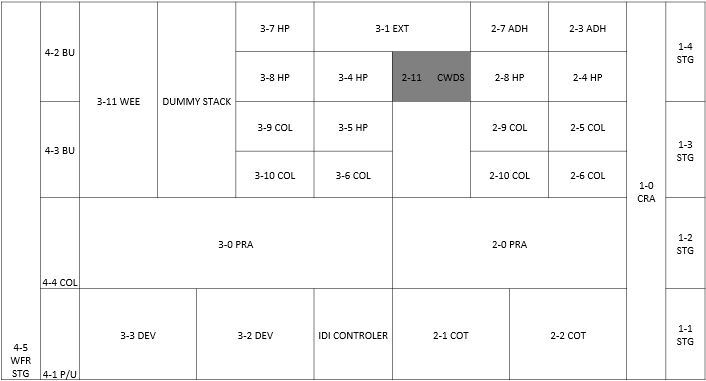

Wafer loading type: Right to Left

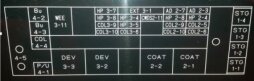

Software version: MK8H2.78(MC) M8B9083D.00 (Block)

Coater unit:

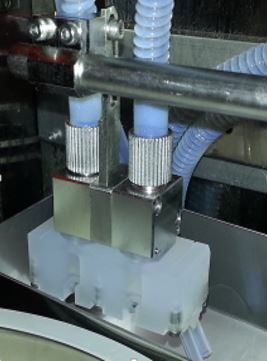

Pump model: RRC

Nozzle count: 3

Development unit:

Dev nozzle: H-Nozzle

Dev nozzle Count: 2

Up/Down move: Cylinder

Rinse nozzle: Stream

1995 vintage.

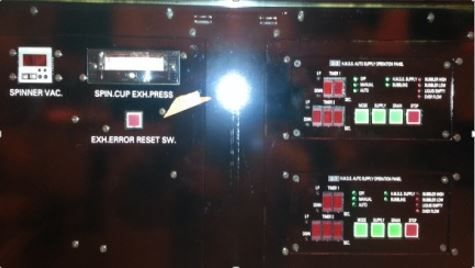

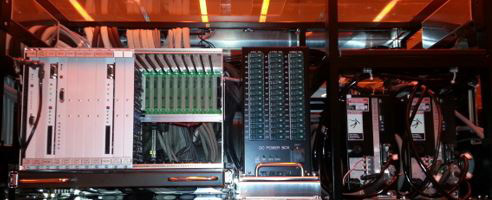

TEL / TOKYO ELECTRON Mark 8 is a photoresist equipment designed for photolithography and semiconductor fabrication processes. It uses cutting-edge technology to precisely expose photosensitive materials to light to create patterns and other images on semiconductor wafers. The system has been widely used in the manufacture of integrated circuits (ICs), and other microelectronic components and devices. TEL MARK8 utilizes a unit-integrated Digital Laser Source Unit (DLSU) for producing a range of wavelengths of laser light, including those in the deep ultraviolet (UV) range. The ultraviolet exposure energy can be set in microjoule increments, allowing for excellent resolution of the imaging process. The laser's Variable Field of View (VFoV) allows for a wide range of exposure field sizes, from a few millimeters to as large as 8 inches (200 mm), allowing for increased flexibility and precision in the lithography process. The machine also includes a stage mechanism, which can move the wafer in three axis directions (X, Y, and Z). In combination with the laser source unit, this allows for accurate and precise exposure of photosensitive materials on the wafer's backside, as well as its front side. The stage also has a very low thermal drift for superior up-time performance and wafer-to-wafer repeatability. TOKYO ELECTRON MARK-8 is also equipped with a Fully Automated Load Lock (FALL), which allows for fast, easy, and safe transfer of multiple wafers from the main chamber to the process chamber. The FALL tool houses up to twenty (20) wafers, while a semi-automated wafer loader is available to increase the number to fifty (50). Processing options for TEL MARK-8 are settings driven by either a manual knob or through a computer, allowing for precise control over processing parameters. The asset also offers additional process options, including advanced draining methods, fault detection functions, and model diagnostics. Finally, the equipment can be customized to meet specific customer requirements, such as additional process parameters, specialized hardware and software, and other additional features. Mark 8 is a versatile, high-precision system that provides excellent accuracy, repeatability, and reliability for precise exposures of photosensitive materials. By optimizing these exposure parameters, the unit is ideally suited for a variety of IC manufacturing and microelectronic device fabrication processes.

There are no reviews yet