Used TEL / TOKYO ELECTRON Mark 8 #9180753 for sale

URL successfully copied!

Tap to zoom

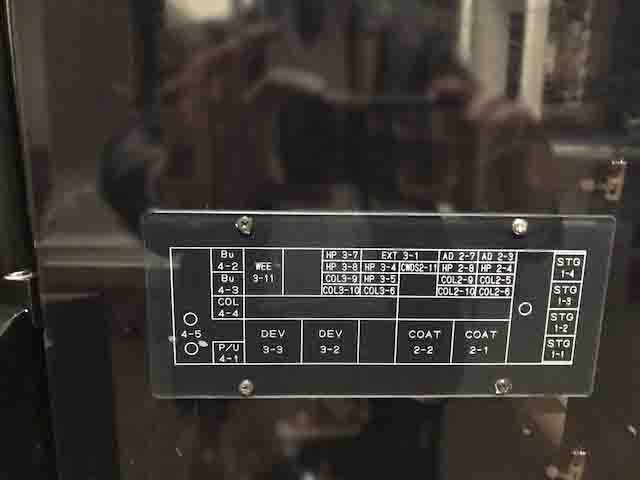

TEL / TOKYO ELECTRON Mark 8 is a photoresist equipment used in creating integrated circuits on both rigid and flexible substrates. It is based on advanced lithography technology, which uses light to pattern an image onto a thin resist layer. The light is projected by a high-precision, variable-focus optical system and is controlled using multiple software and hardware components. The unit supports multiple front end optics capabilities, including advanced overlay, telecentric imaging, long-depth imaging, and high-volume parameter control. The machine also contains an auto-build process engine for optimizing the process parameters in real-time and provides down-line inspection capabilities. TEL MARK8's resist coating for integrated circuits is of a higher precision and quality than other photoresist systems. It is also capable of handling larger substrates and can handle substrates up to 650mm in size. Its high accuracy and fast foundation contribute greatly to the production of integrated circuits with extremely high-speed and accuracy. Additionally, its advanced structural imbalance detecto allows the tool to handle complex 3D structures and increase the production speed and precision. The asset also supports substrate-dependent parameter sets for optimum imaging, providing multiple options for resist coating processes. The model features a high-speed, high-efficiency automatic exposure and develop equipment. This system ensures an extremely high degree of precision and repeatability, which is ideal for process optimization. It also supports multiple exposure and develop modes, such as aperture-controlled, area-selective, and full-field imaging. TOKYO ELECTRON MARK-8 also has a wafer plasma ablation unit that can be used to remove resist films. This machine makes TEL MARK-8 ideal for applications involving thin-film layers, such as MEMs. TOKYO ELECTRON Mark 8 features a wide range of embedded control technologies. It has a high-speed control tool that allows for precise lining, tape positioning, and patterning. It also supports advanced communication protocols such as Gigabit Ethernet, CAN bus, and SPI. This enables the seamless integration of the asset into existing production lines. Mark 8 is designed to meet the highest standards of safety and reliability. It has an automated self-diagnosis model that can detect faults and perform maintenance when needed. The equipment also provides detailed reports and data for analysis, making process optimization easier than ever. MARK-8 also contains an extensive range of safety features that ensure optimal manufacturing performance and reliability.

There are no reviews yet