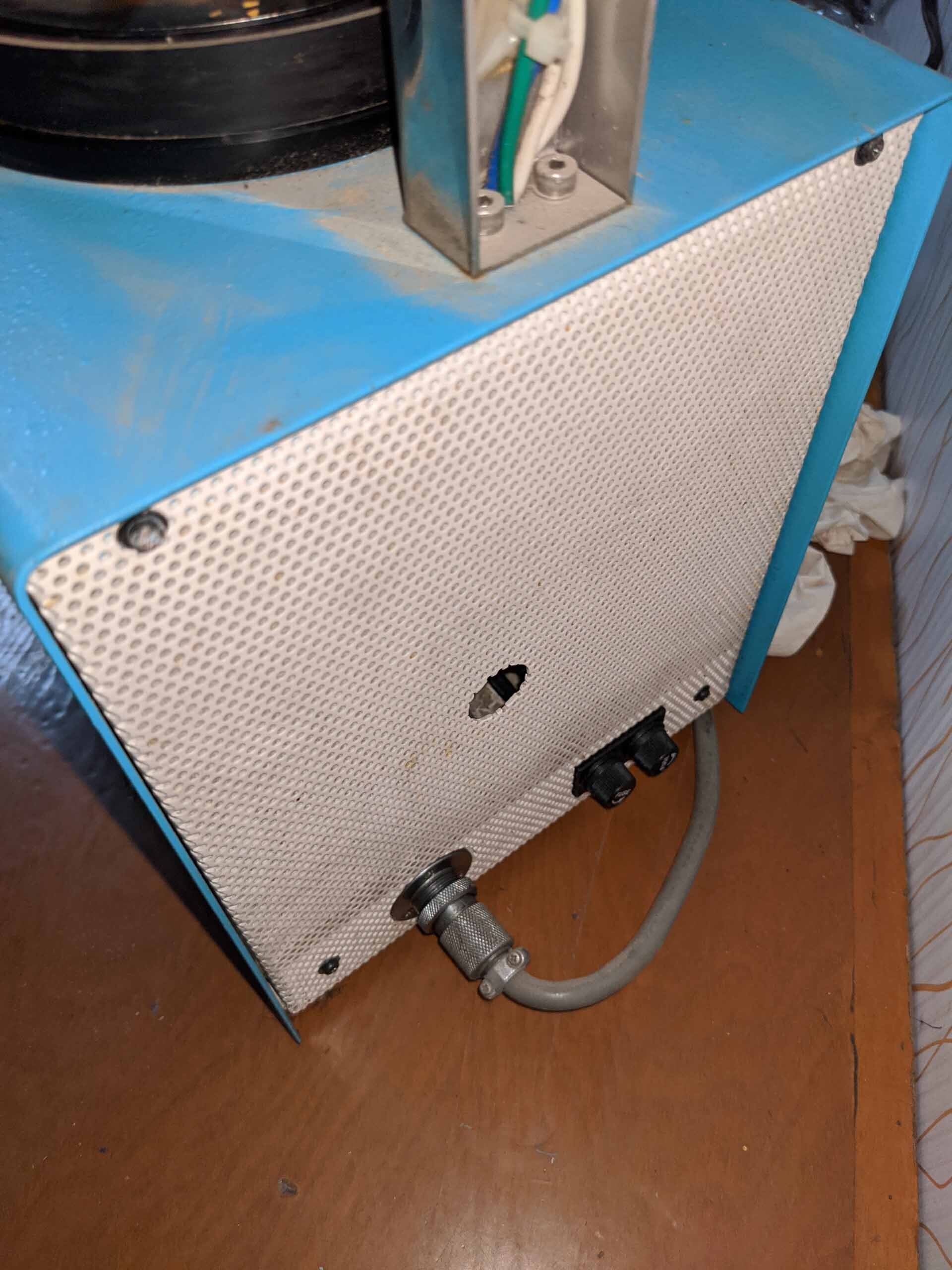

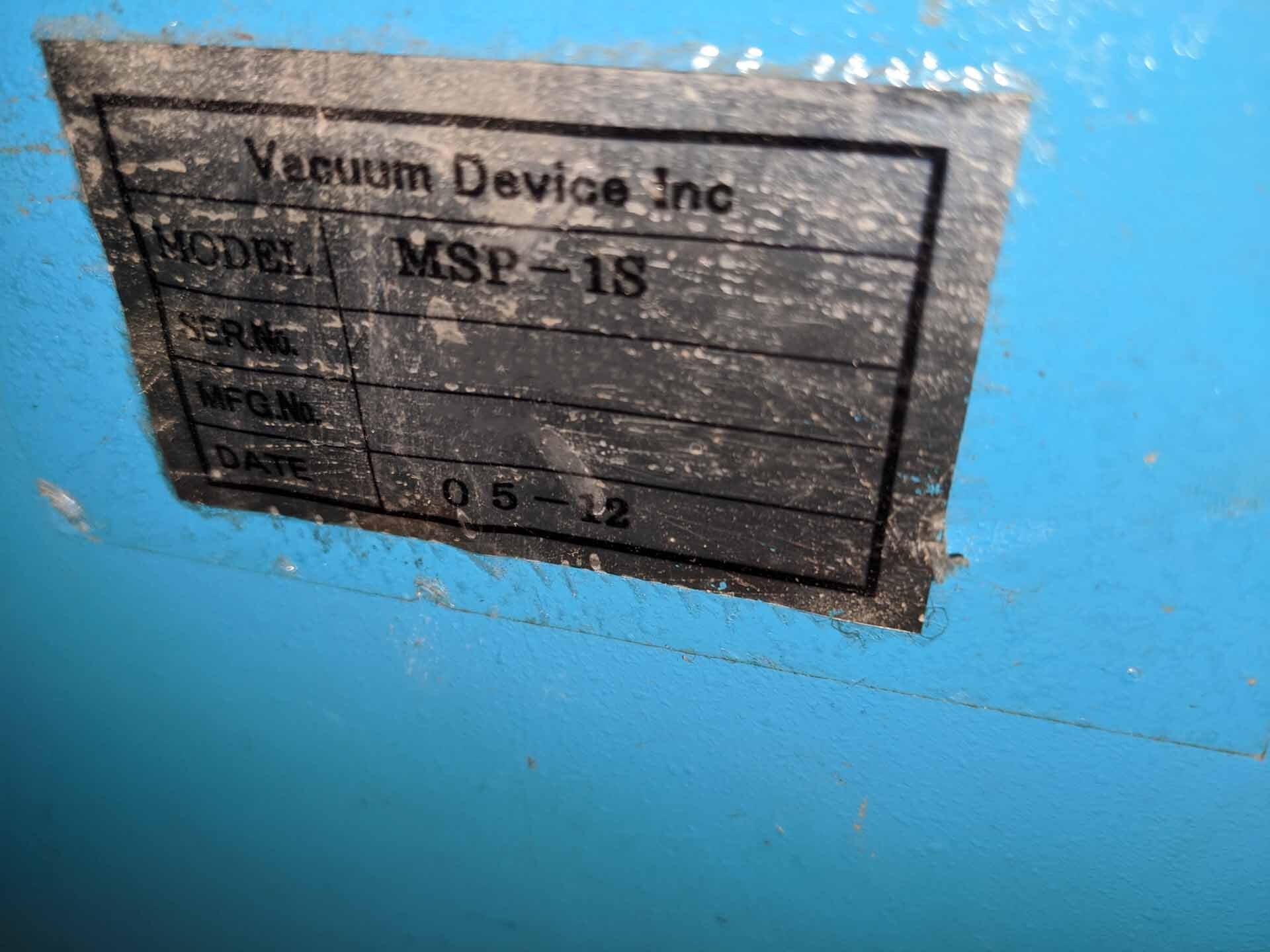

Used VACUUM DEVICE MSP-1S #293597453 for sale

URL successfully copied!

Tap to zoom

VACUUM DEVICE MSP-1S Photoresist System is an automated device designed to facilitate photolithography tasks in the electronics manufacturing industry. This device offers an effective solution to the time-consuming and labor-intensive processes traditionally required in the creation of photomasks and wafers. The core component of the device is a vacuum deposition chamber, which is used to vacuum-deposit a thin, uniform layer of photoresist material onto the substrate surface. The chamber is constructed with a quartz window, which allows light to pass through and be directed to the substrate surface for exposure. MSP-1S also incorporates a light source, typically a UV lamp or laser, which is adjustable for optimal exposure intensity. The device also includes a mapping stage for accurate alignment of the substrate over the illuminated area. This allows for precise exposure of the substrate at multiple points in the process. The mapping stage also allows for the mapping of multiple masks over a single substrate at a time, thus increasing throughput and reducing cycle time. Furthermore, VACUUM DEVICE MSP-1S can run in automatic or semi-automatic modes. The semi-automatic mode permits on-the-fly adjustments and is useful for prototyping and experimentation, while the fully automated mode is optimized for production runs. The automated mode is less labor intensive, and because it requires fewer operators it is faster and more cost effective. Finally, MSP-1S provides comprehensive safety features with particular attention to process safety and environmental regulations. This device is designed to reduce risk of injury to operators, as it runs at a lower power than. In addition, the air circulation system ensures that hazardous fumes are eliminated and collected for safe disposal. Overall, VACUUM DEVICE MSP-1S Photoresist system is an advanced device that provides an efficient and cost-effective solution to the production of photomasks and wafers. This device is capable of automated processing of multiple substrates, with precision, accuracy and repeatability. It also offers a safer and more environmentally friendly alternative to traditional methods of photolithography.

There are no reviews yet