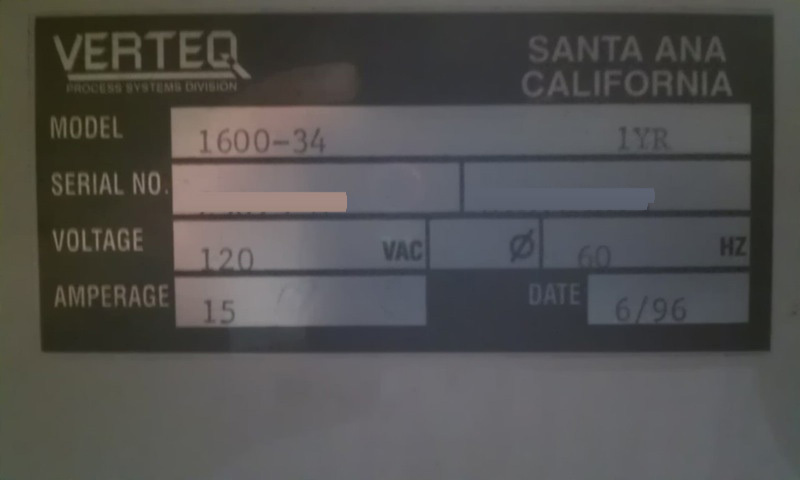

Used VERTEQ 1600-34 #187764 for sale

URL successfully copied!

Tap to zoom

ID: 187764

Wafer Size: 4"

Vintage: 1996

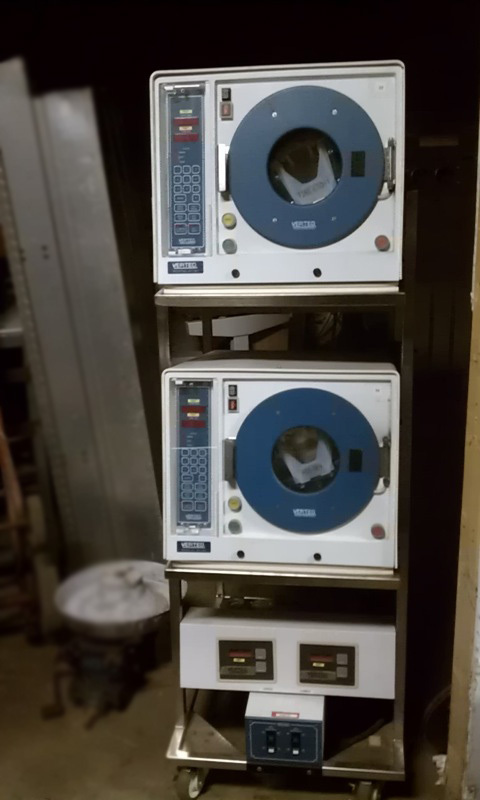

Spin rinse dryer (SRD), 4"

Dual stack

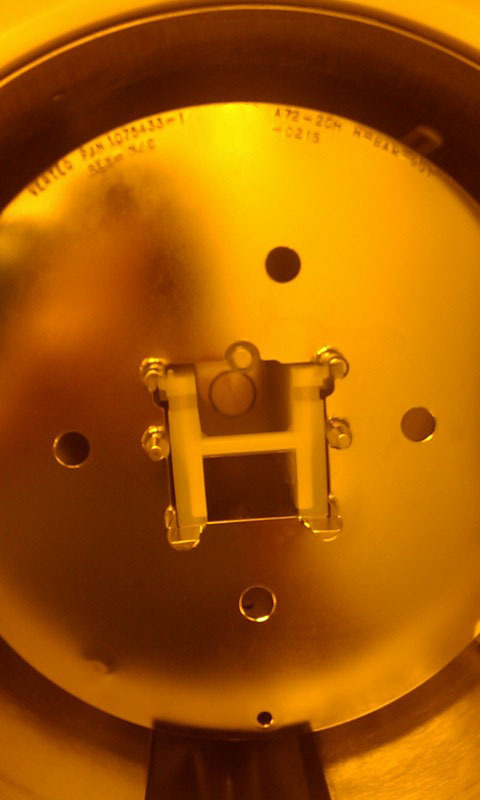

(4) VERTEQ rotors, p/n 1081199-1 a72-39m-06-0215 rev-c h-bar-in

(1) VERTEQ rotor, p/n 1075433-1 a72-20m-0215 h-bar-out rev-n/c

1996 Vintage.

VERTEQ 1600-34 Photoresist Equipment is a leading-edge imaging system, developed to cost-effectively achieve extremely high levels of detail, quality assurance, and cost management in the photoresist applications sector. It offers high-quality imaging with unsurpassed line definition and feature size, with resolutions up to 30um. 1600-34 unit utilizes proprietary ultra-high resolution masks, a unique, small, mirror-based optics machine and an advanced computer-controlled tool, allowing for highly reliable, repeatable and accurate images. The asset also features a fully automated model which includes a sophisticated vision equipment, allowing for the highest possible resolutions and image contrast available. The system's image capture uses a low energy light source, ideal for precision resist processing. The unit also offers a wide range of adjustable parameters, allowing for control over the image resolution, line definition, feature size and edge acuity. In addition to its flexible imaging capabilities, VERTEQ 1600-34 machine features advanced photoresist technology, including advanced material handling, processing, drying and curing operations. The tool has been designed to provide an absolute minimum of photoresist splatter, ensuring the highest possible precision during processing. The asset also offers a wide array of inspection and metrology tools, allowing for added assurance of the feature accuracy and quality of the photoresist layers. The automated inspection module, 3 dimensional (3-D) imaging, waveform analysis, and optical metrology are all components of 1600-34 model, providing the user maximum control over the photoresist equipment. VERTEQ 1600-34 Photoresist System is an efficient and reliable solution for photoresist applications, capable of achieving high levels of accuracy and consistency, while remaining cost effective. Its vision unit, material handling, and automated operation allow for increased operation consistency and quality assurance, making it an ideal choice for photoresist applications in various industries.

There are no reviews yet