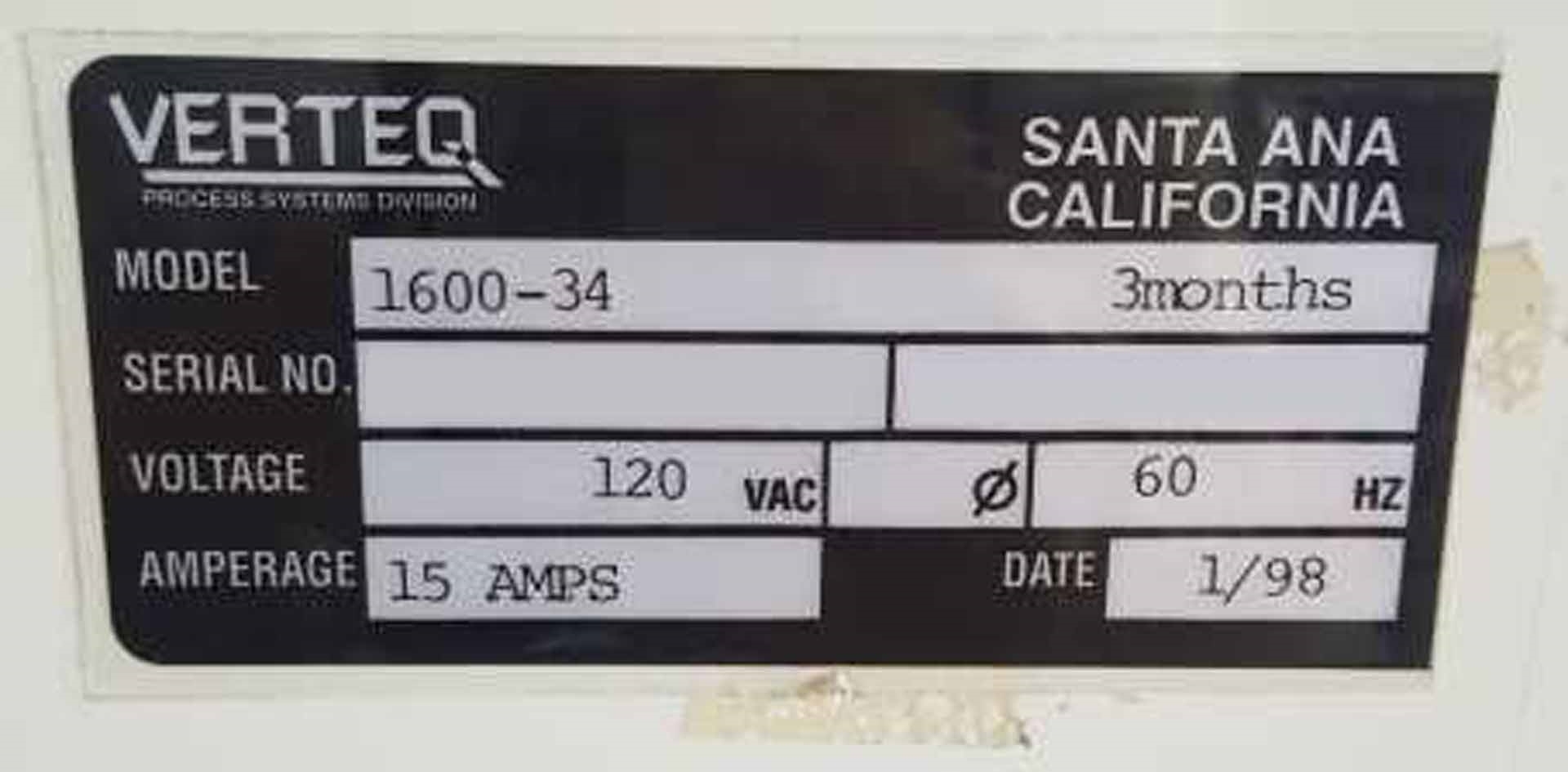

Used VERTEQ 1600-34 #9219680 for sale

URL successfully copied!

Tap to zoom

VERTEQ 1600-34 is an automated photoresist equipment designed for superior precision and reliability in the application of materials used for printed circuit board (PCB) fabrication. The system is equipped with two spin coater heads, a state-of-the-art resist heater, a baked resist heater, and a production tray loading robot. In addition, a purge-only wash feature ensures safe handling of hazardous chemicals in compliant cleanrooms and lab environments. At the heart of 1600-34 is a precision dual-spindle coating head. Both spindles feature high speed and highly precise motorized z-axes, making it easy to quickly adjust the position of the head for optimal application of the photoresist to the PCB. An optional automated diffuser control adjusts the size and shape of the spray to ensure an even and homogeneous film coverage. The unit's motorized conveyor belt and adjustable height conveyor platform make it easy to apply the photoresist to the PCBs at uniform speeds. The machine is also equipped with a resist heater to melt the photoresist, creating uniform films. The resist heater is also designed to quickly cool the PCBs without running the risk of defects due to thermal shock. A baked resist heater allows for simultaneous exposure and heating of two boards. The dual-zone temperature control feature ensures precision baking with both standard and low-temperature photoresists. VERTEQ 1600-34 is capable of handling two boards at a time and is capable of processing up to six boards per hour. The tool's production tray loading robot makes it possible to handle a variety of photoresist materials without having to manually load trays. The asset also comes equipped with a pleated diffuser carriage for superior spray control. In addition, a purge-only wash feature ensures safe handling of hazardous chemicals in compliant cleanrooms and lab environments. This feature supplies a low volume of ultrapure water to clean and reuse the model's chambers and hoses with minimal impact on the environment. 1600-34 provides top-of-the-line performance and precision for PBS fabrication. Its combination of precision coating heads, motorized conveyor belt, adjustable height conveyors, resist heater, baked resist heater, two-zone temperature controls, and robotic loading tray make it an ideal solution for a variety of photoresist applications.

There are no reviews yet